* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download OVERALL SUMMARY OF INSULATION

Survey

Document related concepts

Switched-mode power supply wikipedia , lookup

Portable appliance testing wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Buck converter wikipedia , lookup

Stepper motor wikipedia , lookup

Rectiverter wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Surge protector wikipedia , lookup

Stray voltage wikipedia , lookup

Alternating current wikipedia , lookup

Opto-isolator wikipedia , lookup

Mains electricity wikipedia , lookup

Transcript

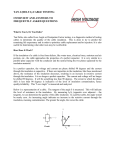

OVERALL SUMMARY OF INSULATION CONDITION OF HT MOTORS – June/July 2012 MOTOR ID KM 2115 KM 4115 I. R. (GΩ) 9.44 4.98 P. I. 9.2 6.5 D. D. 0.7 2.6 WCA Difference (%) R 0.4 0.2 NO ACTION REQUIRED, TEST AFTER 3 YEARS P. I. Ø EAR Tan delta at 20 % Vp Tan delta tip - up Capacitance tip-up Apparent charge Z 0.2 0.2 ф 0 0 I/F 0 0 ALAR M Surge Test (EAR %) 1 1 Tan δ at 20 % Voltage (%) 0.82 1.78 Tan δ Tip-up (%) 0.49 0.30 MONITOR, TEST AFTER 2 YEARS Capacitance Tip-up (%) 3.56 2.54 Apparent Charge (pC) 1070 1570 Inception Voltage (V) 4800 3200 Ratio of +ve to – ve half cycle PD Diagnosis & Action Recommended 1.30 The PD pattern is typical of discharges occurring close to the conductors. This kind of PD is much more severe & needs to be monitored closely. The capacitance tipup is extremely high; indicating discharges in internal voids. Overhauling will not help in such cases. Rewinding/replacement should be planned. 1.10 The PD pattern indicates that there is improper contact between the slot portion conductive varnish & the overhang semi-conductive varnish. The end windings should be cleaned & then conductive/semi-conductive varnish applied in the knuckle region. The high D. D. & tan delta values too indicate contamination; requiring an overhaul. The motor should be re-tested within 6 months; & overhauled at a given opportunity. ACTION RECOMMENDED, TEST AFTER 1 YEAR ACTION MANDATORY, THEN RE-TEST = Polarization Index (> 2, else indicates moisture ingress) D. D. = Dielectric Discharge Ratio (< than 2, else indicates contamination) = Phase Angle (unbalance < 10) I/F = Current Frequency Response (unbalance < 2 %) = Error Area Ratio (< 10 %, else indicates interturn shorts) < 4.0, else indicates severe aging = average increment in tan delta between 0.20 VP and phase voltage (< 0.8, else indicates severe voids) = increment in capacitance between 0.20 VP and phase voltage, divided by the capacitance at 0.20 VP (< 2.5, else indicates significant voids/PD) = summary of all discharges divided by the number of discharges If ratio of +ve to –ve half cycle PD is more than 1.5; PD is close to copper conductors (aging). If PD Ratio is less than 0.5, PD is on the slot surface region (loose coils, improper stress grading or contaminated end-winding). If PD Ratio is between 0.5 to 1.5, PD is distributed throughout the insulation (thermal degradation or de-lamination). If Ø & I/F unbalance is excessive, interturn insulation degradation is indicated.