* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download I. Introduction

Electronic music wikipedia , lookup

Spark-gap transmitter wikipedia , lookup

Three-phase electric power wikipedia , lookup

Power inverter wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Power engineering wikipedia , lookup

Current source wikipedia , lookup

Electrical substation wikipedia , lookup

Electrification wikipedia , lookup

Electronic paper wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Distribution management system wikipedia , lookup

Automotive lighting wikipedia , lookup

Voltage regulator wikipedia , lookup

Stray voltage wikipedia , lookup

Opto-isolator wikipedia , lookup

Surge protector wikipedia , lookup

Power electronics wikipedia , lookup

Power MOSFET wikipedia , lookup

History of electric power transmission wikipedia , lookup

Voltage optimisation wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Alternating current wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Buck converter wikipedia , lookup

Mains electricity wikipedia , lookup

Fluorescent lamp wikipedia , lookup

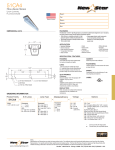

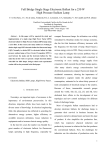

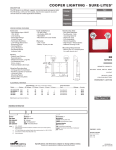

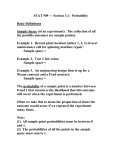

Single Stage Electronic Ballast for High Pressure Sodium Lamps With Low Crest Factor Abstract – In this paper will be reported the study and implementation of a single stage High Power Factor (HPF) electronic ballast for High Pressure Sodium (HPS) lamps using a Half-Bridge Boost Rectifier integrated with an Electronic Ballast based in a LCC filter. In the recent years many authors are working to obtain single stage HPF electronic ballast for fluorescent lamps [1-3]. Normally to obtain HPF in electronic ballast for high pressure sodium lamps a Power Factor Preregulator (PFP) is used between the mains and the electronic ballast [3]. The main idea in this work is to present a simple and cheap electronic ballast with HPF for HPS lamps. This simple solution also presents low crest factor. Design criteria and experimental results will be also presented in the final version of this paper. I. INTRODUCTION Nowadays, an important topic of awareness is the importance of environment preservation. In this direction, important efforts have been made in the diverse areas of knowledge. In electrical engineering field, this phenomenon has reflected in searching for alternatives energy systems, higher efficiency on available resources utilization, losses reduction in equipments and to increase electric energy quality. In the last few years the market was flooded by a great number of electronic ballasts for fluorescent lamps operating in high frequency, especially by compact fluorescent lamps. Its utilization was widely stimulated by Brazilian media for energy economy, due the fact that luminous efficiency increases with the frequency for this kind of lamp. Brazil faced a serious energy crisis in 2001. Many corrective actions were taken to mitigate this serious problem. One of them was the energy rationing which consisted in overtaxing or even cutting energy supply from consumers which exceeds the prefixed energy quotes. Also many electric energy concessionaires had distributed gratuitously compact fluorescent lamps for residential consumers, showing the importance of illumination’s segment inside the global energy consumption, estimated to be about thirty percent of total consumption of electrical energy in the country. Because of these, innumerable research groups around the world, like [1], [2], [3] and [4], have dedicated their efforts to the development of new topologies and new control techniques for different kinds of discharge lamps. Most of magnetic ballast manufacturers had to develop electronic ballasts for discharge lamps to guarantee their survival in business because the consumers started to demand more and more this type of product. It also simplifies the production line, which has expressive physical reduction and productivity increase in relation the line that produces the conventional ballasts. Now, the challenges for industries are the reduction of production costs, the reduction of converter size, unitary power factor and null harmonic distortion which implies in a substantial improvement of energy quality consumed by ballasts. Here in Brazil, the development of electronic ballasts for HID lamps is being made by a few groups of researchers. However in a close future, these ballasts will be in the production lines of main national manufacturers. The porpoise of this paper is to report the development of a low cost single stage HPF electronic ballast for HPS lamps. The design criteria will be presented in this work for the proposed circuit. There are many kind of high-pressure lamps; however, this work will focus only the high-pressure sodium lamps (HPS), widely used in public illumination. The HPS lamps radiate energy on a great part of the visible spectrum [5]. These lamps provide a reasonable color reproduction (it has IRC 23 color reproduction index). They are available up to 130 lm/W of luminous efficiency and color temperature of 2100 K, approximately. The HPS lamps, as any other HID lamps, need ballast to operate correctly. The ballast is additional equipment connected between the power line and the discharge lamp. The ballast has two main functions: to guarantee lamps ignition through the application of a high voltage pulse between the lamp electrodes and to limit the current that will circulate through it. The lamp would be quickly destroyed without current limitation, due the negative resistance characteristic of the lamp, as can be observed in figure 1. The HPS lamps have many particularities when they operate in high frequency, such as: Can be modeled by a resistance in steady state; Can have luminous intensity controlled; The spectrum color reproduction can be modified; Presents the acoustic resonance phenomenon, which can result in the arc extinguishing until 1 the lamp destruction; III. BALLAST DESIGN CRITERIA Positive Resistance Lamp Current Negative Resistance Lamp Voltage Breakdown Voltage Fig. 1. - Typical voltage x current curve for HID lamps. In order to obtain low cost electronic ballast for HPS lamps with HPF a single stage converter was conceived. The idea is to build the PFC using the half-bridge boost rectifier working in discontinuous conducting mode (DCM) integrated with the electronic ballast. Using this simple idea high power factor and low crest factor can be obtained in a single stage converter. II. STUDIED ELECTRONIC BALLAST The studied single stage high power factor electronic ballast for high pressure sodium lamps structure incorporates a bridge rectifier, a half-bridge boost rectifier and an input LC filter to minimize the EMI generated by the DCM input current. Figure 2 shows an electrical diagram of the proposed circuit. Similar circuits have been proposed by other authors using fluorescent lamps. but any paper using this topology for HPS lamps was not found. The capacitor CF in this figure is responsible by the DC bus voltage once the voltage in this capacitor has a low ripple the crest factor in the HPS is minimized. The inductor LPFC is the boost inductor, this inductor must be designed to work in DCM once the MOSFET duty cycle is constant to guarantee the perfect operation of the electronic ballast. The resistor ESR represents the equivalent series resistance of the capacitor Cs, inductor Ls and MOSFETs on resistance. To verify the performance of the proposed system a LCC electronic ballast (figure 3) for a 250 W HPS lamp was designed. The nominal lamp voltage (Vlamp) was obtained from the lamp’s manufacturer datasheet and its value is 100 VRMS. To design the LCC ballast it was added 10 % to consider loses effect. The electronic ballast input power voltage comes from the output of an input bridge rectifier; consequently, this input voltage is mains dependent. In the present design example the mains voltage adopted was Vmains= 127 VRMS. The switching frequency chosen was 68 kHz. Assuming the resistive comportment of the lamp, we can estimate the value of its resistance (R) after ignition using equation 1. Vlamp 2 (1) R 40 P Where P is the lamps power. As it was indicated in [1], the best relationship between the switching frequency and the resonance frequency before the lamp turn on is ω0/ ωs = 3, guaranteeing the high voltage generation for the lamp ignition and limiting the peak current at the MOSFET to acceptable levels. If it was adopted to work at resonance ω0 = ωs in theory we would have the possibility of an infinite voltage generation over the lamp which could be good for a quickly lamp turn on. On the other hand current would also rise to infinite because the impedance of the circuit formed by L, Cs and Cp is null just before the lamp is turned on. This operation mode will result in the MOSFET’s and driver’s destruction. L Ve Cp R Fig. 3. LCC Ballast. For the circuit showed in figure 3, considering the voltage Ve an asymmetrical square wave (from E to 0 V). It is easy to obtain the peak value Vm of the first harmonic from Fourier series. The equation 4 has shown this value: 2E (2) Vm In this study an expression was obtained to determine the peak voltage across the capacitor Cp. This expression, shown in equation 3, is valid before the lamp start up. Vcp Fig. 2. Studied HPF Electronic Ballast. Cs 2E 1 e RESR 4 L F (3) 2 Where, F is the switching frequency. Preliminary tests demonstrated that necessary peak voltage (Vopk) to guarantee the lamp ignition is 3.8 kV. A typical RESR value is 6.5 Ω. Manipulating equation (3) we can obtain the value of inductor L in equation (4). RESR 4 F L 219.5 H 2E ln 1 Vopk 2 L 1 1 1 C p Cs 1 6 L Cp Ve R Fig. 4. – Ballast equivalent circuit after ignition. After lamp ignition the ballast must guaranty that RMS voltage over the lamp do not overcome the nominal value. The RMS lamp voltage Vlamp can be obtained using the well known voltage divider for the circuit shown in figure 4, the equation 9 presents this result: R (9) Vlamp Vm Z Considering the fact that the switching frequency is estimated to be three times lesser then the resonance frequency and, usually, capacitor Cp is, at least, 10 times smaller then capacitor Cs, equation 5 may be simplified into equation 6, because the effect of the capacitance Cs is almost null. F Cs (4) The resonance frequency may be calculated using equation (5). (5) 1 Fo L (6) Manipulating equation (6), it can be obtained the value for the capacitor Cp as it is shown in equation (7). 1 Cp 2, 767nF 2 6 F L (7) To determinate the real value of the RESR, an experimental circuit using a 220 μH inductor L and a 2,7 nF capacitor Cp was stimulated with a 60 V peakto-peak square wave signal, which generated a 660 V signal over the lamp terminals, allowing the determination of RESR using equation 3. This RESR was obtained experimentally and its value was 6.5 Ω. Before the lamp startup a leakage current flows into the lamp. To determine the equivalent lamp resistance before the startup, the following measurement was made: a 10 Ω resistor was placed in series with the lamp. The obtained equivalent lamp resistance was 100 kΩ. If this resistance is taken to account a new RESR = 5.7 Ω could be easily obtained. The reference [2] and our experimental results allow us to consider that after lamps ignition, the lamp resistance is too low considering the Cp reactance. Therefore, it can be deduced the equation 8: 1 (8) // R R CP Consequently, after lamp ignition, the equivalent circuit is showed in figure 4. The modulus of the impedance of the circuit can be calculated with equation 10. To facilitate the design of the LCC filter the parameterized LCsR circuit transfer function was obtained and the result is shown in figure 13. (10) Vlamp 1 Vm , 1 2 2 Where η is the capacitor relationship factor defined as η = Cs/Cp, κ the relationship of switching frequency and resonance frequency of the circuit of figure 4, R is the lamp resistance after startup and τ is the parameterized time constant L . R 2C p Figure 5 presents the relationship between the RMS lamp voltage and the RMS first harmonic voltage, Vlamp/V1stRMS, called as parameterized lamp voltage V, for different values of η as design parameter. Using the graphic of figure 5, a η =180 was adopted. This relationship will allow us to achieve the desired V relationship shifting the frequency after the lamp is turned on. Fig. 5. Transfer Function varying κ for different values of η. With the η relationship, the value of Cs may be obtained using equation 11 for a V=0.78 relationship. 3 Cs 180 Cs C p 498nF Cp (11) IV. SIMULATION RESULTS To validate the proposed system, a half-bridge electronic ballast with the following specification: 250 W HPS lamp, input voltage (127 VAC), DC bus voltage (360 VDC) and operation frequency of (68 kHz), was simulated using the software PSIM® 6.0. Figure 6 shows the current and voltage in the mains without the EMI filter. The voltage in the lamp is showed in figure 7. The crest factor was measured. Tests indicate that ballasts with higher crest factors may result in depreciation of lumen output or reduced lamp life. It was found a crest factor of 1.37 using this ballast. HID lamp recommendations suggest a maximum crest factor of 1.8 for HPS lamps. V. CONCLUSION This paper described single stage high power factor electronic ballast for high pressure sodium lamps. This ballast presents a very low cost because it avoids an external PFP. A high power factor was obtained. The crest factor found was very low because the Electronic Ballast works with low DC bus ripple. The main drawback of this topology is to work in DCM, but for this power level is possible to use this solution with an input EMI filter. VI. ACKNOWLEDGEMENTS The authors wants to thanks CEEE “Companhia Estadual de Energia Elétrica” to the financial support given which made possible the realization of this project. VII. REFERENCES Fig. 6. –Above, voltage and current in the mains, and voltage in the lamp with 250 W below. Fig. 7. –Voltage in the lamp. [1] Bum Suk Kang; Hee Jun Kim; High Power Factor Electronic Ballast for High Pressure Sodium Lamp, TENCON 99. Proceedings of the IEEE Region 10 Conference, Volume: 2, Dec 1999, Page(s): 887 -890 vol.2. [2] Ben-Yaakov, S.; Gulko, M.; “Design and performance of an electronic ballast for highpressure sodium (HPS) lamps, Industrial Electronics”, IEEE Transactions on Volume: 44 Issue: 4, Aug 1997, Page(s): 486 -491. [3] C. Aguilar, A. Ruiz, F. Canales and F. Lee, “Analysis of the Half-Bridge Boost Rectifier as Integrated Electronic Ballast with Power Factor Correction”, Power Electronics Specialists Conference, 2001. PESC. 2001 IEEE 32nd Annual , Volume: 2 , 17-21 June 2001, Pages:707 - 712 vol.2 [4] Bisogno, F.E.; Seidel, A.R.; Holsbach, R.; do Prado, R.N.; Resonant filter applications in electronic ballast, Industry Applications Conference, 2002. 37th IAS Annual Meeting. Conference Record of the, Volume: 1, 2002, Page(s): 348 -354 vol.1 [5] Co, M.A.; Resende, C.Z.; Simonetti, D.S.L.; Vieira, J.L.F.; Almeida, P.C.A.; Microcontrolled electronic gear for low wattage metal halide (MH) and high-pressure sodium (HPS) lamps, Industry Applications Conference, 2002. 37th IAS Annual Meeting. Conference Record of the, Volume: 3, 2002, Page(s): 1863 -1868 vol.3 [6] J.R. Coaton, Lamps and Lighting, fourth edition, Arnold 1997. 4