* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download SPECIFICATION FOR 75 KV,75 mA, DC HV TEST KIT

Survey

Document related concepts

Buck converter wikipedia , lookup

Ground (electricity) wikipedia , lookup

Electrical substation wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Fault tolerance wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Opto-isolator wikipedia , lookup

Stray voltage wikipedia , lookup

Alternating current wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Surge protector wikipedia , lookup

Earthing system wikipedia , lookup

Rectiverter wikipedia , lookup

Automatic test equipment wikipedia , lookup

Telecommunications engineering wikipedia , lookup

Electromagnetic compatibility wikipedia , lookup

Voltage optimisation wikipedia , lookup

Transcript

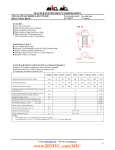

PRODUCT STANDARD

HYDROGENERATOR

HG 08 003 Rev. 00

PAGE 1 of 2

SPECIFICATION FOR 75 KV,75 mA, DC HV TEST KIT

PART A:

PART B:

TECHNICAL SPECIFICATION.

GENERAL CONDITIONS

1.0

INTRODUCTION:

The utility of this will be for the testing of wound stators and rotors of hydro-generator/motors

at various stages of manufacturing and/or erection at different applied voltages. The equipment

must be complete with HVDC Source, Full Wave Rectifier, capacitor Bank, timer, metering &

protective devices. The equipment must be in one / two piece/s and should have following

feature / items.

1.1 One number 230 ± 10% Volts, 50Hz single phase motorized Variac rated for 5.62KVA, Voltage

variation will be step-less 0-75 Kilo Volts in the output. The coil of HT Transformer should be

oil immersed.

2.0

2.1

2.2

TECHNICAL DATA

Input supply :

230 ± 10% volts, 50 ± 5% Hz, 1 Phase AC supply.

Output voltage

: 0 to 75 KV, 75 mA DC

3.0

FEATURES OF 75 KV, 75 mA , DC HV TEST KIT

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

3.11

-

Bobbin/roll should be provided to roll the primary & secondary cables on the equipment.

The equipment should be provided with lifting lugs for lifting by crane. It should also have

handle and four wheels for easy mobility on the shop floor / erection bay.

The kit should have equipment indicators for power on, HT on, Tripped, Overload.

Clips on the free end of secondary cables should be provided for easy connection to the job

under test.

Trip setting shall be Settable at 25/50/75 mA.

The equipment should be safe in operation and should be provided with zero start interlock,

adequate rating relay & fuses in the circuit.

The equipment should be provided with 1 no. stand suitable for 75KV DC for connection,

(by fuse wire etc) to the job under test located at a suitable distance. Arrangement for

earthing with spherical termination of the job will be provided after the test is over.

The equipment front panel mounted meters should be provided with protective covers.

The equipment to be provided with visual and audible alarm facility for "Test under progress".

The system should have in-built short circuit protection.

Metering: The following meters should be provided on the front panel of equipment.

0-250 Volts digital (3 ½ digit) AC Voltmeter having 0.5% accuracy on LT side and

preferable AE/ MECO make. It should display the actual voltage.

- 0-100 Amp digital (3 ½ digit) AC ammeter having 0.5% accuracy on LT side,

preferably AE / MECO make. It should display the actual current.

- 0-100 KV digital (3 ½ digit) HV DC voltmeter having 0.5% accuracy on HV side and

preferable AE/ MECO make. It should display the actual voltage.

-

Xkksiuh; ,oa vf/kdkj lqjf{kr

bl izi=k ij nh xbZ tkudkjh Hkkjr gsoh bysfDVzdYl fyfeVsM dh laEifRr gS bls izR;{k

;k vizR;{k :I ls dEiuh ds fgrks dks uqdlku igqWp

a kus ds fy, dnkfi mi;ksx ugh fd;k tkos

PART A: TECHNICAL SPECIFICATION.

- 0-75 mA digital (3 ½ digit) DC Ammeter having 0.5% accuracy on HV side, preferably

AE / MECO make. It should display the actual current.

Lak'kks/ku %

RSk;kjdrkZ

B.P.SWAIN

gkbMzkt

s ujsVj bathfu;fjax foHkkx

Hkkjr gsoh bysfDVzdYl fyfeVsM

tkap

Wa drkZ

vuqeksnudrkZ

P.K.VERMA

J.K.BHATI

Tkkjh djus

dh fnukad

28.04.10

PRODUCT STANDARD

HYDROGENERATOR

HG 08 003 Rev.00

PAGE 2 of 2

- HT on / off push button with indicating LED lamps, (Non fuseable)

- “HT ON” amber rotary light on top of the equipment.

4.0 CABLES

4.1 Primary cable

Primary cables should be 3 core and Minimum 30 Meters long suitable for connection to single

phase 230 ± 10% volts, 50 ± 5% Hz AC supply. 1100 V grade cable to be used.

4.2 Secondary Cable- Cable should be of flexible copper, 10 meter Long suitable for rated voltage of 75 KV DC

with a special electrode.

- HT side cables should have adequate insulation to withstand the required voltage and test

voltage as per standards.

- Xkksiuh; ,oa vf/kdkj lqjf{kr

- bl izi=k ij nh xbZ tkudkjh Hkkjr gsoh bysfDVzdYl fyfeVsM dh laEifRr gS bls izR;{k

;k vizR;{k :I ls dEiuh ds fgrks dks uqdlku igqWp

a kus ds fy, dnkfi mi;ksx ugh fd;k tkos

-

5.0

Max. Dimension of unit (L x B x H) to be furnished with the offer.

6.0

Net weight with GA drawing to be furnished with the offer.

7.0

PAINTING:

HV test equipment shall be powder coated outside with epoxy paint light gray RAL-7035 and

inside with white epoxy paint and all bright steel components shall be coated with rust

preventive paint before dispatch.

8.0

TEST AND INSPECTION

-

-

9.0

Supplier to submit his QA plan along with offer.

Testing shall be done as per relevant standards. Inspection will be done at supplier’s works by

BHEL representative. Internal testing and QC reports along with one copy instruction manual

shall be furnished for BHEL’s approval before giving call for inspection.

INSTRUCTION MANUAL

-

-

10.0

-

The instructional manual shall consists of following sections. The instruction manual shall be

made on good quality paper (at least 90 gsm) and shall be made in bound volumes suitable for

long term usage in shop.

Introduction.

Photograph of all items of equipment

Description of equipment.

GA drawings.

Schematic diagram./ Circuit diagrams.

Test certificate.

Detailed procedure to operate the equipment ( written in easy language for understanding of

operators)

Dos and Donts

FAQ(Frequently asked Questions ) and answers

Trouble shooting flow chart.

Service centre contact details like address, email address, phone nos, cell nos. etc.

GUARANTEE

As per Annexure-CL

11.0 DOCUMENTATION

- 1 set complete with drawings/leaflets/catalogue and technical information giving full description,

operation, dimensions, weight etc. & fully filled in Annexure-CL along with offer.

12.0 COMPLETENESS OF OFFER

Supplier to confirm compliance of specifications & Annexure-CL clause-by-clause in first

instance itself. Any deviation shall be clearly brought out in the offer, without this the offer will

not considered and will be rejected..