* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Building a BASIC Stamp I Flight Computer (Powerpoint)

Survey

Document related concepts

Power over Ethernet wikipedia , lookup

Mains electricity wikipedia , lookup

Buck converter wikipedia , lookup

Loading coil wikipedia , lookup

Crossbar switch wikipedia , lookup

Telecommunications engineering wikipedia , lookup

Light switch wikipedia , lookup

Gender of connectors and fasteners wikipedia , lookup

Electrical wiring in the United Kingdom wikipedia , lookup

Phone connector (audio) wikipedia , lookup

Industrial and multiphase power plugs and sockets wikipedia , lookup

Transcript

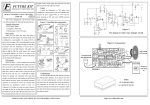

Building a BASIC Stamp I Flight Computer (Paul Verhage design) AEM 1905, Fall 2008 The main item – the homemade (etched and drilled) printed circuit board (PCB). Use the circuit layout diagram to help place components on the printed circuit board. Here are the sockets, 3-pin male header, and row of female receptacles. Here is the BASIC Stamp chip and three other chips – ask for these once your board is completed and checked. Begin building cable connectors by cutting your ribbon cable in 4 equal pieces then separating the individual wires. Take the four green wires and lay them out with a micro-plug. Shrink wrap color, not wire color, will indicate polarity. Plug the micro plug connector together then use the Helping Hands to hold the wire in place. Be sure to heat sink the opposite pin! Solder on each of the 4 wires (gently!) then add the shrink wrap (watch the colors!). Here is the connector when separated. Repeat, making a white, red, and black cable connector as well. These fit together both ways so the shrink wrap will indicate polarity. Notice that your 14-pin socket is actually half of a 28-pin socket, cut apart for you. Use your utility knife to cut out three 3 x 2 pin sections of female receptacle. Cut wide (i.e. waste 1 set of pins with each cut). The sockets, 3-pin header, and female receptacles will go into the non-copper side of the PCB. Using the circuit layout diagram, place them all to make sure they fit the holes. Start soldering just the sockets – they all stick up the same distance so you can solder with the PCB flat on the wood. Always pause to examine your soldering for solder bridges and/or poor connections. When soldering in the 3-pin header, the short pins go through the board. Heat sink the pins one by one, as shown below. Here is the PCB with the four sockets, the 3-pin male header, and the three sets of female receptacles soldered into place. Add the three 1k resistors. Notice that one of them stands on end. Starting now, clip off excess leads on the copper side of the board. (Sockets and such didn’t need clipping – their pins are short.) I ran out of 2.2 k resistors so make one by putting a 1k and a 1.2 k resistor in series. First twist the leads like this. Then solder the twist together and clip off the excess wire on that end. The two 2.2 k (combination) resistors go into the PCB on end as well. Insert the electrolytic capacitor, watching the polarity (+ is marked on the diagram and – is marked on the capacitor itself). Carefully bend the legs of the 5-V voltage regulator, as shown below. Insert the voltage regulator. The metal plate (its own heat sink!) should lie flat on the PCB. Use a machine screw to heat sink the voltage regulator to the PCB. We’ll use a Dremel tool to cut off the excess bolt. Cut the black jumper wire into 4 pieces, strip the ends, bend them into a “U” shape. Insert the jumpers at the four locations indicated on the circuit layout diagram. Add cables for the switch (red), battery pack (white), and indicator LED (green). Polarity is critical on the last two. Use the black cable for the pull-beforeflight connection. Polarity doesn’t matter. Attach the other end of the white cable to the battery pack. Be sure to match polarity! Insert the switch into the switch plate and use hot-glue to hold it there. Solder the red cable to the switch. Insert the LED into the switch plate and use hot-glue to hold it there. Solder the green cable to the LED, watching polarity. Use a wire to short-circuit the audio plug, then reassemble it. Insert the audio jack into the switch plate and use hot-glue to hold it there. Use a multimeter (on the resistance setting) to figure out which two legs of the audio jack get shorted when the plug is inserted – attach the black cable to those two legs. Have your flight computer board inspected then get your BASIC Stamp and three other chips and insert them (the right way around). Connect your flight computer to your battery pack and switch plate. We’ll put batteries in and test them and program them as a class. Here is a light plastic backing (like Correplast) for the flight computer. Use zip ties to attach the backing to the PCB (to cover up the soldering – this will require drilling some more holes) then put velcro on it (to attach the computer in the payload box.) Incorporate the switch plate permanently into one side of your payload box. Make sure your cables will reach to the flight computer and the battery pack, both of which will be attached inside the payload box with velcro.