* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download 0.2W Side View 6014 Red(Au) - LG Innotek

Survey

Document related concepts

Superconductivity wikipedia , lookup

Valve RF amplifier wikipedia , lookup

Operational amplifier wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Surge protector wikipedia , lookup

Power MOSFET wikipedia , lookup

Lumped element model wikipedia , lookup

Thermal runaway wikipedia , lookup

Current mirror wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Rectiverter wikipedia , lookup

Surface-mount technology wikipedia , lookup

Transcript

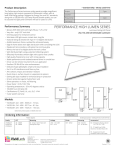

CUSTOMER : . DATE : 2016. 03. 03 . REV : 1.1 . SPECIFICATIONS FOR APPROVAL Side View Type Red SMD LED MODEL NAME : LERRS61E00SM01 RoHS Compliant APPROVAL REMARK APPENDIX Designed Checked Approved 2016.03.03 2016.03.03 2016.03.03 M.S.KIM J.J.CHOI J.J.YOON LGIT Confidential and Proprietary TABLE OF CONTENTS 1. Features ───────── 3 2. Outline Dimensions ───────── 3 3. Applications ───────── 4 4. Absolute Maximum Ratings ───────── 4 5. Electro-Optical Characteristics ───────── 4 6. Bin Structures ───────── 5 7. Typical Characteristic Curves ───────── 6 8. Reliability Test Items and Conditions ───────── 7~8 9. Package and Labeling of Products ───────── 9~12 10. Soldering Conditions ───────── 13 11. Cautions on Use ───────── 14~17 12. Disclaimers ───────── 18 13. Change History of Revision ───────── 19 LG이노텍(주) 2 / 19 13-ETC-0906 LGIT Confidential and Proprietary 1. Features - Lighting Color : Red - Lead Frame Type LED Package : 6.14 x 1.4 x 1.65 (L x W x H) [unit : mm] - Viewing Angle : 120˚ - Chip Material : AlGaInP - Soldering Methods : Reflow Soldering - Taping : 12 mm clear carrier tape & antistatic clear cover tape 2,500 pcs/reel, Φ178 mm Wheel 2. Outline Dimensions ( unit : mm ) POLARITY ②Cathode ③- Recommendable soldering pattern (For reflow soldering) + Anode ① Exposed Cu for soldering ※ Observe the recommended guideline by all means. Cu area for improving heat dissipation Do not use this area for electrical contact. Cu area ≥ 1.48 mm2 per pad Tolerances unless otherwise specified ±0.10mm LG이노텍(주) 3 / 19 13-ETC-0906 LGIT Confidential and Proprietary 3. Applications - Interior and Exterior Illumination, Automotive Lighting * Meets SAE/ECE Automotive Color Requirements 4. Absolute Maximum Ratings Items ( Ta = 25℃ ) Symbols Ratings Unit If 140 mA Ir 10 µA Ifp 200 mA Operating Temperature Topr -40 ~ 100 ℃ Storage Temperature Tstg -40 ~ 100 ℃ Junction Temperature Tj 125 ℃ Forward Current Reverse Current Pulse Forward Current * Soldering Temperature JEDEC-J-STD-020D ESD Classification Class 2 (JESD22-A114) *1) Pulse width = 10 ms, duty cycle ≤ 10% ※ The stresses beyond those listed under absolute maximum ratings may cause permanent damages to the device. These or any other conditions beyond those indicated under recommended operating conditions are not implied. The exposure to the absolute maximum rated conditions may affect device reliability. ※ LEDs are not designed to be driven in reverse voltage. 5. Electro - Optical Characteristics Items ( Ta = 25℃ ) Symbol Condition Min Typ Max Unit Forward Voltage Vf If = 100mA 1.80 - 2.40 V Reverse Current lr Vr =10V - - 10.0 uA Luminous Flux lm If = 100mA 13.0 - 18.0 lm Dominant Wavelength Wd If = 100mA 613 - 622 nm Viewing Angle 2Θ1/2 If = 100mA - 120 - deg Thermal resistance Rthj-s - 120 - °C/W -1.0 - -3.0 mV/°C Typical Temperature Coefficient of Forward Voltage*1) ΔVf / ΔTj If = 100mA *1) Measured at Ta between between 25℃ and 85℃ ※ These values are measured by the LG Innotek optical spectrum analyzer within the following tolerances. - Luminous Flux (Im ) : ±5%, Forward Voltage(Vf ) : ±0.1V ※ Although all LEDs are tested by LG Innotek equipment, some values may vary slightly depending on the conditions of the test equipment. LG이노텍(주) 4 / 19 13-ETC-0906 LGIT Confidential and Proprietary 6. Bin Structures Rank of Luminous Flux (@ 100mA) Rank Rank of Forward Voltage (@ 100mA) Ø v (lm, @ 100mA) Min. Typ. Max. E1 13.0 - 14.0 E2 14.0 - E3 17.0 - Rank Vf (V, @ 100mA) Min. Typ. Max. V1 1.80 - 1.95 17.0 V2 1.95 - 2.10 18.0 V3 2.10 - 2.25 V4 2.25 - 2.40 Rank of Dominant Wavelength (@ 100mA) Rank W1 Wd (nm, @ 100mA) Min. Typ. Max. 613 - 622 ※ Bin structure: Please refer to the following example. Bin Code : E1-W1-V2 (Φv Bin = E1, Wd Bin = W1, Vf Bin = V2) LG이노텍(주) 5 / 19 13-ETC-0906 LGIT Confidential and Proprietary 7. Typical Characteristic Curves Forward Current vs. Forward Voltage Relative Luminous Flux vs. Forward Current Ta = 25℃ Forward Current [mA] Relative Luminous Flux [%] Ta = 25℃ Forward Voltage [V] Forward Current [mA] Spectrum Luminous Flux vs. Temperature Ta 25℃, If = 100mA Relative Luminous Flux [%] Relative Luminous Intensity [%] If = 100mA Wavelength (nm) Tb(°C) Radiation Characteristics Derating Curve Ta 25℃, If = 100mA 30 -60 60 -90 100 Forward Current [mA] 0 -30 50 0 50 90 100 Ambient Temperature[°C] ※ The ambient temperatures for each graph are based on the LG Innotek equipment LG이노텍(주) 6 / 19 13-ETC-0906 LGIT Confidential and Proprietary 8. Reliability Test Items and Conditions 8-1. Criteria for Judging the Damage • Item Symbol Test Condition Forward Voltage Vf Luminous Flux Øv Limit Min Max If = 100mA - Initial Value 1.2 If = 100mA Initial Value 0.8 - Using Stand FR4 PCB Size is 25×25×1.6 mm3 (L×W×H) LG이노텍(주) 7 / 19 13-ETC-0906 LGIT Confidential and Proprietary 8. Reliability Test Items and Conditions 8-2. Reliability Test No Item Test Condition Hour/ Cycles Sample Size Ac/Re Ta = 25℃, If = 140mA 1,000 Hours 77PCS 0/1 Ta = 85℃, RH = 85%, If = 90mA 1,000 Hours 77PCS 0/1 1 Room Temperature Operating Life (RT) 2 High Humidity High Temp. Operating Life (H3TOL) 3 High Temperature Operating Life (HTOL) Ta = 100℃, If = 60mA 1,000 Hours 77PCS 0/1 4 Low Temperature Operating Life (LTOL) Ta = -40℃, If = 140mA 1,000 Hours 77PCS 0/1 5 High Temperature Storage Life (HTSL) Ta = 100℃ 1,000 Hours 77PCS 0/1 6 Low Temperature Storage Life (LTSL) Ta = -40℃ 1,000 Hours 77PCS 0/1 7 Power Temperature Cycle (PTC) Tc = -40℃/85℃, If = 90mA, Dwell : 10min, Transfer : 20min (1hour/ 1cycle), On/Off : 2min 1,000 Hours 77PCS 0/1 8 Temperature Cycling (TC) -40℃~110℃, Dwell : 25 min, Transfer : 5 min 1,000 Hours 77PCS 0/1 9 Vibration Variable Frequency (VVF) 0.06 inch displacement, 20 to 100Hz, 50g 100Hz to 2kHz - 30PCS 0/1 10 Thermal Shock (TS) -40℃/110℃, Dwell : 20 min, Transfer : <10sec 1,000 Cycles 77PCS 0/1 3 times 30PCS 0/1 R1:10㏁, R2:1.5㏀, C:100 (Test Voltage : 2kV) R1 R2 11 ESD Characterization (Human Body Model) 12 Resistance to Solder Heat (RSH) Test for solder conditions 260℃ for 10 sec on solder pads with solder iron - 30PCS 0/1 13 Solderability (SD) Test for solder conditions 215℃ for 3 sec on solder pads - 10PCS 0/1 14 Mechanical Shock (MS) 1500g’s for 0.5ms, 5 blows, 3 orientations 3 times 30PCS 0/1 V S1 D.U.T ※All reliability tests are qualified (Cumulative test results obtained from testing performed in accordance with AEC-Q101). LG이노텍(주) 8 / 19 13-ETC-0906 LGIT Confidential and Proprietary 9. Package and Labeling of Products 9-1. Taping Outline Dimensions Reel ( Unit : mm ) EIAJ-RPM 12 B Packing Materials : Width W1 W2 12mm 9.0 ±0.3 11.9 ±1.0 - Reel : Conductive PS (Black) - Emboss Tape : Conductive PET (limpidity) - Cover Tape : Antistatic PET Base Tape cathode Anode Polarity direction Taping Arrangement Arrangement of Tape ( in case of 2,500ea) (End) (Start) Unloaded Tape (Min. 200mm) LG이노텍(주) Mounted with LED (2,500 pcs) Unloaded Tape (Min. 40mm) 9 / 19 Leading Part (250 ~ 600mm) 13-ETC-0906 LGIT Confidential and Proprietary 9. Package and Labeling of Products 9-2. Label Structure Products are packed in one bag of 2,500 pcs (one taping reel) and a label is affixed on each bag specifying Model , Rank, Quantity and Run number. Label A ( Model, Rank, Q’ty, Run number) Label A ( Model, Rank, Q’ty, Run number) Label B ( Array Model Add… ) - Package : damp-proof package made of aluminum ※. Label A Specifying Lot ID, MES ID, Rank, Quantity, Run No, Rack No, Model Name, MSL Lv. ※. Label B Specifying Lot ID, Array Model, PKG Model, Rank, Run No, Quantity, Rack No Label A Label B Run No indication 1 Code 2 Manufacture Manufacture Site Year Paju :1 Huizhou : 9 LG이노텍(주) 3 2012 : 2 2013 : 3 ··· 2020 : 0 2021 : 1 4 5 6 Manufacture Month Manufacture Date 1~9 : 1~9 10 : A 11 : B 12 : C (01~31) 10 / 19 7 8 9 10 TP # Serial No (00 ~ 99) (00 ~ ZZ) 13-ETC-0906 LGIT Confidential and Proprietary 9. Package and Labeling of Products 9-2. Label Structure ※. Label C Specifying Customer, Date, Model Name, Total Quantity, Outbox ID, Rank info & Quantity Outbox ID. indication 1 2 3 4 5 Manufacture Site PKG Site Box Year Month Date Serial No PKG :S, P Inner Box : I Outer Box : O 2012 : 2 2013 : 3 ··· 2020 : 0 2021 : 1 1~9 : 1~9 10 : A 11 : B 12 : C (01 ~ 31) (001 ~ 999) Paju LG이노텍(주) :P 11 / 19 6 7 8 9 10 13-ETC-0906 LGIT Confidential and Proprietary 9. Package and Labeling of Products 9-3. Packing Specifications Reeled products (numbers of products are 2,500 pcs) are packed in a sealed-off aluminum moisture proof bag along with desiccants (Silica gel). Four aluminum bags (total maximum number of products are 10,000 pcs) packed in an inner box and Six inner boxes are put into an outer box. Label A Vacuum Packing Label A Taping Reel Label B Silica Gel Pb-Free Sticker 1 Bag : 1Reel / 1Silica Gel Inner Box Label B (4ea) Aluminum Moisture Proof Bag Pb-Free Mark Box 1 Inner Box : 4Reel Size (mm) W L H Inner 227 82 258 Outer 530 240 280 Outer Box OPP Tape (50mm) Label C Pb-Free Mark 1 Outer Box : 6 Inner Box LG이노텍(주) 12 / 19 13-ETC-0906 LGIT Confidential and Proprietary 10. Soldering Conditions -. Reflow soldering method is recommended for LEDs assembly. -. LG Innotek does not guarantee the performance of the LEDs assembled by dip soldering method. -. Recommended Soldering Profile (according to JEDEC J-STD-020D) Profile Feature Preheat/Soak Temperature Min(Tsmin) Temperature Max(Tsmax) Maximum time(ts) from Tsmin to Tsmax Pb-Free Assembly Pb-Based Assembly 150℃ 200℃ 60~120 seconds 100℃ 150℃ 60~120 seconds 3℃/ second max. Ramp-up rate (TL to Tp) 3℃/ second max. Liquidus temperature (TL) 217℃ 183℃ Time (tL) maintained above TL 60~150 seconds 60~150 seconds Maximum peak package body temperature (Tp) 260℃ 235℃ Time(tp) within 5℃ of the specified temperature (Tc) 30 seconds 20 seconds Ramp-down rate (Tp to TL) 6℃/second max. 6℃/second max. Maximum Time 25℃ to peak temperature 8minutes max. 6minutes max. -. Reflow or hand soldering at the lowest possible temperature is desirable for the LEDs although the recommended soldering conditions are specified in the above diagrams. -. A rapid cooling process is not recommended for the LEDs from the peak temperature. -. The LEDs encapsulate silicone and have soft surfaces on the tops, which can easily damaged by pressure. Precautions should be taken to avoid strong pressure on the encapsulated part when leveraging the pick and place machines. The pick up nozzles should not directly contact the silicone resin of the LEDs. -. Reflow soldering should not be done more than two times. LG이노텍(주) 13 / 19 13-ETC-0906 LGIT Confidential and Proprietary 11. Cautions on Use 11-1.Moisture Proof Package -. The moisture in the SMD package may vaporize and expand during soldering. -. The moisture can damage the optical characteristics of the LEDs due to the encapsulation. 11-2. During Storage Conditions Temperature Humidity Time before Opening Aluminum Bag 5℃ ~ 30℃ < 50%RH within 1 Year from the Delivery Date after Opening Aluminum Bag 5℃ ~ 30℃ < 60%RH ≤ 672Hours 65±5℃ < 10%RH 10 ~ 24 hours Storage Baking -. MSL Level : 2a 11-3. During Usage -. LED should avoid the direct contact with exposure to hazardous materials such as sulfur, chlorine, phthalate, etc.. -. The silver-plated metal parts on LEDs can be rusted when exposed to corrosive gases. -. The silver-plated metal parts also can be affected not only by the corrosive gases emitted inside of the endproducts but by the gases penetrated from outside environment. -. The corrosive atmosphere must be avoided during the use and storage. -. Extreme environments such as sudden ambient temperature changes or high humidity that can cause condensation must be avoided. LG이노텍(주) 14 / 19 13-ETC-0906 LGIT Confidential and Proprietary 11. Cautions on Use 11-4. Cleaning -. Do not use brushes for cleaning or organic solvents (i.e. Acetone, TCE, etc..) for washing as they may damage the resin of the LEDs. -. Isopropyl Alcohol(IPA) is the recommendable solvent for cleaning the LEDs under the following conditions. Cleaning Condition : IPA, 25℃ max. x 60sec max. -. Ultrasonic cleaning is not recommended. -. Pretests must be followed by the actual cleaning processes to avoid any possible damages to the LEDs. 11-5. Thermal Management -. The thermal design of the end product must be seriously considered even from the beginning stage. -. The co-efficiency between the heat generation and the thermal dissipation is affected by the thermal resistance of the circuit boards and the density of the LED placements together with other components. 11-6. Static Electricity -. Wristbands and anti-electrostatic gloves are strongly recommended and all devices, equipment and machineries must be properly grounded when handling the LEDs which are sensitive against static electricity and surge. -. Precautions are to be taken against surge voltage to the equipment that mounts the LEDs. -. Some unusual characteristics such as significant increase of current leakage, decrease of turn-on voltage, or no operation at a low current can be occurred by damaged LEDs. LG이노텍(주) 15 / 19 13-ETC-0906 LGIT Confidential and Proprietary 11. Cautions on Use 11-7. Recommended Circuit -. The current through each LED must not exceed the absolute maximum rating when design the circuits. -. In general, there can be various forward voltages for LEDs. Different forward voltages in parallel via a single resistor can result different forward currents to each LED, which also can output different luminous flux values. In the worst case, the currents can exceed the absolute maximum ratings which can stress the LEDs. Matrix circuit with a single resistor for each LED is recommended to avoid the luminous flux fluctuations. L1 RL1 RL2 L2 L3 L1 L2 L3 L1 L2 L3 RL3 RL Pic.2. Abnormal Circuit : The current through the LEDs may vary due to the variation in forward voltage (VF) of the LEDs. Pic.1 Recommended circuit in parallel mode : Separate resistor must be used in each LED -. LED should be operated in forward bias. A driving Circuit must be designed so that the LED is not subjected to either forward or reverse voltage while it is off. In particular, if a reverse voltage is continuously applied to the LED, such operation can cause migration resulting in LED damage. -. If reverse voltage is applied to the LEDs, it will damage the LEDs and result in destruction. 11-8. Application Limits of LED Driver IC Controller -. AlGaInP based LED is relatively weak to electrical damage (such as static electricity and over current stress). Forward leakage of LED occurred by such damage in the forward low current region may result in turn-ondelay of Lighting Module, which is dependent on a specific function of driver IC. -. For reasons mentioned above, minimum current level (source start-up current) of LED driver IC must be more than 0.3 mA. LGIT cannot make a guarantee on the LED using in Driver IC with start up current level of < 0.3 mA. -. When parallel circuit LED driver IC is applied in Lighting Module, Hot spot may occur in low current operation region (dimming mode) by difference of LED voltage in low current region. So, driver IC with Individual LED controller is recommended. LG이노텍(주) 16 / 19 13-ETC-0906 LGIT Confidential and Proprietary 11. Cautions on Use 11-9. Soldering Iron -. The recommended condition is less than 5 seconds at 260℃. -. The time must be shorter for the higher temperature. (+10℃ → -1sec). -. The power dissipation of the soldering iron should be lower than 15W when the surface temperature of the device should be controlled at or under 230℃. 11-10. Repair -. Repairing should not be done after the LEDs have been soldered. -. When repairing is unavoidable, a double-head soldering iron should be used. -. If should be confirmed beforehand whether the characteristics of the LEDs will or will not be damaged by repairing. -. When Soldering, do not put stress on the LEDs during heating customer must finish rework within 5sec. under 245℃. -. The head of Iron can not touch copper foil. -. Twin-head type is preferred. (O) (X) 11-11. Eye Safety Guidelines -. Do not directly look at the light when the LEDs are on. -. Proceed with caution to avoid the risk of damage to the eyes when examining the LEDs with optical instruments. 11-12. Manual Handling -. Use Teflon-type tweezers to grab the base of the LED and do not apply mechanical pressure on the surface of the encapsulant. ( encap silicone cure condition : 405min ) CORRECT LG이노텍(주) WRONG 17 / 19 13-ETC-0906 LGIT Confidential and Proprietary 12. Disclaimers -. LG Innotek is not responsible for any damages caused by any accidents or operational environments exceeding the absolute maximum ratings. -. Generally accepted electronic equipment must be used to operate the LEDs in this document. -. Consultation with LG Innotek is recommended for unassured environments or operations to avoid any possible malfunctions or damages of the products or risk of life or health. -. Any unauthorized, without prior written consents from LG Innotek, disassembly is prohibited if purposed for reverse-engineering. All defected LEDs must be reported to LG Innotek and not to be disassembled or analyzed. -. The information or spec can be modified and upgraded without prior notice. LG이노텍(주) 18 / 19 13-ETC-0906 LGIT Confidential and Proprietary SPECIFICATION MODEL LERRS6E00SM01 DOCUMENT No 2015-PLM-D03843 REG.DATE 2015.12.02 REV.No 1.1 REV.DATE 2016.03.03 PAGE 19 Change History of Revision Revision Date 0.0 15.09.07 New establishment 0.1 15.11.11 Characteristic Curves Standardization 1.0 15.12.02 Version Released 1.1 16.03.03 LG이노텍(주) Contents of Revision Change Remark Lm Rank Changed Al Bag Change (MSL indicated on the label A) 19 / 19 13-ETC-0906