* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Hybrid CMOS-SET Devices and Circuits: Modelling - SMDP-VLSI

Survey

Document related concepts

Power engineering wikipedia , lookup

Electrical ballast wikipedia , lookup

History of electric power transmission wikipedia , lookup

Power inverter wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Voltage optimisation wikipedia , lookup

Stray voltage wikipedia , lookup

Surge protector wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Power electronics wikipedia , lookup

Current source wikipedia , lookup

Mains electricity wikipedia , lookup

Alternating current wikipedia , lookup

Buck converter wikipedia , lookup

Transcript

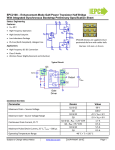

Hybrid CMOS-SET Devices and Circuits: Modelling, Simulation and Design Santanu Mahapatra Outline Introduction: CMOS scaling and emerging devices Single Electron Transistor (SET) Compact Modelling of SET CMOS - SET Hybrid Architectures CMOS - SET co-Simulation SETMOS – A Novel Hybrid CMOS-SET Device Implementation of MV logic and Memory by SETMOS SET Technology – CMOS-SET co-Fabrication Conclusion Introduction Pushing CMOS: the 10 nm wall Key problems of for sub-10nm MOSFET (i) electrostatic limits (ii) source-to-drain tunnelling (iii) carrier mobility (iv) process variations (v) static leakage (vi) Power density After J.D Plummer , Proc IEEE 2001 Aggressive scaling has pushed dimensions towards sub-10nm limits CMOS device Life with and after CMOS Single (Few) Electron Transistor Gate Island Gate dielectric Drain Source Ultra thin dielectric Drain (D) VDS Gate (G) CTD , RD CTD: Drain tunnel junction capacitance CTS: Source tunnel junction capacitance RD : Drain tunnel junction resistance RS : Source tunnel junction resistance CG VGS CTS ,RS Source (S) CG : Gate capacitance C = CG + CTD + CTS SET vs. MOSFET: Device Perspective source SET sourceMOSFET Gate Source Source Drain drain tunneling conductive junctions island Gate Source n+ pn+ junctions p Drain n+ drain conductive n-channel • many electrons simultaneously • electron conduction is one by one participate to conduction • island is conductor, VG only changes the • gate potential invert the channel potential and thus controls tunneling • junctions highly transparent • needs opaque junctions: RT > RQ~26kW •mainly gate controls the threshold • drain/gate controls Coulomb blockade Engineers Like Numbers…. 1. RT > RQ = h/e2 = 26kW 2. e2/C > kBT C < e2/ kBT where = 10 (Memory Application), 40 (Logic Application) C (aF) T = 10 T = 40 (nm) 10 5 1 0.5 18K 37K 195K 370K 4.6K 9K 46K 92K 46 23 4.6 2.3 0.1 1855K 463K 0.5 Present Tech. RT = 0.5-1MW C = 2-3 aF Characteristics of SET (1) IDS vs. VGS @ #VDS 20 e/C= 0.04V 10 101 0.04 V 5 0.06 V -5 -10 -15 -20 -25 -0.08 14 e/C= 0.04V e/CG 12 IDS vs. VGS @10#T 15 0 Drain to source current, I DS (nA) 25 Drain to source current, IDS (nA) Drain to source current, I DS (nA) IDS vs. VDS @ #VGS -0.04 0.0 V 10-1 T = 1K 11.6K [40] 10-2 0.00 0.04 8 23.2K [20] 0.02 V 100 0.08 VDS (V) Drain to source voltage, 10-3 VDS = 0.03V 0.05V 6 0.03V 0.04V 4 2 T = 1K 0 -0.10 -0.05 0.00 0.05 Gate to source voltage, VGS (V) 5.8K [80] 0.02 RTD 0.03 CTD=-0.01 CTS= 0.00 1aF, C0.01 = RTS0.04 = 1MW G= 2aF, Gate to source voltage, VGS (V) 0.10 Characteristics of SET (2) Drain to source current, I DS (nA) Background Charge (BC) effect 9 8 T =1K, VDS = 0.03 V ne n + 0.25e When BC is integer (n) there are no change in SET characteristics, however, it experienced a shift of (BCeffe)/CG on VGS axis when BC is fractional. n - 0.25e 7 6 5 4 3 2 1 0 -0.06 For proper operation, -0.04 -0.02 0.00 0.02 0.04 0.06 Gate to source voltage, VGS (V) 0.08 BC < n + 0.1e A second gate with proper bias can compensate the B.C. Effect! Carrier Transport in SET Drain (D) = e/(2C); VD = ; VS = 0 Gate (G) VIS = (CG/C)VGS + (CTD/C)VDS constant CTD , RD CG Tunneling occurs only when lVISl or lVDIl > D I S D I 1 3 2 ON D I S 3 2 4 Source (S) S 3 CTS ,RS 3 2 2 1 2 0 - - OFF (C.B.) 1 6 0 2 5 3 4 0 - ON SET Simulation Techniques Monte Carlo (SIMON, MOSES) Master Equation (SETTRAN) Macro Model + Accurate + Applicable for any SE device - Time Consuming (specially for current biased SET, resistance) + Faster than MC - Time consuming for big circuits + Spice Compatible - Non Physical A successful implementation of SET as a post-CMOS VLSI Candidate demands spicecompatible COMPACT analytical models SET Compact Analytical Model- MIB* • Based on the Orthodox theory, i.e., charge discrete, energy continuous, etc. D I S IS ID VS 0 VD - IDS = ID I DI S IS ID + IS IDS ID = VD/RD IS = VS/RS 2 At T <<e2/C , VD and VS are either positive or zero *S. Mahapatra et al. EDL 02, IEDM 02,TED 04 The Complete MIB Model I DS I S ( 0 )I D ( 1 ) I S ( 0 )I S ( 1 ) I D ( 1 )I D ( 0 ) I S ( 0 )I S ( 1 ) I D ( 1 )I D ( 0 ) IS (0 ) ID(1) ID( 2 ) I S ( 1 ) IS ( n ) Visland ( 2n 1 ) Visland ( 2n 1 ) and 1 exp where ID( n ) VT VDS Visland ( 2n 1 ) VDS Visland ( 2n 1 ) 1 exp VT VT is thermal voltage and holds the sign of VDS Model is valid for VDS 3e/C and T < e2/(10kBC) Model Verification IDS vs. VGS @ #VDS 10 10.00 T = 10K e/C= 40mV VDS (mV) = 55 12 Drain Current, IDS, (nA) Drain to source current, IDS (nA) 15 IDS vs. VGS @ #T 50 9 30 6 45 20 3 40 10 -20 20K 15K -1 0.10 10 10K -2 0.01 10 -3 10 0.00 5K VDS = 30 mV 0 -40 1.001 0 20 40 60 80 -4 0.00 10 -10 Gate to source voltage, VGS (mV) Symbol: MC Solid Line: Analog MIB 0 10 20 30 40 Gate to source voltage, VGS, (mV) Dotted Line: Digital MIB CTD= CTS= 1aF, CG= 2aF, RTD = RTS = 1MW SET INVERTER VSS = e/2(CG + CT) VSS = e/2(CG + CT) CTS = CTD = CT CG + CT = 4aF T = 5K 12 8.0 8 RD = RS = 1MW 4.0 4 Vout (mV) Input and Output voltage (mV) Vin Vout 12.016 0 CG:CT = -4 1 3 -4.0-8 T = 5K1.6 -12 7 -8.0 CL = 1fF 0.0 -16 -12.0 -20 0 -10 10 0 20 Vin 30 (mV) Time (ns) CG : CT = 3:1 10 40 20 50 60 15 3.5 10 3.0 2.5 5 2.0 0 1.5 -5 1.0 -10 0.5 -15 0.0 -20 -10 0 10 20 VDD to VSS current, I static,(nA) Output, Vout (mV) Power Dissipation in SET Logic* (1) There is a nonzero static current from VDD to VSS when the SET inverter is in Logic HIGH or LOW, however this static current is zero during logic transition, which is just opposite to the CMOS inverter. Input,Vin, (mV) *S. Mahapatra et al. IEDM 02, DAC 02 Power Dissipation in SET Logic (2) 10-7 15 VDD = 20 mV RTS = RTD = 1MW CG = 3aF CTS = CTD = 1aF T=0.1K 10K 20K 50K 5 10-8 50K 20K 10-9 10K 0 +Vdd -5 0.1K Vin 10-10 Vout -10 Power @ 0.1K (W) -Vdd -15 -20 -10 0 Input voltage, Vin (mV) 10 10-11 20 Static Current, I (nA) Output voltage, Vout (mV) 10 Power Dissipation in SET Logic (3) 1. Static Power Dissipation (Pstatic) 2. Dynamic Power Dissipation (Pdynamic) 3. Temperature Induced Dissipation (Pleakage) Leakage Power Ptotal = Pstatic + Pdynamic + Pleakage In SET logic, power dissipation is essentially static: (~ 10-8 W), which is almost 4-5 decades lower than CMOS! SET Random Number Generator* Conventional SET Based Random Bit Stream Random Bit Stream Schematic VOUT Noise Source AMP. COMPARATOR VIN = Const. Memory Node Noise Source Thermal, Shot Noise Single Electron Capture/Emition Noise (Vrms) ~1V ~0.1V Size On Board (10-100 cm2) On Chip (ultra small, ultra low power dissipation) • Room temp. operation (randomness increases with temp.) • RTS ratio greater than one decade (highest) *Toshiba, IEDM 02 CMOS & SET: Competitor/Collaborator? SET Nanoscale device Ultra low power dissipation New functionalities CMOS High Speed Very Stable Technology – Lack of room temperature SCE/DIBL operable technology Power dissipation – Reproducibility at nanoscale Process variations at Low Current drive (~nA) nanoscale Background charge effect Concept of Hybrid CMOS-SET Architecture Practical SET digital circuit applications are likely not feasible with a pure Single Electronics approach, mainly due to its low current drive Combining SET and CMOS, and exploiting the Coulomb Blockade oscillation phenomenon of SET and high current drive facility of CMOS, one can bring out new analog functionalities, (neuron cell, Multiple Valued Logic) which are very difficult to implement by pure CMOS approach. Challenges of Hybrid CMOS-SET Architecture Design Enable advanced SET/CMOS cosimulation and design Development of common technological platform Innovation on new functionalities of hybrid IC architectures, which are really un-paralleled to the pure CMOS circuits. CMOS-SET Co-simulation* (1) Proposed model MIB is implemented in SMARTSPICE** through its Verilog-A (AHDL) interface It is assumed that interconnect capacitances at gate, source and drain terminals are much bigger than the SET device capacitances. Therefore SET characteristics depends only on the nodal voltages. Model parameters are device capacitances (CG,CG2, CTD,CTS), device Resistances (RD,RS) and Background Charge which could be defined through the SPICE MODEL CARD. * S. Mahapatra et al., ICCAD 03 **SILVACO International CMOS-SET Co-simulation (2) SMARTSPICE simulation flow Verilog-A SET module module set(drain, gate1, gate2, source); inout drain, gate1, gate2, source; electrical drain,gate1,gate2,source; SPICE NETLIST SOURCE VerilogA Compiler C file RUN C-compiler .so file SMARTSPICE // Default value of the model parameters parameter real CTS = 1e-18, CTD = 1e-18 parameter real CG = 2e-18, CG2 = 0; parameter real RD = 1e6, RS = 1e6; parameter real BC = 0; analog begin ::::::::::::::::::::::::::::::MIB Subroutine end endmodule Circuit Simulation: Neuron Cell VSS 1.5 M2 M1 M3 VOUT VIN VDD VOFFSET1 VOFFSET2 * M. Goossens, Delft University Press Output VOUT(V) 1.3 T = 300 K 1.1 0.9 0.7 0.5 VOFFSET1 = 1V VOFFSET2 = 1V VOFFSET1 = 0.5V VOFFSET2 = 1V 0.3 0.1 0.0 0.5 1.0 1.5 Input VIN(V) SET : CG = CG2 = 0.04aF, CTD = CTS = 0.02aF, RD = RS = 1MW PMOS: L = 0.5m, W = 0.8m, TOX = 9.74nm, VTH = 0.55 2.0 Circuit Simulation: MVL Cell Quantizer Memory 6 Experimental Simulation Vout(V) 5 Vout VGG 4 3 2 1 0 Vin 1 2 3 Vin(V) SET: CG = 0.27aF, CTD = CTS = 2.7aF, RD = RS = 200kW NMOS: W = 12m, L = 14m, Tox = 90nm, VTH = 0.64V VGG is set to 1.08V and Vout is hard-limited at 5V *H. Inokawa et al., TED ‘03 4 5 EPFL’S Variable Hysteresis Cell* 60 VIN S1 IIN S2 Input Current I IN (nA) IBIAS 0 T = 150 C 50 CG = 0.2aF, 50 nA 40 40 nA 30 CTD = CTS = 0.15aF, 30 nA 20 RD = RS = 1MW 20 nA 10 IBIAS = 10 nA 0 0.00 0.40 0.10 0.20 0.30 40 nA 0.40 30 nA Input Voltage VIN (V) Input Voltage VIN (V) 0.35 0.30 50 nA 20 nA IBIAS = 10 nA 0.25 0.20 0.15 S. Mahapatra and A.M.Ionescu et al. JJAP’04, IEEE NANO ‘04 0 T = 150 C 0.10 0 10 20 30 40 Input Current IIN (nA) 50 60 SETMOS Device – C.B. at A Range! Drain Drain(D) (D) VDS1,MAX e/CG IDS2 Gate (G) (G) IDS1 VDS1 BIAS IIBIAS ~e/C VGS1 VGS1 VDS1 VGS2 If VDS1,MAX <= VTH, MOS is operating just under VTH (subthreshold) VDS2 IBIAS D Log10 IDS2 Source(S) (S) Source Exponentially amplified drain current G S S. Mahapatra et al., IEDM 03, EDL 04 VGS2 SETMOS Device Characteristics (1) CTD = 0.15aF CTS = 0.15aF RD = 1MW RD = 1MW C = 0.5aF Ø ~ 2.5nm 1.20 0.5 1.00 0.4 0.80 0.3 0.2 0.1 VDS (V) = CG = 0.2aF Drain to Source Current, I DS (A) IDS vs VGS @ #VDS T = 1000C IBIAS = 40nA L = 65nm W = 100nm VTH = 0.32V e/CG = 0.8V 0.60 TOX = 1.7nm 0.40 Calibrated 65nm BSIM4 model 0.20 0.00 -1.00 -0.50 0.00 0.50 Gate to Source Voltage, VGS (V) 1.00 [BSIM Web] SETMOS Device Characteristics (2) IDS vs. VGS @ #T CTD = 0.15aF CTS = 0.15aF RD = 1MW RD = 1MW Drain to Source Current IDS (A) CG = 0.2aF VDS = 1V 10-6 L = 65nm W = 100nm 0 T = 25 C VTH = 0.32V 10-7 TOX = 1.7nm 10-8 0 10-9 -225 C Sub Ambient (00C to –1500C) Operation: 1000C 1) Realistic SET (Ø ~ 2.5nm) 10-10 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2) Improved MOS Characteristics in terms of SS, PDP, leakage Gate [I.Aller et al., Voltage ISSCCV‘00 ] to Source GS (V) 2.0 Sub-ambient operation of CMOS At sub-ambient temp. 1) Mobility increases 2) Static Power dissipation decreases 3) Sub. Slope improves 4) Speed increases BULK New Architectures Roadmap Sub-ambient operation Y. Taur and E.J. Nowak, IEDM 97 SETMOS NDR Device Drain (D) Slope: CG/(CTS+CG) IIN Slope: CG/CTD Gate (G) VDS1 IBIAS VIN VGS1 = VIN PDR Log10 IDS2 Source (S) VDS2 = VIN NDR IBIAS VGS2 = VDS1 SETMOS NDR Device Characteristics IIN vs. VIN @ #IBIAS Gate Leakage Effect 6.0 5.0 4.0 VIN VIN IBIAS I BIAS (nA)= 3.0 50nA 2.0 IG 40nA 0 1.0 IG (nA) Input Current, IIN (A) T = 1000C 0.0 0.00 -20 30nA 20nA I 50nA BIAS -40 = 20nA 0.50 1.00 1.50 Input Voltage, VIN (V) -60 0.0 0.5 1.0 VIN (V) 1.5 2.0 2.00 No impact of leakage IG < IBIAS/10 Interconnect Issues in Nanoscale ICs Not only the fundamental limitations of the nano-scaled MOSFET, but also the interconnect limits have threaten to decelerate or halt the historical progression of the semiconductor industry because the miniaturization of interconnects, unlike transistors, does not enhance their performance After K. Banerjee et al. Proc. IEEE 2001 As larger the chips become, the number of local modules grows as l2 (where l is the chip edge length) and the number of interconnects in a generally connected network grows as (l2!) Multiple Valued (MV) Logic: Motivation MV Logic is a logic system where the radix is more than 2. radix (r) = 2 (binary), 3(ternary), 4 (quaternary) Binary MV Analog The information per line carried by binary system (either 0 or 1) is much less than analog system (infinity). That’s why interconnect complexities have always been a problem in Digital (Binary) ICs than Analog one. However, digital systems have other advantages compared to the analog counterpart in terms of precision, stability, noise immunity etc. BUT ARE THOSE ADVANTAGES SOUGHT TO BE FOUND ONLY IN THE BINARY DOMAIN???? MV Logic Applications (i) Complete replacement of Binary world by MV logic may not be possible, however a hybrid binary-MV system can be used to solve the interconnect complexities. (ii) Large scale memories, Content Addressable Memories (iii) Neural Network, Intelligent Systems (iv) Advanced systems, e.g., molecular computing system Pass Gate s0, s1,……..sk (substrates) e0, e1,……..ek (enzymes) 0 (if s=si and e = ei) s (otherwise) MV Logic Implementations Concept of MV logic is NOT AT ALL very new, however its CMOS implementation has always been strugling because: 1. MOSFET is a single threshold device 2. CMOS implementation of MV logic either demands MOSFETs having different threshold voltage on the same wafer or highly asymmetric (like 200:1) device aspect ratio. However, the Coulomb blockade oscillations (multiple threshold points) could be directly linked to MV operations. SETMOS, which combines the features from both SET and CMOS could be an attractive candidate for MV logic and memory realization. SETMOS Quaternary Literal Gate* (1) Literal Gate (axb) : f(x) = r –1 when when a x b else 0 Universal Literal Gate (xs): f(x) = xs = r 1 when x = s S else 0 Here, for quaternary logic system, r = 4, S = (0,1,2,3), and a, b, x, s S. Example: if x = (0,1,2,3) 2x3=(0,0,3,3) and x1,3 = (0,3,0,3) Working Principle: IC I BIAS VZ IBIAS IC VOUT VZ VOUT V IN VGS2 VT VOUT VGS2 VZ VZ VIN VIN *S.Mahapatra and A.M.Ionescu, submitted to TNANO SETMOS Quaternary Literal Gate (2) 04 = 0V, 14 = 0.3V, 24 = 0.6V, 34 = 0.9V 1,3 1.20 x Gate IC = 0.4uA IBIAS = 59nA VGS2 = 0.35V 2 3 x Gate 1.2 0.90 -1000C VOUT (V) VOUT (V) 0.9 -500C 0.60 -1000C -500C 0.6 0 0C 0 0C 0.30 0.00 0.00 0.3 IC = 0.4uA IBIAS = 55nA VGS2 = 0.123V 0.0 0.30 0.60 VIN (V) 0.90 0.0 0.3 0.6 0.9 VIN (V) Using literal gates one can implement the Transmission Gate (T-Gate) which is a building block of all MV logic functions. Binary-to-Quaternary Converter VDD VB1 1.0 04 VB2 0.9 LSB MSB LSB 0.8 MSB VB1 14 0.7 VB2 MSB LSB 24 VDD VB1 0.6 0.5 0.4 VOUT VB2 0.3 MSB LSB 0.2 34 VDD VB1 VOUT (MVL) Voltage (V) 2-to-4 binary MOS-SET hybrid decoder VDD VB2 0.1 0.0 MSB LSB 0 100 200 300 400 Time (ns) 04 = 0V, 14 = 0.3V, 24 = 0.6V, 34 = 0.9V 04 = 0V, 14 = 0.9V 500 Quaternary-to-Binary Converter 1.0 0.9 LSB 0.8 MSB 2 3 x MSB VIN (MVL) x1,3 LSB Voltage (V) 0.7 VIN 0.6 0.5 0.4 0.3 0.2 0.1 0.0 0 100 200 300 Time (ns) 400 500 Interconnect Reduction Scheme Traditional Binary System I1 O1 O1 Module 2 Module 1 O2 I2 I1 O1 Module 1 I2 O2 Global Interconnects B2Q Q2B Local Interconnects O2 Q2B I2 I1 O1 Module 2 I2 Hybrid Binary-MV System O2 B2Q I1 SETMOS MV SRAM (1) IDS VDS IBIAS I0 > I2 I2 NDR I1 IDS I0 IC I2 I1 I0 V0 04 VDS V1 14 V2 24 V3 34 IBIAS VDS Hysteresis I2 IDS VDS V3 V2 I1 I2 V1 I1 I0 V0 IC = (I0 + I2)/2 I0 IK IC IK IDS SETMOS MV SRAM (2) 1.8 2.0 T = 500C 1.6 1.8 1.4 1.6 1.4 1.2 0 1.0 T= 0 C @ 70nA 0.8 T= -1000C @ 70nA 0.6 IBIAS = 80nA 0.4 70nA VDS (V) VDS (V) T = 500C IBIAS = 70nA 1.2 1.0 BC = 0 0.8 BC = 0.1 0.6 0.4 BC = -0.1 60nA 0.2 0.2 0.0 0.0 0 2 4 6 IDS (A) 8 10 12 0 2 4 6 IDS (A) 8 10 SETMOS MV SRAM (3) WLW MW MW BLR BLW IC IR Buffer IBIAS WLR • IR~1A (100 times larger than some other MOS-SET approaches) • Writing is ideally instanteneous, Reading time is in the same order of conventional CMOS SRAM • Minimum Transistors needed to develop one SRAM cell by pure CMOS approach is 12 [U. Cilingiroglu, IEEE CAS II, 2001] SET Technology Unlike CMOS, there is no technology for SET fabrication fixed, well defined SET could be made by Si, Metal, III-V Material or even by Carbon Nanotubes Some of the possible Si-SET technologies are: PADOX – SD [NTT] Undulated Film – MD [Toshiba] Nano-grain PolySi – MD [Hitachi] Electronic SET – SD [Korea] MOS-SET – SD [LETI] SD : Single Dot MD: Multiple Dot E P F L Single Dot SET Fabrication (1) FEEL THE CHALANGE !! 8 inch 0.4mm 5nm ISOLATE SET island Si/SOI wafer LITHOGHRAPHY IN THREE DIMENTIONS ?? Single Dot SET Fabrication (2) PAttern Dipendent OXidation (PADOX)* Idea stressed silicon has a lower oxidation rate EPFL’s Approach : (i) no e-beam (ii) smaller island size *NTT Japan Multi Dot SET Fabrication (1) Multi Dot Device: Non-classical SET 7 5 Gate 4 3 Drain to source current, IDS (nA) Drain to source current, IDS (nA) Drain Source nanograin wire VGS = 0V 2 1 0 -1 Coulomb Blockade -2 -3 -4 -5 -0.1 0.0 0.0 0.0 0.0 5 4 3 2 1 0 -0.2 0.1 Drain to source voltage, V DS (V) (a) 6 (b) VDS = 0.045V -0.1 Advantage: Easier to fabricate than single dot device Difficulties: Modelling and Design 0.0 0.1 Gate to source voltage, V GS (V) 0.2 (c) Multi Dot SET Fabrication (2) EPFL’s nano-grain polysilicon wire technique = 10-20nm CMOS-SET Co-Fabrication* *S. Ecoffey et al. MNE 04 Summary • Single Electron Transistor (SET) is an attractive candidate for future ultra low power nano-electronics. • Due to some of its intrinsic limitations (low current drive, lack of room temperature operable technology) it is unlikely that SET can replace the CMOS world. • However, the unique properties (e.g., Coulomb blockade oscillations) of SETs can be exploited to increase CMOS functionalities by hybrid CMOS-SET approach. • SETMOS is one such hybrid CMOS-SET architecture, which combines the virtues of both devices and exhibits many novel functionalities which are very difficult to achieve by either of these technologies.