* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download lesson topic 8.1 synchros and control

Voltage optimisation wikipedia , lookup

Power engineering wikipedia , lookup

Stray voltage wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Distributed control system wikipedia , lookup

Three-phase electric power wikipedia , lookup

Mathematics of radio engineering wikipedia , lookup

Control theory wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Electrical substation wikipedia , lookup

Control system wikipedia , lookup

Mains electricity wikipedia , lookup

Brushless DC electric motor wikipedia , lookup

History of electric power transmission wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Resilient control systems wikipedia , lookup

Opto-isolator wikipedia , lookup

Commutator (electric) wikipedia , lookup

Alternating current wikipedia , lookup

Resonant inductive coupling wikipedia , lookup

Electric motor wikipedia , lookup

Transformer wikipedia , lookup

Stepper motor wikipedia , lookup

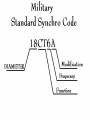

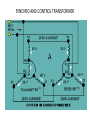

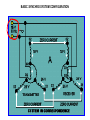

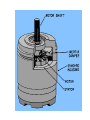

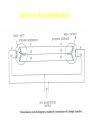

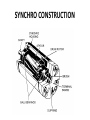

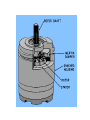

Synchros and Control Transformers Lesson Topic 8.1 LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION SYNCHRO AND CONTROL TRANSFORMER Synchro Identification Type of function C = CONTROL T = TORQUE Frequency 4 = 400hz 6 = 60hz 16TR6a Diameter in inches and tenths of inches (1.51” to 1.6”) Modification a or no letter = Original Specific function D=Differential R=Receiver T=Transformer X=Transmitter LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION SPECIFIC FUNCTION • LETTER • D • R • T • X DESIGNATION DIFFERENTIAL RECEIVER TRANSFORMER TRANSMITTER If the letter b follows the specific function designation the synchro has a rotatable stator. Ex. 1 6 T R b 6 a SEVEN BASIC FUNCTIONAL CLASSES 1. Torque Transmitter = TX 2. Torque Differential Transmitter = TDX 3. Torque Receiver = TR or TRX 4. Torque Differential Receiver = TDR 5. Control Transmitter = CX 6. Control Differential Transmitter = CDX 7. Control Transformer = CT All torque systems will start with a “T”, transmitter have an “X” and receivers an “R”. All control systems will have a “C” for control, transmitter have an “X”. Torque and control synchro systems may NOT be interchangeable. Military Standard Synchro Code • Identification marking synchros. –Example:18CT6A Military Standard Synchro Code 18CT6A -Diameter -Represented in inches. – ex) 18 = 1.8 “ Military Standard Synchro Code 18CT6A • First Letter –Synchro General Function »C – Control Military Standard Synchro Code 18CT6A • Second Letter – Specific Function » T – Transformer » Military Standard Synchro Code 18CT6A • Frequency • Indicated by the last number. • 6 – 60HZ 18CT6A • Modification • Upper-case letter • Indicates how many times a synchro has been factory modified. • ex) A - Original synchro B - First modification etc. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION Synchros are rotary, electromechanical, position sensing devices, resembling a motor, that are used to convert mechanical signals to electrical or vice versa. SYNCHRO AND CONTROL TRANSFORMER • CHARACTERISTICS (a) Physical Synchros are simply variable transformer . Rotor – primary winding w/c maybe rotated 360 degrees. Stator – three stationary winding spaced 120 electrical degrees apart. SYNCHRO CONSTRUCTION A typical synchro has 2 major components: 1. Rotor – composed of a single winding (R1, R2) receiving the excitation voltage from an external source. Salient-pole rotor Drum or wound rotor Just like motors and generators slip rings are attached to the rotor shaft, and the excitation voltage is applied via brushes. 2. The stator is composed of three wye-connected windings (S1,S2,S3). Stators are very similar to the stator of a motor or generator. It is cylindrical in construction made of laminated material on which the stator windings are wound. SYNCHRO FUNDAMENTAL The synchro transmitter resembles a small bipolar 3-phase motor. The stator is wound with a 3 circuit, Y-connected winding. The rotor is wound with a single circuit winding. R-Rotor S-Stator BLOCK AND SCHEMATIC DIAGRAM OF A SYNCHRO The schematic symbols for the synchro transmitter and receiver are the SAME. Synchro Schematic Symbols On the synchro schematic symbol the position of the arrow indicates the angular displacement of the rotor in the figures C, D and E below the displacement is zero degrees. Synchro Fundamentals • 2 types of synchros. – Torque – Control Synchro Fundamentals • Torque synchros provide enough torque to position light loads. – Dial – Pointer • Control synchros provide a small signal that is used to position heavy loads. – gun turrets – missile launchers – Numerous synchro receivers SYNCHRO AND CONTROL TRANSFORMER (TX) (TR) BASIC SYNCHRO SYSTEM CONFIGURATION BASIC SYNCHRO SYSTEM CONFIGURATION The Stator of TX will mirror its induced magnetic field in the stator of TR Rotor is usually geared to a manual or mechanical input. BASIC SYNCHRO SYSTEM CONFIGURATION BASIC SYNCHRO SYSTEM CONFIGURATION CONTROL TRANSFORMER CONTROL TRANSFORMER SYNCHRO AND CONTROL TRANSFORMER SYNCHRO AND CONTROL TRANSFORMER SYNCHRO AND CONTROL TRANSFORMER SYNCHRO AND CONTROL TRANSFORMER Electrically Zeroing • Synchros must be electrically zeroed at installation in order to function in correspondence. • There are three methods. – Voltmeter – Electric Lock – Synchro Tester Voltmeter method • • • • Safest Most accurate Most common method Three Steps – Mechanical Zero (Step 1) • Entails aligning rotor to zero mark. – Coarse Zero (Step 2) • Ensures fine zero step is not 180 deg out of phase. – False Null. – Fine Zero (Step 3) • Ensures exact zero. Voltmeter Method (Step 1) • Mechanical Zero Procedure – Deenergize System. – Place dial pointer to the zero position. – Tape dial pointer down. – Disconnect Stator leads. Voltmeter Method (Step 2) • Course Zero Procedure – Connect a jumper between R-2 and S-3. – Connect meter leads between R-1 and S-2. – Loosen captive screws around synchro housing. • Only enough to allow movement of housing. – – – – – Set meter to volts AC scale. Don PPE. Energize System. Turn housing until 37VAC reading is obtained. Disconnect all meter leads and jumper. Voltmeter Method (Step 3) • Fine Zero Procedure – Deenergize System. – Connect meter leads between S-1 and S-3. – Set meter to volts AC scale. – Don PPE. Voltmeter Method (Step 3) – Energize System. – Turn housing until null reading is obtained. • Maximum reading 2.5 VAC. – De-energize System. – Return system to normal configuration. – Conduct system test. Electrically Zeroing • Electric Lock – Fastest method – Rotors must be free to turn – Caution: do not have system energized for more than 2 minutes. Electrically Zeroing • Synchro Tester – Primary function of synchro tester is to detect faulty synchros. • Can be used to zero synchros • Less accurate since the dial is graduated in ten degree increments. Common System Faults • Most synchro problems are related to wiring or alignment. – Poor installation. – Loose connections. – Broken leads or frayed cable. • Fault symptoms will be present either in all TRs or a single TR. – All TRs • Fault is in TX. – Single TR • Fault is in that TR. Seven Synchro Faults • Rotor Faults – Shorted Rotor – Open Rotor – Reversed rotor • Stator Faults – – – – Shorted Stator Open Stator Reversed Stator 3 Reversed Stator Pairs Rotor Faults • Short – Zero Torque – Blown Fuses • Open – Low Torque – May be 180 degrees out of correspondence. • Reverse – Normal torque – Always 180 degrees out of correspondence. Stator Faults • Short – High torque – Rotor is locked across good winding – Will affect all synchros in a system • Open – Normal torque – Rotor will oscillate between good windings • Note: always check synchro symptoms slowly to ensure accurate indication. Stator Faults • Reverse – Normal torque – Opposite rotation – Will correspond on good winding • 3 Reverse Stators – Normal torque – Same direction – Will lead or lag 120 out of correspondence. Troubleshooting Six step trouble shooting technique. • A strategic approach to troubleshooting – – – – – – (1) Symptom recognition (2) Symptom elaboration (3) List probable faulty function (4) Localize faulty function (5) Localize faulty circuit (6) Failure analysis Troubleshooting • (1) Symptom recognition – Consult tech manual on proper operation to determine if there is a fault. • Many times system is functioning properly • (2) Symptom Elaboration – Record specifics of symptom. – i.e. What, where, how many etc. • (3) List probable faulty function – Decide based on first 2 steps where the problem is. – TX or TR? Troubleshooting • (4) Localize the faulty function – Take readings and prove previous findings. • (5) Localize the faulty circuit – Using readings, determine exact point of fault. • (6) Failure Analysis – Always be able to explain how you fixed it to your chain of command or supervisor. Corrective Maintenance • Common practices when working with synchros. – Never disassemble a synchro. – Always replace defective synchros – Never lubricate a synchro – Never force a synchro into place. Synchros and Control Transformers • Summary QUESTIONS???? Synchros and Control Transformers Lesson Topic 8.1 LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • Synchros play a very important role in the operation of Navy equipment. Synchros are found in just about every weapon system, communication system, underwater detection system, and navigation system used in the Navy. The importance of synchros is sometimes taken lightly because of their low failure rate. However, the technician who understands the theory of operation and the alignment procedures for synchros is well ahead of the problem when a malfunction does occur. The term "synchro" is an abbreviation of the word "synchronous." It is the name given to a variety of rotary, electromechanical, position-sensing devices. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • A synchro resembles a small electrical motor in size and appearance and operates like a variable transformer. The synchro, like the transformer, uses the principle of electromagnetic induction. Synchros are used primarily for the rapid and accurate transmission of information between equipment and stations. Examples of such information are changes in course, speed, and range of targets or missiles; angular displacement (position) of the ship's rudder; and changes in the speed and depth of torpedoes. This information must be transmitted quickly and accurately. Synchros can provide this speed and accuracy. They are reliable, adaptable, and compact. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • Synchros, as stated earlier, are simply variable transformers. They differ from conventional transformers by having one primary winding (the rotor), which may be rotated through 360º and three stationary secondary windings (the stator) spaced 120º apart. It follows that the magnetic field within the synchro may also be rotated through 360º. If an iron bar or an electromagnet were placed in this field and allowed to turn freely, it would always tend to line up in the direction of the magnetic field. This is the basic principle underlying all synchro operations. We will begin the discussion of synchro operation with a few basic points on electromagnets LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • Look at figure 1-8. In this figure, a simple electromagnet is shown with a bar magnet pivoted in the electromagnet's field. In view A, the bar is forced to assume the position shown, since the basic law of magnetism states that like poles of magnets repel and unlike poles attract. Also notice that when the bar is aligned with the field, the magnetic lines of force are shortest. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • If the bar magnet is turned from this position and held as shown in view B, the flux is distorted and the magnetic lines of force are lengthened. In this condition, a force (torque) is exerted on the bar magnet. When the bar magnet is released, it snaps back to its original position. When the polarity of the electromagnet is reversed, as shown in view C, the field reverses and the bar magnet is rotated 180º from its original position. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • Keeping in mind these basic points, consider how the bar magnet reacts to three electromagnets spaced 120º apart as illustrated in figure 19. In this figure, stator coils S1 and S3, connected in parallel, together have the same field strength as stator coil S2. The magnetic field is determined by current flow through the coils. The strongest magnetic field is set up by stator coil S2, since it has twice the current and field strength as either S1 or S3 alone. A resultant magnetic field is developed by the combined effects of the three stator fields. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • Coil S2 has the strongest field, and thus, the greatest effect on the resultant field, causing the field to align in the direction shown by the vector in view A of the figure. The iron-bar rotor aligns itself within the resultant field at the point of greatest flux density. By convention, this position is known as the zerodegree position. The rotor can be turned from this position to any number of positions by applying the proper combination of voltages to the three coils, as illustrated in figure 1-10, view (A), view (B), view (C), view (D), view (E), view (F). LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • In the previous examples, dc voltages were applied to the coils. Since synchros operate on ac rather than dc, consider what happens when ac is applied to the electromagnet in figure 1-11. During one complete cycle of the alternating current, the polarity reverses twice. Therefore, the number of times the polarity reverses each second is twice the excitation frequency, or 120 times a second when a 60-Hz frequency is applied. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • Since the magnetic field of the electromagnet follows this alternating current, the bar magnet is attracted in one direction during onehalf cycle (view A) and in the other direction during the next half cycle (view B). Because of its inertia, the bar magnet cannot turn rapidly enough to follow the changing magnetic field and may line up with either end toward the coil (view C). LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • This condition also causes weak rotor torque. • For these reasons, the ironbar rotor is not practical for ac applications. Therefore, it must be replaced by an electromagnetic rotor as illustrated in figure 1-12. In this figure, both stationary and rotating coils are connected to the same 60Hz source. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • During the positive alternation (view A), the polarities are as shown and the top of the rotor is attracted to the bottom of the stationary coil. During the negative alternation (view B), the polarities of both coils reverse, thus keeping the rotor aligned in the same position. In summary, since both magnetic fields change direction at the same time when following the 60-Hz ac supply voltage, the electromagnetic rotor does not change position because it is always aligned with the stationary magnetic field SYNCHRO CLASSIFICATION, STANDARD MARKING AND SYMBOLS There are two general classifications of synchro systems: 1. Torque systems – designed to move light loads. Dials or pointers for remote indicators like engine order telegraph, remote compass indicators or wind direction indicators. 2. Control systems – designed to move heavy loads. Gun mounts, Radar antenna and missile launchers. The load dictates the type of synchro system. Synchros are designed to operate at one of two frequencies, 60 or 400 Hertz and have excitation voltages of 26 volts or 115 volts. CAUTION: Never connect a 400 Hz synchro to a 60 Hz voltage. They will burn! Torque receivers are electrically identical and physically the same size as torque transmitters. The difference is the addition of some form of damping. (DAMPING – used to prevent oscillations in, or the spinning of receiver rotors. This is accomplished either electrically or mechanically.) Synchro receivers are sensitive to sudden motion or oscillations. BASIC SYNCHRO SYSTEM OPERATION 1. In a torque synchro system when the TX rotor is initially turned the receiver will NOT be in correspondence. 2. The magnetic field around the TX rotor follows the movement of the rotor. 3. The magnetic coupling between the TX rotor and individual stator windings change. 4. The imbalance in stator voltages between TX and TR causes current flow. 5. Current flow in the receiver produces a resultant magnetic field in the receiver identical to that of the transmitter. a. Torque is now applied to the receiver rotor. b. Receiver rotor changes to the same angle as transmitter rotor. c. The stator voltages of TX and TR began to equal out. 6. The torque receiver function is to convert the electrical data supplied to its stator (from the transmitter), back to a mechanical angular position through the movement of its rotor. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • a. Synchros • (1) Synchro Identification - Example 16TR6A • (a) Diameter-The first two digits indicate the diameter of the synchro in tenths of an inch, to the next higher tenth. • (b) Usage-The first letter indicates the general function of the synchro-C for control and T for torque. The next letter indicates the specific function of the synchro, as follows: LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • (d) the last number in the designation indicates the operating frequency - 6 for 60Hz and 4 for 400Hz • (e) The lower case letter following the frequency indicator is the modification designation. • 1) The letter "a" indicates that the synchro design is original. • 2) The first modification indicated by the letter "b" etc. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • 2) Characteristics • (a) Physical • 1) Synchros are simply variable transformers, with one primary winding (the rotor) which may be rotated 360 degrees and three stationary secondary windings (the stator) spaced 120 electrical degrees apart. • 2) Receivers are electrically identical to transmitters, except for the addition of some form of dampening. • a) The transmitter is the unit whose rotor is turned mechanically by gears. • b) The receiver is the unit whose rotor follows the movement of the transmitters rotor. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • • • • • • • • (b) Electrical. 1) A synchro works on the same basis as a transformer. 2) The rotor is the primary and the stator is the secondary. 3) When an AC excitation voltage is applied to the rotor of a synchro transmitter; the resultant current produces an AC magnetic field around the rotor windings 4) This magnetic field is induced into the stator windings. 5) The magnitude of the voltage induced into the stator windings is dependent upon: a) The angular position of the coil with respect to the rotor. b) The amount of AC excitation voltage on the rotor. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • (3) System Operation. • (a) A simple synchro system (TX-TR) consists of a transmitter (TX) electrically connected to a receiver (TR). • (b) Both rotors will be connected in parallel to the same voltage source. • (c) The mechanical input to the TX is electrically transmitted to the TR. • (d) The Tr converts this electrical signal into a mechanical output, which positions either a dial or pointer to indicate the transmitted information. Synchro Systems • Two or more Synchros connected in parallel form a synchro system. – Transmitter (TX) • receives mechanical input • example: Helm is turned by helmsman. – Receiver (TR) • Provides mechanical output. • example: Ships rudder responds to helm. – TXs and TRs will rotate in “correspondence.” • Same angle • Same direction • Same torque Synchro Fundamentals LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • (e) Synchros in correspondence • 1) At correspondence, the voltage in each receiver stator equals that of the corresponding transmitter stator coil. • 2) The receiver's coil voltages oppose the transmitter's coil voltages, each producing equal voltages but the voltages are equal and opposite in magnitude and polarity. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • 3) At this instant no current can flow in the transmitter through S1 and S2 or S3 and S2 windings because the receivers equal but opposite voltages across S1 and S2, and across S3 and S2 oppose the current flow. (voltage is zero) • 4) With no current flow to establish a magnetic field, no force is exerted on the rotors. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • (f) Synchros out of correspondence. • 1) The coupling across the S3 winding has increased. • 2) Thus, the balance between the transmitter and receiver stator voltages is upset. • 3) Current flows in the stator circuit in direct proportion to the voltage imbalance existing in the circuit. • 4) The magnetic polarities established in the system at that particular instant cause each stator winding in the receiver to act as an electromagnet which causes the rotor to turn. • 5) Once the rotors are aligned, stator voltages are equal and opposite and current flow stops and the magnetic fields collapse. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • b. Control Transformers • (1) Definition • (a) Synchro device that compares two signals, the electrical signal applied to its stator and the mechanical signal applied to its rotor. The output is electrical and is taken from the rotor. • (2) CT identification - Same ID system as synchros • (3) Characteristics • (a) Physical • 1) A control transformer has one rotor coil which is capable of rotating among three (3) secondary windings, which are 120 electrical degrees apart. • a) Similar to a synchro transmitter • 2) Rotor is positioned perpendicular to the S2 winding when at electrical zero. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • (b) Electrical • 1) The stator windings (inputs) are excited from a synchro transmitter (typically a CX) or similar device. • 2) Through mutual induction an error voltage is produced in the rotor (electrical output). • 3) The rotor is never connected to an AC supply, it is the output. The stator is considered the primary winding and the rotor is considered the secondary winding of the transformer. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • 4) Rotor position is derived from an external mechanical force. • 5) Control Transformers produce NO TORQUE on their own, but they produce a voltage output from their rotor terminals (R1, R2). • (4) Principles of Operation • (a) Excitation is supplied to the stator from a transmitter. • (b) A voltage is induced into the rotor winding. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • 1) The amplitude and phase of the induced voltage depends on the angular displacement of the CT rotor in respect to the stator's magnetic field. • 2) When the rotor position is perpendicular to the stator field, the voltage across the rotor is minimum. • 3) The maximum output voltage from the rotor of the CT is approximately 55 volts , with a 115 VAC system. • This is found when the rotor is parallel to the stators magnetic field. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • (c) The rotor of the CT will usually be positioned by an external force to null the error voltage. The rotor is then perpendicular to the stator's magnetic field. • (d) The voltage output from the rotor of the CT never becomes zero, but generally at correspondence falls as low as 50-125 millivolts when used in a 115 VAC system. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • c. Simple Servo Loops • (1) CT follow-up servo loop. • (a) Turning the synchro rotor shifts the stator field of the CT, causing an error voltage to be induced into the CT rotor. • (b) The phase and magnitude of the error voltage is determined by the direction and amount that the synchro rotor is turned in relation to the CT rotor. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • (c) The CT rotor error voltage is fed to an amplifier, which in turn drives a servo motor. • (d) The servo motor, through gearing, usually positions a dial or counter and also positions the CT rotor back in angular correspondence with the transmitter's rotor. • This causes the CT rotor error voltage to decrease to zero. • (e) The servo amplifier will then have a zero input and the servo motor will stop. LESSON TOPIC 8.1 SYNCHROS AND CONTROL TRANSFORMERS, THEORY OF OPERATION • d. Servomotor • (1) Servomotors are manufactured AC or DC. • (a) The AC servomotor is usually used to drive light loads at constant speed. • (b) The DC servomotor is usually used to drive heavy loads at variable speeds. SYNCHRO AND CONTROL TRANSFORMER SYNCHRO CONSTRUCTION SYNCHRO AND CONTROL TRANSFORMER