* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download EEEB283 Electrical Machines & Drives

Pulse-width modulation wikipedia , lookup

Buck converter wikipedia , lookup

Power inverter wikipedia , lookup

Utility frequency wikipedia , lookup

History of electric power transmission wikipedia , lookup

Electric power system wikipedia , lookup

Stray voltage wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Three-phase electric power wikipedia , lookup

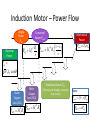

Electrification wikipedia , lookup

Alternating current wikipedia , lookup

Mains electricity wikipedia , lookup

Dynamometer wikipedia , lookup

Power engineering wikipedia , lookup

Induction cooking wikipedia , lookup

Commutator (electric) wikipedia , lookup

Voltage optimisation wikipedia , lookup

Brushless DC electric motor wikipedia , lookup

Electric motor wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Stepper motor wikipedia , lookup

Electric machine wikipedia , lookup

Induction Motor Review By Mr.M.Kaliamoorthy Department of Electrical & Electronics Engineering PSNA College of Engineering and Technology 1 Outline Introduction Construction Concept Per-Phase Equivalent Circuit Power Flow Torque Equation T- Characteristics Starting and Braking References 2 Introduction Induction motors (IM) most widely used IM (particularly squirrel-cage type) compared to DC motors Rugged Lower maintenance More reliable Lower cost, weight, volume Higher efficiency Able to operate in dirty and explosive environments 3 Introduction • IM mainly used in applications requiring constant speed – Conventional speed control of IM expensive or highly inefficient • IM drives replacing DC drives in a number of variable speed applications due to – Improvement in power devices capabilities – Reduction in cost of power devices 4 Induction Motor – Construction Stator balanced 3-phase winding distributed winding – coils distributed in several slots produces a rotating magnetic field a 120o 120o c’ b’ Rotor usually squirrel cage conductors shorted by end rings Rotating magnetic field induces voltages in the rotor Induced rotor voltages have same number of phases and poles as in stator winding c b a’ 120o 5 Induction Motor – Construction 6 Induction Motor – Concept • Stator supplied by balanced 3-phase AC source (frequency f Hz or rads/sec ) – field produced rotates at synchronous speed s rad/sec 2 4 (1) 120 s f ns f P P P where P = number of poles • Rotor rotates at speed m rad/sec (electrical speed r = (P/2) m) • Slip speed, sl – relative speed (2) between rotating field and rotor sl s m • Slip, s – ratio between slip speed m and synchronous speed (3) s s s 7 Induction Motor – Concept • Relative speed between stator rotating field and rotor induces: – emf in stator winding (known as back emf), E1 – emf in rotor winding, Er • Frequency of rotor voltages and currents: f r sf (4) • Torque produced due to interaction between induced rotor currents and stator field • Stator voltage equation: Vs Rs I s j2πf Lls I s E1 • Rotor voltage equation: sEr Rr I r js2πf Llr I r Er Rr s I j 2πf L I r lr r 8 Induction Motor – Concept • E1 and Er related by turns ratio aeff Rs Lls Llr Is + + Vs Im + Lm E1 – Ir – Er Rr/s – • Rotor parameters can be referred to the stator side : E1 aeff Er 2 Rr' aeff Rr I r' I r aeff 2 L'r aeff Lr 9 Induction Motor – Per Phase Equivalent Circuit Rs Is Lls Llr’ Ir ’ + + Lm Vs Im – • • • • • • E1 Rr’/s – Rs – stator winding resistance Rr’ – referred rotor winding resistance Lls – stator leakage inductance Llr’ – referred rotor leakage inductance Lm – mutual inductance Ir’ – referred rotor current 10 Induction Motor – Power Flow Airgap Power Pag Converted Power Pconv Mechanical Power Rr' P 3I ' 2 R ' 1 s Pag 3I r conv r r s s '2 Electrical Power Pout TLm Pin 3VT I L cos Stator Copper Loss (SCL) Rotor Copper Loss (RCL) '2 r ' P 3 I R r PSCL 3I Rs RCL 2 s Rotational losses Prot (Friction and windage, core and stray losses) Note: Pconv 1 s Pag PRCL sPag 11 Induction Motor – Torque Equation • Motor induced torque is related to converted power by: Te Pconv m (5) • Since Pconv 1 s Pag and r 1 s s , hence '2 r 3I Rr' Te s ss Pag (6) • Substituting for Ir’ from the equivalent circuit: 3Rr' Te ss Rr' Rs s Vs 2 2 X ls X lr 2 (7) 12 Induction Motor – T- Characteristic • T- characteristic of IM during generating, motoring and braking 13 Induction Motor – T- Characteristic Maximum torque or pullout torque occurs when slip is: Te Pull out Torque (Tmax) smax Rr' Rs X ls X lr The pullout torque can be calculated using: Trated 2 (8) 2 r 0 s 1 smax rated s 0 Tmax 3 Vs 2 2s R R 2 X X 2 s ls lr s (9) 14 Induction Motor – T- Characteristic Linear region of operation (small s) Te s High efficiency Te Pull out Torque (Tmax) Pout = Pconv – Prot Pconv = (1- s )Pag Trated Stable motor operation s 0 smax rated r s 1 0 15 Induction Motor – NEMA Classification of IM s NEMA = National Electrical Manufacturers Association Classification based on T characteristics Class A & B – general purpose Class C – higher Tstart (eg: driving compressor pumps) Class D – provide high Tstart and wide stable speed range but low efficiency 16 Induction Motor – Starting • Small motors can be started ‘direct-on-line’ • Large motors require assisted starting • Starting arrangement chosen based on: – Load requirements – Nature of supply (weak or stiff) • Some features of starting mechanism: – Motor Tstart must overcome friction, load torque and inertia of motorload system within a prescribed time limit – Istart magnitude ( 5-7 times I rated) must not cause • machine overheating • Dip in source voltage beyond permissible value 17 Induction Motor – Starting • Methods for starting: – Stat-delta starter – Autotransformer starter – Reactor starter – Soft Start 18 Induction Motor – Starting • Star-delta starter – Special switch used – Starting: connect as ‘star’ (Y) • Stator voltages and currents reduced by 1/√3 • Te VT2 Te reduced by 1/3 – When reach steady state speed • Operate with ‘delta’ ( ) connection – Switch controlled manually or automatically 19 Induction Motor – Starting • Autotransformer starter – Controlled using time relays – Autotransformer turns ratio aT • Stator voltages and currents reduced by aT • Te VT2 Te reduced by aT2 – Starting: contacts 1 & 2 closed – After preset time (full speed reached): • Contact 2 opened • Contact 3 closed • Then open contact 1 20 Induction Motor – Starting • Reactor starter – Series impedance (reactor) added between power line and motor – Limits starting current – When full speed reached, reactors shorted out in stages 21 Induction Motor – Starting • Soft Start – For applications which require stepless control of Tstart – Semiconductor power switches (e.g. thyristor voltage controller scheme) employed • Part of voltage waveform applied • Distorted voltage and current waveforms (creates harmonics) – When full speed reached, motor connected directly to line 22 Induction Motor – Braking • Regenerative Braking: – Motor supplies power back to line • Provided enough loads connected to line to absorb power – Normal IM equations can be used, except s is negative – Only possible for > s when fed from fixed frequency source • Plugging: – Occurs when phase sequence of supply voltage reversed • by interchanging any two supply leads – Magnetic field rotation reverses s > 1 – Developed torque tries to rotate motor in opposite direction – If only stopping is required, disconnect motor from line when = 0 – Can cause thermal damage to motor (large power dissipation in rotor) 23 Induction Motor – Braking • Dynamic Braking: – Step-down transformer and rectifier provides dc supply – Normal: contacts 1 closed, 2 & 3 opened – During braking: Contacts 1 opened, contacts 2 & 3 closed – Two motor phases connected to dc supply - produces stationary field – Rotor voltages induced – Energy dissipated in rotor resistance – dynamic braking 24 References • Chapman, S. J., Electric Machinery Fundamentals, McGraw Hill, New York, 2005. • Rashid, M.H, Power Electronics: Circuit, Devices and Applictions, 3rd ed., Pearson, New-Jersey, 2004. • Trzynadlowski, Andrzej M. , Control of Induction Motors, Academic Press, 2001. • Nik Idris, N. R., Short Course Notes on Electrical Drives, UNITEN/UTM, 2008. • Ahmad Azli, N., Short Course Notes on Electrical Drives, UNITEN/UTM, 2008. 25