* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Manual.

Radio transmitter design wikipedia , lookup

Oscilloscope types wikipedia , lookup

Regenerative circuit wikipedia , lookup

Integrating ADC wikipedia , lookup

Oscilloscope history wikipedia , lookup

Transistor–transistor logic wikipedia , lookup

Analog-to-digital converter wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Operational amplifier wikipedia , lookup

Josephson voltage standard wikipedia , lookup

Current source wikipedia , lookup

Schmitt trigger wikipedia , lookup

Valve RF amplifier wikipedia , lookup

Electrical ballast wikipedia , lookup

Power electronics wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Current mirror wikipedia , lookup

Voltage regulator wikipedia , lookup

Power MOSFET wikipedia , lookup

Surge protector wikipedia , lookup

Opto-isolator wikipedia , lookup

Switched-mode power supply wikipedia , lookup

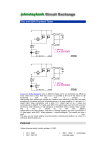

Arieh Nachum Industrial Semiconductors – SCR, Triac, Diac and PUT EB-3127 2 Arieh Nachum Industrial Semiconductors – SCR, Triac, Diac and PUT EB-3127 1_8 © All rights reserved to DEGEM Systems. The material in this book may not be copied, duplicated, printed, translated, re-edited or broadcast without prior agreement in writing from DEGEM Systems. 20a Eliyau Eitan St., Rishon-Lezion P.O.Box 5340, Rishon-Lezion 75151 Israel Tel: 972-3-9535400 Fax: 972-3-9535423 E-mail: [email protected] Site: www.degem.com I Contents Preface ............................................................................................................. II Experiment 1 – Silicon Controlled Rectifier and GTO ............................... 1 1.1 1.2 The SCR thyristor ................................................................................. 1 The GTO thyristor ................................................................................. 5 Experiment 2 – Triac and Diac .................................................................... 14 2.1 2.2 The triac .............................................................................................. 14 The diac ............................................................................................... 17 Experiment 3 – Programmed Uni Transistor............................................. 26 Experiment 4 – Troubleshooting ................................................................. 35 EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT II Preface The experiments in this manual are meant to be run on the experiment board EB-3127 with the Universal Training System EB-3100. The EB-3100 includes: 5 voltages power supply (+12V, +5V, –5V, –12V and –12V to +12V variable voltage). 2 voltmeters. Ampere-meter. Frequency counters up to 1MHz. Logic probe (High, Low, Open, Pulse, Memory). Logic analyzer with 8 digital inputs and trigger input. Two channel oscilloscope (with spectrum analysis while connecting to the PC). Function generator (sine, triangle and square wave signals) up to 1MHz. 3.2" color graphic display with touch panel for signal and measurement display. USB wire communication with the PC. 20 key terminal keyboard. 10 relays for switching the plug-in boards or for planting faults. 48 pin industrial very low resistance connector for plug-in boards' connection. Transparent sturdy cover covers the upper part of the plug-in boards in order to protect the board's components that should be protected. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT III The EB-3100 boards are: Electricity and Electronics EB-3121 Ohm and Kirchoff Laws and DC circuits EB-3122 Norton, thevenin and superposition EB-3123 AC circuits, signals and filters EB-3124 Magnetism, electromagnetism, induction and transformers Semiconductor Devices EB-3125 Diodes, Zener, bipolar and FET transistors characteristics and DC circuits EB-3126 Bipolar and FET transistor amplifiers EB-3127 Industrial semiconductors – SCR, Triac, Diac and PUT EB-3128 Optoelectronic semiconductors – LED, phototransistor, LDR, 7-SEG. Linear Electronics EB-3131 Inverter, non-inverter, summing, difference operational amplifiers EB-3132 Comparators, integrator, differentiator, filter operational amplifiers EB-3135 Power amplifiers EB-3136 Power supplies and regulators EB-3137 Oscillators, filters and tuned amplifiers Motors, Generators and Inverters EB-3141 Analog, PWM DC motor speed control, step motor control, generators EB-3142 Motor control – optical, Hall effect, motor closed control EB-3143 AC-DC and DC-AC conversion circuits EB-3144 3 Phase motor control Digital Logic and Programmable Device EB-3151 AND, OR, NOT, NAND, NOR, XOR logic components & Boolean algebra EB-3152 Decoders, multiplexers and adders EB-3153 Flip-flops, registers, and counters sequential logic circuits EB-3154 555, ADC, DAC circuits EB-3155 Logic families Microprocessor/Microcontroller Technology EB-3191 Introduction to microprocessors and microcontrollers EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT IV The EB-3127 is connected to the EB-3100 via a 48 pin industrial connector. It has a built-in microcontroller that identifies (for the EB-3100 system) the experiment board when it is being plugged into the system, and starts a selfdiagnostic automatically. The following figure describes the EB-3127 experiment board. B1 B2 B3 B4 50K +12V A R1 1K TRIAC G 0.1 A DIAC Vvar B5 12V A AC POWER SUPPLY 5K SCR G R2 91K A TRIAC G K B A C7 0.1 50 Hz 60 A C13 R3 1K G 10n C8 1n EB-3127 Panel Layout EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT K R8 100 Vo R4 10K V The experiment method: The system uses an external switching power supply for safety reasons. The power supply low voltage output is converted to the 5 voltages by linear regulators for noise reduction. Two potentiometers on the panel are used to setup the variable voltage and the function generator amplitude. The system cut-off the voltages in overload and displays a massage about that. The plug-in cards are connected directly to system without any flat cable for noise and resistance reduction. The 10 relays are change over relays that can switch active and passive components. Every selecting of a relay configuration is saved in a non-volatile memory located on the connected plug-in card. The components are located on the board with silk screen print of the analytical circuit and component symbols. The central part of the experimenting board includes all the circuit block drawings and all the hands on components, test points and banana sockets. The protected components are located on the circuit board upper side, clearly visible to the student and protected by a sturdy transparent cover. On plugging the experiment board, it sends a message to the EB-3100 which includes the board's number and which of its block are faulty. If there is a faulty module (B1-B8), it will be displayed on the screen. The experiment board checks itself while it is being plugged. This is why, during the plug-in, any banana wire should not be connected on the experiment board. 5 LEDs should turn ON on the top right. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT VI The system includes 5 power supply outputs. The system checks these voltages and turns ON the LEDs accordingly. +12V +5V –5V –12V – – – – Red LED Orange LED Yellow LED Green LED The fifth voltage is a variable voltage (Vvar) controlled by a slider potentiometer. The LED of the Vvar is both green and red: when the Vvar voltage is positive – the color is red and when it is negative – the color is green. There are no outlets for the power supply voltages on the The voltages are supplied only to the 48 pin connector. TSP-3100 panel. The experiment boards take these voltages from the 48 pin connector. EB-3100 Screens: The system has 3 operating screens: DVM, Oscilloscope and Faults. Moving from one screen to another is done by the Options/Graph key. The keyboard is always at Num Lock position. The keys can also be used as function keys. In order to do so, we have to press once on the Num Lock key and then on the required key. The keyboard returns automatically to Num Lock mode. On scope screen, pressing the Num Lock key and then the Digital key will change the screen to Digital signal screen display. Pressing the Num Lock key and then the Analog key will change the screen to Analog signal screen display. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT VII DVM Screen: DVM V1 [V] 0.00 V2–V1 [V] 0.00 Fout [KHz] 5.00 V2 [V] 0.00 I [mA] 0.0 Cin [Hz] 5.00 I (+5V) [mA] I (+12V) [mA] 0 0 I (–5V) [mA] I (–12V) [mA] 0 0 Num Lock V1 is the voltage measured between V1 inlet and GND. V2 is the voltage measured between V2 inlet and GND. V2–V1 is the voltage measured between V1 and V2. It enables us to measure floating voltage. I is the current measured between A+ and A– inlets. Cin displays the frequency is measured in the Cin inlet. The EB-3100 includes a function generator. The frequency of the function generator is displayed in the Fout field and can be set by the arrow keys or by typing the required values. The square wave outlet is marked with the sign . Near the analog signal outlet there is a sine/triangle switch marked with the signs / . EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT VIII Scope Screen: CH1 3.0VCH2 3.0V t 50s CH1 1.0V Num Lock Analog Run The scope and the display parameters (CH1 Volt/div, CH2 Volt/div, time base Sec/div, Trigger Channel, Trigger rise/fall, Trigger Level) appear on the bottom of the screen. The Up and Down arrow keys highlight one of the fields below. The required field can be selected by touching it and can be changed by the Up and Down arrows. The function generator amplitude is changed by the amplitude potentiometer. The sampling and display can be stopped by pressing the Num Lock key and then pressing the Stop (8) key. Performing a single sampling is done by pressing the Num Lock key and then pressing the Single (9) key. Running again the sampling is done by pressing the Num Lock key and then pressing the Run (7) key. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT IX Digital Screen: Pressing the Num Lock key and then the Digital key on scope screen displays the Digital screen. D0 D1 D2 D3 D4 D5 D6 D7 D0 D1 D2 D3 D4 D5 D6 D7 t 50s TRIG Num Lock Digital Run Check that. The logic analyzer includes 8 digital inlets and one trigger signal inlet. The controller waits for trigger and when it encounters a trigger pulse it samples the 8 digital inputs. If a trigger pulse is not found the sampling will be according to the time base. The sampling and display can be stopped by pressing the Num Lock key and then pressing the Stop (8) key. Performing a single sampling is done by pressing the Num Lock key and then pressing the Single (9) key. Running again the sampling is done by pressing the Num Lock key and then pressing the Run (7) key. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT X Logic Probe: The EB-3100 Logic Probe includes 5 LEDs indicating the Logic Probe (LP) input state – High, Low, Open (unconnected), Pulses and Memory (registering single pulse). The Logic Probe also has a TTL/CMOS switch that determines which logic level is selected. When the LP is connected to a point with a voltage blow 0.8V (for TTL) or 1.3V (for CMOS), the L green LED should turn ON. When the LP is connected to a point with a voltage above 2.0V (for TTL) or 3.7V (for CMOS), the H red LED should turn ON. The voltage between these levels turns ON the OP orange LED. Fault Screen: The EB-3100 includes 10 relays for fault insertion or for switching external components. The fault screen is selected by the Options/Graph key. FAULTS Please choose Fault No.: 0–9 Activated fault Number: 0 Num Lock Typing a fault number and pressing ENTER operates the required relay for the required fault. Fault No. 0 means No Fault. Which relay creates the required fault is registered in the plug-in experiment board controller. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT XI On entering a fault number, the system addresses the experiment board controller and asks for the relay number. After that, it executes the required fault. The experiment board controller saves the last registered fault number in its memory. This memory is non-volatile. This is why the system does not allow us to enter a fault number when no experiment board is plugged. When an experiment board that a certain fault (other than zero) is registered in its memory is plugged into the system, a warning message appears on the system's screen. This feature enables the teacher to supply the students various experiment boards with planted faults for troubleshooting. Note: It is recommended (unless it is otherwise required), to return the experiment board fault number to zero before unplugging it. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT XII EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 1 Experiment 1 – Silicon Controlled Rectifier and GTO Objectives: Introducing the SCR (Silicon Controlled Rectifier). SCR circuits. Igniting and extinguishment of SCR. Equipment Required: EB-3100 EB-3127 Banana wires Discussion: 1.1 The SCR thyristor The special semi conductors include a unique family called thyristors. These components have only two operational states: cutoff and conducting. The SCR (Silicon Controlled Rectifier) is a component with three triggers: Anode (A), Cathode (K) and Gate (G). The component is described as follows: A G K Figure 1-1 The SCR is designated to cause a current flow from the anode to the cathode. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 2 The SCR is build from four integrated layers of P and N as follows: A G P N P N K Figure 1-2 To understand the SCR operation we can describe it with an equal electronic circuit as follows: A Q2 P N P P N Q1 G Q1 Q2 N K Figure 1-3 When we connect the SCR to a voltage, plus (+) to A and minus (–) to K and don't supply voltage to the gate (G), the two transistors are at cutoff. Supplying a pulse (even for a short period of time) to the gate causes transistor Q2 to conduct. This conducting creates a basic current for transistor Q1. This current conducts and causes current flow the Q2 base. This current maintains transistor Q2 in conducting, which maintains transistor Q1 in conducting even if the pulse at the gate stops. This type of switching is called regenerative switching including the positive feedback. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 3 The SCR characteristic looks as follows: I IL VX IH VH VB V Figure 1-4 At backward voltage the SCR is like a diode. It does not conduct until it breaks-over. The SCR components are designed for highly break-over voltages (in order to avoid this situation). VX is larger than 400V. In frontal voltage the SCR can breaks-over in one of the three following cases: 1. The voltage on it is bigger than VH (Holding Voltage) and a current pulse is received at the gate. This is the desired ignition. 2. When the voltage between the anode and Cathode rises above the frontal break-over VB (Break-over Voltage). In this state, a dripping current flows at transistor Q1, which causes the conducting of Q2 and thus increases the conducting of Q1 until the two transistors are conducting. This is usually not the desirable ignition, thus the SCR is programmed to very high VB voltages (over 400V). EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 4 3. A very fast increase of voltage on VAK (the voltage between the anode and the Cathode), even if VAK is smaller than VB. To avoid this situation a capacitor is sometimes added in parallel to the SCR as described in the following example: R A V C G K Figure 1-5 The capacitor prevents the very fast increase in voltage of the VAK. The major advantage of the SCR is its very short switching time thanks to the regenerative switching. It reduces the voltage drop on it and allows the productions of SCR components, which can withstand very large current (tens to hundreds ampere). The SCR disadvantage is its shutdown. The only way to shutdown the SCR is to decrease the current flowing through it below the maintenance current. A transistor can also switch current in a similar way. The advantage of the transistor is that its shutdown is done by simply stopping the current at the base. Its disadvantage is that its switching time is longer and during the switching a relatively high voltage is developed on it, thus it cannot be used for switching large currents. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 5 1.2 The GTO thyristor The gate turnoff (GTO) thyristor is a semiconductor device that can be turned ON and OFF via a gate signal. Like a conventional thyristor, the GTO thyristor can be turned ON by a positive gate signal (g > 0). However, unlike the thyristor, which can be turned OFF only at a zero crossing of current, the GTO can be turned OFF at any time by the application of a gate signal equal to 0. The GTO thyristor is simulated as a resistor RON, an inductor LON, and a DC voltage source Vf connected in series with a switch. The switch is controlled by a logical signal depending on the voltage Vak, the current lak, and the gate signal g. + A Anode K Cathode g Gate A lak SW GTO Logic Vak RON Vf LON + - K Vak lak g Figure 1-6 The Vf, RON and LON parameters are the forward voltage drop while in conduction, the forward conducting resistance, and the inductance of the device. The GTO thyristor turns ON when the anode-cathode voltage is greater than Vf and a positive pulse signal is present at the gate input (g > 0). When the gate signal is set to 0, the GTO thyristor starts to block but its current does not stop instantaneously. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 6 Because the current extinction process of a GTO thyristor contributes significantly to the turnoff losses, the turnoff characteristic is built into the model. The current decrease is approximated by two segments. When the gate signal becomes 0, the current lak first decreases from the value Imax (value of lak when the GTO thyristor starts to open) to lmax/10, during the fall time (Tf), and then from Imax/10 to 0 during the tail time (Tt). The GTO thyristor turns OFF when the current lak becomes 0. The latching and holding currents are not considered. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 7 Preparation questions: 1. In the following circuit, what happens when Vvar goes up and then returns to 0V? 12V R1 1K VA Vvar (a) (b) (c) (d) 2. VG The LED turns ON and then turns OFF. The LED turns OFF and then turns ON. The LED turns ON and does not turn OFF. The LED is affected by Vvar. In the following circuit, what happens when the switch is pressed and released? 12V R1 1K VA Vvar (a) (b) (c) (d) VG The lamp turns ON and then turns OFF. The lamp is affected by Vvar. The lamp turns OFF and then turns ON. The lamp turns ON and does not turn OFF. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 8 3. How can we switch off the lamp when it is ON? (a) (b) (c) (d) By pressing the pushbutton switch twice. By disconnecting the circuit voltage. By pressing the pushbutton for a long time. By pressing the pushbutton for a short period of time. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 9 Procedure: Step 1: Connect the EB-3100 to the power supply. Step 2: Connect the power supply to the Mains. Step 3: Turn ON the trainer. The DVM screen should appear on the display. Step 4: Plug the EB-3127 into the EB-3100. Step 5: Observe the display and check that the experiment board name appear and no fault is detected. The EB-3127 includes the power supply outlets +12V, Vvar and AC power supply. The Vvar is a variable voltage outlet of the range –12V to +12V that can be changed by the Vvar slider potentiometer on the EB3100. Step 6: Implement the following circuit in B2: 12V R1 1K VA Vvar VG Step 7: Set the Vvar voltage to 0V. Step 8: Connect a voltmeter to point VA. The voltage should be equal to 10.5V. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 10 Step 9: Gradually raise Vvar until voltage VA drops to 0.8V. Find the required VG value for the SCR's break-over. Step 10: Lower voltage VG to 0V. Is the SCR was shutdown and VA was increases to 12V and back? Step 11: Disconnect the 12V voltage from the 1K resistor and connect it back. VA should drop to 0V. Step 12: Repeat step 9 and find the gate's exact ignition voltage. Step 13: Replace the LED and the 1K resistor with the lamp. Step 14: Repeat steps 9 and 10 with the lamp. Did you managed to turn off the lamp after turning it on? Step 15: Implement the following circuit: 12V The lamp should be OFF. Step 16: Press the pushbutton switch. The lamp should turn ON. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 11 Step 17: Release the pushbutton switch. The lamp should remain ON. Step 18: How can the lamp be turned OFF? EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 12 Summary questions: 1. In the following circuit, what happens when Vvar goes up and then returns to 0V? 12V R1 1K VA Vvar (a) (b) (c) (d) 2. VG The LED turns ON and does not turn OFF. The LED is affected by Vvar. The LED turns ON and then turns OFF. The LED turns OFF and then turns ON. In the following circuit, what happens when the switch is pressed and released? 12V R1 1K VA Vvar (a) (b) (c) (d) VG The lamp is affected by Vvar. The lamp turns ON and then turns OFF. The lamp turns ON and does not turn OFF. The lamp turns OFF and then turns ON. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 13 3. How can we switch off the lamp when it is ON? (a) (b) (c) (d) By pressing the pushbutton for a short period of time. By pressing the pushbutton switch twice. By pressing the pushbutton for a long time. By disconnecting the circuit voltage. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 14 Experiment 2 – Triac and Diac Objectives: Introducing the triac and diac. Triac and diac circuits. Igniting and extinguishment of the triac and diac. Equipment Required: EB-3100 EB-3127 Banana wires Discussion: 2.1 The triac The triac is a tyristor with three triggers, which conduct current in two directions. It is similar to two SCR components connected in parallel and in an inverted way and is described as follows: A1 G A2 Figure 2-1 The triac is build from 5 NPNPN layers. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 15 The triac characteristic is described as follows: I IL IH VB VH VH V VB IH IL Figure 2-2 The triac is used for controlling the power in the consumer by moving the phase with the following circuit (the circuit is called a Dimmer). Load ~ R1 R2 C2 G C1 Figure 2-3 Before igniting the triac, a very low current flows at the load and all the source voltage drops on the double RC filter. This voltage is divided and moved at the VC phase. When VG passes the ignition voltage, the triac ignites and conduct until the input voltage half cycle is finished. When the input voltage drops to 0V, the triac is shutdown and the ignition procedure is repeated in inverted voltage. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 16 Vi t VG t IL t Figure 2-4 Limitation of the potentiometer reduces the wave power at the gate and the ignition angle, thus reducing the average current in the consumer. The use of a double filter enables bigger than 10o phase movements. When the power in the consumer activated by the Mains is controlled, it is difficult to reach large ignition angles. The reason is that the triac ignition voltage is low (less than 1V) and the Mains voltage is high. To increase the triac ignition voltage we use a component called diac. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 17 2.2 The diac The diac is a tyristor with only two legs. It is designated (opposed to the others) to be ignited by a voltage larger than its VB. It VB voltage is small. There are different diacs with VB voltage ranging from 10V to 15V. The diac characteristic is as follows: I VB VB V Figure 2-5 When the voltage on the diac passes the VB voltage, the diac breaks-over and behaves as a conducting diode. This behavior is similar in both directions. Adding a diac to the triac gate increases substantially the ignition voltage of the triac and thus enables a much better power control in high voltages. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 18 A practical dimmer circuit is the following one: L1 100H ~ C1 0.1 R1 3.3K R2 250K C2 0.1 R3 R4 15K 100 C3 0.1 Figure 2-6 A coal potentiometer is not designated for high voltages. When the potentiometer is set to a very low resistance (almost a short circuit), a relatively high current flows, which causes the potentiometer burning. Resistor R1 aimed to prevent this low resistance state. The main problem in the dimmer circuit (described in figure 2-6) is the current jump at each ignition. The current rises at once and creates electromagnetic waves radiation. To cause a gradual increase of the current, a filter (comprises of L1 coil and C1 capacitor) is connected. The coil is called a Chock. Remember that the coil should withstand the current passing through the consumer. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 19 Preparation questions: 1. What is the purpose of the potentiometer in the following circuit? A B VAC ~ 47K Triac G 0.1 (a) (b) (c) (d) 2. To control the triggering voltage. To control the triggering voltage and phase. To control the phase of the triggering voltage. To control the lamp voltage. What happens to the gate voltage when the triac is ignited? (a) (b) (c) (d) It goes down. It goes up. It does not change. It goes up and down. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 20 3. What is the purpose of the diac in the following circuit? A B VAC ~ 47K Triac G 0.1 (a) (b) (c) (d) Diac To slow the ignition. To decrease the triggering voltage level. To increase the triggering voltage level. To make the ignition faster. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 21 Procedure: Step 1: Connect the EB-3100 to the power supply. Step 2: Connect the power supply to the Mains. Step 3: Turn ON the trainer. The DVM screen should appear on the display. Step 4: Plug the EB-3127 into the EB-3100. Step 5: Observe the display and check that the experiment board name appear and no fault is detected. Step 6: Implement the following circuit in B3: A B VAC ~ 47K Triac G 0.1 Step 7: Change the potentiometer to minimum. Step 8: Connect the scope probe CH1 to point A. Step 9: Connect the scope probe CH2 to point B. Step 10: Compare the two signals VA and VB. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 22 Step 11: Change the potentiometer until the lamp turns ON. Step 12: Draw these two signals one below the other. Step 13: Move the scope probe CH2 the point G. Step 14: Add the gate voltage signal below the two drawn signals. Step 15: Move the potentiometer to the center. Step 16: Draw again the three signals VA, VB, and VG one below the other. Step 17: Move the potentiometer to the maximum. Step 18: Draw again the three signals VA, VB, and VG one below the other. Step 19: What is the signal maximum power (in percentage) that can be achieved in this circuit? Step 20: Implement the following circuit in B3: A B VAC ~ 47K Triac G 0.1 Diac Step 21: Change the potentiometer to minimum. Step 22: Connect the scope probe CH1 to point A. Step 23: Connect the scope probe CH2 to point B. Step 24: Compare the two signals VA and VB. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 23 Step 25: Change the potentiometer until the lamp turns ON. Step 26: Draw these two signals one below the other. Step 27: Move the scope probe CH2 the point G. Step 28: Add the gate voltage signal below the two drawn signals. Step 29: Move the potentiometer to the center. Step 30: Draw again the three signals VA, VB, and VG one below the other. Step 32: Move the potentiometer to the maximum. Step 32: Draw again the three signals VA, VB, and VG one below the other. Step 33: What is the signal maximum power (in percentage) that can be achieved in this circuit? EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 24 Summary questions: 1. What is the shape of the VA voltage in the following circuit? A B VAC ~ 47K Triac G 0.1 (a) (b) (c) (d) EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 25 2. How the diac affects the power control in the following circuit? A B VAC ~ 47K Triac G 0.1 (a) (b) (c) (d) Diac Te control range is shortened. The control range is expanded. It does not affect the power control. It makes the power control more stable. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 26 Experiment 3 – Programmed Uni Transistor Objectives: Introducing the PUT (Programmed Uni Transistor). PUT circuits. Igniting and extinguishment of the PUT. Equipment Required: EB-3100 EB-3127 Banana wires Discussion: The PUT is very similar to the SCR with one distinction – its gate location. The component's structure, its symbol and its equal circuit is described in the following drawing: A A Q1 G Q2 P N P N K A G G K K Figure 3-1 The difference between the PUT and the SCR is in its ignition method. Supplying a pulse at its gate will not ignite the PUT. Here the gate is used to determine the VB voltage which ignites the component. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 27 The PUT is used for pulses output. The following circuit is a typical one. V V R1 R2 A R1 R2 A G C K Vo G Equivalent Circuit C R3 R3 R4 K Vo R4 Figure 3-2 The voltage divider (comprised from R2 and R3) determines the gate voltage (Vo). The anode voltage equals the loaded capacitor C voltage and its voltage increases according to the time constant R1 C . When VA is approximately larger by 0.5V from VG, the PUT breaks-over. A regenerative feedback is created and the PUT voltage drops instantly while unloading the capacitor. A high voltage pulse appears on R4. The capacitor unloading causes a drop at the anode voltage until the PUT is shutdown and the process repeat itself. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 28 At the output voltage Vo we get pulses, which their cycle time is a function of the time constant R1 C . VA t Vo t Figure 3-3 While the PUT is ignited, the VG voltage drops a little above the Vo. This enables the unloading of the capacitor; otherwise the unloading will be very small. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 29 Preparation questions: 1. Before PUT is ignited, what is the value of the PUT anode voltage VA? 12V 91K 1K C5 A G 10n C6 1n (a) (b) (c) (d) 2. K Vo 100 10K It equals the source voltage 12V. It follows the capacitor voltage. 0V 10.9V Before PUT is ignited, what is the value of the PUT kathode voltage VK? 12V 91K 1K C5 A G 10n C6 1n (a) (b) (c) (d) K Vo 100 10K It equals the source voltage 12V. It follows the capacitor voltage. 0V 10.9V EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 30 3. Before PUT is ignited, what is the value of the PUT gate voltage VG? 12V 91K 1K C5 A G 10n C6 1n (a) (b) (c) (d) K Vo 100 10K It equals the source voltage 12V. It follows the capacitor voltage. 0V 10.9V EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 31 Procedure: Step 1: Connect the EB-3100 to the power supply. Step 2: Connect the power supply to the Mains. Step 3: Turn ON the trainer. The DVM screen should appear on the display. Step 4: Plug the EB-3127 into the EB-3100. Step 5: Observe the display and check that the experiment board name appear and no fault is detected. Step 6: Implement the following circuit in B5: 12V 91K 1K C5 A G 10n C6 1n K Vo 100 Step 7: Connect the scope probe CH1 to point A. Step 8: Draw the signal received on the screen. Step 9: Connect the scope probe CH2 to point Vo. 10K Step 10: Draw the received signal below the signal received at point A. Step 11: Move the scope probe CH2 to point G. Step 12: Draw the received signal below the above signals. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 32 Summary questions: 1. What is the shape of the VG in the following circuit? 12V 91K 1K C5 A G 10n C6 1n K Vo 100 10K (a) (b) (c) (d) Constant and equal to 10.9V. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 33 2. What is the shape of the VA in the following circuit? 12V 91K 1K C5 A G 10n C6 1n K Vo 100 10K (a) (b) (c) (d) Constant and equal to 10.9V. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 34 3. What is the shape of the VK in the following circuit? 12V 91K 1K C5 A G 10n C6 1n K Vo 100 10K (a) (b) (c) (d) Constant and equal to 10.9V. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 35 Experiment 4 – Troubleshooting Objectives: Troubleshooting faults in an electrical circuit. Equipment required: EB-3100 EB-3121 Banana wires Discussion: The EB-3100 includes 10 relays for fault insertion or for switching external components. The fault screen is selected by the Options/Graph key. FAULTS Please choose Fault No.: 0–9 Activated fault Number: 0 Num Lock Typing a fault number and pressing ENTER operates the required relay for the required fault. Fault No. 0 means No Fault. Which relay creates the required fault is registered in the plug-in experiment board controller. On entering a fault number, the system addresses the experiment board controller and asks for the relay number. After that, it executes the required fault. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 36 The experiment board controller saves the last registered fault number in its memory. This memory is non-volatile. This is why the system does not allow us to enter a fault number when no experiment board is plugged. When an experiment board that a certain fault (other than zero) is registered in its memory is plugged into the system, a warning message appears on the system's screen. This feature enables the teacher to supply the students various experiment boards with planted faults for troubleshooting. Note: It is recommended (unless it is otherwise required), to return the experiment board fault number to zero before unplugging it. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 37 Procedure: Step 1: Connect the EB-3100 to the power supply. Step 2: Connect the power supply to the Mains. Step 3: Turn ON the trainer. The DVM screen should appear on the display. Step 4: Plug the EB-3127 into the EB-3100. Fault No. 1: Step 5: Use the B1 and B3 components and implement the following circuit. A B VAC ~ A 47K Triac G A 0.1 Step 6: Enter fault no. 1. What is the fault? (a) (b) (c) (d) Gate G is disconnected. The low anode is disconnected from GND. The high anode is disconnected from the lamp. There is no voltage source. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 38 Fault No. 2: Step 7: Use the B1 and B2 components and implement the following circuit. 12V Step 8: Enter fault no. 2. What is the fault? (a) (b) (c) (d) The lamp is disconnected. The SCR gate is disconnected. The SCR kathode is disconnected. There is no voltage source. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 39 Fault No. 3: Step 9: Use the B1 and B3 components and implement the following circuit. A B VAC ~ A 47K Triac G A 0.1 Step 10: Enter fault no. 3. What is the fault? (a) (b) (c) (d) Gate G is disconnected. The low anode is disconnected from GND. The high anode is disconnected from the lamp. There is no voltage source. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 40 Fault No. 4: Step 11: Use the B1 and B3 components and implement the following circuit. A B VAC ~ A 47K Triac G A 0.1 Step 12: Enter fault no. 4. What is the fault? (a) (b) (c) (d) Gate G is disconnected. The low anode is disconnected from GND. The high anode is disconnected from the lamp. There is no voltage source. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 41 Fault No. 5: Step 13: Implement the following circuit using the B1 and B3 components. A B VAC ~ A 47K Triac G 0.1 A Diac Step 14: Enter fault no. 5. What is the fault? (a) (b) (c) (d) The potentiometer is disconnected. The anode connected to GND is disconnected. The lamp is disconnected. There is no voltage source. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 42 Fault No. 6: Step 15: Implement the following circuit using the B1 and B3 components. A B VAC ~ A 47K Triac G 0.1 A Diac Step 16: Enter fault no. 6. What is the fault? (a) (b) (c) (d) The potentiometer is disconnected. The anode connected to GND is disconnected. The lamp is disconnected. There is no voltage source. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 43 Fault No. 7: Step 17: Implement the following circuit using the B1 and B3 components. A B VAC ~ A 47K Triac G 0.1 A Diac Step 18: Enter fault no. 7. What is the fault? (a) (b) (c) (d) The potentiometer is disconnected. The anode connected to GND is disconnected. The lamp is disconnected. There is no voltage source. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT 44 Fault No. 8: Step 19: Use the B5 components and implement the following circuit. 12V 91K 1K C5 A G 10n C6 1n K Vo 100 10K Step 20: Enter fault no. 8. What is the fault? (a) (b) (c) (d) R4 is disconnected. R5 is disconnected. R3 is disconnected. There is no voltage source. EB-3127 – Industrial Semiconductors – SCR, Triac, Diac and PUT