* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Sample pages 1 PDF

High-temperature superconductivity wikipedia , lookup

Terahertz metamaterial wikipedia , lookup

Nitrogen-vacancy center wikipedia , lookup

State of matter wikipedia , lookup

Nanochemistry wikipedia , lookup

Tunable metamaterial wikipedia , lookup

History of metamaterials wikipedia , lookup

Hall effect wikipedia , lookup

Superconducting magnet wikipedia , lookup

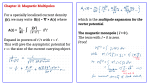

Aharonov–Bohm effect wikipedia , lookup

Condensed matter physics wikipedia , lookup

Scanning SQUID microscope wikipedia , lookup

Geometrical frustration wikipedia , lookup

Curie temperature wikipedia , lookup

Neutron magnetic moment wikipedia , lookup

Superconductivity wikipedia , lookup

Giant magnetoresistance wikipedia , lookup