Occlusal Adjustment via Selective Cutting of Natural Teeth.* (Part 1)

... of the mandible away from the centric relation occluded position. If there is proper coupling, anterior contact will take place within one-half thousandth of an inch (.0005) or within the first degree of rotation of the mandible away from the centric relation occluded position. This resultant "dis-o ...

... of the mandible away from the centric relation occluded position. If there is proper coupling, anterior contact will take place within one-half thousandth of an inch (.0005) or within the first degree of rotation of the mandible away from the centric relation occluded position. This resultant "dis-o ...

Structure

... Nowadays, people use more and more machine elements to increase the efficiency of machines. Take a car as an example. It is composed of many machine elements like lever, linkage, drive system, belts, bearings, clutch, gears, crank, cam, brake and ratchets. Furthermore, a screw jack can be used to ra ...

... Nowadays, people use more and more machine elements to increase the efficiency of machines. Take a car as an example. It is composed of many machine elements like lever, linkage, drive system, belts, bearings, clutch, gears, crank, cam, brake and ratchets. Furthermore, a screw jack can be used to ra ...

Mechanics

... Nowadays, people use more and more machine elements to increase the efficiency of machines. Take a car as an example. It is composed of many machine elements like lever, linkage, drive system, belts, bearings, clutch, gears, crank, cam, brake and ratchets. Furthermore, a screw jack can be used to ra ...

... Nowadays, people use more and more machine elements to increase the efficiency of machines. Take a car as an example. It is composed of many machine elements like lever, linkage, drive system, belts, bearings, clutch, gears, crank, cam, brake and ratchets. Furthermore, a screw jack can be used to ra ...

Types of filling materials

... subsequently filling has an element of risk of damaging the pulp of the tooth. The heat from the preparation, exposing the inner tooth surfaces to the bacteria in the mouth or simply the depth of the required preparation. This may, although rarely, lead to the requirement of root canal treatment and ...

... subsequently filling has an element of risk of damaging the pulp of the tooth. The heat from the preparation, exposing the inner tooth surfaces to the bacteria in the mouth or simply the depth of the required preparation. This may, although rarely, lead to the requirement of root canal treatment and ...

File

... Gear down: DC motor manufacturers that also produce the corresponding gear down for a motor must list the gear down ratio. The gear down acts to increase torque and reduce rpm. The No Load RPM value given is always that of the last output shaft after the gear down. To find the angular velocity of th ...

... Gear down: DC motor manufacturers that also produce the corresponding gear down for a motor must list the gear down ratio. The gear down acts to increase torque and reduce rpm. The No Load RPM value given is always that of the last output shaft after the gear down. To find the angular velocity of th ...

Mechanical Workshop - Mid

... its speed or rotation are dependent on each other This is a basic characteristic, it is a ...

... its speed or rotation are dependent on each other This is a basic characteristic, it is a ...

External gear pump

... rotor speed. These pumps can not withstanding high pressures and generally used for low-pressure and high-volume flow applications. The important advantages of nonpositive displacement pumps are lower initial cost, less operating maintenance because of less moving parts, simplicity of operation, hig ...

... rotor speed. These pumps can not withstanding high pressures and generally used for low-pressure and high-volume flow applications. The important advantages of nonpositive displacement pumps are lower initial cost, less operating maintenance because of less moving parts, simplicity of operation, hig ...

Transmission Components

... • The load between these two parts is taken in friction developed by the strain of the press fit • Manufacturing tolerances are very tight for this type of connection – For a 0.25” diameter shaft with a class FN2 fit ...

... • The load between these two parts is taken in friction developed by the strain of the press fit • Manufacturing tolerances are very tight for this type of connection – For a 0.25” diameter shaft with a class FN2 fit ...

Mechanisms - DOWNEND SCHOOL

... is greater than the load, the load moves faster (and further) than the effort. Velocity ratio = ...

... is greater than the load, the load moves faster (and further) than the effort. Velocity ratio = ...

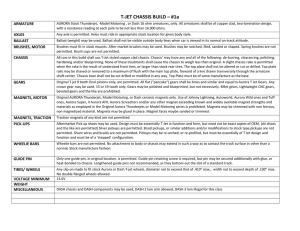

T-JET CHASSIS BUILD – #1a

... hardening and/or blueprinting. None of these treatments shall cause the chassis to weigh less than original. A slight chassis rake is permitted when the rake is the result of undersized front tires, or larger than stock rear tires. The top plate shall not be altered or cut or drilled. Top plate rail ...

... hardening and/or blueprinting. None of these treatments shall cause the chassis to weigh less than original. A slight chassis rake is permitted when the rake is the result of undersized front tires, or larger than stock rear tires. The top plate shall not be altered or cut or drilled. Top plate rail ...

Topic5.Presentation.ICAM

... For the simple machine of Problem 1, determine: (a) the distance moved by the effort to move the load through a distance of 0.9m, (b) the effort which would be required to raise a load of 200kg, assuming the same efficiency, (c) the efficiency if, due to lubrication, the effort to raise the 160kg lo ...

... For the simple machine of Problem 1, determine: (a) the distance moved by the effort to move the load through a distance of 0.9m, (b) the effort which would be required to raise a load of 200kg, assuming the same efficiency, (c) the efficiency if, due to lubrication, the effort to raise the 160kg lo ...

Torque - Chain & Drives

... power is measured in kilowatts (kW). Horsepower (hp) = Kilowatts (kW) X 1.341 • With gear systems the power needed is dependent upon the load, speed and efficiency. ...

... power is measured in kilowatts (kW). Horsepower (hp) = Kilowatts (kW) X 1.341 • With gear systems the power needed is dependent upon the load, speed and efficiency. ...

Simple Machines - Miss Woods` Class

... Problems: For each of the following examples calculate: Work input, Work output, Efficiency, and Mechanical advantage and determine whether it is a speed or force advantage a. You push a 600N box up a ramp that is 10m long. The ramp is 5m high, and you put in 350N of effort. b. You use a first class ...

... Problems: For each of the following examples calculate: Work input, Work output, Efficiency, and Mechanical advantage and determine whether it is a speed or force advantage a. You push a 600N box up a ramp that is 10m long. The ramp is 5m high, and you put in 350N of effort. b. You use a first class ...

Axle

... This is a special type of bevel gear that has its teeth at right angles to the plane of the wheel. It attaches to a spur gear, or pinion gear at right-angles. Driven Gear This is a name given to any gear that is not connected to a power source and is therefore driven by the driver gear. Driver Gear ...

... This is a special type of bevel gear that has its teeth at right angles to the plane of the wheel. It attaches to a spur gear, or pinion gear at right-angles. Driven Gear This is a name given to any gear that is not connected to a power source and is therefore driven by the driver gear. Driver Gear ...

Mechanisms

... engine allowing the train to be pulled up very steep slopes. In the space below draw the symbol for Rack and Pinion. ...

... engine allowing the train to be pulled up very steep slopes. In the space below draw the symbol for Rack and Pinion. ...

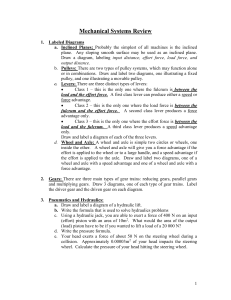

Review for Wednesday`s Test

... – A driver component that initiates the motion – At least a driven component that receive the motion and transfers it – Some systems might also contain intermediate components between the driver and driven components ...

... – A driver component that initiates the motion – At least a driven component that receive the motion and transfers it – Some systems might also contain intermediate components between the driver and driven components ...

Mechanisms Levers Class 1 levers:

... Where there are two gears of different sizes, the smaller gear will rotate faster than the larger gear. The difference between these two speeds is called the velocity ratio, or the gear ratio, and can be calculated using the number of teeth. The formula is: Gear ratio = number or teeth on driven gea ...

... Where there are two gears of different sizes, the smaller gear will rotate faster than the larger gear. The difference between these two speeds is called the velocity ratio, or the gear ratio, and can be calculated using the number of teeth. The formula is: Gear ratio = number or teeth on driven gea ...

Practice Problem set 3

... Left sprocket # teeth =24, driven sprocket # teeth =12, driving sprocket #teeth=36, rear wheel hub # teeth=6 5. The large piston in a hydraulic lift has a radius of 250 cm2. What force must be applied to the small piston with an area of 25 cm2 in order to raise a car of mass 1500 kg? ...

... Left sprocket # teeth =24, driven sprocket # teeth =12, driving sprocket #teeth=36, rear wheel hub # teeth=6 5. The large piston in a hydraulic lift has a radius of 250 cm2. What force must be applied to the small piston with an area of 25 cm2 in order to raise a car of mass 1500 kg? ...

Grade 8 Science

... like the wheel and axle, use rotation, but they transfer the rotation to a different axis, the gears are not attached, they use teeth that mesh together. The teeth on gears are very specifically designed. Their shape is one that allows them to be in contact with each other for as long as possibl ...

... like the wheel and axle, use rotation, but they transfer the rotation to a different axis, the gears are not attached, they use teeth that mesh together. The teeth on gears are very specifically designed. Their shape is one that allows them to be in contact with each other for as long as possibl ...

Lecture #25

... Although no friction forces were assumed to be acting on the slide in the analysis presented, forces that would be associated with slide motion in certain applications could be included in the analysis. Such examples include the use of a rack to move a slide on a lathe. The machining operations bein ...

... Although no friction forces were assumed to be acting on the slide in the analysis presented, forces that would be associated with slide motion in certain applications could be included in the analysis. Such examples include the use of a rack to move a slide on a lathe. The machining operations bein ...

Gear Trains

... The rotary force produced on the output shaft. When a motor is stalled it is producing the maximum amount of torque that it can produce. Hence the torque rating is usually taken when the motor has stalled and is called the stall torque. The motor torque is measured in ounce-inches (in the English sy ...

... The rotary force produced on the output shaft. When a motor is stalled it is producing the maximum amount of torque that it can produce. Hence the torque rating is usually taken when the motor has stalled and is called the stall torque. The motor torque is measured in ounce-inches (in the English sy ...

Mechanical Systems

... • force exerted on the lever to make it move is the effort force • the mass of the object being moved is called the load • distance between fulcrum and load is called the load arm ...

... • force exerted on the lever to make it move is the effort force • the mass of the object being moved is called the load • distance between fulcrum and load is called the load arm ...

Gear Trains

... Torque: The rotary force produced on the output shaft. When a motor is stalled it is producing the maximum amount of torque that it can produce. Hence the torque rating is usually taken when the motor has stalled and is called the stall torque. The motor torque is measured in ounce-inches (in the En ...

... Torque: The rotary force produced on the output shaft. When a motor is stalled it is producing the maximum amount of torque that it can produce. Hence the torque rating is usually taken when the motor has stalled and is called the stall torque. The motor torque is measured in ounce-inches (in the En ...

Gear Trains

... Torque: The rotary force produced on the output shaft. When a motor is stalled it is producing the maximum amount of torque that it can produce. Hence the torque rating is usually taken when the motor has stalled and is called the stall torque. The motor torque is measured in ounce-inches (in the En ...

... Torque: The rotary force produced on the output shaft. When a motor is stalled it is producing the maximum amount of torque that it can produce. Hence the torque rating is usually taken when the motor has stalled and is called the stall torque. The motor torque is measured in ounce-inches (in the En ...

Gear

A gear or cogwheel is a rotating machine part having cut teeth, or cogs, which mesh with another toothed part to transmit torque, in most cases with teeth on the one gear being of identical shape, and often also with that shape on the other gear. Two or more gears working in a sequence (train) are called a gear train or, in many cases, a transmission; such gear arrangements can produce a mechanical advantage through a gear ratio and thus may be considered a simple machine. Geared devices can change the speed, torque, and direction of a power source. The most common situation is for a gear to mesh with another gear; however, a gear can also mesh with a non-rotating toothed part, called a rack, thereby producing translation instead of rotation.The gears in a transmission are analogous to the wheels in a crossed belt pulley system. An advantage of gears is that the teeth of a gear prevent slippage.When two gears mesh, and one gear is bigger than the other (even though the size of the teeth must match), a mechanical advantage is produced, with the rotational speeds and the torques of the two gears differing in an inverse relationship.In transmissions with multiple gear ratios—such as bicycles, motorcycles, and cars—the term gear, as in first gear, refers to a gear ratio rather than an actual physical gear. The term describes similar devices, even when the gear ratio is continuous rather than discrete, or when the device does not actually contain gears, as in a continuously variable transmission.