* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Practical Assessment of Sanitizers Steve Gray November

Survey

Document related concepts

Water splitting wikipedia , lookup

Biological aspects of fluorine wikipedia , lookup

Water pollution wikipedia , lookup

Nucleophilic acyl substitution wikipedia , lookup

Acid dissociation constant wikipedia , lookup

Electrolysis of water wikipedia , lookup

Sodium hypochlorite wikipedia , lookup

Internal energy wikipedia , lookup

Acid strength wikipedia , lookup

Acid–base reaction wikipedia , lookup

Freshwater environmental quality parameters wikipedia , lookup

Transcript

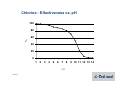

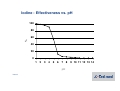

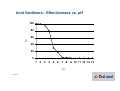

Practical Assessment of Sanitizers Steve Gray November 14, 2012 – Fort Worth, TX Internal 1 Presentation Overview • Discuss sanitizer regulation • What identifies it as a sanitizer • Label Information • Advantageous and disadvantageous of the various sanitizer types • Sanitizer specifics Internal Why Do We Sanitize? • For product safety purposes Consumer health and satisfaction • • • • Internal For product quality purposes Job security Most water supplies are not bacteria free To comply with the regulations Regulatory Agencies •EPA Regulates the registration and approval of sanitizers •FDA Regulates the use of sanitizers on food contact surfaces Internal FDA • U.S. Code of Federal Regulations 21 CFR 178.1010: Compliance and regulation for Food Contact applications Identifies ingredients for sanitizer formulations and approved concentration ranges • Non-food contact applications do not need to adhere to 21 CFR 178.1010 Internal EPA EPA – Environmental Protection Agency • The agency responsible for sanitizer registration and approval under the FIFRA Federal Insecticide, Fungicide, Rodent Act • They approve the product, master label and assign the product registration number • Sanitizers are approved for use as a pesticide • All sanitizers must be registered for use in each state Each states fees are different Internal Criteria for Sanitizer Acceptance • A chemical sanitizer that reduces the microbial levels of two standard organisms: Staphylococcus aureus Escherichia coli • By 99.999% or 5 logs, in 30 seconds, at 25°C for food contact claims • By 99.9% or 3 logs, within 5 minutes for non-food contact surfaces Internal EPA Has Defined Four Categories of Hard Surface Antimicrobial Treatments Based on General Level of Effectiveness: • Sterilants • Disinfectants • Sanitizers • Antiseptics and Germicides Internal Definition of Some Key Terms Sanitizer / Sanitize: • When used at a specified dilution; an agent that reduces the microbial contaminants on inanimate surfaces to levels considered safe from a public health standpoint. • Regulated by the EPA Claims based on specific testing protocol • FDA regulates & categorizes into two types: No-rinse food contact surfaces Non-food contact surfaces Internal Label Information Premium Peroxide II Premium Peroxide II is a peroxyacetic acid-based sanitizer/disinfectant developed for the following uses: Institutional/Industrial Sanitizer and Disinfectant for Previously Cleaned Hard Non-Porous Food Contact Surfaces in: Dairies, Wineries, Breweries, Food and Beverage Plants, Poultry Egg Facilities and Animal Housing. Hard, Non-Porous Surface Disinfection in: Hospitals, Schools, Industrial Facilities, Office Buildings, Veterinary Clinics. Bacteria, Fungi, and Slime Control in: Cooling Water and Evaporative Cooler Systems, Reverse Osmosis and Ultra Filtration Systems. Active Ingredients : Peroxyacetic Acid .........5.6% Hydrogen Peroxide..... 26.5% Inert Ingredients : ........ 67.9% Total: .........................100.0% Internal EPA Registration No. 63838-1-4959 EPA Registration No. 69994-CA-01 Label Information Premium Peroxide II SANITIZING FOOD CONTACT SURFACES It is a violation of Federal Law to use this product in a matter inconsistent with its labeling. This product can be used in Federally Inspected Meat and Poultry Facilities as a sanitizer. Prior to sanitizing, remove gross food particles, then wash with a detergent solution, followed by a potable water rinse. Sanitize with a concentration of 1.0 ounce Premium Peroxide II dissolved in 5 gallons of water (0.16% v/v concentration, or 98 ppm active peroxyacetic acid). At this dilution Premium Peroxide II is effective against Staphylococcus aureus, Escherichia coli, Salmonella choleraesuis, and Listeria monocytogenes. Use immersion, coarse spray or circulation techniques as appropriate to the equipment. All surfaces should be exposed to sanitizing solution for a period of at least 60 seconds or more if specified by a governing code. Allow to free Drain. Do not rinse. Internal Sanitizing Methods •Physical Heat Steam Hot Water •Chemical Internal Difference Between Disinfecting & Sanitizing • “A disinfectant is a chemical that completely destroys all organisms listed on its label. The organisms it kills are disease causing bacteria and pathogens, and it may or may not kill viruses and fungi. From a legal standpoint (EPA guidelines), disinfectants must reduce the level of pathogenic bacteria by 99.999% during a time frame of greater than 5 minutes but less than 10 minutes”. • “A sanitizer is a chemical that reduces the number of microorganisms to a safe level. It doesn't need to eliminate 100% of all organisms to be effective. Sanitizers do not kill viruses and fungi, and in a food service situation the sanitizer must reduce the bacteria count by 99.999%. Sanitizers are required to kill 99.999% of the infectious organisms present within 30 seconds”. Internal 13 Non-Chemical Methods of Sanitizing 1. HOT WATER SANITIZING: • PMO states must be employed at a temperature of not less than 170°F (76. 7°C) as determined at the discharge point, for at least 5 minutes. • Enclosed systems are easiest to sanitize with hot water • Takes considerable time to complete • Verify the equipment is designed for this purpose Internal Non-Chemical Methods HOT WATER SANITIZING: ADVANTAGES: • Relatively inexpensive (No Chemical) and readily available • Offers excellent heat penetration into difficult areas • Broad spectrum of kill • Non-corrosive Internal Non-Chemical Methods HOT WATER SANITIZING: DISADVANTAGES: • Takes considerable time to complete • Can be very energy inefficient • Can be very hard on equipment • Can lead to film formation – (mineral deposits) • It can be quite dangerous!! Internal Non-Chemical Methods 2. STEAM SANITIZING: • May be employed in a closed system when the temperature of the drainage at the outlet is not less than 200°F (93.3°C) for at least 5 minutes. • Except for aseptic operations steam is not normally recommended because: Heat stress Not energy efficient Detrimental effect on rubber Time constraints Internal The Ideal Sanitizer for Food Processing Plants Would Be: • • • • • • • • • Internal Non-toxic Quick acting Broad spectrum THE PERFECT SANITIZER Rapid kill MEETING ALL CRITERIA Stable ABOVE CURRENTLY DOES Non-corrosive NOT EXIST Easy-to-use Inexpensive Recognized by EPA and FDA accordingly Chlorine Dioxide Hypochlorite’s Iodophors CHEMICAL SANITIZERS Ozone Quats Carboxylic Acid Sanitizers Acid Sanitizers Peroxyacetic Acid Internal Hypochlorite's – “Chlorines” • • • • • They are most commonly used in the food and dairy industry Very economical and effective for plant use Can be either in powdered or liquid form Can be considered hazardous and corrosive Most effective at a neutral or weakly acidic condition and become less effective above a 8.5 pH • Use cost $0.58/100 gals of solution Internal Hypochlorite's FDA allowable non-rinse claim max 200 PPM of available chlorine ADVANTAGES: • Broad spectrum of kill • Colorless and non-staining • Easy to handle • Most economical to use • Low Foam Dilutions: Internal Hypochlorite’s DISADVANTAGES: • Short shelf life (liquids have limited stability) • Can be quite corrosive - “Yikes” Rusting, pitting • Adverse effect on plastics and rubber Brittle • Environmental impact Becoming increasingly controlled & prohibited Form Trichlorohalomethanes Internal Chlorine - Effectiveness vs. pH 100 80 % 60 40 20 0 1 2 3 4 5 6 7 pH Internal 8 9 10 11 12 13 14 Iodophors • Iodophors are a combination of iodine with non-ionic wetting agents • They are usually acidified for stability • Iodophors are generally less corrosive at proper use concentrations than chlorine sanitizers • The lower the pH the more effective the iodine sanitizer • Use cost $1.8/100 gals of solution Internal Iodophors Dilutions: FDA allowable non-rinse claim 12.5 to 25 PPM available iodine ADVANTAGES: • Quick kill on a wide range of microorganisms • Good soil tolerance • Provide an acidified rinse for mineral control • Good visual indicator – foot baths, hand sanitizing Internal Iodophors DISADVANTAGES: • Some formulas are expensive to use • Temperatures above 90°F increase staining effect • Potential staining of porous and certain plastic surfaces Internal Iodine - Effectiveness vs. pH 100 80 % 60 40 20 0 1 2 3 4 5 6 7 pH Internal 8 9 10 11 12 13 14 Quaternary Ammonium Compounds • Commonly called “Quats” • Variations of compounds available (1, 2, 3 and 4 chain) • Varying generations of QAC • They are non-corrosive to most equipment • Good soil tolerance • Efficacy influenced by the hardness of the water • Most commonly associated with environmental sanitizing purposes • Acidified quats may be used to combat the effect of hard water • Use cost of QAC $1.95/100 gals of solution Internal Quaternary Ammonium Compounds FDA allowable non-rinse claim max 200 PPM of active QAC ADVANTAGES: • Temperature stable, long shelf life • Forms a bacteriostatic film (residual) – environmental advantage • Non-corrosive, colorless and normally non-irritating to skin • Stable in presence of organic matter • Varying generations of QAC offerings can improve efficacy Dilutions: Internal Quaternary Ammonium Compounds DISADVANTAGES: • Slow to dissipate (residual problem) – culture product disadvantage • Not considered to have broad spectrum properties • Sensitivity to water hardness • Can be detrimental to waste water systems Internal Peroxyacetic Acid • Commonly referred to as PAA sanitizers • Sanitizers based on peracetic acid and hydrogen peroxide mixtures • Are strong oxidizers and work on similar basis as chlorine based sanitizers • They kill microorganisms by penetrating the cell wall and disrupting cell metabolism • Fast acting • Colorless • Pungent smell - Primarily in “Neat State” Internal • Use cost $3.43/100 gals of solution Peroxyacetic Acid FDA allowable non-rinse claim at use dilution specified on label ADVANTAGES: • Broad spectrum kill over broad pH range up to 7.5 pH • They are more environmental and effluent friendly Dilutions: • Phosphate free • Breaks down to vinegar and water • • • • Internal Effective at cold temperature use Non-foaming Especially effective on Biofilms Note - it has been shown that bacteria within a Biofilm are up to 1,000x’s more resistant to some sanitizers Peroxyacetic Acid DISADVANTAGES: • Some concern with corrosion • Cannot be controlled by conductivity • Strong offensive odor • More expensive compared to other sanitizers • Are not available in bulk quantities Internal Acid-Anionic Sanitizers • Are a mixture of acids and wetting agents • Provide double action: sanitize and provide acidified rinse to control milkstone • Their germicidal properties are based upon the lower pH and the activity of the wetting agents at this low pH • They are generally slower acting than oxidizing sanitizers like hypochlorite and PAA sanitizers • Acid sanitizers are most effective between a pH of 2.0 to 3.5, with many becoming ineffective above 4 pH • Use cost $2.03/100 gals of solution Internal Acid Sanitizers - Effectiveness vs. pH 100 80 % 60 40 20 0 1 2 3 4 5 6 7 pH Internal 8 9 10 11 12 13 14 Acid-Anionic Sanitizers: Dilutions: FDA allowable non-rinse claim at use dilution specified on label ADVANTAGES: • Non-staining, stable, long shelf life • Visual detection – foam • Removes and prevents milkstone and waterstone formation • Effective against a wide spectrum of microorganisms • Normally non-corrosive to stainless steel • Can be controlled with conductivity Internal Acid-Anionic Sanitizers DISADVANTAGES: • Effective at acid pH only • Some products generate foam in recirculation • Contribute to phosphate loading • Low activity against spore forming organisms • Slower acting Internal Carboxylic Acid Sanitizers • More commonly known as fatty acid sanitizers • Are a mixture of fatty acids and wetting agents • Usually contain a mineral acid and because of makeup have significantly reduced foam • Provide double action: Sanitize and provide acidified rinse • Their germicidal properties are based upon the lower pH and the activity of the wetting agents at this low pH • They are generally slower acting than oxidizing sanitizers • Fatty acid sanitizers are most effective at a pH of 2.0 to 3.5 • Use cost $1.90/100 gals of solution Internal Carboxylic Acid Sanitizers - Effectiveness vs. pH 100 80 % 60 40 20 0 1 2 3 4 5 6 7 8 pH Internal 9 10 11 12 13 14 Carboxylic Acid Sanitizers Dilutions: FDA allowable non-rinse claim at use dilution specified on label ADVANTAGES: Internal • • Non-staining, stable, long shelf life Very minimal foam production • • Contribute little to phosphate loading Removes and prevents milkstone and waterstone formation • • Effective against a wide spectrum of microorganisms Can be controlled with conductivity Carboxylic Acid Sanitizers DISADVANTAGES: • Effective at acid pH levels below 3.5 only • Are less effective at lower temperatures (<50°F) • Corrosive to metals other than stainless steel • Can effect plastics and rubber • Are costly to use but less than PAA Internal Alternative Antimicrobial Agents • Chlorine Dioxide • Ozone Internal Chlorine Dioxide • Sodium chlorite solution and an acid activator • Is an effective antimicrobial agent • It is a gas that is soluble in water – exists as a gas in H2O • Fogging Process and Food Storage Areas • Also used predominately as an environmental sanitizer • Typical use is at concentrations of chlorine dioxide between 1 to 50 PPM Internal Chlorine Dioxide • ClO2 is a chemical oxidizer, but does not chlorinate. • ClO2 is a powerful biocide that is effective in air or in water over a wide pH range. • ClO2 is a deodorizer. • Does not form chlorinated organic by-products Internal Chlorine Dioxide Dilutions: FDA allowable non-rinse claim at use dilution specified on label ADVANTAGES: • Very strong oxidizer • Not readily affected by organic soiling • Very Effective in removing Biofilms • Very minimal foam production • Is 3 to 4x more potent than chlorine • Effective against a wide spectrum of microorganisms • Less corrosive to stainless steel • Less pH sensitive Internal Chlorine Dioxide DISADVANTAGES: • Safety concern, toxicity – 10x more toxic than chlorine gas - ? • Limited Shelf Life after generation (in some cases) • Multiple products – some types require the need of an activator or an onsite generator • Costly with initial capital cost of on-site generator • Individual packets are costly to use but offer a safer alternative Internal Ozone • Ozone is formed when oxygen molecules collide with oxygen atoms to produce O3 • Is an effective antimicrobial agent • Is a powerful and naturally unstable oxidizing gas • Excellent broad spectrum of germicidal activity • Typically more effective than chlorine or chlorine dioxide • Primary use is for treatment of water Internal Ozone • FDA: Approved as a non-rinse food contact surface sanitizer in 2001 ADVANTAGES: • Very strong oxidizer and is fast reacting • Decomposes rapidly with no harmful residual • Better antimicrobial properties than chlorine and chlorine dioxide • Effective against a wide spectrum of microorganisms Internal Ozone DISADVANTAGES: • Extremely unstable – as a result must be generated / produced on-site • Safety concern, is very irritating and toxic • Extremely reactive and corrosive • No measurable residual to detect for efficacy • No organic tolerances • Costly with initial capital cost of generator and operational costs Internal Specifics to Consider When Deciding to Use a Sanitizer: • Select a properly registered EPA sanitizer • It must be capable of performing the intended function What organisms do you wish to kill? • What is the application? Food Contact – CIP – follow non-rinse compliance Non-Food Contact – Environmental – no non-rinse compliance • It is in violation to reuse sanitizer solution to sanitize a food contact surface • You must understand their limitations and choice is dependant upon application Internal What Can Effect Sanitizer Performance? Surface Cleanliness • YOU CANNOT SANITIZE AN UNCLEAN SURFACE SOIL and DETERGENT CAN: Protect the microbial cell Inactivate the sanitizer Surface Contact • Must contact the cell wall • Soil and non-smooth surfaces can affect this Contact Time • The longer the contact time the greater the efficacy Internal What Can Effect Sanitizer Performance? Proper Temperature and Concentration • Generally increased temperature = increased efficacy Some exceptions are Iodophors and Chlorine • Increased concentration = increased efficacy Must remain within FDA (non-rinse compliance) guidelines Shock Effect pH Conditions • Especially true for acid and chlorine sanitizers • This is significant between wash and rinse cycles Internal Build Up of Resistance • Sanitizers destroy 99.999% of the bacteria present under normal conditions • The sanitizing agent must result in irreversible damage referred to as microbial death • In the presence of 1,000,000 bacteria, 10 will survive • You now have a source for future contamination • Continued exposure to sub-lethal levels of sanitizer results in an increase in resistance • In essence applications less than lethal and in short duration result in selective culturing of resistant strains Internal How to Avoid the Build-Up of Resistance • Be sure concentration levels are met, maintained, and recorded • Insure adequate contact time is reached • Alternate between differing sanitizers • Occasional shocking of the system is recommended Internal Sanitizers Are Not a Substitution For: AN EFFICIENT CLEANING PROGRAM THANK YOU Internal THANK YOU Preguntas/Questions? Internal 56 The ideal sanitizer for food processing plants would be: Internal 1. Non-Toxic 2. Quick Acting 3. Broad Spectrum 4. Non-Corrosive 5. Easy To Use 6. Inexpensive 7. Recognized by EPA, USDA, FDA, USPHS, FSIS You should consider the following when deciding on which sanitizer to use: 1. Properly registered EPA sanitizer. 2. It must be capable of performing intended function. 3. Must have a product with a complete label and use directions, as well as test kits. Internal 4. Sanitizers must be stored in original containers. 5. Sanitizers (all chemicals) should not be stored near food ingredients. 6. Waste disposal systems can be affected by sanitizer selection. Chemical Sanitation • Effectiveness Based on: • Exposure Time • More microorganisms - Longer exposure time • Colonies die in logarithmic pattern • Different types of organisms die at different rates • Temperature • Generally, the hotter the temperature, the more effective the chemical sanitizer Internal Effectiveness of Chemical Sanitizers • Concentration • Follow label • More not necessarily better • pH • Differs depending of Type of Sanitizer • Cleanliness • Soil can react with sanitizers and neutralize them Internal Effectiveness of Chemical Sanitizers • Water Hardness • Calcium and Magnesium in hard water neutralize Quats • Can add chelating agent • Bacterial Attachment • Attachment to surfaces make bacteria more resistant to sanitizers Internal Ideal Sanitizers • Destroy vegetative microorganisms • Work well in different environments • Dissolve in water • Inexpensive, easy to use, readily available • Should not irritate skin • Should not have offensive odor Internal HOT WATER SANITIZING must be employed at a temperature of not less than 170oF (76.7oC) as determined at the discharge point, for at least five minutes. Hot water sanitizing is very effective for either raw or pasteurized product contact surfaces. Enclosed systems are easiest to sanitize with hot water but even tanks can be hot water sanitized. Many times problem equipment and systems respond best to hot water sanitizing. Internal STEAM SANITIZING may be employed in a closed system when the temperature of the drainage at the outlet is not less than 200oF (93.3oC) for at least five minutes. Steam is not normally recommended because of heat stresses; waste of energy; detrimental effect on rubber; condensation; and other negative effects on plant operations. Internal The most popular types of sanitizers used in the food processing industry are: 1. Chlorine compounds (Hypochlorites, Elemental Chlorine, Organic Chlorine) 2. Iodophors or iodine compounds 3. Quaternary ammonia compounds 4. Acid sanitizers 5. Others: Peracetic Acid & Hydrogen Peroxide, Hydrogen Peroxide, Mixed Halogens Internal The ideal sanitizer for food processing plants would be: Internal 1. Non-Toxic 2. Quick Acting 3. Broad Spectrum 4. Non-Corrosive 5. Easy To Use 6. Inexpensive 7. Recognized by EPA, USDA, FDA, USPHS, FSIS You should consider the following when deciding on which sanitizer to use: 1. Properly registered EPA sanitizer. 2. It must be capable of performing intended function. 3. Must have a product with a complete label and use directions, as well as test kits. Internal 4. Sanitizers must be stored in original containers. 5. Sanitizers (all chemicals) should not be stored near food ingredients. 6. Waste disposal systems can be affected by sanitizer selection. Chemical Sanitation • Effectiveness Based on: • Exposure Time • More microorganisms - Longer exposure time • Colonies die in logarithmic pattern • Different types of organisms die at different rates • Temperature • Generally, the hotter the temperature, the more effective the chemical sanitizer Internal Effectiveness of Chemical Sanitizers • Concentration • Follow label • More not necessarily better • pH • Differs depending of Type of Sanitizer • Cleanliness • Soil can react with sanitizers and neutralize them Internal Effectiveness of Chemical Sanitizers • Water Hardness • Calcium and Magnesium in hard water neutralize Quats • Can add chelating agent • Bacterial Attachment • Attachment to surfaces make bacteria more resistant to sanitizers Internal Ideal Sanitizers • Destroy vegetative microorganisms • Work well in different environments • Dissolve in water • Inexpensive, easy to use, readily available • Should not irritate skin • Should not have offensive odor Internal HOT WATER SANITIZING must be employed at a temperature of not less than 170oF (76.7oC) as determined at the discharge point, for at least five minutes. Hot water sanitizing is very effective for either raw or pasteurized product contact surfaces. Enclosed systems are easiest to sanitize with hot water but even tanks can be hot water sanitized. Many times problem equipment and systems respond best to hot water sanitizing. Internal STEAM SANITIZING may be employed in a closed system when the temperature of the drainage at the outlet is not less than 200oF (93.3oC) for at least five minutes. Steam is not normally recommended because of heat stresses; waste of energy; detrimental effect on rubber; condensation; and other negative effects on plant operations. Internal The most popular types of sanitizers used in the food processing industry are: 1. Chlorine compounds (Hypochlorites, Elemental Chlorine, Organic Chlorine) 2. Iodophors or iodine compounds 3. Quaternary ammonia compounds 4. Acid sanitizers 5. Others: Peracetic Acid & Hydrogen Peroxide, Hydrogen Peroxide, Mixed Halogens Internal Hypochlorites Iodophors CHEMICAL SANITIZERS Quats Peracetic Acid Internal Acid Sanitizers CLO2 Hypochlorites: Hypochlorites are the most common type of chlorine sanitizers used in the food and the dairy industry. They are economical and effective for plant use. Sodium or calcium hypochlorites at varying strengths may be purchased in either granular or liquid form. Chlorine in the undiluted form can be hazardous and corrosive. Care should be taken to prepare proper strengths and to prevent personal injury and damage to equipment. The bactericidal effect of active chlorine is best at neutral or weakly acidic condition and becomes less effective above a 8.5pH. Internal Chlorine Dioxide • Less effective than chlorine at pH 6.5 • More effective at pH 8.5 • Treating sewage • Works over broader range of pH • Less corrosive • Fewer off-odors Internal Hypochlorites: LCS, PCS, EXTRACT-2 ADVANTAGES: Internal 1. Powerful sanitizers controlling a wide range of microorganisms 2. Deodorizes 3. Non-poisonous to man at use concentrations 4. Colorless and non-staining 5. Easy to handle 6. Most economical to use DISADVANTAGES: 1. Short shelf life (liquids have limited stability) 2. Adverse affect on skin 3. Corrosive on some metals with prolonged contact USE CONCENTRATIONS: 50 to 100 ppm available chlorine should be employed for sanitizing large equipment and utensils, and 200 ppm for spraying applications of large equipment. The contact time for effective sanitation should be long enough to produce complete kill of bacteria; usually 10 seconds or longer. Internal Method of Application Temperature Minimum Range o F Minimum Minimum Available Time Residual Chlorine Exposure Chlorine ppm min. min. o C Circulation 75-90 24-32 100 2 50 Spraying 75-90 24-32 250 2 50 Fogging ---- ---- 400 2 50 75-90 24-32 100 2 50 ---- ---- 50 --- --- Immersion Bottle Rinse When low er temperatures are used w ith hypochlorite sanitizers, the contact time or strength should be increased. For each 18 oF (10 oC) drop in temperature, the strength of solution or contact time should be doubled. Internal Internal Iodophors: Iodophors are a combination of iodine with non-ionic wetting agents, and are acidified for stability. Iodophors are generally less corrosive at proper use concentrations than chlorine sanitizers. The lower the pH the more effective the iodine sanitizer. Internal IODOPHORS Internal Iodophors: Rapidyne®, Iosan®, Maxidyne™, ZZZ ADVANTAGES: Internal 1. Possess quick microbicidal action on a wide range of microorganisms. 2. In proper use dilution, they are non-staining, non-corrosive, non-irritating to skin, with no residual film. 3. Possess good storage stability. 4. Effective in cold solution. 5. Effective in soft and hard water conditions. D IS A D V A N T A G E S : 1. S o m e fo rm u la s a re e x p e n s ive to u s e . 2. S h o u ld n o t b e u s e d a t te m p e ra tu re s a b o ve 1 2 0 o F . 3. P o te n tia l s ta in in g of p o ro u s and c e rta in p la s tic s u rfa c e s . 4. G e rm ic id a l a c tio n a d ve rs e ly a ffe c te d b y h ig h ly a lk a lin e w a te r or c a rry-o ve r of h ig h ly a lk a lin e d e te rg e n t s o lu tio n s . U S E C O N C E N T R A T IO N S : E q u ip m e n t a n d u te n s ils re q u ire s o lu tio n s p ro vid in g 1 2 .5 -2 5 p p m o f Io d in e . Internal The following table gives minimum standards for sanitizing with iodine compounds. Method of Temperature Minimum Minimum Minimum Application Range Available Time Iodine Exposure Iodine ppm o F min. min. o C Circulation 50-70 10-21 12.5 2 2 Spraying 50-70 10-21 12.5 2 5 Fogging ---- ---- 25 2 5 50-70 10-21 12.5 2 5 ---- ---- 5 --- --- Immersion Bottle Rinse Internal Residual Internal Quaternary Am m onium Com pounds: These are com m only called "quats". They are non-corrosive to dairy equipment, and their germ icidal activity is less affected by the presence of organic m atter than other sanitizers. The bactericidal effectiveness of quaternary ammonium compounds is influenced by the hardness of the w ater. Acidified quats m ay be used to com bat the affect of hard, alkaline w ater. They are also less effective against certain spoilage (gram negative) bacteria. Recent data indicates that acidified quaternary compounds m ay Internal offer substantial protection against Listeria. Quat Generations • 1st generation = Alkly dimethyl benzyl ammonium chloride (ADBAC) – effected by hard water. • 2nd generation = Alkyl dimethyl ethlybenzyl ammonium chloride (EBC) – too expensive for most markets. • 3rd generation = mixture of ABDAC and EBC quat with improved biological efficacy. • 4th generation = dialkylmethyl amines (DAMA) is quaternized with methyl chloride forming mixtures of three quats improving hard water tolerence but with less water solubility. • 5th , 6th, 7th generations = continued synergistic combinations are being developed Internal Quaternary Ammonium Compounds Internal Quat: Teramine™, Bio Hatch, Q-Max 25 ADVANTAGES: Internal 1. Stable, long shelf life 2. Forms a bacteriostatic film 3. Non-corrosive and normally non-irritating to skin 4. Stable in presence of organic matter 5. Good soil penetration qualities D ISAD VANTAGES: 1. M ore expensive to use than chlorine or iodine 2. Incom patible w ith com m on anionic detergent com ponents. 3. Slow to dissipate (residual problem ) 4. Germ icidal efficacy varies and is selective in som e m icroorganism s. U SE CONC ENTR ATION S: As a disinfectant of equipment 200 ppm (1:500) w as found to be sufficient to reduce bacterial counts, w hile on non-food contact Internal surfaces 600-1200 ppm m ay give best results. Hydrogen Peroxide Based Products: are strong oxidizing agents and can be considered a strong bactericide. It has the ability to change the environment so that it becomes unsuitable for the growth of organisms. Extreme care should be exercised in handling hydrogen peroxide. It is a strong oxidizing agent and is potentially explosive. Internal Hydrogen Peroxide Internal Acid Sanitizers: are a mixture of acids and wetting agents. Their germicidal properties are based upon the lower pH and the activity of the wetting agents at this low pH. They are generally slower acting than halogen sanitizers like hypochlorite sanitizers. Acid sanitizers are most effective at a pH of 2.3-3.5, with many becoming ineffective above 4 pH. Mixtures of peracetic acid and hydrogen peroxide (peroxyacetic acid) have been shown to have excellent oxidizing properties and to be effective against a broad range of bacteria. These are highly corrosive, difficult to handle, and should be used with Internal caution. Peracetic Acid Internal Acid Sanitizers: Acidet®, Mega-San™, RPM ADVANTAGES: Internal 1. Non-staining, stable, long shelf life 2. Non objectionable odor 3. Removes and prevents milkstone and waterstone formation 4. Effective against a wide spectrum of microorganisms 5. Stable in concentrated form or use dilutions 6. Germicidal action enhanced by high temperatures 7. Normally non-corrosive to stainless steel 8. Provides short-duration residual sanitizing effect on stainless steel equipment DISADVANTAGES: 1. Effective at acid pH only 2. Some products generate foam in recirculation 3. Low activity against spore forming organisms 4. Corrosive to metals other than stainless steel 5. Some formulas are expensive to use USE CONCENTRATIONS: 100-200 ppm anionic surfactant with specific lowered pH. Internal Peroxyacetic Acid: West Agro Premium Peroxide Sanitizers based on peracetic acid and hydrogen peroxide are strong oxidizers. They kill microorganisms by penetrating the cell wall and disrupting cell metabolism. ADVANTAGES: Internal 1. Broad spectrum kill 2. Effective in cold water 3. Do not contribute to BOD loading 4. Non-foaming; no phosphate DISADVANTAGES: Internal 1. Has been demonstrated to cause corrosion 2. Difficult to titrate in use solution and not controllable by conductivity 3. Use solutions are not shelf stable 4. Not effective in alkaline pH 5. Handling/storage can be potential problems 6. Strong offensive odor 7. Storage must be at 20-30oC 8. Extremely expensive compared to other sanitizers 9. Not available in bulk due to product degradation C H A RA C T ERIS T IC S O F S A N IT IZ IN G C H EM IC A LS H YP O C H L O R IT E S (L IQ U ID ) IO D O P H O R S QU ATER NAR Y A M M O N IU M C OMPO UND S A C ID -A N IO N IC SU RFAC TAN TS A c tive a g a in st a ll m ic ro o rg a n ism s a n d b a c te rio p h a g e . A c tive a g a in st sp o re s a t h ig h te m p e ra tu re s, lo n g c o n ta c t tim e . A c tive a g a in st a ll m ic ro o rg a n ism s e xc e p t b a c te ria l sp o re s a n d b a c te rio p h a g e . A c tive a g a in st m a n y m ic ro o rg a n ism s. S lo w a c tivity a g a in st c o lifo rm s a n d c o m m o n se a fo o d sp o ila g e b a c te ria . N o t e ffe c tive a g a in st sp o re s a n d b a c te rio p h a g e . A c tive a g a in st m a n y m ic ro o rg a n ism s & b a c te rio p h a g e . N o t e ffe c tive a g a in st sp o re s. In e xp e n sive U n sta b le S h o rt sh e lf life E a sily d isp e n se d a n d c o n tro lle d . E xp e n sive S ta b le L o n g sh e lf life E a sily d isp e n se d a n d c o n tro lle d . E xp e n sive S ta b le L o n g sh e lf life E a sily d isp e n se d a n d c o n tro lle d . E xp e n sive S ta b le L o n g sh e lf life E a sily d isp e n se d a n d c o n tro lle d . C o rro sive to so m e m e ta ls. N o n -c o rro sive N o n -c o rro sive N o n -c o rro sive to sta in le ss ste e l. C o rro sive to o th e r m e ta ls. Internal CHARACTERISTICS OF SANITIZING CHEMICALS HYPOCHLORITES (LIQUID) Internal IODOPHORS QUATERNARY AMMONIUM COMPOUNDS ACID-ANIONIC SURFACTANTS Adverse effect on skin Non-foaming Non-irritating to skin Non-irritating to skin. Foam formation with highpressure sprayer. Adverse effect on skin. Foam formation with high-pressure sprayer. Non-film forming Non-film forming Leaves objectionable film. Leaves residual film. CHARACTERISTICS OF SANITIZING CHEMICALS HYPOCHLORITES (LIQUID) IODOPHORS QUATERNARY AMMONIUM COMPOUNDS ACID-ANIONIC SURFACTANTS Chlorine odor Poor penetration qualities. Decreased effectiveness in presence of organic m aterial. Iodine odor Good penetration qualities. Decreased effectiveness in presence of organic material. No odor Good penetration qualities. Effective in presence of organic m aterial. No odor Good penetration qualities. Effective in presence of organic m aterial. Ineffective above pH 8.5 Slow acting at or above pH 7.0 Effective over wide range of pH Optim um effect iveness at pH 1.9-2.2; ineffective above pH 3.0. Dissipates rapidly from solutions o above 120 F. Should not be used above o 120 F. Stable to tem perature changes. Effectiveness increases at higher tem peratures. Internal RECOMMENDED SANITIZERS Specific areas or conditions may require different sanitizing compounds. The following list indicates where particular types of sanitizers are recommended. (CONCENTRATIONS IN PPM) RECOMMENDED SANITIZER SPECIFIC AREA OR CONDITION RAPIDYNE BACTERIOSTATIC FILM CONCRETE FLOORS CONVEYOR BELTS COOLER W ALLS & CEILINGS HAND SANITIZER HARD W ATER HIGH IRON W ATER ODOR CONTROL PLASTIC CRATES POROUS SURFACES PROCESSING EQUIPMENT (ALUMINUM) PROCESSING EQUIPMENT (S.S.) RINSE W ATER TREATMENT RUBBER BELTS TIRES W ALLS W ATER SUPPLY TREATMENT -25 -25 25 25 -25 -25 25 -25 25 --- Internal LCS EXTRACT 2 -1000-5000 300-500 --200 -200 -200 200 2-7 --200 2-7 BIO HATCH ACIDET RPM 150-200 500-800 -500-800 ---150-200 -150-200 150-200 150-200 ---150-200 -- 100 ----130 -----130 ------ PRODUCT MegaSan Q Max 25 TriSan Acidet Rapidyne WA Premium Peroxide HDA Bleach Internal CORROSION RATE (in./yr. E-4) 0.06 0 0.19 0.06 0 0 0.09 0.16 0.03 0.13 0 0.03 0.03 0.06 0.16 7.72 CONCENTRATION (Oz. per Gallon) 0.17 0.33 0.28 0.57 0.17 0.33 0.23 0.46 0.088 0.176 0.40 0.80 0.57 1.14 100 ppm 200 ppm CONCENTRATION (Vol : Vol) 1 : 768 1 : 354 1 : 448 1 : 224 1 : 768 1 : 354 1 : 560 1 : 280 1 : 1455 1 : 727.5 1 : 320 1 : 160 1 : 224 1 : 112 100 ppm 200 ppm Passivated Plates Average Corrosion Rate in Inches per Year. Duplicate Plates @ 50C on 304 Stainless Steel Coupons 9 200 ppm Normal Strength Corrosion Rate (10E-4) 8 7 2 X Strength 6 5 4 3 100 ppm 2 1:768 1:384 1:448 1:224 1:768 1:384 1:560 1:280 1:727.5 1:1455 1:160 1:112 1:224 1:320 1 0 A h e Pr m iu 25 ne dy ac D A pi et ax an aS m r Pe ox e id Internal e Bl H W Ra id Ac M eg an iS Tr Q M Cleaning Agents PRODUCT MegaSan Q Max 25 TriSan Acidet Rapidyne 1 WA Premium Peroxide HDA Bleach Internal CORROSION RATE (in./yr. E-4) 0.69 1.66 0.69 0.85 0.57 0.47 0.88 1.04 0.66 0.91 0.72 1.95 0.97 0.88 5.12 6.97 CONCENTRATION (Oz. per Gallon) 0.17 0.33 0.28 0.57 0.17 0.33 0.23 0.46 0.088 0.176 0.40 0.80 0.57 1.14 100 ppm 200 ppm CONCENTRATION (Vol. : Vol.) 1 : 768 1 : 354 1 : 448 1 : 224 1 : 768 1 : 354 1 : 560 1 : 280 1 : 1455 1 : 727.5 1 : 320 1 : 160 1 : 224 1 : 112 100 ppm 200 ppm Unpassivated Plates Average Corrosion Rate in Inches per Year Duplicate Plates @ 50C on 304 Stainless Steel Coupons 8 200 ppm Corrosion Rate (10E-4) 7 6 100 ppm 2 X Strength 5 4 1:160 3 2 1:384 1:768 1:224 1:448 1:280 1:768 1:384 1:727.5 1:1455 1:560 1:112 1:224 1:320 1 0 D A A h e Pr m ne dy iu m ro Pe x id e Internal c ea Bl H W pi Ra t 25 n Sa ax ide Ac M a eg an iS Tr Q M Cleaning Agents Normal Strength Colors Theme colors R G B Internal 109 16 61 130 R G B 255 51 0 R G B 0 146 209 R G B 119 173 28 R G B 248 179 35 R G B 115 111 169