* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download RA 65/FA 65 5

Survey

Document related concepts

Schmitt trigger wikipedia , lookup

Operational amplifier wikipedia , lookup

German Luftwaffe and Kriegsmarine Radar Equipment of World War II wikipedia , lookup

Surge protector wikipedia , lookup

Crossbar switch wikipedia , lookup

Valve RF amplifier wikipedia , lookup

Nanogenerator wikipedia , lookup

Voltage regulator wikipedia , lookup

Current mirror wikipedia , lookup

Power electronics wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Transcript

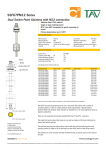

VA Flow Meters VA Flow Meters VA Flow Meters RA 65/FA 65 RA 65/FA 65 RA 65/FA 65 Limit switches MSK1/MSK12/MSKW Design and applications Low voltage directive In order to realize a local display with a Above 50 V AC/ 75 V DC, contacts are subject monitoring function the flowmeter Measuring units RA 65 and FA 65 are to the EU Low-Voltage Directive. The user is can be equipped with limit switches. based on the variable area float principle. required to verify their use accordingly. In pipelines the RA 65 is installed by The limit switch consists of a connector means of screwed pipe joints and the housing and a bistable reed contact. FA 65 is mounted between flanges. The Proper use A magnet integrated in the float switches this reed contact. The limit switch is guided in a The user is responsible for assessing the guide slot on the back of the protective tube application, for use as prescribed, and for measuring range. In case of inductive or VA flow meters RA 65 and FA 65 are material compatibility as regards the liquid capacitive load applications, e.g. caused by customized with a scale specific for the damage arising from incorrect or improper In dependence on their geometry such peaks medium to be measured. RA 65 and FA 65 use of the devices. also occur in lines, if they exceed a certain length. It is therefore recommended to use an are used in plant engineering (e.g. furnace construction and water treatment). Pressure surges can cause glass breakage, additionally available arc suppression relay and should therefore generally be avoided. “MSR”. This increases the switching capacity which are adjustable throughout the entire should be observed. capacitive peaks. It thereby ensures a long The equipment from Kirchner und Tochter has been In all other respects we advise following the lifetime of the contact. tested in compliance with applicable installation recommendations specified in CE-regulations of the European Community. Code VDI/VDE 3513, Sheet 3. Technical data of the limit switches sensor an output signal can be generated Switching voltage 50V AC/75V DC 50V AC/75V DC valid version of our documents can be found under 0,5 A 0,5 A Switching capacity 10 W/VA 10 W/VA this URL: www.kt-web.de The Kirchner und Tochter QM-System is normally open (N/O) 9001:2008. The quality is systematically MSKW Switching voltage 50V AC/75V DC Switched current 0,5 A Switching capacity 5 W/VA Dielectric strength 110V AC/200V DC -20 to +90°C Temperature range ¹) Switching function Connection diagram 1) -5- 230V AC/400V DC -20 to +90°C certified in accordance with DIN-EN-ISO ●● perspex half-shell as shatter protection By installing an linear displacement which is proportional to the height setting Technical data supplied without liability. The current ●● armature with protective steel tube employed as detectors too. available on request. MSK12 Design measuring range, these units can be The respective declaration of conformity is Switched current Dielectric strength 230V AC/400V DC Temperature range1) -20 to +90°C Switching function normally closed (N/C) Connection diagram ●● calibrated borosilicate measuring cone By installation of electrical limit switches, The limit values given in the data sheet and avoids the appearance of inductive and KLA GS transparent fluids and gases. Each unit is The manufacturer shall not be liable for any current and voltage peaks may occur. KLA Standard most suitable for the flow measurement of product used in his process. contactors or solenoid valves, uncontrolled MSK1 an inspection window. suitability of the flow meters for his case of and can be adjusted throughout the entire Design borosilicate glass measuring cone is located inside a protection steel tube with ●● reliable due to simple mode of operation of the flow meter. The technical documents provide a detailed ●● with limit switches usable as detectors explanation of the function and measuring principle of VA flow meters. ●● optionally analogue output 4 - 20 mA adapted to the continuously increasing demands. ●● scales specific for the media to be measured ●● optionally explosion-protected design change over (CO) The temperature resistance of the flow meter is crucial. A. Kirchner & Tochter GmbH Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de · e-mail: [email protected] Version 3.5 -6- A. Kirchner & Tochter GmbH Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de · e-mail: [email protected] Version 3.5 A. Kirchner & Tochter GmbH Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de · e-mail: [email protected] Version 3.5 -1- VA Flow Meters VA Flow Meters (Rp) RA 65/FA 65 RA 65/FA 65 Types Design Description RA 65 With threaded connection FA 65 With flange connection RA 65 / FA 65-EM With linear displacement sensor RA 65 / FA 65-MSK1 With switching contact (Normally open) RA 65 / FA 65-MSK12 With switching contact (Normally closed) RA 65 / FA 65-MSKW With switching contact (Change over) Technical Data Size Pipe fitting 9,5 Rp ¼ Rp 3/8 Rp ½ 28 32 39 12 16 20 308 310 312 25 19 Rp ½ Rp ¾ Rp 1 39 48 55 20 25 32 413 420 424 45 30 Rp 1 Rp 1 ¼ Rp 1 ½ 55 67 74 32 40 50 424 428 430 60 Rp 1 ¼ Rp 1 ½ Rp 2 67 74 90 40 50 63 428 430 445 70 Rp 1 ½ Rp 2 Rp 2 ½ Rp 3 74 90 111 131 50 63 75 90 430 445 446 450 90 36 FA 65: PN 10 at 20 °C RA 65: PN 10 at 20 °C Max. operating pressure See table measuring ranges on page 3 Thermal endurance 80 °C, optionally 100 °C Ambient temperature 90 °C Turn-down ration 1:10 Accuracy class Error limit (G) Linear limit (qG) VDE/VDI 3513 page 2 (08/2008) 1,6 % 50 % Connection RA 65 Two-part pipe fitting: Insert with cylindrical internal thread to ISO 7-1 Size Connection FA 65 Flanges PN 10 to DIN EN 1092-1, others on request 9,5 Corrosion protection Epoxy paint kiln-dried, traffic blue (RAL 5017), satin-finished C2 43 1) S355 Threaded joint 19 Grey cast iron, size 9,5 S355 Measuring glass Borosilicate glass Splinter shield Perspex Gaskets Standard: 1.4571 optionally: PVC, PP, PVDF or PTFE with lead core Floats for gases 1) Aluminium optionally: PVC, PP, PTFE, PVDF or 1.4571 With limit contacts 1) 1.4571 with magnetic core (liquids) PVC with magnetic core (gases) -2- the height setting of the flow meter. This signal RA 65 FA 65 can be displayed in 4-20mA or 0-10V to realise a remote indication. The sensor is connected via the enclosed M12 x 1mm connector. 1) DN L H 10 15 10 15 20 25 260 25 20 25 40 360 60 25 40 50 360 70 50 65 360 90 360 45 D Compact Design ●● Realise remote indication d4 k Screws Most helpful for SPS integration 4mA. 4 4 4 4 4 4 M12 M12 M12 M12 M12 M12 14 14 M12 14 14 14 75 4 85 4 110 4 M12 M12 M16 M12 14 18 115 68 85 4 150 88 110 4 165 102 125 4 M12 M16 M16 M12 18 18 165 102 125 4 185 122 145 4 M16 M16 18 18 40 45 40 45 58 68 105 58 115 68 150 88 60 65 60 65 75 85 Technical Data Linear displacement sensor EM Measuring range Size 9,5 19 Length: 655 mm 36 43 (min. and max. measuring range; all intermediate measuring ranges are possible) Measuring range m³/h H2O Measuring range m³/h air at STP ¹) 0,5 20 0,006 0,3 – – 5 l/h 200 l/h – – 0,06 3,3 Measurement range [A...B] 160mm Repeatability ≤ 0,1% from measurement range ≤ dependent upon position sensor Linearity deviation ≤ 1% v.E. Temperature drift ≤ ± 0,006 % /K RA 65 Threaded connection FA 65 Flange connection DN max. operating pressure bar at 20°C Size *) A Ambient temperature -25°C... +70° 19 37 Operating voltage 15... 30 VDC Rp ¼ Rp ¼ Rp ½ 10 15 10 30 45 Idle current ≤ 15mA 36 46 Output function Four-wire, analogue output 43 47 Voltage output → Load resistor 0... 10 V ≥ 4,7 k Ω Current output → Load resistor 4...20 mA ≤ 0,4 k Ω Sampling rate 200 Hz Connection Connector, M12 x 1 Protection class IP67 Operating voltage display LED, green Measurement range display LED, yellow, position sensor in detection range 0,012 0,12 – – 0,12 1,2 0,15 1,6 – – 1,5 16 Rp ½ Rp 3/4 Rp 1 10 15 20 25 10 0,1 0,3 – – 1 3 1,3 3,6 – – 13 36 Rp 1 Rp 1 ¼ Rp 1 ½ 25 40 10 *) 0,4 0,8 – – 4 8 4 8 – – 40 80 Rp 1 ¼ Rp 1 ½ Rp 2 40 50 8 0,9 1,6 – – 9 16 5 16 – – 50 160 Rp 1 ½ Rp 2 Rp 2 ½ Rp 3 50 65 8 Measuring ranges for other substances and operating conditions on request. Linear displacement sensor not available for Size 9,5 Connection diagram 1) at STP: at standard conditions (0 °C and 1,013 bar abs.) 1) Floats of small sizes are nonguided. Size 30 and larger: Partly with guided float. Optionally sizes 9,5 (without limits switches only) and 19 are deliverable. A detailed table is available on request. Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de · e-mail: [email protected] Version 3.5 Measuring range indication via LED performs stable operation only after approx. d2 Thread 30 A. Kirchner & Tochter GmbH Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 High level of reproducibility in the range of 3.7mA to around 4mA and Qty 90 95 90 95 105 115 ●● ●● ●● ●● Please notice that the sensor has a blind zone Standard NBR optionally FPM, EPDM, silicone Floats for liquids 1) 1) 43 Malleable cast iron, galvanized Flanges FA 65 principle delivers an output signal proportional to FA 65 36 Heads RA 65 H A Materials Precision steel tube made of P235 L d for bonding and welding sleeves 30 Protective sleeve The linear displacement sensor based on the Hall RA 65 SW d ¹) Nominal pressure Corrosion class Linear displacement sensor EM Dimensions A. Kirchner & Tochter GmbH Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de · e-mail: [email protected] Version 3.5 -3- A. Kirchner & Tochter GmbH Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 The thermal endurance of the flow meter is crucial. Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de · e-mail: [email protected] Version 3.5 -4- VA Flow Meters VA Flow Meters (Rp) RA 65/FA 65 RA 65/FA 65 Types Design Description RA 65 With threaded connection FA 65 With flange connection RA 65 / FA 65-EM With linear displacement sensor RA 65 / FA 65-MSK1 With switching contact (Normally open) RA 65 / FA 65-MSK12 With switching contact (Normally closed) RA 65 / FA 65-MSKW With switching contact (Change over) Technical Data Size Pipe fitting 9,5 Rp ¼ Rp 3/8 Rp ½ 28 32 39 12 16 20 308 310 312 25 19 Rp ½ Rp ¾ Rp 1 39 48 55 20 25 32 413 420 424 45 30 Rp 1 Rp 1 ¼ Rp 1 ½ 55 67 74 32 40 50 424 428 430 60 Rp 1 ¼ Rp 1 ½ Rp 2 67 74 90 40 50 63 428 430 445 70 Rp 1 ½ Rp 2 Rp 2 ½ Rp 3 74 90 111 131 50 63 75 90 430 445 446 450 90 36 FA 65: PN 10 at 20 °C RA 65: PN 10 at 20 °C Max. operating pressure See table measuring ranges on page 3 Thermal endurance 80 °C, optionally 100 °C Ambient temperature 90 °C Turn-down ration 1:10 Accuracy class Error limit (G) Linear limit (qG) VDE/VDI 3513 page 2 (08/2008) 1,6 % 50 % Connection RA 65 Two-part pipe fitting: Insert with cylindrical internal thread to ISO 7-1 Size Connection FA 65 Flanges PN 10 to DIN EN 1092-1, others on request 9,5 Corrosion protection Epoxy paint kiln-dried, traffic blue (RAL 5017), satin-finished C2 43 1) S355 Threaded joint 19 Grey cast iron, size 9,5 S355 Measuring glass Borosilicate glass Splinter shield Perspex Gaskets Standard: 1.4571 optionally: PVC, PP, PVDF or PTFE with lead core Floats for gases 1) Aluminium optionally: PVC, PP, PTFE, PVDF or 1.4571 With limit contacts 1) 1.4571 with magnetic core (liquids) PVC with magnetic core (gases) -2- the height setting of the flow meter. This signal RA 65 FA 65 can be displayed in 4-20mA or 0-10V to realise a remote indication. The sensor is connected via the enclosed M12 x 1mm connector. 1) DN L H 10 15 10 15 20 25 260 25 20 25 40 360 60 25 40 50 360 70 50 65 360 90 360 45 D Compact Design ●● Realise remote indication d4 k Screws Most helpful for SPS integration 4mA. 4 4 4 4 4 4 M12 M12 M12 M12 M12 M12 14 14 M12 14 14 14 75 4 85 4 110 4 M12 M12 M16 M12 14 18 115 68 85 4 150 88 110 4 165 102 125 4 M12 M16 M16 M12 18 18 165 102 125 4 185 122 145 4 M16 M16 18 18 40 45 40 45 58 68 105 58 115 68 150 88 60 65 60 65 75 85 Technical Data Linear displacement sensor EM Measuring range Size 9,5 19 Length: 655 mm 36 43 (min. and max. measuring range; all intermediate measuring ranges are possible) Measuring range m³/h H2O Measuring range m³/h air at STP ¹) 0,5 20 0,006 0,3 – – 5 l/h 200 l/h – – 0,06 3,3 Measurement range [A...B] 160mm Repeatability ≤ 0,1% from measurement range ≤ dependent upon position sensor Linearity deviation ≤ 1% v.E. Temperature drift ≤ ± 0,006 % /K RA 65 Threaded connection FA 65 Flange connection DN max. operating pressure bar at 20°C Size *) A Ambient temperature -25°C... +70° 19 37 Operating voltage 15... 30 VDC Rp ¼ Rp ¼ Rp ½ 10 15 10 30 45 Idle current ≤ 15mA 36 46 Output function Four-wire, analogue output 43 47 Voltage output → Load resistor 0... 10 V ≥ 4,7 k Ω Current output → Load resistor 4...20 mA ≤ 0,4 k Ω Sampling rate 200 Hz Connection Connector, M12 x 1 Protection class IP67 Operating voltage display LED, green Measurement range display LED, yellow, position sensor in detection range 0,012 0,12 – – 0,12 1,2 0,15 1,6 – – 1,5 16 Rp ½ Rp 3/4 Rp 1 10 15 20 25 10 0,1 0,3 – – 1 3 1,3 3,6 – – 13 36 Rp 1 Rp 1 ¼ Rp 1 ½ 25 40 10 *) 0,4 0,8 – – 4 8 4 8 – – 40 80 Rp 1 ¼ Rp 1 ½ Rp 2 40 50 8 0,9 1,6 – – 9 16 5 16 – – 50 160 Rp 1 ½ Rp 2 Rp 2 ½ Rp 3 50 65 8 Measuring ranges for other substances and operating conditions on request. Linear displacement sensor not available for Size 9,5 Connection diagram 1) at STP: at standard conditions (0 °C and 1,013 bar abs.) 1) Floats of small sizes are nonguided. Size 30 and larger: Partly with guided float. Optionally sizes 9,5 (without limits switches only) and 19 are deliverable. A detailed table is available on request. Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de · e-mail: [email protected] Version 3.5 Measuring range indication via LED performs stable operation only after approx. d2 Thread 30 A. Kirchner & Tochter GmbH Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 High level of reproducibility in the range of 3.7mA to around 4mA and Qty 90 95 90 95 105 115 ●● ●● ●● ●● Please notice that the sensor has a blind zone Standard NBR optionally FPM, EPDM, silicone Floats for liquids 1) 1) 43 Malleable cast iron, galvanized Flanges FA 65 principle delivers an output signal proportional to FA 65 36 Heads RA 65 H A Materials Precision steel tube made of P235 L d for bonding and welding sleeves 30 Protective sleeve The linear displacement sensor based on the Hall RA 65 SW d ¹) Nominal pressure Corrosion class Linear displacement sensor EM Dimensions A. Kirchner & Tochter GmbH Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de · e-mail: [email protected] Version 3.5 -3- A. Kirchner & Tochter GmbH Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 The thermal endurance of the flow meter is crucial. Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de · e-mail: [email protected] Version 3.5 -4- VA Flow Meters VA Flow Meters (Rp) RA 65/FA 65 RA 65/FA 65 Types Design Description RA 65 With threaded connection FA 65 With flange connection RA 65 / FA 65-EM With linear displacement sensor RA 65 / FA 65-MSK1 With switching contact (Normally open) RA 65 / FA 65-MSK12 With switching contact (Normally closed) RA 65 / FA 65-MSKW With switching contact (Change over) Technical Data Nominal pressure FA 65: PN 10 at 20 °C RA 65: PN 10 at 20 °C Max. operating pressure See table measuring ranges on page 3 Size Pipe fitting 9,5 Rp ¼ Rp 3/8 Rp ½ 28 32 39 12 16 20 308 310 312 25 19 Rp ½ Rp ¾ Rp 1 39 48 55 20 25 32 413 420 424 45 30 Rp 1 Rp 1 ¼ Rp 1 ½ 55 67 74 32 40 50 424 428 430 60 Rp 1 ¼ Rp 1 ½ Rp 2 67 74 90 40 50 63 428 430 445 70 Rp 1 ½ Rp 2 Rp 2 ½ Rp 3 74 90 111 131 50 63 75 90 430 445 446 450 90 36 43 80 °C, optionally 100 °C Ambient temperature 90 °C Turn-down ration 1:10 Accuracy class Error limit (G) Linear limit (qG) VDE/VDI 3513 page 2 (08/2008) 1,6 % 50 % Connection RA 65 Two-part pipe fitting: Insert with cylindrical internal thread to ISO 7-1 Size Connection FA 65 Flanges PN 10 to DIN EN 1092-1, others on request 9,5 Corrosion protection Epoxy paint kiln-dried, traffic blue (RAL 5017), satin-finished C2 1) S355 Threaded joint 19 Grey cast iron, size 9,5 S355 Measuring glass Borosilicate glass Splinter shield Perspex Gaskets 1) 43 Malleable cast iron, galvanized Flanges FA 65 principle delivers an output signal proportional to the height setting of the flow meter. This signal RA 65 Standard: 1.4571 optionally: PVC, PP, PVDF or PTFE with lead core Floats for gases 1) Aluminium optionally: PVC, PP, PTFE, PVDF or 1.4571 With limit contacts 1) 1.4571 with magnetic core (liquids) PVC with magnetic core (gases) can be displayed in 4-20mA or 0-10V to realise a remote indication. The sensor is connected via the enclosed M12 x 1mm connector. 1) DN L H 10 15 10 15 20 25 260 25 20 25 40 360 60 25 40 50 360 70 50 65 360 90 360 45 Compact Design ●● Realise remote indication D d4 k Screws Thread Most helpful for SPS integration 4mA. 4 4 4 4 4 4 M12 M12 M12 M12 M12 M12 14 14 M12 14 14 14 75 4 85 4 110 4 M12 M12 M16 M12 14 18 115 68 85 4 150 88 110 4 165 102 125 4 M12 M16 M16 M12 18 18 165 102 125 4 185 122 145 4 M16 M16 18 18 90 95 90 95 105 115 40 45 40 45 58 68 105 58 115 68 150 88 60 65 60 65 75 85 Technical Data Linear displacement sensor EM Measuring range (min. and max. measuring range; all intermediate measuring ranges are possible) Size Measuring range m³/h H2O Measuring range m³/h air at STP ¹) 9,5 0,5 20 0,006 0,3 19 Length: 655 mm 36 43 – – 5 l/h 200 l/h – – 0,06 3,3 Measurement range [A...B] 160mm Repeatability ≤ 0,1% from measurement range ≤ dependent upon position sensor Linearity deviation ≤ 1% v.E. Temperature drift ≤ ± 0,006 % /K RA 65 Threaded connection FA 65 Flange connection DN max. operating pressure bar at 20°C Size *) A Ambient temperature -25°C... +70° 19 37 Operating voltage 15... 30 VDC Rp ¼ Rp ¼ Rp ½ 10 15 10 30 45 Idle current ≤ 15mA 36 46 Output function Four-wire, analogue output 43 47 Voltage output → Load resistor 0... 10 V ≥ 4,7 k Ω Current output → Load resistor 4...20 mA ≤ 0,4 k Ω Sampling rate 200 Hz Connection Connector, M12 x 1 0,012 0,12 – – 0,12 1,2 0,15 1,6 – – 1,5 16 Rp ½ Rp 3/4 Rp 1 10 15 20 25 10 0,1 0,3 – – 1 3 1,3 3,6 – – 13 36 Rp 1 Rp 1 ¼ Rp 1 ½ 25 40 10 *) 0,4 0,8 – – 4 8 4 8 – – 40 80 Rp 1 ¼ Rp 1 ½ Rp 2 40 50 8 0,9 1,6 – – 9 16 5 16 – – 50 160 Rp 1 ½ Rp 2 Rp 2 ½ Rp 3 50 65 8 Measuring ranges for other substances and operating conditions on request. Linear displacement sensor not available for Size 9,5 Protection class IP67 Operating voltage display LED, green Measurement range display LED, yellow, position sensor in detection range Connection diagram 1) at STP: at standard conditions (0 °C and 1,013 bar abs.) 1) Version 3.5 Measuring range indication via LED performs stable operation only after approx. d2 Qty 30 A. Kirchner & Tochter GmbH Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 High level of reproducibility in the range of 3.7mA to around 4mA and Floats of small sizes are nonguided. Size 30 and larger: Partly with guided float. Optionally sizes 9,5 (without limits switches only) and 19 are deliverable. A detailed table is available on request. -2- ●● ●● ●● ●● Please notice that the sensor has a blind zone Standard NBR optionally FPM, EPDM, silicone Floats for liquids 1) FA 65 FA 65 36 Heads RA 65 H A Materials Precision steel tube made of P235 L d for bonding and welding sleeves 30 Protective sleeve The linear displacement sensor based on the Hall RA 65 SW d ¹) Thermal endurance Corrosion class Linear displacement sensor EM Dimensions Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de · e-mail: [email protected] A. Kirchner & Tochter GmbH Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Version Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de e-mail: · [email protected] 3.5 -3- A. Kirchner & Tochter GmbH Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 The thermal endurance of the flow meter is crucial. Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de · e-mail: [email protected] Version 3.5 -4- VA Flow Meters VA Flow Meters VA Flow Meters RA 65/FA 65 RA 65/FA 65 RA 65/FA 65 Limit switches MSK1/MSK12/MSKW Design and applications Low voltage directive In order to realize a local display with a Above 50 V AC/ 75 V DC, contacts are subject monitoring function the flowmeter Measuring units RA 65 and FA 65 are to the EU Low-Voltage Directive. The user is can be equipped with limit switches. based on the variable area float principle. required to verify their use accordingly. In pipelines the RA 65 is installed by The limit switch consists of a connector means of screwed pipe joints and the housing and a bistable reed contact. FA 65 is mounted between flanges. The Proper use A magnet integrated in the float switches this reed contact. The limit switch is guided in a The user is responsible for assessing the guide slot on the back of the protective tube application, for use as prescribed, and for measuring range. In case of inductive or VA flow meters RA 65 and FA 65 are material compatibility as regards the liquid capacitive load applications, e.g. caused by customized with a scale specific for the damage arising from incorrect or improper In dependence on their geometry such peaks medium to be measured. RA 65 and FA 65 use of the devices. also occur in lines, if they exceed a certain length. It is therefore recommended to use an are used in plant engineering (e.g. furnace construction and water treatment). Pressure surges can cause glass breakage, additionally available arc suppression relay and should therefore generally be avoided. “MSR”. This increases the switching capacity which are adjustable throughout the entire should be observed. capacitive peaks. It thereby ensures a long The equipment from Kirchner und Tochter has been In all other respects we advise following the lifetime of the contact. tested in compliance with applicable installation recommendations specified in CE-regulations of the European Community. Code VDI/VDE 3513, Sheet 3. Technical data of the limit switches sensor an output signal can be generated Switching voltage 50V AC/75V DC 50V AC/75V DC valid version of our documents can be found under 0,5 A 0,5 A Switching capacity 10 W/VA 10 W/VA this URL: www.kt-web.de The Kirchner und Tochter QM-System is normally open (N/O) 9001:2008. The quality is systematically MSKW Switching voltage 50V AC/75V DC Switched current 0,5 A Switching capacity 5 W/VA Dielectric strength 110V AC/200V DC -20 to +90°C Temperature range ¹) Switching function Connection diagram 1) -5- 230V AC/400V DC -20 to +90°C certified in accordance with DIN-EN-ISO ●● perspex half-shell as shatter protection By installing an linear displacement which is proportional to the height setting Technical data supplied without liability. The current ●● armature with protective steel tube employed as detectors too. available on request. MSK12 Design measuring range, these units can be The respective declaration of conformity is Switched current Dielectric strength 230V AC/400V DC Temperature range1) -20 to +90°C Switching function normally closed (N/C) Connection diagram ●● calibrated borosilicate measuring cone By installation of electrical limit switches, The limit values given in the data sheet and avoids the appearance of inductive and KLA GS transparent fluids and gases. Each unit is The manufacturer shall not be liable for any current and voltage peaks may occur. KLA Standard most suitable for the flow measurement of product used in his process. contactors or solenoid valves, uncontrolled MSK1 an inspection window. suitability of the flow meters for his case of and can be adjusted throughout the entire Design borosilicate glass measuring cone is located inside a protection steel tube with ●● reliable due to simple mode of operation of the flow meter. The technical documents provide a detailed ●● with limit switches usable as detectors explanation of the function and measuring principle of VA flow meters. ●● optionally analogue output 4 - 20 mA adapted to the continuously increasing demands. ●● scales specific for the media to be measured ●● optionally explosion-protected design change over (CO) The temperature resistance of the flow meter is crucial. A. Kirchner & Tochter GmbH Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de · e-mail: [email protected] Version 3.5 -6- Kirchner A. & Tochter GmbH Fon:2065 +49 9609-0 · Fax: +49 2065 9609-22 Version Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de · e-mail: [email protected] 3.5 Kirchner A. & Tochter GmbH Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de · e-mail: [email protected] Version 3.5 -1- VA Flow Meters VA Flow Meters VA Flow Meters RA 65/FA 65 RA 65/FA 65 RA 65/FA 65 Limit switches MSK1/MSK12/MSKW Design and applications Low voltage directive In order to realize a local display with a Above 50 V AC/ 75 V DC, contacts are subject monitoring function the flowmeter Measuring units RA 65 and FA 65 are to the EU Low-Voltage Directive. The user is can be equipped with limit switches. based on the variable area float principle. required to verify their use accordingly. In pipelines the RA 65 is installed by The limit switch consists of a connector means of screwed pipe joints and the housing and a bistable reed contact. FA 65 is mounted between flanges. The Proper use A magnet integrated in the float switches this reed contact. The limit switch is guided in a The user is responsible for assessing the guide slot on the back of the protective tube application, for use as prescribed, and for measuring range. In case of inductive or VA flow meters RA 65 and FA 65 are material compatibility as regards the liquid capacitive load applications, e.g. caused by customized with a scale specific for the damage arising from incorrect or improper In dependence on their geometry such peaks medium to be measured. RA 65 and FA 65 use of the devices. also occur in lines, if they exceed a certain length. It is therefore recommended to use an are used in plant engineering (e.g. furnace construction and water treatment). Pressure surges can cause glass breakage, additionally available arc suppression relay and should therefore generally be avoided. “MSR”. This increases the switching capacity which are adjustable throughout the entire should be observed. capacitive peaks. It thereby ensures a long The equipment from Kirchner und Tochter has been In all other respects we advise following the lifetime of the contact. tested in compliance with applicable installation recommendations specified in CE-regulations of the European Community. Code VDI/VDE 3513, Sheet 3. Technical data of the limit switches sensor an output signal can be generated Switching voltage 50V AC/75V DC 50V AC/75V DC valid version of our documents can be found under 0,5 A 0,5 A Switching capacity 10 W/VA 10 W/VA this URL: www.kt-web.de The Kirchner und Tochter QM-System is normally open (N/O) 9001:2008. The quality is systematically MSKW Switching voltage 50V AC/75V DC Switched current 0,5 A Switching capacity 5 W/VA Dielectric strength 110V AC/200V DC -20 to +90°C Temperature range ¹) Switching function Connection diagram 1) -5- 230V AC/400V DC -20 to +90°C certified in accordance with DIN-EN-ISO ●● perspex half-shell as shatter protection By installing an linear displacement which is proportional to the height setting Technical data supplied without liability. The current ●● armature with protective steel tube employed as detectors too. available on request. MSK12 Design measuring range, these units can be The respective declaration of conformity is Switched current Dielectric strength 230V AC/400V DC Temperature range1) -20 to +90°C Switching function normally closed (N/C) Connection diagram ●● calibrated borosilicate measuring cone By installation of electrical limit switches, The limit values given in the data sheet and avoids the appearance of inductive and KLA GS transparent fluids and gases. Each unit is The manufacturer shall not be liable for any current and voltage peaks may occur. KLA Standard most suitable for the flow measurement of product used in his process. contactors or solenoid valves, uncontrolled MSK1 an inspection window. suitability of the flow meters for his case of and can be adjusted throughout the entire Design borosilicate glass measuring cone is located inside a protection steel tube with ●● reliable due to simple mode of operation of the flow meter. The technical documents provide a detailed ●● with limit switches usable as detectors explanation of the function and measuring principle of VA flow meters. ●● optionally analogue output 4 - 20 mA adapted to the continuously increasing demands. ●● scales specific for the media to be measured ●● optionally explosion-protected design change over (CO) The temperature resistance of the flow meter is crucial. A. Kirchner & Tochter GmbH Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de · e-mail: [email protected] Version 3.5 -6- A. Kirchner & Tochter GmbH Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de · e-mail: [email protected] Version 3.5 A. Kirchner & Tochter GmbH Fon: +49 2065 9609-0 · Fax: +49 2065 9609-22 Dieselstraße 17 · D-47228 Duisburg Internet: www.kt-web.de · e-mail: [email protected] Version 3.5 -1-