* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Efficient hydrogenation of organic carbonates, carbamates and

Cracking (chemistry) wikipedia , lookup

Fischer–Tropsch process wikipedia , lookup

George S. Hammond wikipedia , lookup

Marcus theory wikipedia , lookup

Bottromycin wikipedia , lookup

Asymmetric induction wikipedia , lookup

Elias James Corey wikipedia , lookup

Baylis–Hillman reaction wikipedia , lookup

Discodermolide wikipedia , lookup

Hofmann–Löffler reaction wikipedia , lookup

Physical organic chemistry wikipedia , lookup

Ene reaction wikipedia , lookup

Stille reaction wikipedia , lookup

Enantioselective synthesis wikipedia , lookup

Wolff–Kishner reduction wikipedia , lookup

Ring-closing metathesis wikipedia , lookup

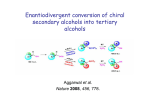

Kinetic resolution wikipedia , lookup

Petasis reaction wikipedia , lookup

Strychnine total synthesis wikipedia , lookup

Asymmetric hydrogenation wikipedia , lookup