* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download PowerPoint ****

Survey

Document related concepts

Emissions trading wikipedia , lookup

2009 United Nations Climate Change Conference wikipedia , lookup

German Climate Action Plan 2050 wikipedia , lookup

Politics of global warming wikipedia , lookup

IPCC Fourth Assessment Report wikipedia , lookup

Climate change mitigation wikipedia , lookup

Economics of climate change mitigation wikipedia , lookup

Views on the Kyoto Protocol wikipedia , lookup

Carbon governance in England wikipedia , lookup

Mitigation of global warming in Australia wikipedia , lookup

Carbon emission trading wikipedia , lookup

Low-carbon economy wikipedia , lookup

Transcript

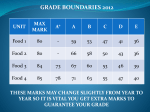

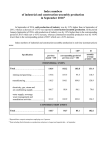

The Impact of Stricter Standards on CO2 Emission Across Industries School of Economics and Management Beihang University Dongwen Tian 2017.06.21 Introduction Methodology and data Results Conclusions 1 • Introduction The CO2 emissions with the increasing greenhouse effect is now the global concern • China has become the largest CO2 emitter in the world, and has implemented many policies to control it • The reduction of the emissions will inevitably influence the growth of GDP • However, Chinese government is making its effort to control the emissions 1 Introduction Policies implemented in China • The 11th five-year plan (2006) to improve the production and consumption structure and build a stable, economic, clean and safe energy supply system • China’s national programme to address climate change (2007) Clarified the specific objectives, principles, key industries and actions to cope with the climate change • China’s policies and actions for addressing climate change (each year since 2008) Introduced various methods to control the emissions across industries • The 12th five-year plan (2011) To control the emissions and establish the low-carbon product standards 2 Methodology and data IOA (input-output analysis): to estimate the emissions across 17 manufacturing industries in China (2000-2014) Direct Carbon Emissions Coefficient The emissions of various types of energy (including coal, coke, crude oil, gasoline, diesel, kerosene, fuel oil, natural gas) are calculated based on the equation provided by IPCC: NCV CEF 2 Methodology and data net calorific value NCV China Energy Statistical Yearbook CO2 emission factor CEF 2006 IPCC Guidelines for National Greenhouse Gas Inventories Direct Carbon Emissions Coefficient kg(CO2)/kg(energy) Coal Coke Crude oil Gasoline Kerosene Diesel Fuel oil Natural gas 2.055 3.043 3.065 2.985 3.088 3.161 3.2 37 1.996 2 Method and data The direct carbon emission of an industry: E d i coni i the emission factor con the consumption of different types of energy of an industry • Collect the output data of selected industries from World InputOutput Table from WIOD • With the carbon emission and output data, get the direct carbon emission coefficient, reflecting the emission per unit output 2 Methodology and data Complete Emission Coefficient get the following equation from the IO model: x x = Ax + y (1) B (I A)1 I (2) Cf Cd [(I A)1 I] (3) the output of an economy A the direct consuming coefficient matrix Cd the direct carbon emission coefficient B the complete consuming coefficient matrix Cf the complete emission coefficient 2 Methodology and data Data: • consumption of various types of energy: China Energy Statistical Yearbook • input-output data: WIOD • trade data: UNComtrade Observation Duration: 2000-2014 2 Methodology and data Addressing industry classification differences across divergent datasets 1. China Energy Statistical Yearbook before and after 2011: make adjustments to get a unique classification 2. Input-Output table - China Energy Statistical Yearbook: make adjustments 3. The classification got above - SITC Rev.3: correspondence by Sheng Bin (2002) 2 Methodology and data • The results are not unique • Adopt the decomposition by Erick Dietzenbacher and Bart Los (1998) • The change of the emissions can be represented as: Q CL0 F0 S0 C1LF0 S0 C1L1FS0 C1L1F1S0 or: Q CL1F1S1 C0 LF1S1 C0 L0 FS1 C0 L0 F0S 2 Methodology and data The 4 effects: 1 Q (CL0 F0 S0 CL1F1S1 ) 2 direct carbon emission technique effect 1 (C1LF0 S0 C0 LF1S1 ) 2 input-output technique effect 1 (C1 L1FS0 C0 L0 FS1 ) 2 scale effect 1 (C1 L1 F1S C0 L0 F0 S ) 2 composition effect 3 • Results Analyze the embodied CO2 emissions in export of 17 manufacturing industries • Divide the change into 4 parts (SDA methods) • To report the results clearer, take 6 industries for example 3 Results Fig1 The Embodied CO2 Emission (2000-2014) 600 Manufacture of Textile,Wearing,Leather and Related Products 500 Manufacture of Electrical Machinery and Apparatus 400 Manufacture of Furniture and other Manufacture 300 Manufacture of Computers, Communication and Other Electronic Equipment 200 Other Manufacture of Machinery 100 Manufacture of Raw Chemical Materials and Chemical Products 0 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 3 Results Fig2 The Direct Carbon Emission Technique Effect 60 40 Manufacture of Textile,Wearing,Leather and Related Products 20 Manufacture of Electrical Machinery and Apparatus 0 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 Manufacture of Furniture and other Manufacture -20 -40 Manufacture of Computers, Communication and Other Electronic Equipment -60 Manufacture of Raw Chemical Materials and Chemical Products -80 Other Manufacture of Machinery -100 The Impact of Policy on Direct Carbon Emission Technique Effect Unit: Mt Industries 2007 2011 Manufacture of Electrical Machinery and Apparatus Manufacture of Textile, Wearing, Leather and Related Products Manufacture of Computers, Communication and Other Electronic Equipment Manufacture of Basic Metal Manufacture of Furniture and other Manufacture Other Manufacture of Machinery Manufacture of Raw Chemical Materials and Chemical Products Manufacture of Metal Products Manufacture of Transport Equipment Manufacture of Rubber and Plastics Products Manufacture of Non-metallic Mineral Products Manufacture of Foods, Beverages and Tobacco Processing of Petroleum, Coking and Processing of Nuclear Fuel Manufacture of Paper and Paper Products Processing of Timber, Manufacture of Wood, Bamboo, Rattan, Palm, and Straw Products Manufacture of Medicines Printing and Reproduction of Recording Media -39.0084 -37.4590 -32.4861 -26.9742 -25.8066 -23.2055 -19.7342 -16.1244 -13.0731 -8.45348 -5.22916 -3.24017 -2.26023 -1.68533 -18.7347 -7.32803 -7.27106 -8.0618 -8.06132 -8.82455 -2.48799 -5.49650 -6.39260 -1.98868 -1.84048 -0.55965 -1.47626 -0.61271 -1.34080 -0.16083 -1.01297 -0.49432 -0.07882 -0.38504 3 Results Fig3 The Input-Output Technique Effect 60 Manufacture of Textile,Wearing,Leather and Related Products 40 Manufacture of Raw Chemical Materials and Chemical Products 20 Processing of Petroleum, Coking and Processing of Nuclear Fuel 0 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 Printing and Reproduction of Recording Media -20 Manufacture of Medicines -40 Manufacture of Computers, Communication and Other Electronic Equipment -60 The Impact of Policy on Input-Output Technique Effect Unit:Mt Industries The impact in 2006 Manufacture of Computers, Communication and Other Electronic Equipment Manufacture of Textile, Wearing, Leather and Related Products Manufacture of machinery and equipment n.e.c. Manufacture of Electrical Machinery and Apparatus Manufacture of Transport Equipment Manufacture of Furniture and other Manufacture Manufacture of Metal Products Manufacture of Non-metallic Mineral Products Manufacture of Rubber and Plastics Products Manufacture of Basic Metal Manufacture of Raw Chemical Materials and Chemical Products Manufacture of Foods, Beverages and Tobacco Manufacture of Paper and Paper Products Processing of Timber, Manufacture of Wood, Bamboo, Rattan, Palm, and Straw Products Manufacture of Medicines Printing and Reproduction of Recording Media Processing of Petroleum, Coking and Processing of Nuclear Fuel -50.16908429 -16.52394149 -13.35607896 -13.20908489 -7.741291194 -6.136039361 -4.892446087 -4.192773484 -3.123142541 -2.859727388 -2.453539618 -1.439742958 -1.126969622 -1.024964910 -0.650035547 -0.484915074 -0.362959975 3 Results Fig4 The Scale Effect 120 100 80 60 40 Manufacture of Textile,Wearing,Leather and Related Products Manufacture of Electrical Machinery and Apparatus Manufacture of Furniture and other Manufacture 20 0 Manufacture of Computers, Communication and Other Electronic Equipment -20 Other Manufacture of Machinery -40 -60 -80 Manufacture of Raw Chemical Materials and Chemical Products 3 • Results No common tendency in composition effect across industries: the proportion of some industries increased, while that of others decreased • Obtain total composition effect across 17 manufacturing industries to find the influences 3 Results Fig5 The Composition Effect 60 40 20 0 2001 -20 -40 -60 -80 -100 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 Industries Manufacture of Foods,Beverages and Tobacco Manufacture of Computers, Communication and Other Electronic Equipment Manufacture of Furniture and other Manufacture Manufacture of Medicines Processing of Timber,Manufacture of Wood,Bamboo,Rattan,Palm,and Straw Products Manufacture of Textile,Wearing,Leather and Related Products Printing and Reproduction of Recording Media Manufacture of Transport Equipment Manufacture of Paper and Paper Products Processing of Petroleum, Coking and Processing of Nuclear Fuel Other Manufacture of Machinery Manufacture of Rubber and Plastics Products Manufacture of Electrical Machinery and Apparatus Manufacture of Non-metallic Mineral Products Manufacture of Metal Products Manufacture of Basic Metal Manufacture of Raw Chemical Materials and Chemical Products complete emission composition composition coefficient(kg/$US) in 2008 in 2009 0.822991464 2.20% 2.48% 1.071265843 20.24% 22.04% 1.168669010 1.196966938 13.54% 0.58% 14.00% 0.73% 1.199181778 0.58% 0.57% 1.261232709 1.573029054 1.736641502 1.813952340 1.849853737 1.898443523 2.101171691 2.108339425 2.290608398 2.567848774 2.607778583 2.667433121 16.43% 0.21% 4.92% 0.53% 1.53% 8.49% 2.28% 11.49% 1.72% 4.05% 6.43% 4.79% 17.67% 0.23% 4.99% 0.62% 1.17% 8.27% 2.44% 11.96% 1.85% 3.74% 3.02% 4.23% 3 • Results The financial crisis at the end of 2008 and its impact reflected clearly in 2009 • The export composition was improved in 2009, and the emissions was reduced by the effect • To make more comprehensive, sum the proportion of 9 industries with lower complete emission effect in 2009, find • it increased from 59.21% to 63.33% • while the proportion of the other 8 industries with higher coefficients declined from 40.79% to 36.67% 4 Conclusions Decomposing the change of trade embodied CO2 emissions in into 4 parts, conclude: • The 11th five-year plan made firms to employ low-carbon input to reduce the emissions • The 12th five-year plan forced firms to reduce emissions by using more cleaner energy and upgrading techniques • Firms with low technique were forced to exit the market • However, the impacts of policies were different across industries • Although financial crisis did do harm to the economy, it seemed to have reduced the emissions by improving export composition Thank You!