* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

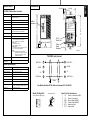

Download Terminator I/O Installation and I/O Manual

Three-phase electric power wikipedia , lookup

Electric power system wikipedia , lookup

Control system wikipedia , lookup

Electrification wikipedia , lookup

Power inverter wikipedia , lookup

History of electric power transmission wikipedia , lookup

Power over Ethernet wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Audio power wikipedia , lookup

Power engineering wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Voltage regulator wikipedia , lookup

Amtrak's 25 Hz traction power system wikipedia , lookup

Analog-to-digital converter wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Distribution management system wikipedia , lookup

Voltage optimisation wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Schmitt trigger wikipedia , lookup

Alternating current wikipedia , lookup

Power electronics wikipedia , lookup

Buck converter wikipedia , lookup

Mains electricity wikipedia , lookup

Power supply wikipedia , lookup