* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download resonant material processing using (ultra-)short

Survey

Document related concepts

Ultrahydrophobicity wikipedia , lookup

Microelectromechanical systems wikipedia , lookup

Superconductivity wikipedia , lookup

Synthetic setae wikipedia , lookup

Low-energy electron diffraction wikipedia , lookup

Strengthening mechanisms of materials wikipedia , lookup

Optical tweezers wikipedia , lookup

Metamaterial wikipedia , lookup

Transformation optics wikipedia , lookup

Ferromagnetism wikipedia , lookup

Metamaterial cloaking wikipedia , lookup

Photoconductive atomic force microscopy wikipedia , lookup

Negative-index metamaterial wikipedia , lookup

Nanochemistry wikipedia , lookup

Transcript

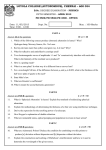

RESONANT MATERIAL PROCESSING USING (ULTRA-)SHORT LASER PULSES Ref-No: TA-CPA-1538-LZH MBM ScienceBridge GmbH BACKGROUND The invention relates to the usage of a tunable, resonant electromagnetic field for both, the targeted fabrication of structures with dimensions smaller than the used beam diameter and the targeted fabrication of ultra small particles. Therefore the electromagnetic field that is created by an ultra short laser pulse on the surface of an object is superposed with an external field to achieve a resonance rise specific to the processed material. PROBLEM Alexander Brinkmann 0551-30724 159 [email protected] www.sciencebridge.de DEVELOPMENT STATUS Proof of concept PATENT SITUATION The conventional fabrication of micro- or nano-structured surfaces is of great interest for a huge amount of industrial or R&D branches. Using (ultra) short lasers, so called LISOS ("laser induced self organizing structures") can be produced quite easily. Since the process is taking place in close vicinity to the ablation threshold, it in general takes little laser intensities to fabricate these LISOS. But in order to machine larger areas the average laser power needs to be increased to several kilo watts. Taking today's state of the art, this again results in high acquisition and maintenance costs for the needed laser systems consequently raising the inhibition threshold in industry. DE 102012025294(A1) pending WO 2014102008(A2) pending CATEGORIES //Physical sciences //Optics, photonics and laser technology SOLUTION When an electromagnetic field (e.g. that of a laser) hits a surface, it propagates within the irradiated material and, depending on the laser geometry used and the properties of the material, modes develop. If now the material is excited resonantly (i.e. with a frequency that is specific to said material) these modes create standing waves leading to a local increase or decrease of the electromagnetic field on the surface. Hills are represented by nodes, valleys by antinodes. The emerging structures have dimensions which are in the order of the wavelength of the laser making them considerably smaller than the actual beam diameter. The goal is now to find these resonance conditions for a variety of materials and to reliably adjust them. In order to achieve that goal, it has been found especially favorable to apply an external electric or magnetic field that superposes the electromagnetic field of the laser. That way, one can directly www.inventionstore.de 1/2 Powered by TCPDF (www.tcpdf.org) control and adjust the shape of the resonant modes and therefor structural surface parameters like the relative pattern distance or the average height distribution. ADVANTAGES Only due to the resonant material processing technique a diversity of industrial applications become economically feasible or at least much more cost effective. Reduction of the necessary laser power Targeted development of nano- and micro-structures Easy adjustment and control of the resonance conditions through external fields Usage of more efficient materials. SCOPE OF APPLICATION Some application areas of the resonant material processing technique are mentioned below: Lowering of the reflexion of semiconductors resulting in an increase of the efficiency of photovoltaics Increasing the sensitivity of photo detectors Increasing the surface of the effective area for catalytical applications (e.g. increasing the effectiveness of LiCoO2-cathodes used in Lithium-Ion batteries) for tribological applications (e.g. to increase and locally confine friction parameters) for medical purposes (e.g. controlling cell growth, proliferation and adhesion) Modification of surface properties on the micrometer scale by amplifying chemical reactions (like oxidations) in the vicinity of nodes or antinodes Functionalization of surfaces (e.g. for lowering the wetting) Controlled fabrication of ultra small particles. www.inventionstore.de 2/2