* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Highly transmissive luminescent down

Survey

Document related concepts

Magnetic circular dichroism wikipedia , lookup

Smart glass wikipedia , lookup

Birefringence wikipedia , lookup

Ellipsometry wikipedia , lookup

3D optical data storage wikipedia , lookup

Harold Hopkins (physicist) wikipedia , lookup

Atmospheric optics wikipedia , lookup

Ultraviolet–visible spectroscopy wikipedia , lookup

Cross section (physics) wikipedia , lookup

Retroreflector wikipedia , lookup

Rutherford backscattering spectrometry wikipedia , lookup

Optical tweezers wikipedia , lookup

Silicon photonics wikipedia , lookup

Dispersion staining wikipedia , lookup

Transcript

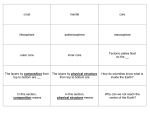

Highly transmissive luminescent down-shifting layers filled with phosphor particles for photovoltaics Anastasiia Solodovnyk,1,2,3,* Karen Forberich,2 Edda Stern,1 Janez Krč,4 Marko Topič,4 Miroslaw Batentschuk,2 Benjamin Lipovšek4 and Christoph J. Brabec1,2,3 2 1 Bavarian Center for Applied Energy Research (ZAE Bayern), Haberstr. 2a, 91058 Erlangen, Germany Institute of Materials for Electronics and Energy Technology (i-MEET), Friedrich-Alexander-Universität ErlangenNürnberg (FAU), Martensstr. 7, 91058 Erlangen, Germany 3 Erlangen Graduate School in Advanced Optical Technologies (SAOT), FAU,Paul-Gordan-Str. 6, 91052 Erlangen, Germany 4 Laboratory of Photovoltaics and Optoelectronics (LPVO), Faculty of Electrical Engineering, University of Ljubljana, Tržaška cesta 25, SI-1000 Ljubljana, Slovenia *[email protected] Abstract: We study the optical properties of polymer layers filled with phosphor particles in two aspects. First, we used two different polymer binders with refractive indices n = 1.46 and n = 1.61 (λ = 600 nm) to study the influence of Δn with the phosphor particles (n = 1.81). Second, we prepared two particle size distributions D50 = 12 µm and D50 = 19 µm. The particles were dispersed in both polymer binders in several volume concentrations and coated with thicknesses of 150-600 µm onto glass substrates. Experimental results and numerical simulations show that the layers of the higher refractive index binder with larger particles result in the highest optical transmittance in the visible light spectrum. Finally, we used numerical simulations to determine optimal layer composition for application in realistic photovoltaic devices. ©2015 Optical Society of America OCIS codes: (230.7405) Wavelength conversion devices; (160.5690) Rare-earth-doped materials; (290.5850) Scattering, particles; (160.2540) Fluorescent and luminescent materials. References and links 1. EUPVSEC, 2014, Press Release, “The European Photovoltaic Solar Energy Conference and Exhibition 2014 Confirms the Future of PV as a Major Electricity Source,” https://www.photovoltaicconference.com/pressnews/press-releases/english/2044-pr-e-26sept2014.html. 2. B. S. Richards, “Enhancing the performance of silicon solar cells via the application of passive luminescence conversion layers,” Sol. Energy Mater. Sol. Cells 90(15), 2329–2337 (2006). 3. W. H. Weber and J. Lambe, “Luminescent greenhouse collector for solar radiation,” Appl. Opt. 15(10), 2299– 2300 (1976). 4. A. Goetzberger and W. Greube, “Solar energy conversion with fluorescent collectors,” Appl. Phys. (Berl.) 14(2), 123–139 (1977). 5. E. Klampaftis and B. S. Richards, “Improvement in multi-crystalline silicon solar cell efficiency via addition of luminescent material to EVA encapsulation layer,” Prog. Photovolt. Res. Appl. 19(3), 345–351 (2011). 6. E. Klampaftis, D. Ross, S. Seyrling, A. N. Tiwari, and B. S. Richards, “Increase in short-wavelength response of encapsulated CIGS devices by doping the encapsulation layer with luminescent material,” Sol. Energy Mater. Sol. Cells 101, 62–67 (2012). 7. W. G. van Sark, K. W. J. Barnham, L. H. Slooff, A. J. Chatten, A. Büchtemann, A. Meyer, S. J. McCormack, R. Koole, D. J. Farrell, R. Bose, E. E. Bende, A. R. Burgers, T. Budel, J. Quilitz, M. Kennedy, T. Meyer, C. M. Donegá, A. Meijerink, and D. Vanmaekelbergh, “Luminescent Solar Concentrators - A review of recent results,” Opt. Express 16(26), 21773–21792 (2008). 8. E. Klampaftis, D. Ross, K. R. McIntosh, and B. S. Richards, “Enhancing the performance of solar cells via luminescent down-shifting of the incident spectrum: A review,” Sol. Energy Mater. Sol. Cells 93(8), 1182–1194 (2009). 9. X. Pi, Q. Li, D. Li, and D. Yang, “Spin-coating silicon-quantum-dot ink to improve solar cell efficiency,” Sol. Energy Mater. Sol. Cells 95(10), 2941–2945 (2011). 10. S. Kalytchuk, S. Gupta, O. Zhovtiuk, A. Vaneski, S. V. Kershaw, H. Fu, Z. Fan, E. C. H. Kwok, C.-F. Wang, W. Y. Teoh, and A. L. Rogach, “Semiconductor Nanocrystals as Luminescent Down-Shifting Layers To Enhance #235055 - $15.00 USD Received 23 Feb 2015; revised 10 Apr 2015; accepted 11 Apr 2015; published 6 May 2015 (C) 2015 OSA 1 Jun 2015 | Vol. 5, No. 6 | DOI:10.1364/OME.5.001296 | OPTICAL MATERIALS EXPRESS 1296 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. the Efficiency of Thin-Film CdTe/CdS and Crystalline Si Solar Cells,” J. Phys. Chem. C 118(30), 16393–16400 (2014). Q. Y. Zhang and X. Y. Huang, “Recent progress in quantum cutting phosphors,” Prog. Mater. Sci. 55(5), 353– 427 (2010). H. K. Park, J. H. Oh, and Y. R. Do, “Toward scatter-free phosphors in white phosphor-converted light-emitting diodes,” Opt. Express 20(9), 10218–10228 (2012). D. C. Chen, Z. G. Liu, Z. H. Deng, C. Wang, Y. G. Cao, and Q. L. Liu, “Optimization of light efficacy and angular color uniformity by hybrid phosphor particle size for white light-emitting diode,” Rare Met. 33, 348–352 (2014). R. Hu and X. Luo, “A model for calculating the bidirectional scattering properties of phosphor layer in white light-emitting diodes,” J. Lightwave Technol. 30(21), 3376–3380 (2012). P. F. Liaparinos, “Light wavelength effects in submicrometer phosphor materials using Mie scattering and Monte Carlo simulation,” Med. Phys. 40(10), 101911 (2013). S. N. Lipnitskaya, K. D. Mynbaev, V. E. Bugrov, A. R. Kovsh, M. A. Odnoblyudov, and A. E. Romanov, “Effects of light scattering in optical coatings on energy losses in LED devices,” Tech. Phys. Lett. 39(12), 1074– 1077 (2013). B. K. Park, H. K. Park, J. H. Oh, J. R. Oh, and Y. R. Do, “Selecting morphology of Y3Al5O12:Ce3+ phosphors for minimizing scattering loss in the pc-LED package,” J. Electrochem. Soc. 159(4), J96–J106 (2012). K. Y. Qian, J. Ma, W. Fu, and Y. Luo, “Research on scattering properties of phosphor for high power white light emitting diode based on Mie scattering theory,” Wuli Xuebao, Acta Phys. Sin. 61, 204201 (2012). H. K. Park, J. H. Oh, and Y. R. Do, “Toward scatter-free phosphors in white phosphor-converted light-emitting diodes: reply to comments,” Opt. Express 21(4), 5074–5076 (2013). V. Y. F. Leung, A. Lagendijk, T. W. Tukker, A. P. Mosk, W. L. Ijzerman, and W. L. Vos, “Interplay between multiple scattering, emission, and absorption of light in the phosphor of a white light-emitting diode,” Opt. Express 22(7), 8190–8204 (2014). P. C. Wang, Y. K. Su, C. L. Lin, and G. S. Huang, “Improving performance and reducing amount of phosphor required in packaging of white LEDs With TiO2-doped silicone,” IEEE Electron Device Lett. 35, 657–659 (2014). B. Lipovšek, J. Krč, and M. Topič, “Optimization of Microtextured Light-Management Films for Enhanced Light Trapping in Organic Solar Cells Under Perpendicular and Oblique Illumination Conditions,” Photovoltaics, IEEE Journal of 4(2), 639–646 (2014). B. Lipovšek, University of Ljubljana, Faculty of Electrical Engineering, Tržaška 25, 1000 Ljubljana, Slovenia, and A. Solodovnyk, K. Forberich, E. Stern, C. J. Brabec, J. Krč, and M. Topič are preparing a manuscript to be called “Optical model for simulation and optimization of luminescent down-shifting layers filled with phosphor particles for photovoltaics”. Y. Kuwano, K. Suda, N. Ishizawa, and T. Yamada, “Crystal growth and properties of (Lu,Y)3Al5O12,” J. Cryst. Growth 260(1-2), 159–165 (2004). A. Čampa, “NIKA - model for extracting refractive indices.,” in Proceedings of the 48th International Conference on Microelectronics, Devices and Materials & the Workshop on Ceramic Microsystems, D. Belavič, and I. Šorli, eds. (Otočec, Slovenia., 19 - 21 September, 2012). C. F. Bohren and D. R. Huffman, Absorption and Scattering of Light by Small Particles (Wiley-VCH Verlag GmbH, 2007). 1. Introduction Photovoltaics is one of the most promising solutions to the world’s energy demand problem. By the year 2050, it is expected to provide about 16% of the entire global electricity [1]. The increase in efficiency and the drop in the production costs of solar modules are, therefore, of great importance. Modern solar cell devices cannot use the entire incident solar spectrum [2]. This is due to the fact that the optimum efficiency requires a certain band gap. This leads to thermalization losses in the UV- and near-UV spectral region. Luminescent down-shifting (LDS) is known for decades as an approach to improve the conversion efficiency of various devices in the short-wavelength spectral region [3, 4]. Separate layers or blocks of polymer filled with photoluminescent materials are put in front of the device to modify the incident spectrum. The layer converts the UV and near-UV photons into photons in the visible spectrum via photoluminescence process, thus, increasing the amount of incident “useful” photons. Recently developed materials allow this method to be applied to photovoltaics. Klampaftis et al. achieved increased efficiency of multi-crystalline silicon and CIGS (Cu(In,Ga)Se2) solar cells [5, 6]. They used EVA (ethylene vinyl acetate copolymer) encapsulation layers doped with organic dyes. Semiconductor quantum dots have been also used for LDS purposes in photovoltaics [7, 8]. Their small sizes and sensitivity to surrounding medium enable the #235055 - $15.00 USD Received 23 Feb 2015; revised 10 Apr 2015; accepted 11 Apr 2015; published 6 May 2015 (C) 2015 OSA 1 Jun 2015 | Vol. 5, No. 6 | DOI:10.1364/OME.5.001296 | OPTICAL MATERIALS EXPRESS 1297 production of transparent layers with tunable absorption and emission bands [9, 10]. Such layers can be adjusted to specific photovoltaic devices and raise their overall efficiency. However, both material types share such disadvantages as high re-absorption, followed by luminescence efficiency drop, and unknown long-term stability. Producers of modern solar modules guarantee stable efficiency for 20 years. Therefore, LDS films have to remain stable and efficient for the same period of time to become a real market technology. Phosphors form the third group of possible luminescent materials for LDS layers [11]. Typically, they have large Stokes shift, high photoluminescent quantum yield (PLQY), and long-term stability. Phosphors have a high refractive index n from 1.6 to 2.6 depending on the crystal lattice. This is why their usual particle sizes of several µm represent the main drawback for photovoltaic application: adding phosphors to transparent polymer binder results in strong light scattering and, therefore, reflection losses. Scattering by phosphor particles embedded in transparent silicones has been studied in depth within the field of solid-state lighting [12–20]. There are two main approaches to reduce the scattering in the layers: matching the refractive indices of the particles and the binder and using particles of large sizes. Park et al. proved experimentally that large phosphor particles produce less scattering and lead to higher light outputs [12, 17]. This is especially true for phosphors with spherical shapes [19]. Lipnitskaya et al. simulated light losses for binder materials with n = 1.4-1.8 and YAG (Y3Al5O12, n = 1.83) particles with sizes up to 50 µm [16]. They found that losses increased with increasing n of the binder due to total internal reflection on the air-binder interface. They also predicted that particles of 50 µm would cause the least light scattering. All these studies concentrate on optical transmittance and reflectance of layers for blue and yellow light that are used for white light creation in LEDs. Luminescent down-shifting for photovoltaics requires a detailed study of the optical properties of such layers under solar irradiation. There are, furthermore, only a few experimental studies on systems with varied particle size distributions [13], binders [21], and their resultant scattering properties. To the best of our knowledge, no extensive studies on the scattering of phosphors under the solar spectrum have been carried out. We examined the optical properties of phosphor-filled polymer layers on glass. We varied such parameters as the refractive index of the binder, particle size distribution and particle volume concentration (PVC) in the layers. We estimated how these parameters influence optical transmittance of the layers and confirmed the experimental results with simulations using our computational model CROWM [22, 23]. Our aim was to achieve the highest possible transmittance of visible light with the exception of the phosphor absorption region. Finally we calculated the optical transmittance through such phosphor-filled layers with silicon wafers as a substrate. Our results show that scattering by phosphors particles can enhance the light-coupling into the silicon and prove that our concept has promise. 2. Experimental 2.1 Materials Phosphor powder GAL 545L (Intematix Corp., USA) was used for this study. It belongs to the garnet family with a modified structure of Lu3Al5O12:Ce3+. The refractive index of the bulk material is n ~1.86-1.81 for visible wavelengths λ = 400-800 nm [24]. To prepare different particle size distributions, we used a wet-sieving process with nylon grid mesh size 15 µm (Linker Industrie-Technik). Binder materials are described in Table 1. LIM (“low-index” matrix), and HIM (“highindex” matrix) are both solution-processable and form stable, smooth layers. #235055 - $15.00 USD Received 23 Feb 2015; revised 10 Apr 2015; accepted 11 Apr 2015; published 6 May 2015 (C) 2015 OSA 1 Jun 2015 | Vol. 5, No. 6 | DOI:10.1364/OME.5.001296 | OPTICAL MATERIALS EXPRESS 1298 Table 1. Properties of the chosen matrix materials LIM (low-index) and HIM (highindex) Matrix Binder Name Supplier LIM low-index matrix QSil 218 (A+B) ACC Silicones Ltd., UK SA251P Nagase ChemteX Corp., Japan HIM high-index matrix Mixing Ratio Viscositya, Pa·s nb (λ=600 nm) Addition cure silicone elastomer 10:1 2.2 1.46 Acrylic oligomer and acrylic monomer with (1-hydroxycyclohexyl)phenylketone 99% (Sigma Aldrich) 97:3 2.1 1.61 Type a b From product datasheets. Calculated. See sections 2.4 and 3.1 for detail. 2.2 Layer preparation To prepare the solutions, we slowly added phosphor powder to the liquid binders while stirring continuously. The films were then coated by doctor blade onto glass substrates (float glass, 25 × 25 × 1 mm) and dried. LIM layers were dried at 100°C for 60 min. Layers of HIM were first pre-dried at 140°C for 30 min, then cooled in the refrigerator at 7°C for 10 min, and additionally hardened upside down for 10 min under UV illumination (UV-Belichtungsgerät 1, isel AG) to avoid particle sedimentation. The chosen binders showed different shrinkage ratios. To achieve the same particle volume concentrations in different layers we adjusted weight concentrations of the particles in the initial dispersions. The thicknesses of the layers were in the range 150-600 µm. Phosphor particles were homogeneously dispersed. 2.3 Characterization methods To characterize phosphor powder we used field-emission scanning electron microscope (FESEM Carl-Zeiss ULTRA plus, Oberkochen, Germany). To determine photoluminescent excitation and emission spectra we used the fluorescence spectrometer Jasco FP-8200 with a 450 W Xenon lamp. To measure particle size distributions, we used a particle analyzer LS-100Q (BeckmanCoulter, Krefeld, Germany). To measure spectroscopic data of pure binder layers and of the phosphor-filled layers we used a Perkin Elmer Lambda 950 high performance double beam spectrometer including a 150 mm integrating sphere with a photomultiplier and a InGaAs detector. Samples were placed in transmission and reflection ports of the sphere (glass substrate before the layer with respect to illumination) to measure the total and diffused transmittance and reflectance respectively. Due to the side losses caused by scattering, the sum of total transmittance, total reflectance and absorbance was only 94 ± 2% for all characterized layers. To estimate the thickness of the dried layers, we used a Nikon Eclipse L150 confocal microscope. 2.4 Computational model To determine refractive indices and absorption coefficients of the binders, we used the homebuilt software NIKA [25]. The software employs an algorithm based on the one-dimensional transfer matrix method to find the solution for the complex refractive index throughout the spectral range without knowing the dielectric dispersion functions of the material. The input data are: the measured thickness, illumination incident angle and, the reflectance and transmittance spectra of binder layers deposited on the glass substrate. #235055 - $15.00 USD Received 23 Feb 2015; revised 10 Apr 2015; accepted 11 Apr 2015; published 6 May 2015 (C) 2015 OSA 1 Jun 2015 | Vol. 5, No. 6 | DOI:10.1364/OME.5.001296 | OPTICAL MATERIALS EXPRESS 1299 To perform optical simulations of the luminescent down-shifting layers, we used the optical simulator CROWM (Combined Ray Optics / Wave Optics Model), developed by Lipovšek et al. [22]. The optical simulator is based on the combination of three-dimensional ray tracing and one-dimensional transfer matrix methods. They are used together to analyze light propagation through thick and thin layers, respectively. Volumetric scattering at the phosphor particles is modeled in CROWM by employing the Mie scattering theory and the so-called effective scattering approach. Further details of the optical model can be found in [23]. 3. Results and Discussion 3.1 Materials The calculated optical constants of the two binders LIM and HIM are given in Fig. 1(a). The measured transmittance, reflectance, and absorptance of neat LIM and HIM layers deposited on glass are shown in Fig. 1(b). The reflectance of the HIM (“high-index” matrix) on glass is higher because of the higher refractive index. Note that both materials do not absorb in the visible light region. Fig. 1. (a) Calculated with NIKA index of refraction and extinction coefficient dispersions of the chosen matrix materials LIM (low-index) and HIM (high-index); (b) Transmittance (T), reflectance (R), and absorbance (A) of the coatings on glass (layer thicknesses between 290 and 370 µm). Figure 2 shows the morphology and the photoluminescent excitation and emission spectra of the phosphor particles. For the simulations, we assumed particles to be spherical, which is well justified, as can be seen in Fig. 2(a). Fig. 2. Properties of the phosphor particles GAL 545L (modification of Lu3Al5O12:Ce3+): (a) SEM image of the powder; (b) photoluminescence excitation (PLE) and emission (PL) spectra. #235055 - $15.00 USD Received 23 Feb 2015; revised 10 Apr 2015; accepted 11 Apr 2015; published 6 May 2015 (C) 2015 OSA 1 Jun 2015 | Vol. 5, No. 6 | DOI:10.1364/OME.5.001296 | OPTICAL MATERIALS EXPRESS 1300 3.2 Influence of matrix refractive index on layer transmittance We show the optical properties of layers with varied matrices in Fig. 3 for the case of two binders (LIM and HIM), two values of particle volume concentration (PVC = 6%, 18%), different layer thicknesses (200 – 650 μm), and the initial particle size distribution (see further). A wavelength of λ = 600 nm was chosen to analyze the optical properties of the layers in the visible light outside of the PLE spectrum of the phosphor. Thus, the photoluminescence effect is not present in the measurements at this stage. Results indicate that the transmittance of LDS layers based on the high-index (HIM) binder is 5-7% higher compared with LIM-based layers. There are two major reasons for that. Firstly, the decrease in the difference between the refractive indices of the binder and the particles leads to decreased reflection at the particle interfaces. And secondly, according to the Mie scattering theory [26], the angular distribution of the scattered light becomes narrower with a smaller difference in the refractive indices of the phosphor and the binder. This means that a higher portion of light propagates in the near-specular forward direction. Thus, the optical transmittance increases for HIM-based LDS layers. Our optical model was calibrated for the given phosphor particles in a given layer. Using the calibrated model, we simulated the layers of both binders and with all of the experimental concentrations [23]. Good agreement between the experiment and the simulations can be observed. We think that the discrepancies are mainly caused by experimental errors, such as: possible inhomogeneities in the coating thickness, possible slight sedimentation of particles during the curing process and, most of all, the side losses in the layers. Total internal reflection on the interfaces of HIM layers as well as significant light scattering contributed to the increased side losses and measurement errors. Fig. 3. Comparison of experimental data (solid lines) and simulation results (dotted lines) of (a) total transmittance and (b) total reflectance of coated layers at λ = 600 nm depending on their thickness and particle volume concentration (PVC) in the binders LIM (n = 1.45, squares) and HIM (n = 1.61, stars). Arrows follow the increase in the refractive index of the matrix. 3.3 Influence of particle size distributions on layer transmittance Particles of different sizes have different light scattering capabilities that are mainly characterized by the extinction efficiency and the angular distribution of the scattered light [26]. These capabilities primarily depend on the electromagnetic properties of the surrounding medium and the particle diameter. Broad particle size distributions contain particles with different light scattering properties. To verify the influence of the phosphor size distributions on the transmittance and reflectance of the LDS layers, we divided the particles into “small” (mean 18.8 µm) and “large” (mean 11.3 µm) fractions via sieving the initial particles provided by the producer. Figure 4 shows the calculated extinction efficiencies in LIM and HIM for the experimentally produced particle size distributions. Note, that smaller particles have larger extinction efficiencies. #235055 - $15.00 USD Received 23 Feb 2015; revised 10 Apr 2015; accepted 11 Apr 2015; published 6 May 2015 (C) 2015 OSA 1 Jun 2015 | Vol. 5, No. 6 | DOI:10.1364/OME.5.001296 | OPTICAL MATERIALS EXPRESS 1301 Fig. 4. Calculated extinction efficiency (Qext) as a function of phosphor particle diameter in LIM (n = 1.45) and HIM (n = 1.61). Also shown are different particle diameter distributions (right axis), where “Initial” – initial powder size distribution (mean 12.2 µm), and the two sieved distributions: “Large” (mean 18.8 µm) and “Small” (mean 11.3 µm). Simulations were done for the wavelength λ = 600 nm, where the particle refractive index is n = 1.81. Based on these simulation results, we then produced layers in two binders, LIM and HIM, with the “small” fraction and “large” fraction size distributions. Particle volume concentrations (PVC) were kept constant again. Figure 5 shows the values of the total transmittance of these layers with the PVC’s 6% and 13% for the wavelength λ = 600 nm deposited onto glass. The transmittance increases by 9-11% in both binder systems when “large” fraction particles are used instead of “small” fraction particles. Also as expected the transmittance drops with increasing particle concentration. Two major effects influence the increase of the optical transmittance in the layers when we use the “large” fraction distribution of the phosphor particles. First, particles in the “large” fraction scatter light less efficiently compared with the particles in the “small” fraction (see Fig. 4). This means that light is more likely to propagate in the forward direction in the layer with larger particles. Second, particle number density changes as a function of particle radius ~r3 when we change particle size distribution. We kept the particle volume concentration constant, and thus, put fewer particles of larger sizes into the coatings with the “large” fraction phosphor. Therefore, light ray “meets” fewer particles as it propagates through the layer and the scattering becomes less pronounced. To ensure that the change of the particles size distribution caused the increase in transmittance, we simulated the layers with CROWM. We used the model, calibrated for the initial particle size distribution layers. Again, good agreement between the simulation and experimental results was achieved. The discrepancies are attributed mainly to the experimental errors, as explained before. #235055 - $15.00 USD Received 23 Feb 2015; revised 10 Apr 2015; accepted 11 Apr 2015; published 6 May 2015 (C) 2015 OSA 1 Jun 2015 | Vol. 5, No. 6 | DOI:10.1364/OME.5.001296 | OPTICAL MATERIALS EXPRESS 1302 Fig. 5. Influence of particle size distribution in LIM (n = 1.45, squares) and HIM (n = 1.61, stars) at λ = 600 nm on the total transmittance of layers with particle volume concentration: (a) PVC = 6%; (b) PVC = 13%. Arrows follow transition from the small fraction (“Small”) to the large fraction (“Large”) particles in one binder. Comparison of experimental data (solid lines) and simulation results (dotted lines). Inset: Photo of the coating in HIM with “large” fraction particles, PVC = 6%, thickness 250 µm. 3.4 Optical transmittance of phosphor-filled matrices depending on substrate So far the characterization of the luminescent down-shifting layers was performed for layers deposited onto glass. All the measurements were performed in air. However, in a realistic photovoltaic application, the layers are laminated directly onto the top of a solar cell. Therefore, it is not enough to optimize phosphor-filled layers only on glass substrates. One must keep in mind that the optical transmittance of the LDS layers is different depending on the substrate, i.e. solar cell device. In this case the reflectance at the interfaces depends also on the refractive index of the upper layer of the solar cell, the surface texture commonly used for light-trapping, the angle of incidence, etc. CROWM allows us to simulate the changes that can be expected in case if a phosphorfilled layer is laminated onto a solar cell. Figure 6 shows the simulated transmittance in the substrate, or the amount of light that is coupled into the substrate, for the structures on glass and on a silicon wafer. Flat interfaces were assumed in all the simulations for simplicity, although realistic pyramidal textures (in the case of silicon) could also be included in the model. The results for the structure “air / LDS layer / glass” are in agreement with the results from above, where the transmittance of the samples was shown (actual structure “air / LDS layer / glass / air”). As the refractive index of the binder comes closer to the refractive index of the particles, scattering is reduced, and transmittance increases. However, simulations reveal that the maximum transmission occurs for a refractive index slightly lower than the exact value of the refractive index of the phosphor. We think that for this refractive index, scattering is already mostly suppressed. At the same time the somewhat lower refractive index of the binder material results in a lower reflectance at the air / LDS layer interface, and thus, higher overall transmittance. Note that the maximum achievable transmittance value for HIM layers with the phosphor particles is about 92% (see Fig. 6). 4% of light gets additionally lost at the interface “glass / air” during the experimental measurements. Taking into account the unavoidable measurement error in the integrating sphere, we can, therefore, assume that the layers with “large” fraction phosphor particles in HIM (see Fig. 5) are fully optimized and highly transmissive. As a rule, the use of phosphor particles in polymer coatings on glass leads to a pronounced drop in the optical transmittance. This is, however, not necessarily true for the layers on silicon wafer (or in fact, on any other substrate with a higher index of refraction than the binder). In fact, our simulations resulted in an unexpected and interesting finding: they show that in such a case particles can actually increase the amount of light transmitted to the wafer! Compare the structures “air / LDS layer / silicon” and “air / binder / silicon”. We #235055 - $15.00 USD Received 23 Feb 2015; revised 10 Apr 2015; accepted 11 Apr 2015; published 6 May 2015 (C) 2015 OSA 1 Jun 2015 | Vol. 5, No. 6 | DOI:10.1364/OME.5.001296 | OPTICAL MATERIALS EXPRESS 1303 have two regions where the transmittance of the particle-filled layer is higher than that of the neat binder layer. This phenomenon is due to the particle scattering and can be explained as follows: At the left peak there is already significant back-reflection present at the front internal interface (LDS layer / air) due to the total internal reflection of scattered light, which propagated outside the escape cone defined by the critical angle. So the back-scattered light from particles cannot fully escape at the front side, yet there is still good transmission into the silicon below, as here no total reflection can occur. So the back-scattered light from particles cannot fully escape at the front side, yet there is still good transmission into the silicon below. The right peak matches the optimal refractive index grading condition, which additionally increases (specular) transmission through the structure. Therefore, phosphor-filled LDS layers can increase light-coupling into silicon and could possibly complement other light-coupling techniques in photovoltaics. Fig. 6. Simulation results of the total transmittance of the LDS layers at λ = 600 nm with (“LDS layer”) and without (“binder”) phosphor particles coated on glass and on silicon wafer (n = 3.933, no absorption in silicon is assumed) depending on binder‘s refractive index nb. (Layer thickness 230µm, particle volume concentration 13%). 4. Summary In conclusion, we have demonstrated experimentally and numerically ways to increase optical transmittance of the phosphor-filled polymer layers in the visible light spectral region. Our results prove that two separate approaches combined lead to the highly transmissive LDS layers with decreased back-scattering. The following conclusions can be drawn: 1. Polymer binders with high refractive indices (close to the n of particles) are desired for luminescent down-shifting (LDS) layers with phosphor particles. Particles embedded in these binders produce less scattering, thus, the layers become nearly transparent. Although high refractive index silicones cause total internal reflection at the internal silicone/air interfaces, and thus, high losses in LEDs, this can be beneficially used for efficient light confinement in photovoltaic devices. Silicon wafers have refractive index n≈3.9, so no total internal reflection effect can occur on the interface LDS layer / silicon. The measured optical transmittance of the layers in HIM binder (n = 1.61) with phosphor particles is close to the theoretical maximum. #235055 - $15.00 USD Received 23 Feb 2015; revised 10 Apr 2015; accepted 11 Apr 2015; published 6 May 2015 (C) 2015 OSA 1 Jun 2015 | Vol. 5, No. 6 | DOI:10.1364/OME.5.001296 | OPTICAL MATERIALS EXPRESS 1304 2. Particle size distribution should be narrow and contain large phosphor particles. Small particles of a few microns in size should be screened out, since such particles cause strong light scattering. Scattering becomes less pronounced for larger particles and virtually constant for the particles larger than 20-30 µm (Fig. 4). Therefore, we do not see a need to further increase the size of the phosphor particles in the LDS layers. 3. Scattering of the phosphor particles in the LDS layers may increase the overall light harvesting in the solar cell. Optical simulations should be used to determine the desired properties of the LDS layers and to tailor them specifically for the chosen PV application. Our model reproduces experimental results fairly well and can be used efficiently to this end. As the next step towards, we are currently working on light-conversion processes in the phosphor-filled LDS layers. Due to their complexity, they are regarded as a separate research topic. Acknowledgments The authors thank D. Riedel and U. Peschel for inspiring discussions paving the way for new ideas. The authors also thank J. Gast for the lab work, I. Bulatova for the image design, ACC Silicones Ltd. and Nagase ChemteX Corp. for material supply. This work was supported by the Bavarian Academic Center for Central, Eastern and Southeastern Europe (BAYHOST), Erlangen Graduate School in Advanced Optical Technologies (SAOT), and the Bavarian Research Foundation (BFS) #1006-11. We acknowledge support by Deutsche Forschungsgemeinschaft and Friedrich-AlexanderUniversität Erlangen-Nürnberg (FAU) within the funding programme Open Access Publishing. #235055 - $15.00 USD Received 23 Feb 2015; revised 10 Apr 2015; accepted 11 Apr 2015; published 6 May 2015 (C) 2015 OSA 1 Jun 2015 | Vol. 5, No. 6 | DOI:10.1364/OME.5.001296 | OPTICAL MATERIALS EXPRESS 1305