* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download 1 - SPDC

Survey

Document related concepts

Skin effect wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Stepper motor wikipedia , lookup

Voltage optimisation wikipedia , lookup

Stray voltage wikipedia , lookup

Electrical ballast wikipedia , lookup

Mains electricity wikipedia , lookup

Opto-isolator wikipedia , lookup

Buck converter wikipedia , lookup

Current source wikipedia , lookup

Lumped element model wikipedia , lookup

Earthing system wikipedia , lookup

Power MOSFET wikipedia , lookup

Rectiverter wikipedia , lookup

Thermal runaway wikipedia , lookup

Alternating current wikipedia , lookup

Current mirror wikipedia , lookup

Transcript

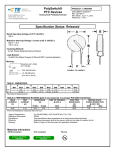

P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters 1 2 3 4 5 6 7 8 9 10 11 12 13 14 P62.42.2™/D2 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters Sponsor Surge Protective Devices Committee of the IEEE Power and Energy Society P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters 1 2 3 Abstract: <Select this text and type or paste Abstract—contents of the Scope may be used> Keywords: <Select this text and type or paste keywords> 4 P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters 1 2 3 4 5 6 7 8 9 10 Introduction A PTC device is one which undergoes a change in resistance of typically several decades over a very narrow temperature range. These devices consist working material arranged between two metal electrodes. The working material is a special type of either ceramic (see clause 5.1), or polymer (see clause 4.1). PTCs are widely used as coordinating elements in telecom applications (see clause 6.1), where they switch to a high resistance when subjected to a fault, thus mitigating damage to equipment, but in normal operation have a low resistance which minimizes the amount of power dissipated. This standard describes PTC construction, their voltage-current characteristics, characteristic properties, ratings and circuit examples iii P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters 1 Contents 2 3 1. Overview .................................................................................................................................................... 4 1.1 Scope ................................................................................................................................................... 4 4 2. Normative references.................................................................................................................................. 5 5 3. Definitions .................................................................................................................................................. 5 6 7 8 9 10 11 4. Polymeric PTC ........................................................................................................................................... 5 4.1 Construction ........................................................................................................................................ 5 4.2 Operation ............................................................................................................................................. 6 4.3 Production............................................................................................................................................ 7 4.4 Ratings ................................................................................................................................................. 7 4.5 Characteristics ..................................................................................................................................... 8 12 13 14 15 16 17 5. Ceramic PTC .............................................................................................................................................10 5.1 Construction .......................................................................................................................................10 5.2 Operation ............................................................................................................................................12 5.3 Ceramic PTC Production ....................................................................................................................15 5.4 Ratings ................................................................................................................................................16 5.5 Characteristics ....................................................................................................................................16 18 19 20 6. Applications...............................................................................................................................................18 6.1 Telecom Coordinating Element ..........................................................................................................18 21 22 1. Overview 23 1.1 Scope 24 25 26 The C62.42 guide series covers surge protective components (SPCs) used in power and telecom surge protective devices (SPDs) and equipment ports. This part on Positive Temperature Coefficient Devices (PTC) technology SPCs covers: 27 - Construction 28 - Operation 29 - Production 30 - Ratings 31 - Characteristics 32 - Application examples iv P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters 1 2 2. Normative references 3 4 5 6 The following referenced documents are indispensable for the application of this document (i.e., they must be understood and used, so each referenced document is cited in text and its relationship to this document is explained). For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments or corrigenda) applies. 7 none 8 3. Definitions 9 10 For the purposes of this document, the following terms and definitions apply. The IEEE Standards Dictionary: Glossary of Terms and Definitions1 should be consulted for terms not defined in this clause. 11 12 4. Polymeric PTC 13 4.1 Construction 14 15 16 17 The active material in a polymeric PTC is made by loading a conductive medium, typically carbon black, into a molten polymer. This polymer must have an adequate amount of crystallinity when cooled, for reasons that will become clear from the following discussion. The amount of conductive medium added depends on the nature of the medium, and on the cold resistance to be achieved. 18 19 20 21 22 23 24 25 As the mixture is cooled, it starts to crystallize. As it does, the conductive medium is expelled from the crystalline region into the amorphous region. The result is an increasing concentration of conductive medium in the amorphous region. As the crystalline region of the polymer grows during the cooling process, the amorphous region shrinks, until the density of conductive medium is sufficient to allow the formation of conductive chains. Further shrinkage of the amorphous region causes the chains to grow. When the chains are long enough to form a bridge between the electrodes, the resistance of the device drops - slowly at first, and then precipitously. Further cooling results in a further decrease in resistance, but at a lower rate. This process is characterized by an R-T curve, such as that shown in Figure 1. 1 IEEE Standards Dictionary: Glossary of Terms and Definitions is available at http://shop.ieee.org. 5 P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters 1.0E+05 Relative resistance 1.0E+04 1.0E+03 1.0E+02 1.0E+01 1.0E+00 1.0E-01 0.0 20.0 40.0 60.0 80.0 100.0 120.0 140.0 160.0 180.0 Temperature, °C 1 Figure 1 — An example of an RT curve for a polymeric PTC 2 3 4 4.2 Operation 5 6 7 8 9 Operation of the device occurs by traversing the R-T curve in the opposite direction from that just described. The temperature of the device on the R-T curve is a combination of the ambient temperature and an incremental temperature due to I2R heating. Because of this combination, the current required to switch a device is a function of the ambient temperature, and is characterized by a derating curve such as that shown in Figure 2. 1.8 Multiply 23 o C hold or trip current value by 1.6 1.4 1.2 1 0.8 0.6 0.4 0.2 0 -40 -30 -20 -10 0 10 20 30 40 o Temperature, C 10 6 50 60 70 80 90 100 P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters 1 2 Figure 2 — Example of a derating curve for either hold or trip current 3 4.3 Production 4 5 6 7 The production process begins by extruding the mixture of conductive medium and polymer into relatively thin sheets. Foil electrodes are then attached to both sides of the sheet, forming what is often called plaque. Devices are made by punching chips out of the plaque, and attaching leads to the chips. The resulting device may, or may not be encapsulated, depending on the application. 8 4.4 Ratings 9 10 11 The ratings listed on a data sheet typically include a hold current, a trip current, and a resistance range. Among these, the cold resistance range is the key parameter, because it determines the hold current, trip current, and time-to-trip ratings. 12 4.4.1 Cold resistance 13 14 15 16 17 18 The cold resistance of the device is the resistance measured at a standard ambient temperature, usually 20 oC or 25 oC. As described in clause 4.1, the cold resistance of the device depends on its material composition. Because the density of carbon chains is not precisely uniform over the plaque, the resistance of any given chip punched from the plaque varies over a range of values. The minimum and maximum values of resistance [Rmin and Rmax, respectively] for devices made from these chips are specified on the data sheet for the device. 19 4.4.2 Hold and trip currents 20 21 22 23 24 25 For a typical device, a plot of hold/trip current [they are the same for a given device] for a possible range of production lots is shown in Figure 3. The upper and lower lines shown in the plot are the 99.8% confidence lines for the distribution. If the confidence level is reduced, the confidence lines will move closer together; and the hold and trip currents will also move closer together. However reducing the confidence level will increase the probability that the customer will receive a part that is out of spec; unless a selection step is added to the production process to eliminate out-of-spec parts. 26 27 28 29 30 31 In Figure 3, the trip current is determined as the value of current corresponding to Rmin, and the hold current is determined as the value of current corresponding to R1max (the resistance one hour after a trip event). Moving the resistance window will change the hold and trip currents, as will expanding or contracting the resistance window. Data is typically taken over a wider resistance range than will occur in production, to better establish the regression line, and to better show options for placement of the resistance window. Plots similar to Figure 3 can be made for the process variables of any device. 7 P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters Regression 99.8% Confidence Rmin R1max Current Trip Current Rmin R1max Hold Current Resistance 1 2 Figure 3 — An illustration of a dispersion plot of hold/trip current versus resistance 3 4.5 Characteristics 4 5 6 The Characteristics listed on a data sheet typically include a maximum operating voltage, a maximum abnormal current, and a time-to-trip value at a specified current. Resistance recovery time [a characteristic] may also be measured, but is generally not specified. 7 4.5.1 Time to Trip 8 9 10 11 12 13 14 As was the case for hold and trip currents, the time for a device to trip at a specified current is also a function of resistance. Figure 4 shows a typical time-to-trip versus current plot, for a single device at room temperature. Devices of lower resistance will have a time-to-trip curve that lies above the curve shown in Figure 4. Devices of higher resistance will have a time-to-trip curve that lies below the curve shown in Figure 4. At higher temperatures the line moves down (faster trip times for a given current). At lower temperatures the line moves up (longer trip times for a given current). The curve moves up or down with temperature, according to the derating curve for the device (see Figure 2). 8 Fault Current P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters Time-to-Trip 1 2 Figure 4 — A typical time-to-trip versus current for a single device at room temperature 3 4.5.2 Resistance Recovery Time 4 5 6 7 8 9 10 11 12 13 A device which is tripped by a fault current greater than the rated trip current for the device will stay in the tripped state until the fault power is removed. Once the power is removed the device will cool, and the resistance will drop toward the cold resistance. The rate at which it returns has a significant dependence on a number of things, including the amount of the fault current, the rate of heat transfer out of the device, and the size of the device. An example of one of many possible resistance recovery curves is shown in Figure 5. Typically an hour is allowed for the resistance to stabilize near its cold value; and on the data sheet this value of resistance is listed as R1max. Often a value of resistance near R1max is achieved in a much shorter time than one hour. The time scale of the figure depends significantly on a number of things, including the amount of the fault current, the rate of heat transfer out of the device, and the size of the device. 9 P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters Relative resistance 1000000 10000 100 1 1 10 100 1000 10000 Relaxation time, seconds 1 Figure 5 — The general shape of a resistance recovery curve. 2 3 5. Ceramic PTC 4 5.1 Construction 5 6 7 8 9 PTC thermistors are made of doped polycrystalline ceramic on the basis of barium titanate. Generally, ceramic is known as a good insulating material with a high resistance. Semiconduction and thus a low resistance are achieved by doping the ceramic with materials of a higher valency than that of the crystal lattice. Part of the barium and titanate ions in the crystal lattice is replaced with ions of higher valencies to obtain a specified number of free electrons which make the ceramic conductive. 10 11 12 13 14 15 16 The material structure is composed of many individual crystallites (figure 6). At the edge of these monocrystallites, the socalled grain boundaries, potential barriers are formed. They prevent free electrons from diffusing into adjacent areas. The result is high resistance of the grain boundaries. However, this effect is neutralized at low temperatures. High dielectric constants and sudden polarization at the grain boundaries prevent the formation of potential barriers at low temperatures enabling a smooth flow of free electrons. The PTC resistance RPTC is composed of individual crystal and grain boundary resistances. The grain boundary resistance is strongly temperature dependent. 17 RPTC = Rgrain + Rboundary 18 Rboundary = f (T) 10 P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters 1 2 3 4 5 6 7 8 9 10 11 Figure 6 — A representation of the polycrystalline structure of a ceramic PTC thermistor Above the ferroelectric Curie temperature, dielectric constant and polarization decline so far that there is strong growth of the potential barriers and thus of resistance. In a certain range of temperature above the Curie temperature TC, the resistance of the PTC thermistor rises exponentially. Beyond the range of the positive temperature coefficient the number of free charge carriers is increased by thermal activation. The resistance then decreases and exhibits a negative temperature characteristic (NTC) typical of semiconductors (see figure 7). In Figure 7, TC = ferroelectric Curie temperature and α = temperature coefficient. With rising temperature, the resistance of the PTC thermistor initially decreases and rises then steeply. Beyond the range of the positive temperature coefficient the resistance again decreases, which can lead to thermal run-away if the thermistor is operated in this region. 12 13 14 Figure 7 — An example of an RT curve for a ceramic PTC 11 P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters 1 5.2 Operation 2 3 4 5 A current flowing through a thermistor may cause sufficient heating to raise the thermistor's temperature above the ambient. As the effects of self-heating are not always negligible, a distinction has to be made between the characteristics of an electrically loaded thermistor and those of an unloaded thermistor. The properties of an unloaded thermistor are also termed "zero-power characteristics". 6 5.2.1 Unloaded thermistors 7 8 9 The zero-power resistance value R (T) is the resistance value measured at a given temperature T with the electrical load kept so small that there is no noticeable change in the resistance value if the load is further reduced. For test voltages, please refer to the individual types (mostly ≤ 1.5 V). 10 11 12 Figure 8 shows the typical dependence of the zero-power resistance on temperature. Because of the abrupt rise in resistance (the resistance value increases by several powers of ten), the resistance value is plotted on a logarithmic scale (ordinate) against a linear temperature scale (abscissa). 13 Figure 8 — Typical resistance/temperature characteristic 14 15 In Figure 8: 16 RPTC = f (TPTC) 17 RR Rated PTC resistance (resistance value at 25 °C) 18 Rmin Minimum resistance 19 TRmin Temperature at Rmin 20 Rref Reference resistance: Rref = 2 • Rmin 12 P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters Reference temperature (resistance value reaches Rref = 2 • Rmin) 1 Tref 2 5.2.2 Electrically loaded thermistors 3 4 5 When a current flows through the thermistor, the device will heat up more or less by power dissipation. This self-heating effect depends not only on the load applied, but also on the thermal dissipation factor G th of the thermistor itself. 6 Self-heating of a PTC thermistor resulting from an electrical load can be calculated as follows: 7 P V I dH dT Gth (T T A ) C th dt dt 8 9 P Power applied to PTC T Instantaneous temperature of PTC 10 V Instantaneous value of PTC voltage TA Ambient temperature 11 I Instantaneous value of PTC current Cth Heat capacity of PTC 12 dH/dt Change of stored heating energyover time dT/dt Change of temperature over time 13 Gth Thermal dissipation factor of PTC 14 15 16 The properties of electrically loaded PTC thermistors (in self-heated mode) are better described by the I/V characteristic than by the R/T curve (see figure 9). It illustrates the relationship between voltage and current in a thermally steady state in still air at 25 °C. 13 P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters 1 Figure 9 — I/V characteristic of a PTC thermistor 2 3 In Figure 9: 4 Ir Residual current at applied voltage Vmax (current is balanced) 5 Vmax Maximum operating voltage 6 VR Rated voltage (VR < Vmax) 7 VBD Breakdown voltage (VBD > Vmax) 8 9 10 11 12 13 Figure 10 illustrates the two operating states of a PTC fuse. In rated operation of the load the PTC resistance remains low (operating point A1). Upon overloading or shorting the load, however, the power consumption in the PTC thermistor increases so much that it heats up and reduces the current flow to the load to an admissible low level (operating point A2). Most of the voltage then lies across the PTC thermistor. The remaining current is sufficient to keep the PTC in high-resistance mode ensuring protection until the cause of the overcurrent has been eliminated. 14 P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters 1 Figure 10 — Operating states of a PTC thermistor for overcurrent protection 2 3 In Figure 10: 4 a) Rated operation 5 b) Overload operation 6 RL Load resistance 7 IS Switching current 8 IR Rated current 9 RPTC PTC resistance 10 5.3 Ceramic PTC Production 11 12 13 14 15 Mixtures of barium carbonate, titanium oxide and other materials whose composition produces the desired electrical and thermal characteristics are ground, mixed and compressed into disks, washers, rods, slabs or tubular shapes depending on the application. These blank parts are then sintered, preferably at temperatures below 1400 °C. Afterwards, they are carefully contacted, provided with connection elements depending on the version and finally coated or encased. 15 P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters 1 5.4 Ratings 2 3 4 The ratings listed on a data sheet typically include rated current, switching current, and a rated resistance. Among these, the cold resistance (rated resistance) is the key parameter, because it determines the hold current, trip current, and time-to-trip ratings in combination with the physical dimensions. 5 5.4.1 Rated Resistance RR 6 7 The rated resistance RR is the resistance value at temperature T R. PTC thermistors are classified according to this resistance value. The temperature TR is 25 °C, unless otherwise specified. 8 9 10 As described in Clause 5.2.1 the resistance is determined by the grain boundaries of the ceramic material. Because of impurities during the production process the potential barriers and therefore the rated resistance varies over a range of values. The resistance tolerance is specified on the data sheet for the device. 11 12 13 As opposed to most PTC thermistors made of polymeric materials, ceramic PTC thermistors always return to their initial resistance value, even after frequent heating/cooling cycles. This is an issue only if the PTC resistance is a significant fraction of the total circuit resistance 14 5.4.2 Rated current IR and Switching current IS 15 16 17 It is important to know at which current the PTC thermistor will not trip and at which currents the thermistor will reliably go into high-resistance mode. For this reason we specifiy the rated current I R and the switching current IS. 18 Rated current IR: At currents ≤ IR the PTC thermistor reliably remains in low-resistance mode. 19 Switching current IS: At currents ≥ IS the PTC thermistor reliably goes into high-resistance mode. 20 The currents specified in the data sheets refer to TA = 25 °C, unless otherwise stated. 21 5.5 Characteristics 22 23 24 The characteristics listed on a ceramic PTC data sheet typically include a time-to-trip value at a specified current, a maximum operating voltage, and a maximum switching current. The voltage dependence of resistance may also be shown. 25 5.5.1 Switching time ts 26 27 The switching time tS. is the time it takes at applied voltage for the current passing through the PTC to be reduced to half of its initial value. The tS values apply to TA = 25 °C. 28 29 30 31 32 33 34 35 The dynamic heating behavior of the PTC thermistor is determined by the specific heat capacity of the titanate material, which is approx. 2.7 Ws/Kcm3. At short switching times (less than 5 s with commonly used overcurrent protection devices) heat dissipation through the surface and lead wires is virtually negligible. Almost the entire electrical dissipation is consumed to heat up the ceramic material, to increase the temperature above the reference temperature and thus to produce a stable operating point on the R/T characteristic. When dissipation increases with rising difference between device temperature and ambient, only a small amount of excess energy remains for heating the component and the result is the switching time curves as a function of switching current shown in Figure 11. 16 P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters 1 2 Figure 11 — Switching times tS of some PTC thermistors (parameter: different geometries) 3 versus switching current IS (measured at 25 °C in still air) 4 5.5.2 Maximum Switching current ISmax 5 6 7 8 In electrically loaded PTC thermistors electrical power is converted into heat. The high loads generated for a short period of time during the heating phase (the PTC thermistor is in low-resistance mode when the operating voltage is applied) are limited by the specification of the maximum permissible switchting current ISmax and the maximum operating voltage V max in the specification. 9 10 The number of heating processes is also an important criterion. The permissible number of switching cycles not affecting function or service life is given in the specification as well. 11 12 13 14 A ceramic PTC thermistor which is tripped by a fault current greater than the rated switching current for the device will stay in the tripped state until the fault power is removed. After a few minutes only ceramic PTC thermistors return to their initial resistance value thus enabling very fast resumption of operation of the protected equipment. 15 5.5.3 Voltage dependence of resistance 16 17 18 19 20 21 22 23 The resistance of the ceramic PTC thermistor is composed of the grain resistance and the grain boundary transition resistance. Particularly in the hot state, the strong potential barriers are determining resistance. Higher voltages applied to the PTC thermistor therefore drop primarily at the grain boundaries with the result that the high field strengths dominating here produce a break-up of the potential barriers and thus a lower resistance. The stronger the potential barriers are, the greater is the influence of this "varistor effect" on resistance. Below the reference temperature, where the junctions are not so marked, most of the applied voltage is absorbed by the grain resistance. Thus the field strength at the grain boundaries decreases and the varistor effect is quite weak. 17 P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters 1 2 3 4 5 Figure 12 shows the typical dependence of resistance on field strength. It can be seen that the difference in resistance is largest between R(E1), R(E2) and R(E3) at temperature Tmax and thus in the region of maximum resistance. Due to this dependence on the positive temperature coefficient of the field strength, operation on high supply voltages is only possible with PTC thermistors that have been designed for this purpose by means of appropriate technological (grain size) and constructional (device thickness) measures. 6 7 This behavior is characteristic of ceramic PTCs, but not of polymeric PTCs which do not exhibit a voltage dependence of resistance. 8 9 10 Figure 12 — Influence of field strength E on the R/T characteristic (varistor effect), where αR1 > αR2 > αR3 11 6. Applications 12 6.1 Telecom Coordinating Element 13 14 15 16 17 18 19 For telecommunications circuits, a major application is as a coordinating element between primary and secondary protectors. Figure 13 shows a generic circuit for a protector. The primary protector is a device which limits high amplitude lightning surges, but which can have a significant surge let-through in the process. Typically this device is a GDT. The secondary protector is a device which can’t handle high amplitude surges, but which can limit the remnant surge to the lowest value consistent with the operating voltage of the system. Typically this device is a thyristor which has a lower operating threshold than the GDT. 18 P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters Equipment Primary Protection Secondary Protection Coordination Element 1 Figure 13 — Reference circuit for a surge protector 2 3 4 5 6 7 8 In Figure 13 the coordinating element, generally a resistor, is placed between the primary and secondary protection, and is put there so that an incident surge current will develop enough voltage to fire the primary protector. In the absence of a coordinating element the secondary protection (thyristor) would operate before the primary protection (GDT), due to its lower operating threshold. When this happens the secondary protector is subjected to the full surge, which generally destroys it. 9 A PTC is ideal for this resistor for three reasons: 10 11 12 13 14 15 Because the PTC switches to a high resistance state when subjected to a fault, the amount of power it has to dissipate is minimized. So if V is the fault voltage, a fixed resistor of value Rlow would have to dissipate V2/Rlow, whereas a PTC only has to dissipate V2/Rhigh, where Rhigh >> Rlow As a result the PTC can be relatively small, and doesn’t reach a high temperature. In contrast, a fixed resistor needs to be large enough to handle the highest current reached in a power contact condition, and generally gets quite hot while doing so. 16 17 18 19 20 21 22 A PTC Thermistor’s resistance is depending on the temperature of the component which itself depends on the power consumption of the PTC as well as the ambient temperature situation. These two parameters are exactly those limiting the maximum energy of any following component to be protected. Unlike other technologies (e.g. semiconductor solutions) a PTC thermistor does not use single parameters like voltage or current to detect whether to fuse or not. Instead it is only reacting on the energy consumption in total. Therefore energy peaks that do not harm any of the following components do not cause an interruption of a telecom line. 23 24 25 26 Advantages of a ceramic PTC: For many telecom applications the balance between the tip and ring (often referred to as longitudinal balance) is essential. As opposed to other technologies (not self resettable fuses, polymeric PTC Thermistors), ceramic PTC thermistors always return to their initial resistance 19 P62.42.4 October 2013 Draft Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports - Part 4 Thermally Activated Current Limiters 1 2 3 4 5 6 7 value, even after frequent heating/cooling cycles. The balance of the line is maintained under all circumstances. A ceramic PTC thermistor which is tripped by a fault current greater than the rated switching current for the device will stay in the tripped state until the fault power is removed. After a few minutes only ceramic PTC thermistors return to their initial resistance value thus enabling very fast resumption of operation of the protected equipment. Advantages of a polymeric PTC: 8 9 10 Unlike a ceramic PTC the resistance of the active material in a polymeric PTC is independent of frequency (reactive elements may be introduced by the packaging), minimizing the impact on the performance of systems with high frequency signals 11 12 13 14 The resistance of a polymeric PTC is independent of voltage; unlike ceramic PTCs where the series impedance drops as voltage is increased. Because of this effect, the DC resistance of a ceramic PTC has to be higher than a polymeric PTC for a given coordinating impedance, resulting in a higher insertion loss. 20