* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Application Note

Brushed DC electric motor wikipedia , lookup

Power engineering wikipedia , lookup

History of electric power transmission wikipedia , lookup

Voltage optimisation wikipedia , lookup

Stray voltage wikipedia , lookup

Electrical ballast wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Ground (electricity) wikipedia , lookup

Fault tolerance wikipedia , lookup

Fuse (electrical) wikipedia , lookup

Stepper motor wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Electrical substation wikipedia , lookup

Mercury-arc valve wikipedia , lookup

Power electronics wikipedia , lookup

Two-port network wikipedia , lookup

Mains electricity wikipedia , lookup

Buck converter wikipedia , lookup

Current source wikipedia , lookup

Protective relay wikipedia , lookup

Opto-isolator wikipedia , lookup

Thermal runaway wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Power MOSFET wikipedia , lookup

Surge protector wikipedia , lookup

Electrical wiring in the United Kingdom wikipedia , lookup

Alternating current wikipedia , lookup

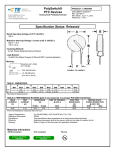

PolyTron™ PTC Devices Application Guidelines Post Trip Resistance, R1 - The maximum resistance measured one hour after trip or reflow, measured at 23°C. Power Dissipation, Pd - Power dissipated from device when in tripped state (Pd = Ileakage * VPTC). Ideally as small as possible. Max. Trip Time - PTC response time, from onset of fault current to trip. Ideally, as small as possible, except for special applications (i.e., motor drive, motor control). 3. Operational Modes, Benefits and Limitations Contents 1 2 3 4 Introduction Definition of Terms Operational Modes, Benefits and Limitations. Understanding Key Parameters and Selecting the Right PolyTron™ PTC Device Positive Temperature Coefficient (PTC) devices are simple, inexpensive, but critical circuit components that protect against overload or short-circuit (fault) conditions. Although multiple differences exist between PTCs and traditional one-time fuses, probably the most notable is that PTCs can allow current to flow after the fault is cleared without replacing the fuse, often referred to as resettable. PTC exhibit a positive temperature coefficient (resistance increases exponentially with increased temperature) allowing them to protect circuits exposed to increased currents or temperature. The Positive Temperature Coefficient (PTC) device protects itself and the circuit by increasing its internal resistance in the event of a short-circuit or overcurrent, as shown by the graph below. 5 Typical Applications 6 Summary 7 Contact, Ordering Information and Additional Resources 1. Introduction This application note introduces the basic concepts of PolyTron™ PTC devices, their main features, benefits and typical applications. A detailed description of their operation, fault and protection modes, and typical circuit diagram is given. Additional application information, specific product details, and contact and ordering information are available at www.CooperBussmann.com. 2. Definition of Terms Note the terms below are related to all DC parameters: Hold Current, Ihold - maximum current a PTC device can sustain for four (4) hours without tripping, at 23°C. Maximum Current, Imax - maximum current a PTC device can withstand without damage at rated voltage. Max. Voltage, Vmax - maximum voltage device can withstand without damage at Imax. Trip Current, Itrip - minimum current that will switch or trip a PTC from low-to-high resistance state, at 23°C. Initial Resistance, Ri - The PTC resistance in initial state, measured at 23°C. 1 Figure 1. Positive and Negative Temperature Coefficient Curves. A Negative Temperature Coefficient (NTC) is a device in which the internal resistance decreases as the temperature increases. This feature makes NTCs useful in applications such as push-pull amplifiers, battery protection and sensor applications. Overly simplified, the operation of PTC devices can be described by two distinct modes: ON and OFF. - -The “ON” or “tripped” mode corresponds to the state in which the device is operational, providing high resistance and, hence, circuit protection until the fault condition, short or overcurrent, is removed. “Tripping” refers to the quick transition from low to high resistance, and it happens when a certain current level is exceeded. - -The “OFF” or “normal” mode corresponds to the normal low resistance state, in which the PTC device is “invisible” to the circuit, i.e., there are no through losses due to them. This state can also be seen as a standby mode. - -For reference purposes, the resistance ratio between ON vs.OFF state is in the 6-10x range. PTCs are comprised of a mix of conductive and non-conductive materials. Under normal conditions the current flows easily through the conductive material, but as the current increases, the conductive particles heat up and the internal composition changes, limiting the current in the circuit. The device remains in this state until the current drops and the material cools down allowing the material to return to its initial composition (low resistance mode) as illustrated below. PTCs are intended to protect both primary and secondary circuits and are always connected in series with the load. PTCs are not sensitive to polarity. In some cases, such as sensitive or expensive loads where increased circuit protection is needed, both supply lines are protected as shown below. All lines including the ground are typically protected In most telecommunication equipment (base stations, routers, gateways, etc.), where multiple supply lines are (potentially) exposed to external faults. Figure 4. Typical PTC Application: Single/Multiple Supply Line Protection. In the figures above, additional inductors and capacitors are used on the power supply lines to help filter the noise and EMI often generated by motors to avoid affecting other surrounding electronic devices powered from the same lines. For more complete circuit protection against ESD faults and short-circuit, PTCs are typically complemented by ESD suppressors, providing full circuit protection (current and voltage), as shown below in the USB application. Figure 2. Conductive Paths for Normal and Tripped States. PTCs come in different sizes, shapes and packages - SMD, radial and axial (see below) - making them suitable for many circuit protection, package and solder reflow requirements. Figure 5. Typical PTC Use for a USB 3.0 Application. In the USB case above, the PTC device protects the circuit against shortcircuit or overload on the USB supply line, whereas the ESD suppressors protect the data lines against any voltage spikes that can damage the microcontroller or the load. Cooper Bussmann offers a complete range of overcurrent and overvoltage protection solutions, including the PTC, one time fuses, and ESD suppressors. These Cooper Bussmann solutions are suited to fit even the most complex application requirements in terms of currents, voltages, response time, and temperature range. Figure 3. SMD and Radial Leaded PTC Families Suited for Many Applications. 2 One-Time vs. PTC Below is a short summary of the differences between PTC devices and One-Time fuses. Leakage Current: • One Time – after overload, no current flows • PTC – limits current flow to a low leakage level Fault Current: • One Time – similar to interrupting rating, fuse will completely interrupt the current at this amp rating • PTC – the maximum current the device can limit; the current is not interrupted Operating Voltage Rating: • One Time – many fuses can be rated up to 600V • PTC – generally not rated above 60V; though there are some 250V for telecommunications d. How fast does your PTC response need to be? - This greatly depends on the application. Please consult the data sheet. Give yourself at least a 10-20% margin to ensure proper operation, especially for capacitive loads. e. What is the maximum power dissipation during the tripped state? - For some specific battery powered applications with strict standby or operation current, the tripped current (and indirectly the power dissipation) is very important. f. What is the resistance ratio (normal vs. tripped)? - This is important to know in determining the voltage drop across the PTC device during normal or tripped state. g. Verify the installation layout for proper selection product type. - Cooper Bussmann offers Radial or SMD solutions. Help for answering these or any of your other design questions are found in our catalog or data sheets. Additionally our experts are happy to assist you via email at [email protected]. Hold Current Rating: Some of the information contained in the data sheets (specification, graphs, • One Time – radial fuses have ratings up to 30A and sometimes higher or others) is further explained below. • PTC – generally no higher than 14A Temperature Derating: • One Time – percent of rating usually only varies from approximately 90 to 110% • PTC – extremely important as percent of rating can range from 40 to150% Resistance: • One Time – have low resistance • PTC – generally have about twice the resistance of similarly rated fuses Time Current Characteristics: From a typical Cooper Bussmann PTC data sheet, one may read this PTC component has a maximum voltage allowed of 16Vdc, and the maximum current allowed is 40A. In terms of currents, the hold current is 0.75A and the trip current is 1.5A. This device has a 0.3W maximum power dissipation and takes 0.4sec to trip at max 8A. This PTC has an initial resistance of 0.11Ω that increases to 0.23Ω in tripped mode. Additionally, some graphs are included in the data sheet, such as Trip Time vs. Fault Current below. • One Time – are available in fast-acting and time-delay • PTC – time-current curves are most similar to a time-delay fuse 4. Understanding Key Parameters and Selecting the Right PolyTron™ PTC Device for Your Application Before selecting a PTC device for your application, ask a few basic questions: a. What is the normal operating current (Ihold) expected in the circuit? - Select a PTC device that gives at least a 20% margin over your calculated current figure if operating at room temperature. For lower or higher temperature operation, as the margin varies with the temperature, please consult the derating graph, and detailed explanation below. b. What is the maximum circuit voltage (Vmax)? - Ensure long operating life select a device that can withstand the maximum voltage in your circuit. c. What is the maximum fault current (Imax) in your circuit? - Ensure long operating life select a device that can withstand the maximum current in your circuit. For capacitive loads always account for in-rush currents. 3 Figure 6. Trip Time vs. Fault Current. Each colored line represents a different value PTC device. Following the dark blue line from the top of the graph to the bottom, the PTC device represented trips in: - 1000sec @ 0.2A - 1sec @ 0.3A - 0.2sec @ 1A - 0.03sec @ 2A - 0.01sec @ 3A Based on application specific requirements, a designer could select the device with proper response time and maximum current for his application. The Trip Time vs. Current, measured at different operating temperatures (0°C, 20°C and 60°C), as shown below. Thermal Derating Curve, shown below. Figure 8. Trip Time vs. Trip Current Dependence. From the graph above one can easily understand the temperature influence on the trip time and current. Figure 7. Thermal Derating Graph. Operating temperature greatly affects the performance of the PTC device. Looking at the graph above, one can select the temperature (horizontal axis) with the derating point (vertical axis). For example, the 100% derating point intersects the line at 20°C. To better understand this graph and the PTC behavior, let us look at three different cases using the graph above. For illustration purposes, let us assume that 20°C and 100% derating corresponds to a current Ihold = 1A. - When the PTC device operates at -20°C, the % derating is 130%. In this case, the new current would be I(-20°C) = Ihold *1.3 = 1.3A - Lastly, when the PTC device operates at 80°C, this corresponds to a 50% derating. The new current would be I(80°C)= Ihold *0.5 = 0.5A In this case, for a 5A trip current: - The trip/response time is about 1sec @ 60°C - About 10sec @ 20°C - About 10,000sec @ 0°C In other words, the higher the temperature, the shorter the trip time. The designer should understand the variation in trip time with temperature and consider how the trip time affects the specific application. 5. Typical Applications Similar to traditional, one-time fuses, there are an unlimited number of applications for PTC devices. There is simply no reliable, safe circuit design without basic fuse protection. In addition to the ubiquitous USB 2.0 and USB 3.0 applications as shown previously, some typical applications are shown below. The protection mechanism works the same way regardless of the application. In summary, the PTC hold current (Ihold) is: - 1.3A at -20°C - 1A at 20°C - 0.5A at 80°C So, in other words, by increasing the operating temperature (above room temperature), the hold (or trip) currents are reduced by a factor of 0.5 (50%).The opposite is true for low temperatures. By decreasing the operating temperature (under room temperature) to -20°C, the hold (or trip) currents are increased by a factor of 1.3 (130%). The designer must be aware of the variation of the circuit’s operating temperature and apply the correct derating to ensure proper circuit protection operation. Figure 9. Rechargeable Battery Pack. This is a typical rechargeable battery pack for cell phones, MP3, and cameras, but the analogy of its functionality can be easily extended for any other rechargeable systems. In this case the PTC device is used to protect the charging system as well as the load. The PTC is typically mounted very close to the battery and charging module, so that any temperature increase is easily and quickly detected, ensuring a proper response time. 4 Figure 10. Notebook Protection for I/O Ports, USB and A/V. In this notebook, or generally, for any computer, netbook, or e-book application, the input and output ports are protected by PTC devices (an ESD suppressor is also recommended). The potential for a short-circuit/overload event is very real and PTC devices are ideally suited for this application. Without a resettable overcurrent protection device, the application would require expensive service and long down time (imagine taking your laptop to a computer service shop every time the one-time fuse needs replacing). Figure 12. Telecommunication Equipment (PBX, Modulators, Mixers, Etc.). Some additional PTC applications include, but are not limited to: Medical Equipment - CT-scan, MRI, ultrasound, O2 pumps, portable equipment. Industrial Power and Transmission - fans, motors, heaters, pumps, transformers, monitors, automated meter reading. White Goods - Dash panels, embedded consumer electronics. Test and Measurement Telecommunications and Networking - amplifiers, power supplies, routers, gateways, Power over Ethernet (PoE). Computer & Peripherals - HDD, USB, battery pack charging, audio/video boards, cooling fans for supply/processor. Automotive Electronics - mirror and seat motors, power door lock, stereo/DVD player equipment, dimming/interior light, GPS, sunroof, USB to stereo interface, other CAN/LIN bus protection. Consumer Electronics - Video gaming systems, HDTVs, GPS, DVD players, stereos, MP3. Battery & Rechargeable Devices 7. Summary Figure 11. Motor/Blower/Fan Protection. In this simplified DC motor drive circuit, the PTC device is designed to protect the power supply and motor from any shortcircuit or overload condition. The PTC should be selected to carry the inrush current and expected overload current spikes in addition to the normal operating current of the motor. 5 Positive Temperature Coefficient devices (PTCs), are simple, inexpensive, but critical circuit protection components with similar behavior to traditional fuses. However, being resettable is a great advantage in some applications. PTCs can be used in any circuit application, regardless of complexity or cost. Cooper Bussmann offers a complete range of overcurrent and overvoltage protection solutions, including PTC, one time fuses, and ESD suppressors. 7. Contact and Ordering Information Application Engineering • Call 636-527-1270 • E-mail: [email protected] Design Kits • DKPPR-18835-R Radial PolyTron™ PTCs • DKPPS-18836-R SMD PolyTron™ PTCs Online Resources (www.cooperbussmann.com/elx) • • • • Data Sheets www.cooperbussmann.com/DatasheetsElx Application Notes Ordering Product Samples Product Profiler Technical Reference and Competitive Cross www.cooperbussmann.com/ProductSearch.aspx © 2011 Cooper Bussmann www.cooperbussmann.com 6 Reorder # 4072 0811 PDF Only