* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download NEPTUNE Power Low Voltage Circuit - APL-UW Website

Resilient control systems wikipedia , lookup

Standby power wikipedia , lookup

Audio power wikipedia , lookup

Wireless power transfer wikipedia , lookup

Fault tolerance wikipedia , lookup

Control system wikipedia , lookup

Portable appliance testing wikipedia , lookup

Power over Ethernet wikipedia , lookup

Current source wikipedia , lookup

Power factor wikipedia , lookup

Stray voltage wikipedia , lookup

Power inverter wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Protective relay wikipedia , lookup

Electrification wikipedia , lookup

Voltage optimisation wikipedia , lookup

Amtrak's 25 Hz traction power system wikipedia , lookup

Three-phase electric power wikipedia , lookup

Ground (electricity) wikipedia , lookup

Electric power system wikipedia , lookup

Surge protector wikipedia , lookup

History of electric power transmission wikipedia , lookup

Power MOSFET wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Electrical substation wikipedia , lookup

Earthing system wikipedia , lookup

Power engineering wikipedia , lookup

Mains electricity wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Opto-isolator wikipedia , lookup

Buck converter wikipedia , lookup

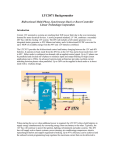

NEPTUNE Power System Low Voltage Circuit Preliminary Design Review Tim McGinnis Dec 4-5, 2003 NEPTUNE Low Voltage Requirements • SPE1 Average and peak power delivery to the Node Science Connectors for a particular node shall not be less than 3.3 kW and 9.3 kW, respectively. • SPE3 Power delivery to the user shall be at two voltage levels: 48VDC and 400VDC. • SPE4 1.3 kW of 48VDC power shall be available to the Node Science Connectors at each node. Note: Assumes 700W internal load Power System Specifications • Each 400V user circuit shall have a maximum current capacity of 23A (9300 W) that shall be available at any or all science connectors • Each 48V user circuit shall have a maximum current capacity of 27 A (1300 W) ) that shall be available at any or all science connectors • The Power System must be able to detect a ground fault of <100 µA on any of the science connector power conductors and to isolate that conductor from the internal power circuit. • All external circuits shall have a deadface switch that will provide galvanic isolation in the event of a ground fault. Power System Specifications (cont’d) • The Power System shall have an interface to the Observatory Control System (OCS) which would allow users to define and schedule power settings such as power cycling, changes in power requirements, etc. • The Power System must be able to detect a over-current fault on any of the science connector power circuits and disconnecting the faulted circuit. The current limit will be set by the user through the OCS. • The Power System shall be capable of monitoring the total load requests for both of the output voltages and controlling the power to the loads so as not to exceed the Power System operating limits. • All circuits providing power to external loads will have isolation from each other, seawater and all internal circuits. Electrical Specifications PARAMETER Input Voltage: External Load Control Number of External Loads 400VDC 48VDC Internal Load Control Number of Internal Loads 48VDC +5, +/- 12VDC Ground Fault Detection Ground Fault Isolation Over-current Protection Isolation between circuits Seawater ground isolation Surge and Spike Protection Noise Filtering SPECIFICATION 48 VDC & 400VDC 8 9.2 kW (22.5A) to any or all loads (includes 48V External Loads) 1.2 kW (25A) to any or all loads 16 100W (2A) to any load, 800W total TBD 100 μA Full galvanic Programmable by user >XX V > XX MΩ VERIFICATION Testing Testing Testing Testing Testing Testing Testing Design and Testing Design and Testing Design and Testing Design and Testing Mechanical Requirement PARAMETER Thermal Management: Dimensions Connectors Mounting REQUIREMENT Immersed in Flourinert TBD TBD TBD COMPLIANCE Analysis and Testing Design Design Design Environmental Requirement PARAMETER Temperature range EMC and EMI Shock and vibration REQUIREMENT per Neptune Power System Requirement Document per Neptune Power System Requirement Document per Neptune Power System Requirement Document COMPLIANCE Analysis and Testing Analysis and Testing Analysis and Testing Mission Assurance Requirement PARAMETER Lifetime REQUIREMENT 30 years FIT Rate 1000 FITS (?) COMPLIANCE Design, Modeling and Accelerated Life Testing Design, Modeling and Accelerated Life Testing LV Circuit Description • • • • • 400V & 48V bus voltage monitoring 48V-5V/12V DC-DC Converter External Load Control & Monitoring Ground Fault Monitoring & Isolation Internal Load Control & Monitoring 400V & 48V Bus Voltage Monitoring • Resistor Voltage Divider • Isolation Amplifier to maintain isolation between 400V and Controller 48V:5/12V Converter • • • • • • • Controller requires 5V, +/-12V Relay control inputs require +12V Current sensors require +/- 12V Isolation amps require +/- 12V DCS components require +12V Need to confirm all voltage and power requirements LV Converter PCB will use COTS/MIL level converter modules • Design will include 100% redundancy, minimize possibility of single point failures COTS/MIL Level DC-DC Converters • High MTBF • MIL Qualification • Environmental Stress Screening on each module External Load Control & Monitoring • • • • 8 science connectors (4 for MARS) 400V, max I = 23 A (9300 W) 48V, max I = 27 A (1300 W) Max current available at any single connector or the total of all connectors - typical current is much lower • Need power switching and current monitoring for both voltages on all connectors • Need to monitor ground fault current on both power busses • Need deadface relay on both legs for galvanic fault isolation External Load Control & Monitoring • 8 Science Connectors • ROV/Underwater Mateable • Rated for 3000V/30A • ~10 conductors 2 - 400V 2 - 48V 4 - Ethernet 2 - Time Distribution External Load Control & Monitoring • Solid state MOSFET switch – can interrupt DC current – non-zero off-state leakage – if cable cut, small fault current could result – non-zero on-state resistance – results in device heating External Load Control & Monitoring • Mechanical relay – provides complete galvanic isolation – has near-zero on-state resistance – cannot interrupt DC current without arcing and damage to switch I 400VDC I 48VDC Science Connector External Load Control & Monitoring • Mechanical/Solid State Hybrid – Solid state switch to make/break current – Mechanical relay to provide galvanic “deadface” isolation in case of faulted instrument External Load Control & Monitoring • Heating problem with MOSFETs can be reduced by: – Paralleling devices • 600V relay has RDS(on) of 0.13Ω • With single device I = 25A, PD = (25)2 * 0.13 = 81W • With 4 paralleled devices I = 25/4 A, PD = (6.25)2 * 0.4 = 5W – Operating the devices in liquid (Fluorinert) External Load Control & Monitoring Device Rating (V) PD @ 25A RDS(on) (Ω) (W) 2 devices in parallel (W) 4 devices in parallel (W) 8 devices in parallel (W) 100 0.009 5.6 1.4 0.4 0.09 200 0.02 13 3.1 0.8 0.20 500 0.08 50 12.5 3.1 0.78 600 0.13 81 20.3 5.1 1.27 800 0.25 156 39.1 9.8 2.44 1000 0.40 250 62.5 15.6 3.91 External Load Control & Monitoring • Paralleling MOSFETS requires good current sharing • Need to select parts with similar RDS(on) and good PCB design • RDS(on) goes up with temperature so there is some inherent current balancing External Load Control & Monitoring • NEPTUNE long life requirement may require hermetically sealed components • International Rectifier has proposed a module with: – 6 paralleled Hi-rel MOSFETS in hermetically sealed case – Entire die from single wafer – Good matching of key parameters – Less expensive than discretes in quantities of 100’s Internal Load Control • Provide 12V & 48V power switching to internal loads – Optical transport equipment – Data Communications Network equipment – Controller – Time Distribution equipment – Engineering sensors – Power System electronics and sensors Internal Load Control • Do not need isolation or deadface relays • Maximum current through any device: – Optical Equipment = 48W @ 73W = 1.5A – DCS Router = 12V @ 165W = 13.8A • Switching can be accomplished with single MOSFET devices Low Voltage Power Requirements (Preliminary) (in Watts) Fiber Optics Equipment +5V 50 Communications Routers Controller +12V 300 350 15 10 Sensors 24 Relays 22 Totals +48V 65 406 300 Over-current Protection • Controller would have maximum current setting from Observatory Control System • Over-current trip point can vary – lights or pump may turn on in response to an event • Controller monitors current and opens switch if overcurrent trip point exceeded Ground Fault Monitoring • Difficult to protect individual user circuits if they all connect to 400V or 48V bus • Differential ground fault monitoring only sensitive to ~10mA • Most reasonable option for high sensitivity is to monitor bus potentials relative to seawater • If fault is detected, need to cycle power off to all loads to find faulted circuit • Users need to know about this potential load disconnection – may need to provide their own batteries 400VDC 400V External Loads 400VDC input 400RET 48VDC 400V-48V DC-DC converter 48V External Loads 48RET Iso Amp 48V-12V DC-DC converter Iso Amp Iso Amp 12V -12V Node Control Circuitry 48V-5V DC-DC converter 5V Internal Circuit Isolated from External Circuits 0V 12V Internal Loads 400V-48V DC-DC converter ??? 48V Internal Loads Status • Built prototype circuit board and dummy load for 1 science connector circuit • 48 V and 400V circuit with: – Current sensor – MOSFET switch 1 for 48V 6 in parallel for 400V – Mechanical deadface relay • MOSFETS run hot in air at rated current – need to test in Fluorinert