* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Development of a 60 kHz, 180 kW, Over 85% Efficiency Inductive

Electrical substation wikipedia , lookup

Current source wikipedia , lookup

Audio power wikipedia , lookup

Transformer wikipedia , lookup

Electrification wikipedia , lookup

Electrical ballast wikipedia , lookup

Three-phase electric power wikipedia , lookup

Power engineering wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Utility frequency wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Stray voltage wikipedia , lookup

History of electric power transmission wikipedia , lookup

Magnetic core wikipedia , lookup

Galvanometer wikipedia , lookup

Power MOSFET wikipedia , lookup

Transformer types wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Amtrak's 25 Hz traction power system wikipedia , lookup

Opto-isolator wikipedia , lookup

Spark-gap transmitter wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Voltage regulator wikipedia , lookup

Power inverter wikipedia , lookup

Voltage optimisation wikipedia , lookup

Distribution management system wikipedia , lookup

Wireless power transfer wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Buck converter wikipedia , lookup

Alternating current wikipedia , lookup

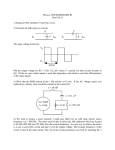

energies Article Development of a 60 kHz, 180 kW, Over 85% Efficiency Inductive Power Transfer System for a Tram Seung-Hwan Lee 1 , Jae-Hee Kim 2 and Jun-Ho Lee 2, * 1 2 * School of Electrical and Computer Engineering, University of Seoul, Seoul 02504, Korea; [email protected] Metropolitan Transportation Research Center, Korea Railroad Research Institute, Uiwang 16105, Korea; [email protected] Correspondence: [email protected]; Tel.: +82-31-460-5040 Academic Editor: Hongjian Sun Received: 7 October 2016; Accepted: 8 December 2016; Published: 16 December 2016 Abstract: Conventional contact-based train power transfer systems have high maintenance costs and safety issues and cause noise and additional aerodynamic drag. Instead of the conventional system, a loosely coupled online wireless power transfer (WPT) system for a train is proposed in this paper. The operating frequency of the proposed design is 60 kHz to ensure a low flux density and a high-efficiency system with a large air gap. In addition, a new transmitter track and pick-up geometry for 60 kHz operation are designed using finite element analysis (FEA). The proposed design is evaluated theoretically and experimentally. By using the simulated results, a new 180 kW, 15 m test-bed for a tram is constructed. The total power transfer efficiency is greater than 85% at the rated output power, and the loss distribution in the system is identified. Electromagnetic field (EMF) radiation and the voltage induction at the rail are measured for safety evaluation. The measured EMF satisfied international guidelines. Keywords: wireless power transfer (WPT); inductive power transfer; on-line electric vehicle (OLEV); coil design; hybrid train 1. Introduction Since the 1970s, most urban rail systems have been powered by overhead wires (or 3rd rails) and onboard pantographs. The overhead wire was a key enabling technology for electric trains. However, this conventional contact-based power supply system caused several issues: firstly, the mechanical wear of the overhead wires and pantographs required their periodical replacement, which results in high maintenance costs. Secondly, pantographs cause additional energy losses and noise problems because of their aerodynamic resistance (8% loss and they are the dominant noise source according to [1–3]). This is an important issue for high-speed trains because the aerodynamic losses are proportional to the square of the speed. Thirdly, the height of the overhead wire is an important limiting factor of the capacities of passenger and freight trains. In most of cargo ports, diesel-engine-powered trains that have a low efficiency and high air pollution are used because the height of the overhead wires is lower than the height of the freight containers and cranes. Lastly, overhead wires are dangerous to the general public because they carry high voltages (60 Hz, 25 kV) and currents without any sheaths. According to U.S. Federal Transit Administration, 48 people were killed or injured by touching overhead lines in 2000–2006 [4]. In this research, a loosely coupled wireless power transfer (WPT) system that is well-known to be suitable for a high-efficiency, high-power, large air-gap power transfer system is investigated as an alternative to conventional overhead wires for trains. A train powered by the WPT system has the following advantages: (1) no wear occurs, and regular maintenance is not required; (2) no energy loss Energies 2016, 9, 1075; doi:10.3390/en9121075 www.mdpi.com/journal/energies Energies 2016, 9, 1075 Energies 2016, 9, 1075 2 of 14 2 of 15 following advantages: (1) no wear occurs, and regular maintenance is not required; (2) no energy loss or noise noise caused caused by by the the pantographs pantographs exists; exists; (3) (3) no no capacity capacity limitations limitations caused caused by by the the overhead overhead wires wires or exist; and and (4) (4) no no high high voltage voltage wire wire is is exposed exposed to to the the general general public. public. exist; Many researchers have investigated WPT systems for trains [1,2,5–11]. [1,2,5–11]. Kawamura al. [1] [1] Many researchers have investigated WPT systems for trains Kawamura et et al. explored non-resonant and resonant WPT systems and proposed a new resonant WPT system with explored non-resonant and resonant WPT systems and proposed a new resonant WPT system with mm air-gap air-gap for for trains trains in. in. However, the efficiency efficiency of of the the proposed proposed WPT WPT system system was was less less than than 70% aa 22 mm However, the 70% at that small air gap, which is not suitable for MW level high-speed trains. Lee et al. proposed in 2012 at that small air gap, which is not suitable for MW level high-speed trains. Lee et al. proposed in transmitter and pick-up designs for a single-phase 20 kHz kW for a train Their 2012 transmitter and pick-up designs for a single-phase 20100 kHz 100WPT kW system WPT system for a[7]. train [7]. paper focused on reductions in the transmitter and pick-up sizes with a constant pick-up output Their paper focused on reductions in the transmitter and pick-up sizes with a constant pick-up output voltage. However, However, the the authors authors did did not not focus focus on on the the efficiency efficiency and and electromagnetic-field electromagnetic-field safety safety (EMF (EMF voltage. safety), although although those those factors factors are are the the key key metrics metrics for for the the evaluation WPT safety), evaluation of of high-power high-power large large air-gap air-gap WPT systems. Furthermore, the proposed system was not evaluated experimentally. In summary, the WPT systems. Furthermore, the proposed system was not evaluated experimentally. In summary, the WPT research for for trains trains began began in in the the 1980s, 1980s, but but an an efficient efficient high-power high-power large large air-gap air-gap system system that that could could research potentially replace replace the the conventional conventional overhead overhead wire wiresystem systemhas hasnot notbeen beendeveloped developedyet. yet. potentially In this paper, a new design for a single-phase 60 kHz, 180 kW online WPT system with aa 77 cm cm In this paper, a new design for a single-phase 60 kHz, 180 kW online WPT system with air-gap for In In contrast to the previous studies, the air-gap for aa tram tramisisproposed proposedand andevaluated evaluatedexperimentally. experimentally. contrast to the previous studies, operating frequency of the WPT system is increased to 60 kHz, which is three times higher than the the operating frequency of the WPT system is increased to 60 kHz, which is three times higher than the the 20 kHz system reported in in [12] the 20 kHz system reported [12]totoachieve achieveaahigh-efficiency high-efficiencyhigh-power high-powerWPT WPT system system with with aa compact size size transmitter transmitter and and pick-up. pick-up. Furthermore, Furthermore, the the Ohmic Ohmic losses losses caused caused by by the the high high operating operating compact frequency are considered in the system design to achieve a net efficiency greater than 85%. The frequency are considered in the system design to achieve a net efficiency greater than 85%. The designs designs of the 60 kHz transmitter track and pick-up are evaluated using a finite element analysis of the 60 kHz transmitter track and pick-up are evaluated using a finite element analysis (FEA) and (FEA) andcircuit equivalent circuit analysis. the FEAresults, and analytical a 15 m,track 200 and kW equivalent analysis. Using the FEA Using and analytical a 15 m, 200results, kW transmitter transmitter track and three 60 kW pick-ups are fabricated and mounted under the 180 kW tram. The three 60 kW pick-ups are fabricated and mounted under the 180 kW tram. The proposed system is proposed system is evaluated comparison of and the analytical, FEA, and experimental results. evaluated by comparison of thebyanalytical, FEA, experimental results. Power Transfer TransferSystem System 2. Development of the 180 kW Level Inductive Power 2.1. Configuration of the Target Target System System A block diagram frequency resonant diagram of the WPT system system for the tram is shown in Figure 1. A high frequency inverter which is installed on the wayside delivers 60 kHz sinusoidal current to the wayside delivers kHz sinusoidal current to the the series-tuned series-tuned transmitter. Then, the transmitter coil which is installed on the ground plane generates a magnetic field transmitter. Then, the transmitter coil which is installed on the ground plane generates a magnetic that with the pick-up coil. The pick-up which iswhich installed at the bottom the tram fieldcouples that couples with the pick-up coil. The pick-up is installed at theofbottom of transfers the tram voltage and current to the voltage regulator. Finally, the voltage regulator supplies a constant voltagea transfers voltage and current to the voltage regulator. Finally, the voltage regulator supplies to the tram battery air gap between and the pick-up is and 7 cm. Because constant voltage tocharger. the tramThe battery charger. Thethe airtransmitter gap between the transmitter the pick-upthe is air gapBecause between andthe thetransmitter pick-up is and verythe large, leakage inductances of theinductances transmitter 7 cm. thethe airtransmitter gap between pick-up is very large, leakage and the pick-up are very compared to their mutual inductance. Seriesinductance. or parallel resonance tuning of the transmitter and thebig pick-up are very big compared to their mutual Series or parallel of the transmitter pick-up coil are required achieve a high-efficiency systemlarge[13]. resonance tuning and of the transmitter and pick-uptocoil are required to achievelarge-power a high-efficiency A series-series (SS) tuned resonant topology is used in this research because its resonant frequency is power system [13]. A series-series (SS) tuned resonant topology is used in this research because its independent of the load variation and distance change [13]. the SS topology allows the for resonant frequency is independent of the load variation andFurthermore, distance change [13]. Furthermore, easy manipulation voltage stresses ofofthe and coils as itcapacitors will be demonstrated inwill the SS topology allowsof forthe easy manipulation thecapacitors voltage stresses of the and coils as it following section.in the following section. be demonstrated Figure 1. Overall configuration of the target tram system. Figure 1. Overall configuration of the target tram system. Energies 2016, 9, 1075 3 of 15 Energies 2016, 9, 1075 3 of 14 2.2. High-Frequency Transmitter and Pick-Up Design 2.2. High-Frequency Transmitter and Pick-Up Design 2.2.1. Design Considerations 2.2.1. Design Considerations In this study, design of the transmitter and pick-up was based on the 100 kW, 20 kHz WPT system In thiselectric study,vehicles design (OLEVs) of the transmitter and pick-up wasdesign, based on 100 kW, 20 kHz WPT1 for on-line in [7,12]. Using the baseline the the following factors in Table system for on-line electric vehicles (OLEVs) in [7,12]. Using the baseline design, the following factors have been considered in the design of the transmitter and pick-up coil geometries. In Korea, two in Table 1 have considered the design of the transmitter and60pick-up coilthis geometries. Korea, frequencies are been allowed for high in power WPT systems, 20 kHz and kHz. For research, In a 60 kHz two frequencies are allowed for high power WPT systems, 20 kHz and 60 kHz. For this research, a 60 operation has been selected unlike the 20 kHz systems found in the literature. As shown in Figure 2, kHz operation has been selected unlike the 20 kHz systems found in the literature. As shown in the induced voltage at the pick-up is proportional to the frequency (ω), mutual inductance (M), Figure the induced at the coil pick-up proportional to the frequency mutual inductance and the2,current of thevoltage transmitter (I1 ). isThe transmitter current or the(ω), mutual inductance of (M), and the current of the transmitter coil (I 1). The transmitter current or the mutual inductance of a a 60 kHz WPT system can be decreased to one third of those of a 20 kHz WPT system. Therefore, 60 kHz WPT system can be decreased to one third ofefficiency, those of asmaller 20 kHztransmitter WPT system. Therefore, the the 60 kHz operation is selected for high coil-to-coil and pick-up coil 60 kHz operation is selected for high coil-to-coil efficiency, smaller transmitter and pick-up coil sizes, sizes, and low magnetic field radiation. and low magnetic field radiation. Table 1. Wireless power transfer (WPT) system design requirements. Table 1. Wireless power transfer (WPT) system design requirements. Design Parameters Design Parameters Operating frequency Operating frequency Track length Track length Output voltage Output voltage Magnetic field radiation Magnetic field radiation Values Values 60 kHz 15 15 m m 750 DC 750 V VDC 6.25 µT 6.25 μT Design Parameters Design Parameters Air-gap Air-gap Output power Output power Coil-to-coil efficiency Coil-to-coil efficiency - - Values Values 7 cm7 cm 180 kW 180 kW OverOver 95% 95% - Figure 2. An equivalent circuit of a series-series tuned Wireless power transfer (WPT) system. Figure 2. An equivalent circuit of a series-series tuned Wireless power transfer (WPT) system. 2.2.2. Transmitter Design 2.2.2. Transmitter Design In the first step of the system design, a geometry of the transmitter coil has been determined. In the first step of the system design, a geometry of the transmitter coil has been determined. The number of turns and the width of the transmitter was determined considering the radiated The number of turns and the width of the transmitter was determined considering the radiated magnetic flux density to the air. According to IEC 62110 and International Commission on Nonmagnetic flux density to the air. According to IEC 62110 and International Commission on Non-Ionizing Ionizing Radiation Protection (ICNIRP) guideline [14,15], the radiated flux density should be smaller Radiation Protection (ICNIRP) guideline [14,15], the radiated flux density should be smaller than than 6.25 μT at three measurement positions placed horizontally 20 cm away from the outer surface 6.25 µT at three measurement positions placed horizontally 20 cm away from the outer surface of the of the tram and 50, 100 and 150 cm away from the ground. The tram was 2.6 m wide and the distance tram and 50, 100 and 150 cm away from the ground. The tram was 2.6 m wide and the distance of of outer surface of the tram from its center was 1.3 m. Therefore, the measurement positions are 1.5 outer surface of the tram from its center was 1.3 m. Therefore, the measurement positions are 1.5 m m away from the center of the tram and 50, 100 and 150 cm away from the ground. Since the radiated away from the center of the tram and 50, 100 and 150 cm away from the ground. Since the radiated flux density decreases as the distance increases, the flux density at the height of 50 cm is most flux density decreases as the distance increases, the flux density at the height of 50 cm is most intensive intensive in all three positions. Therefore, the IEC standard can be satisfied if the flux density at the in all three positions. Therefore, the IEC standard can be satisfied if the flux density at the height height of 50 cm is satisfied and this is the critical point in terms of the EMF safety. of 50 cm is satisfied and this is the critical point in terms of the EMF safety. Radiated magnetic flux density from the transmitter coil to the air can be calculated using Figure Radiated magnetic flux density from the transmitter coil to the air can be calculated using Figure 3 3 and Equation (1): and Equation (1): N µ0μI1,rms µ0μI1,rms , , B== − (1) ∑ 2πr2πi1 − 2πr 2πi2 i =1 where, where, N N is is the the number numberof ofturns turnsof ofthe thecoil, coil,I1,rms I1,rms is is the the rated rated current current of ofthe thetransmitter transmittercoil, coil,ri1 ri1 and andrri2i2 are the distance from a i-th turn of the transmitter coil to the observation point. are the distance from a i-th turn of the transmitter coil to the observation point. It should be noted that the magnetic flux density in the air is proportional to the product of the current and the number of turns (Ampere-turn), therefore, the radiated magnetic flux density at the measurement point is the same if the Ampere-turns are the same. As shown in [7,12,16], Amp-turn of the transmitter track for OLEV buses was 240 (240 Arms, 1-turn) to induce 500 Vrms at 20 kHz, 25 cm with multiple E-shaped ferrite cores that were placed under the coil (see the 3D model of the transmitter in Figure 4a). The E-shaped cores of the transmitter were helpful in augmenting the flux linkage between the transmitter and the pick-up. Unlike the design in [16,17], the number of turns of the transmitter coil is increased to four and the rated current of the winding is decreased significantly which 2016, is helpful Energies 9, 1075 in improving the coil-to-coil efficiency. The self-inductance of the simulated 4 of 15 transmitter winding was 576 μH and required capacitance for 60 kHz tuning was 12.2 nF. Energies 2016, 9, 1075 4 of 14 air-gap. In this research, Amp-turn of the new transmitter track was the same as the previous design, but the track width and the number of turns were changed. Using (1), the radiated magnetic flux density at the critical point of a 240 Amp-turn coil reached the 6.25 μT when the width of the coil is 48 cm. Therefore, the width of the track was 48 cm. Rated current of the track was determined regarding the availability of a 60 kHz operating Litz-wire. A 25 mm2 Litz-wire (60 μm/strand, 9000 strands, ampacity of 75 Arms) which was readily available in the laboratory was selected as a Figure 3. 3. Reference Reference geometry for for the the calculation calculation of of the the radiated radiated magnetic magnetic flux flux density. Figure transmitter winding. Therefore,geometry selected current rating of the transmitter was 60 Armsdensity. and the number of turns was four. In summary, the proposed transmitter was a four-turn, 15 m (L) × 0.48 m (W) coil It shouldE-shaped be noted that thecores magnetic the airthe is proportional themodel product the with multiple ferrite that flux weredensity placedinunder coil (see theto3D ofofthe current and the number of turns (Ampere-turn), therefore, the radiated magnetic flux density at the transmitter in Figure 4a). The E-shaped cores of the transmitter were helpful in augmenting the flux measurement is the sameand if the Ampere-turns are the design same. As shown in linkage betweenpoint the transmitter the pick-up. Unlike in [16,17], the[7,12,16], numberAmp-turn of turns ofof thetransmitter transmitter track for OLEVtobuses wasthe 240rated (240 current Arms , 1-turn) induceis500 Vrms at 20 kHz, 25 cm the coil is increased four and of the to winding decreased significantly air-gap. In this research, Amp-turn of the new transmitter track was the same as the previous design, which is helpful in improving the coil-to-coil efficiency. The self-inductance of the simulated but the track widthwas and576 theμH number of turnscapacitance were changed. (1), thewas radiated magnetic flux transmitter winding and required for 60Using kHz tuning 12.2 nF. (a) (b) density at the critical point of a 240 Amp-turn coil reached the 6.25 µT when the width of the coil is 48 cm.Figure Therefore, the width of the track wasits48 cm. Rated current of thesuppression: track was determined regarding 4. Designed transmitter coil and tuning method for voltage (a) a schematic of 2 the availability a 60 transmitter kHz operating A 25 mm method Litz-wire (60transmitter µm/strand, the designedof4-turn track;Litz-wire. (b) distributed tuning of the coil. 9000 strands, ampacity of 75 Arms ) which was readily available in the laboratory was selected as a transmitter It should be noted thatcurrent the radiated magnetic flux density notthedependent the winding. Therefore, selected rating of the transmitter was 60inA(1) and number ofon turns rms is operating frequency. That is, the magnetic flux density distributions of the 60 kHz and 20 kHz was four. In summary, the proposed transmitter was a four-turn, 15 m (L) × 0.48 m (W) coil with systems are the same if the number of turns andunder the current thethe coils the same. However, the multiple E-shaped ferrite cores that were placed the coilof (see 3Dare model of the transmitter in transmitter coil of a 60 kHz system has three times higher voltage than a 20 kHz system because of Figure 4a). The E-shaped cores of the transmitter were helpful in augmenting the flux linkage between the transmitter bigger reactance (ωL). This high voltage of the coil increases the length of theoftransmitter track the and the pick-up. Unlike the design in [16,17], theasnumber of turns the transmitter increases and handling the the highrated voltage stress one of the big challenges in implementing the oncoil is increased to four and current of was the winding is decreased significantly which is helpful line WPT system. Because the coil inductance was 576 μH, of thethe voltage applied at the end-terminal of in improving the coil-to-coil efficiency. The self-inductance simulated transmitter winding was the µH coil and wasrequired 13 kVrms capacitance which overwhelms the tuning insulation of commercial wires and capacitors. In 576 for 60 kHz waslevels 12.2 nF. Figure 3. Reference geometry for the calculation of the radiated magnetic flux density. this paper, a new transmitter coil winding method was proposed in order to reduce the voltage stress of the coil as shown in Figure 4b. Instead of connecting the tuning capacitors (12.2 nF) at the endterminals of the coil, three 47 nF capacitor-banks (series-connected seven 0.33 μF, 150 kVAR film capacitors) were connected at the end-terminals of inner three-turns and two 110 nF capacitor-banks (series-connected three 0.33 μF, 150 kVAR film capacitors) were connected at the end of the last turn. As mentioned earlier, this SS topology was good at reducing the voltage stresses of the coils and capacitors by distributing the capacitors. Using this distributed capacitor method, voltages across (a) (b) Figure 4. Designed transmitter coil and its tuning method for voltage suppression: (a) a schematic of Figure 4. Designed transmitter coil and its tuning method for voltage suppression: (a) a schematic of the designed 4-turn transmitter track; (b) distributed tuning method of the transmitter coil. the designed 4-turn transmitter track; (b) distributed tuning method of the transmitter coil. It should be noted that the radiated magnetic flux density in (1) is not dependent on the It should be noted thatis,the radiated magnetic flux density in (1) is not onand the operating operating frequency. That the magnetic flux density distributions of dependent the 60 kHz 20 kHz frequency. That is, the magnetic flux density distributions of the 60 kHz and 20 kHz systems are systems are the same if the number of turns and the current of the coils are the same. However, the the same ifcoil theofnumber of turns and current the coils are the same. thebecause transmitter transmitter a 60 kHz system hasthe three timesofhigher voltage than a 20However, kHz system of coil of a 60 kHz system has three times higher voltage than a 20 kHz system because of the track bigger the bigger reactance (ωL). This high voltage of the coil increases as the length of the transmitter reactance (ωL). This high voltage of thestress coil increases asthe thebig length of the transmitter track increases increases and handling the high voltage was one of challenges in implementing the onand handling the high voltage stress was one of the big challenges in implementing the on-line WPT line WPT system. Because the coil inductance was 576 μH, the voltage applied at the end-terminal of system. Because the coil inductance was 576 µH, the voltage applied at the end-terminal of the coil the coil was 13 kVrms which overwhelms the insulation levels of commercial wires and capacitors. In this paper, a new transmitter coil winding method was proposed in order to reduce the voltage stress of the coil as shown in Figure 4b. Instead of connecting the tuning capacitors (12.2 nF) at the endterminals of the coil, three 47 nF capacitor-banks (series-connected seven 0.33 μF, 150 kVAR film capacitors) were connected at the end-terminals of inner three-turns and two 110 nF capacitor-banks (series-connected three 0.33 μF, 150 kVAR film capacitors) were connected at the end of the last turn. Energies 2016, 9, 1075 5 of 15 was 13 kVrms which overwhelms the insulation levels of commercial wires and capacitors. In this paper, a new transmitter coil winding method was proposed in order to reduce the voltage stress of the coil as shown in Figure 4b. Instead of connecting the tuning capacitors (12.2 nF) at the end-terminals of the coil, three 47 nF capacitor-banks (series-connected seven 0.33 µF, 150 kVAR film capacitors) were connected at the end-terminals of inner three-turns and two 110 nF capacitor-banks (series-connected three 0.33 µF, 150 kVAR film capacitors) were connected at the end of the last turn. As mentioned earlier, this SS topology was good at reducing the voltage stresses of the coils and capacitors by distributing the capacitors. Using this distributed capacitor method, voltages across every turn of the transmitter coil reduced to 3 kVrms without disturbing its magnetic field distribution at the track. Photos of the transmitter track and the capacitors will be shown in a subsequent section. 2.2.3. Pick-Up Design In the following step, the geometry of the pick-up was determined. The key factor in designing the pick-up was the required induced voltage at the pick-up with the selected transmitter coil. A required mutual inductance value to obtain 750 VDC at the output of the pick-up has been calculated using Equation (2): Vout,DC 4 M= √ (2) × π 2I1,rms × ω where, Vout,DC = 750 VDC is the rectified output voltage of pick-up, ω is the angular operating frequency, √ 2 and 4/π are scale factors for getting root mean square (rms) values from peak values. Using (2), the required mutual inductance for 750 VDC output was 30 µH. It should be noted that the required mutual inductance is 90 µH if the operating frequency is 20 kHz. That is, a 20 kHz system needs a pick-up that has larger number of turns and larger size core to achieve this three times larger mutual inductance. The width, length and the number of channels of the pick-up were the same as the design in the literature (920 mm (W) by 600 mm (L), 4 channel) [7,12] in order to utilize readily available ferrite cores. In order to fully utilize the circulating magnetic flux, the one-winding layer at the center was connected in series with another one winding layer on the left or right wing side. This series-connection of two layers of the center and left or right side windings was called a “channel” and there were in total four channels in a pick-up and the four channels were connected in parallel so as to achieve the target output power (Figure 5a,b). In this research, the number of turns and corresponding height of the pick-up was changed using FEA simulations that result in the required mutual inductance. Using ANSYS MAXWELL, the mutual inductance has been calculated as the number of turns of the layers increase from 1-turn × 2 layers on the left wing, 1-turn × 4 layers on the center, 1-turn × 2 layers on the right wing. The mutual inductance reached 30.3 µH when the number of turns of the pick-up was 4-turns × 2 layers on the left wing, 4-turns × 4 layers on the center, 4-turns × 2 layers on the right wing. As demonstrated in [12], the number of turns of the OLEV was 28/64/28 turns which is equivalent to 7-turns × 4 layers on the right side, 8-turns × 8 layers on the center, 7-turns × 4 layers on the left side. However, the 60 kHz system has 8 (4-turns × 2 layers)/16 (4-turns × 4 layers)/8 (4-turns × 2 layers) turns. The final size of the selected pick-up design was 60 cm (L) × 92 cm (W) × 5.1 cm (H) for 60 kW output. Figure 6 compares the height and number of turns of the designed pick-up to 20 kHz pick-up in the literature. It should be noted that the number of turns and height of the new pick-up are much smaller than in the 20 kHz system design. Tuning capacitors were connected in between the windings at center and side windings so as to reduce the voltage stresses at the windings. Net self-inductance of the pick-up at its output terminal was L2 = 71.3 µH and the required tuning capacitance was C2 = 98.7 nF. The geometric parameters of the transmitter and pick-up are summarized in Table 2. Also, simulated self- and mutual inductances of the designed system are summarized in Table 3. It should be noted that the mutual inductance was very small compared to the self-inductances of the transmitter and pick-up (coupling coefficient k = 0.15) that shows the loose coupling between the coils [13]. turns which is equivalent to 7-turns × 4 layers on the right side, 8-turns × 8 layers on the center, 7turns × 4 layers on the left side. However, the 60 kHz system has 8 (4-turns × 2 layers)/16 (4-turns × 4 layers)/8 (4-turns × 2 layers) turns. The final size of the selected pick-up design was 60 cm (L) × 92 cm (W) × 5.1 cm (H) for 60 kW output. Figure 6 compares the height and number of turns of the designed pick-up to2016, 20 kHz height of Energies 9, 1075pick-up in the literature. It should be noted that the number of turns and6 of 15 the new pick-up are much smaller than in the 20 kHz system design. (a) (b) Figure 5. Designed receiver windingand andtuning tuning method augmentation Figure 5. Designed receivercoil coiland and its its winding method for for fluxflux augmentation and and voltage suppression: the designed receiver coil;distributed (b) distributed tuning of method of voltage suppression:(a) (a)aa schematic schematic ofofthe designed receiver coil; (b) tuning method the receiver coil. the receiver coil. Energies 2016, 9, 1075 6 of 14 (a) (b) Figure 6. Comparison of the new andand thethe previous pick-up for 60 60 kHz kHz Figure 6. Comparison of the new previous pick-updesign: design:(a) (a)new newpick-up pick-up design design for operation; (b) previous pick-up design forfor 2020 kHz operation; (b) previous pick-up design kHzoperation. operation. Tuning capacitors were connected in between the windings at center and side windings so as to Table 2.atSummary of the designed transmitter andof pick-up geometries. reduce the voltage stresses the windings. Net self-inductance the pick-up at its output terminal was L2 = 71.3 μH and the required tuning capacitance was C2 = 98.7 nF. The geometric parameters of Geometric Transmitter Pick-Up the transmitter and pick-up parameters are summarized in Table 2. Also, simulated selfand mutual inductances (mm) 15,000 of the designed systemLength are summarized in Table 3. It should be noted that the600 mutual inductance was Width (mm) 480 920 very small compared to the self-inductances of the transmitter and pick-up (coupling coefficient k = Height (mm) 50 51 0.15) that shows Number the loose between the coils4[13]. of coupling turns per layer 4 Number of layers 1 8 Number of modules 1 3 Table 2. Summary of the designed transmitter and pick-up geometries. Geometric parameters Transmitter Length (mm) 15,000 Width (mm) 480 Transmitter Circuit Parameters Height (mm) 50 Simulated Measured Number of turns per layer 4 Self-inductance (µH)of layers 576 Number 1557 Mutual-inductance Number(µH) of modules 30.3 133.3 Pick-Up 600 920 Pick-Up 51 Simulated Measured 4 71.3 8 79 3 Table 3. Simulated and measured circuit parameters of the transmitter and the pick-up. Tuning capacitor (nF) 12.7 13.7 96.4 87.2 Equivalent series 0.75 1.2 0.1 0.24 Table 3. Simulated resistance (Ω) and measured circuit parameters of the transmitter and the pick-up. Tuned frequency (kHz) 58.8 57.5 60.1 60.5 Circuit Parameters Self-inductance (μH) Mutual-inductance (μH) Tuning capacitor (nF) Equivalent series resistance (Ω) Tuned frequency (kHz) Transmitter Simulated Measured 576 557 30.3 33.3 12.7 13.7 0.75 1.2 58.8 57.5 Pick-Up Simulated Measured 71.3 79 96.4 87.2 0.1 0.24 60.1 60.5 Control stability of the designed system has been checked using the calculated parameters of the Energies 2016, 9, 1075 7 of 15 Control stability of the designed system has been checked using the calculated parameters of the system. According to [13,18], the control stability of a series-tuned WPT system is dependent on the coupling coefficient and impedance of the pick-up coil. If the system has unwanted multiple resonant frequencies or bifurcation phenomena, the power supply inverter cannot be operated at the tuned frequency which results in a degradation of the power transfer efficiency and power level. In order to avoid the bifurcation, the following condition needs to be met: R L > kωL2 (3) where RL is the equivalent resistance of the load, k is the coupling coefficient, ω is the angular operating frequency, and L2 is the self-inductance of the pick-up. Since the equivalent load resistance RL decreases as the load power increases and the output voltage is constant, the load resistance at the rated operation should be considered for the stability check. As the coupling coefficient of the designed system was 0.15 and ωL2 was 27 Ω, kωL2 was 4 Ω. The lowest resistance value of the designed system is 8.5 Ω when the load power is 60 kW at 750 VDC . Therefore, the designed system does not have any additional resonant frequencies. Rated output of the designed pick-up was 60 kW and three pick-ups were connected in parallel to achieve a 180 kW transfer as shown Energies 2016, 9, 1075 in Figure 7a. 7 of 14 (a) (b) (c) Figure 7. 7. Finite Finite element element analysis analysis (FEA) (FEA) model model and and simulated simulated magnetic magnetic flux flux density density distribution distribution at at its its Figure rated operation: (a) a top view of the designed WPT system; (b) a cross-sectional view; (c) magnetic rated operation: (a) a top view of the designed WPT system; (b) a cross-sectional view; and (c) magnetic flux density density distribution distributionat at180 180kW kWtransfer. transfer. flux 2.2.4. Design Evaluation Using Finite Element Analysis (FEA) 2.2.4. Design Evaluation Using Finite Element Analysis (FEA) Using FEA simulations (ANSYS MAXWELL, Release 17.2, ANSYS Inc., Canonsburg, PA, USA), Using FEA simulations (ANSYS MAXWELL, Release 17.2, ANSYS Inc., Canonsburg, PA, USA), it has been demonstrated that the coil-to-coil power transfer efficiency is greater than 95% at the tuned it has been demonstrated that the coil-to-coil power transfer efficiency is greater than 95% at the tuned frequency and the radiated magnetic field at the observation point was less than 6 μT at for 60 kHz frequency and the radiated magnetic field at the observation point was less than 6 µT at for 60 kHz 180 kW transfer power. Simulated magnetic flux density distribution is shown in Figure 7c and the 180 kW transfer power. Simulated magnetic flux density distribution is shown in Figure 7c and the simulated efficiency dependences of the system on the load and operating frequency are shown in simulated efficiency dependences of the system on the load and operating frequency are shown in Figure 8b,c (red “×”). Figure 8b,c (red “×”). (a) (b) Using FEA simulations (ANSYS MAXWELL, Release 17.2, ANSYS Inc., Canonsburg, PA, USA), it has been demonstrated that the coil-to-coil power transfer efficiency is greater than 95% at the tuned frequency and the radiated magnetic field at the observation point was less than 6 μT at for 60 kHz 180 kW transfer power. Simulated magnetic flux density distribution is shown in Figure 7c and the simulated dependences of the system on the load and operating frequency are shown Energies 2016,efficiency 9, 1075 8 of in 15 Figure 8b,c (red “×”). (a) (b) (c) Figure 8. Equivalent coil-to-coil model and its theoretical and FEA simulated coil-to-coil efficiencies: Figure 8. Equivalent coil-to-coil model and its theoretical and FEA simulated coil-to-coil efficiencies: (a) equivalent circuit model; (b) efficiency vs. load; (c) efficiency vs. operating frequency. (a) equivalent circuit model; (b) efficiency vs. load; and (c) efficiency vs. operating frequency. 2.3. Theoretical Evaluation of the Designed System Using Table 3, the power transfer efficiency, resonant voltage, and current waveform have been calculated with circuit simulation software. It should be noted that the lumped-parameter circuit model is valid if the wavelength of the electromagnetic field (EMF) is more than ten times larger than the characteristic lengths of the system [13]. The largest length of the designed system was the transmitter track length (15 m), and the wavelength was 5 km. Therefore, the proposed design can be analyzed with the lumped-parameter circuit modeling technique. According to [13], coil-to-coil efficiency of a SS system follows (4): 1 ηss = 1+ R2 NR L + R L + R2 ωM 2 · R1 RL (4) where R1 and R2 are the series resistances of the transmitter and pick-up, respectively; N is the number of pick-ups; RL is the load resistance; M is the mutual inductance between the transmitter and the pick-up; ω is the angular frequency, respectively. Figure 8a shows the equivalent circuit model of the SS WPT system. Figure 8b,c compares the calculated coil-to-coil efficiency using Equation (4) and the results of FEA depending on the load and operating frequency change. The x-axis of Figure 8b is the percent of the load compared to its rated output power. It should be noted that the theoretical coil-to-coil efficiency matches very well with the FEA results and the maximum coil-to-coil efficiency was over 95% at the rated operation. However, the efficiency degraded as the load reduces and the efficiency decreased to 71% when the load is 5% of its rated value. Mistuning of the operating frequency also affected the efficiency. The coil-to-coil efficiency decreased to 65% (or 91%) when the operating frequency is 40 kHz (or 80 kHz). The WPT system was not sensitive to the operating frequency if the operating frequency output power. It should be noted that the theoretical coil-to-coil efficiency matches very well with the FEA results and the maximum coil-to-coil efficiency was over 95% at the rated operation. However, the efficiency degraded as the load reduces and the efficiency decreased to 71% when the load is 5% of its rated value. Mistuning of the operating frequency also affected the efficiency. The Energies 2016, 9, 1075 9 of 15 coil-to-coil efficiency decreased to 65% (or 91%) when the operating frequency is 40 kHz (or 80 kHz). The WPT system was not sensitive to the operating frequency if the operating frequency is over the tuned frequency, however, the efficiency decreased very fast as the operating frequency was lower is over the tuned frequency, however, the efficiency decreased very fast as the operating frequency was than the tuned frequency. lower than the tuned frequency. 3. Experimental Experimental Evaluation Evaluation 3. 3.1. Experimental Experimental Setup Setup 3.1. For the the experimental experimentalevaluation, evaluation,aatram tramwhich whichisispowered poweredby byaaconstant constant800 800VVDC DC voltage voltage source source For from an an overhead overhead wire wirewas was changed changedto to get get power power from fromthe theWPT WPTsystems. systems. Figure Figure 99 shows shows the the overall overall from configuration of the developed are shown in configuration developed WPT WPT system systemand andphotographs photographsofofthe thedeveloped developedsystem system are shown Figure 10.10.The target , ,110 the in Figure The targettram tramequipped equippedan an800 800 VVDC 110AADC (88kW) kW) Li-ion Li-ion battery battery pack, and the DC DC(88 proposed 180 kW asas a fast charger for for the the battery. A 200AkW fixedproposed kW WPT WPTsystem systemwas wasused used a fast charger battery. 200full-bridge kW full-bridge frequency resonant pulse pulse amplitude modulation (PAM)(PAM) inverter has been as the as power fixed-frequency resonant amplitude modulation inverter hasdeveloped been developed the supply.supply. power Figure Figure 9. 9. Equivalent Equivalent block block diagram diagram of of the the developed developed test-bed. test-bed. The developed PAM inverter changed its peak output voltage depending on the output current level, but its duty ratio and operating frequency were fixed. In order to control the amplitude of DC link voltage of the inverter, a four-leg interleaved step-down converter was used. A constant 800 VDC voltage source for the overhead wire was used as the converter’s input power, and the converter controlled its output voltage for the PAM inverter. At the output terminal of the PAM inverter, a 1-to-5 transformer was used for impedance matching. The input impedance of the designed WPT system was 50 Ω at 60 kHz and the rated input voltage and current of the designed transmitter was 3000 Vrms , 60 Arms . Since the peak DC input voltage from the grid was 800 V, the transfer ratio was set to 1-to-5. Photographs of the PAM inverter and DC-DC converter are shown in Figure 10d,e. A series-tuned 0.48m (W) × 15 m (L) four-turn transmitter track was installed inside of a rail. As mentioned in the previous section, a 60 µm (strand diameter) 9000-strand Litz-wire was used for the transmitter winding. This 60 µm Litz-wire was very good against the skin-effect loss at 60 kHz because the diameter of the strands were very small compared to the skin-depth of the copper at that frequency (250 µm at 60 kHz). The E-shaped ferrite cores were made of a high-frequency high-permeability ferrite material, PL-13. Measured self-inductance of the transmitter coil was 557 µH and the measured capacitance was 13.7 nF as shown in Table 3. Photographs of the transmitter and capacitors are shown in Figure 10a–c. At the bottom of the tram, three 60 kW pick-ups and a voltage regulator were installed and delivered power to the battery. The air-gap between the transmitter and the pick-up was 7 cm. The output terminals of the pick-ups were connected to diode rectifiers, and a boost regulator was used to supply a constant output voltage 800 VDC . An 80 µm, 2250-strand Litz-wire was used for the coil, and ferrite cores were used to build the M-shape pick-up core, as shown in Figure 5a. A 220 nF capacitor array (20 in series × 8 in parallel) was connected in series with the pick-up coil for tuning and Energies 2016, 9, 1075 10 of 15 its measured capacitance was 87.2 nF. Photographs of the one of pick-ups and capacitors are shown in Figure 10f,g. As shown in Figure 10h, three 60 kW pick-ups were connected in parallel to transfer 180 kW to the tram. Measured circuit parameters of the transmitter and pick-up are summarized in Table 3. It should be noted that the measured circuit parameters agreed very well with the simulated results. A boost regulator has been used to supply constant voltage to the tram. Unlike the wireless voltage control system in [17], the current controller of the wayside inverter and the voltage controller of the boost regulator operated independently. The twelve output channels of the three pick-ups were connected to the twelve legs of the boost regulator as shown in Figure 11. The regulator interleaved the twelve legs to mitigate the voltage and current ripple at the output. A photograph of the fabricated voltage regulator is shown in Figure 10i. Energies 2016, 9, 1075 9 of 14 (a) (b) (h) (c) (d) (e) (f) (g) (i) (j) Figure 10. Photographs of the developed test-bed: (a) transmitter; (b) transmitter tuning capacitor Figure 10. Photographs of the developed test-bed: (a) transmitter; (b) transmitter tuning capacitor bank; bank; (c) transmitter tuning capacitor; (d) the PAM inverter; (e) interleaved DC-DC converter; (f) pick(c) transmitter tuning capacitor; (d) the PAM inverter; (e) interleaved DC-DC converter; (f) pick-up up winding; (g) pick-up tuning capacitors; (h) installed three pick-ups; (i) pick-up output voltage winding; (g) pick-up tuning capacitors; (h) installed three pick-ups; (i) pick-up output voltage regulator; regulator; and (j) target tram. and (j) target tram. The developed PAM inverter changed its peak output voltage depending on the output current level, but its duty ratio and operating frequency were fixed. In order to control the amplitude of DC link voltage of the inverter, a four-leg interleaved step-down converter was used. A constant 800 VDC voltage source for the overhead wire was used as the converter’s input power, and the converter controlled its output voltage for the PAM inverter. At the output terminal of the PAM inverter, a 1to-5 transformer was used for impedance matching. The input impedance of the designed WPT with the simulated results. A boost regulator has been used to supply constant voltage to the tram. Unlike the wireless voltage control system in [17], the current controller of the wayside inverter and the voltage controller of the boost regulator operated independently. The twelve output channels of the three pick-ups were connected to the twelve legs of the boost regulator as shown in Figure 11. The regulator interleaved the twelve legs to mitigate the voltage and current ripple at the output. Energies 2016, 9, 1075 11 of A 15 photograph of the fabricated voltage regulator is shown in Figure 10i. Figure 11. Block diagram of the boost regulator and its connection. Figure 11. Block diagram of the boost regulator and its connection. 3.2. Experimental Results 3.2. Experimental Results 3.2.1. 3.2.1. Efficiency Efficiency Measurement Measurement The power The power transfer transfer efficiency efficiency of of the the test-bed test-bed has has been been measured measured using using aa power power analyzer. analyzer. Dependencies of the power transfer efficiency on the operating frequency and load change Dependencies of the power transfer efficiency on the operating frequency and load change were were measured and are shown in Figure 12a,b. Measured total efficiency of the system was 85% at 60 kHz and 172 kW output whereas the simulated efficiency was 90%. The power transfer efficiency decreased to 78% when the load was 30% of the rated output. In addition, the efficiency decreased to 83% when the operating frequency was 65 kHz, while the test-bed was tuned at 60 kHz. The efficiency degradation due to the mistuning of the operating frequency was not very critical when the operating frequency is close to the tuned frequency. The discrepancy between the simulation and measured results originated from the DC-DC converter and output-voltage regulator, which were not included in the simulation. Efficiencies of the individual components were shown in Figure 12c at the rated operation to evaluate the system performance. It should be noted that all the components exhibited over 95% and the resonant inverter had over 98% efficiency because of the zero voltage switching (ZVS) control. The voltage regulator had the lowest efficiency compared to other components. The coil-to-coil efficiency was 95%, as expected in Section 2.3. Although the individual efficiency of the power generator (including the input DC-DC converter, PAM inverter, and transformer) was greater than 97%, the total efficiency of the resonant inverter was 93%, which was lower than the coil-to-coil efficiency. Figure 12d shows the measured loss distribution in the system. The dominant losses originated from the input DC-DC converter, transformer, transmitter, and output-voltage regulator; therefore, the losses in these components should be reduced to achieve over 90% net efficiency. A circuit simulation has been carried out with the parameters in Table 3 using LTspice to evaluate the measured results. The simulation model is shown in Figure 13a. The input DC-DC converter and output-voltage regulator were not included in the simulation model. and 172 kW output whereas the simulated efficiency was 90%. The power transfer efficiency decreased to 78% when the load was 30% of the rated output. In addition, the efficiency decreased to 83% when the operating frequency was 65 kHz, while the test-bed was tuned at 60 kHz. The efficiency degradation due to the mistuning of the operating frequency was not very critical when the operating frequency is close to the tuned frequency. The discrepancy between the simulation and measured results from the DC-DC converter and output-voltage regulator, which were not included Energies 2016, 9,originated 1075 12 of 15 in the simulation. Efficiencies of the individual components were shown in Figure 12c at the rated operation to evaluate the voltage system performance. be noted that all the components exhibited over and and The output and currentItofshould the full-bridge inverter were calculated using the95% model the resonant inverter had over 98% efficiency because of the voltage switching (ZVS) control. compared to the measured results, as shown in Figure 13b,c. It zero should be noted that the output current The voltage regulator had the lowest efficiency compared to other components. The coil-to-coil lags the voltage because the operating frequency (60 kHz) was slightly higher than the tuned frequency was 95%, as expected in Section 2.3. Although the individual efficiency of the power of theefficiency transmitter (58 kHz) for the implementation of ZVS. Since the resonant inverter of this research generator (including the input DC-DC converter, PAM inverter, and transformer) was greater than was a PAM type, the ZVS operation is guaranteed in every load power if the system operates in ZVS 97%, the total efficiency of the resonant inverter was 93%, which was lower than the coil-to-coil modeefficiency. at its rated output power. Therefore, the ZVS operation was checked at 172 kW transfer as Figure 12d shows the measured loss distribution in the system. The dominant losses shown in Figure 13. Simulated output voltage and current matched very well with the measured originated from the input DC-DC converter, transformer, transmitter, and output-voltage regulator; output voltagethe of the PAM inverter. therefore, losses in these components should be reduced to achieve over 90% net efficiency. (a) (b) (c) (d) Figure 12. Measured efficiency and loss of the test-bed: (a) total efficiency vs. load; (b) total efficiency Figure 12. Measured efficiency and loss of the test-bed: (a) total efficiency vs. load; (b) total efficiency vs. operating frequency; (c) measured efficiencies of the components; and (d) measured losses of the vs. operating frequency; developed system. (c) measured efficiencies of the components; and (d) measured losses of the developed system. A circuit simulation has been carried out with the parameters in Table 3 using LTspice to Energies 2016, 9, 1075 12 of 14 evaluate the measured results. The simulation model is shown in Figure 13a. The input DC-DC converter and output-voltage regulator were not included in the simulation model. (a) Figure 13. Cont. Energies 2016, 9, 1075 13 of 15 (a) (b) (c) Figure13. 13.Simulated Simulatedand andmeasured measuredinverter inverteroutput outputvoltage voltageand andcurrent currentwaveforms: waveforms:(a) (a)Circuit Circuit Figure simulation model; (b) Simulated results at 180 kW transfer; and (c) Measured results at 172 kW simulation model; (b) Simulated results at 180 kW transfer; and (c) Measured results at 172 kW transfer. transfer. 3.2.2. Electromagnetic-Field Safety The output voltage and current of the full-bridge inverter were calculated using the model and According to ICNIRP guidelines [15], the recommended maximum is compared to the measured results, as shown in Figure 13b,c. It shouldmagnetic be notedfield that density the output 6.25 µT (rms) when the operating frequency is from 3 kHz to 150 kHz. In order to evaluate the EMF current lags the voltage because the operating frequency (60 kHz) was slightly higher than the tuned safety of theofdesigned high-frequency high-power WPT system, the magnetic near inverter the WPTof frequency the transmitter (58 kHz) for the implementation of ZVS. Since thefield resonant system has been measured following the measurement procedure in guidelines in IEC 62110 [14] and this research was a PAM type, the ZVS operation is guaranteed every load power if the system plotted in Figure Mean of the measured magnetic flux density at the three positions was 4.1 operates in ZVS 14. mode at its rated output power. Therefore, the ZVS operation was checked at µT 172 which is lowerasthan the in ICNIRP guidelines. kW transfer shown Figure 13. Simulated output voltage and current matched very well with the Energies 2016, 9, 1075 13 of 14 measured output voltage of the PAM inverter. 3.2.2. Electromagnetic-Field Safety According to ICNIRP guidelines [15], the recommended maximum magnetic field density is 6.25 μT (rms) when the operating frequency is from 3 kHz to 150 kHz. In order to evaluate the EMF safety of the designed high-frequency high-power WPT system, the magnetic field near the WPT system has been measured following the measurement procedure guidelines in IEC 62110 [14] and plotted in Figure 14. Mean of the measured magnetic flux density at the three positions was 4.1 μT which is lower than the ICNIRP guidelines. (a) (b) Figure 14. Magnetic field radiation measurement positions and measured results: (a) measurement Figure 14. Magnetic field radiation measurement positions and measured results: (a) measurement positions; (b) measured magnetic flux density. positions; (b) measured magnetic flux density. 4. Conclusions 4. Conclusions Overhead lines have been used for decades as power supplies for electric trains; however, Overhead lines have been used for decades as power supplies for electric trains; however, overhead lines have high maintenance costs and safety issues, and cause noise and aerodynamic overhead lines have high maintenance costs and safety issues, and cause noise and aerodynamic drag. drag. Therefore, it is desirable to develop a new non-contact-based high-power high-efficiency Therefore, it is desirable to develop a new non-contact-based high-power high-efficiency power-supply power-supply system that is safe and economical. In this research, a new loosely coupled 180 kW system that is safe and economical. In this research, a new loosely coupled 180 kW online WPT system online WPT system for a train with a 7 cm air gap and a total efficiency greater than 85% was for a train with a 7 cm air gap and a total efficiency greater than 85% was proposed. The operating proposed. The operating frequency of the WPT system was 60 kHz, which was three times higher frequency of the WPT system was 60 kHz, which was three times higher than OLEV buses in order than OLEV buses in order to improve the efficiency and power density. The transmitter and pick-ups to improve the efficiency and power density. The transmitter and pick-ups were designed using a were designed using a FEA simulation. The coil-to-coil efficiency, EMF safety has been considered in FEA simulation. The coil-to-coil efficiency, EMF safety has been considered in the design procedure. the design procedure. Simulated and calculated coil-to-coil efficiency was greater than 95%, and the Simulated and calculated coil-to-coil efficiency was greater than 95%, and the EMF radiation level EMF radiation level was lower than 6.25 μT. A new 180 kW, 15 m, 60 kHz WPT test-bed with a 7 cm was lower than 6.25 µT. A new 180 kW, 15 m, 60 kHz WPT test-bed with a 7 cm air gap has been air gap has been constructed and tested experimentally. A resonant inverter, DC-DC converter, and 1-to-5 transformer have been used as the pulse-amplitude-modulated power supply of the WPT system. A transmitter was buried under the ground, and resonant capacitors were connected in series with the transmitter coil. Three series-tuned pick-ups were installed under a test tram and connected in parallel. Measured resonant-inverter voltage and current matched very well with the circuit simulation results. Net power transfer efficiency at the rated output was greater than 85%. Efficiency Energies 2016, 9, 1075 14 of 15 constructed and tested experimentally. A resonant inverter, DC-DC converter, and 1-to-5 transformer have been used as the pulse-amplitude-modulated power supply of the WPT system. A transmitter was buried under the ground, and resonant capacitors were connected in series with the transmitter coil. Three series-tuned pick-ups were installed under a test tram and connected in parallel. Measured resonant-inverter voltage and current matched very well with the circuit simulation results. Net power transfer efficiency at the rated output was greater than 85%. Efficiency dependencies on the load and operating frequency change were evaluated. Efficiencies of all components were measured and the loss distribution of the system was analyzed. Measured magnetic field radiation level satisfied international safety guidelines. Acknowledgments: This research was supported by a grant (16RTRP-B097048-02) from Railroad Technology Development Program funded by Ministry of Land, Infrastructure and Transport (MOLIT) of Korean government and Korea Agency for Infrastructure Technology Advancement (KAIA). Author Contributions: Jun-Ho Lee and Jae-Hee Kim conceived and designed the experiments; Seung-Hwan Lee performed the experiments; Seung-Hwan Lee and Jae-Hee Kim analyzed the data; Seung-Hwan Lee and Jun-Ho Lee wrote the paper. Conflicts of Interest: The authors declare no conflict of interest. References 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. Kawamura, A.; Kuroda, G.; Zhu, C. Experimental results on contact-less power transmission system for the high-speed trains. In Proceedings of the IEEE Power Electronics Specialists Conference (PESC 2007), Orlando, FL, USA, 17–21 June 2007; pp. 2779–2784. Winter, J.; Mayer, S.; Kaimer, S. Inductive power supply for heavy rail vehicles. In Proceedings of the 2013 3rd International, Electric Drives Production Conference (EDPC), Nuremberg, Germany, 29–30 October 2013. Technologies–Aerodynamic Optimization of Pantographs. Available online: http://www.railway-energy. org/tfee/index.php?ID=220&TECHNOLOGYID=5&SEL=210 (accessed on 1 October 2016). Commuter Rail Safety Study. Available online: https://transit-safety.fta.dot.gov/publications/sso/ CRSafetyStudy/html/CRSS.html (accessed on 1 October 2016). PRIMOVE True e-Mobility. Available online: http://primove.bombardier.com/application/light-rail/ (accessed on 1 October 2016). Hwang, K.; Kim, S.; Kim, S.; Chun, Y.; Ahn, S. Design of wireless power transfer system for railway application. Int. J. Railw. 2012, 5, 167–174. [CrossRef] Lee, S.; Jung, G.; Shin, S.; Kim, Y.; Song, B.; Shin, J.; Cho, D. The optimal design of high-powered power supply modules for wireless power transferred train. In Proceedings of the Electrical Systems for Aircraft, Railway and Ship Propulsion (ESARS), Bologna, Italy, 16–18 October 2012. Bolger, J. Roadway Power and Control System for Inductively Coupled Transportation System. EP Patent EP0289868A2, 9 November 1988. Tseng, L.; Tseng, D. Inductive Charging of a Moving Electric Vehicle’s Battery. U.S. Patent 5,311,973, 17 May 1994. Vietzke, O.; Czainski, R. Conductor Arrangement for Producing an Electromagnetic Field and Route for Vehicles, in Particular for Road Automobiles, Comprising the Conductor Arrangement. CA Patent App. CA 2839528A1, 17 January 2013. Woronowicz, K. System and Method for Transferring Electric Energy to a Vehicle Using Segments of a Conductor Arrangement Which Can Be Operated Independently. U.S. Patent US9331527B2, 3 May 2016. Shin, J.; Song, B.; Lee, S.; Shin, S.; Kim, Y.; Jung, G.; Jeon, S. Contactless power transfer systems for on-line electric vehicle (OLEV). In Proceedings of the 2012 IEEE International Electric Vehicle Conference (IEVC), Greenville, SC, USA, 4–8 March 2012. Lee, S.-H. Design Methodologies for Low Flux Density, High Efficiency, kW Level Wireless Power Transfer Systems with Large Air Gaps. Ph.D. Thesis, University of Wisconsin, Madison, WI, USA, 2013. International Electrotechnical Commission (IEC). Electric and Magnetic Field Levels Generated by AC Power Systems–Measurement Procedures with Regard to Public Exposure; IEC 62110; International Electrotechnical Commission: Geneva, Switzerland, 2009. Energies 2016, 9, 1075 15. 16. 17. 18. 15 of 15 International Commission on Non-Ionizing Radiation Protection (ICNIRP). Guidelines for Limiting Exposure to Time-Varying Electric, Magnetic, and Electromagnetic Fields (Up to 300 GHz). Health Phys. 1998, 74, 494–522. Shim, H.-W.; Kim, J.-W.; Cho, D.-H. An analysis on power variance of SMFIR structure. In Proceedings of the 2014 IEEE Wireless Power Transfer Conference (WPTC), Jeju City, Korea, 8–9 May 2014; pp. 189–192. Kim, J.H.; Lee, B.S.; Lee, J.H.; Lee, S.H.; Park, C.B.; Jung, S.M. Development of 1-MW inductive power transfer system for a high-speed train. IEEE Trans. Ind. Electron. 2015, 62, 6242–6250. [CrossRef] Wang, C.S.; Stielau, O.; Covic, G. Design considerations for a contactless electric vehicle battery charger. IEEE Trans. Ind. Electron. 2005, 52, 1308–1314. [CrossRef] © 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).