* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download CPCCBC5004A - Builders Academy Australia

Survey

Document related concepts

Building regulations in the United Kingdom wikipedia , lookup

Sustainable landscaping wikipedia , lookup

Architecture of Madagascar wikipedia , lookup

Building insulation materials wikipedia , lookup

Green building wikipedia , lookup

Bush carpentry wikipedia , lookup

Earthbag construction wikipedia , lookup

Sustainable architecture wikipedia , lookup

Ultra-high-temperature ceramics wikipedia , lookup

Composite material wikipedia , lookup

Ceramic engineering wikipedia , lookup

Transcript

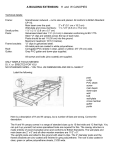

Identify and describe the properties of building materials. Ensure suitable building materials are selected for application. Supervise the acceptance, safe handling and storage of materials on site. Supervise testing of materials on site for suitability and fitness for purpose. Establish records of materials testing and report on testing process conformance or otherwise. The way in which buildings are built and constructed are governed by the National Construction Codes of Australia (NCC). The NCC applies to all states and territories through their own building control laws. The NCC is produced and maintained by the Australian Building Codes Board (ABCB) on behalf of the Australian Government and each state and territory government For society to function effectively it must have a way to mediate the relationships between people and private and public organisations. This is achieved by enacting laws that address contracts, criminal activity, property and many other aspects of society. Acts Regulations Codes of Practice Standards (Australian) Most Australian houses consist of similar materials. Builders will choose materials after taking into account: Location; Climate; Building codes and standards; Architectural requirements; Client’s needs. Typical construction materials include concrete, metals, masonry, timber, fibrocement, glass, insulation, plaster, plastics, ceramics, and paints. Concrete Concrete is a composite building material made from a combination of aggregate and a binder such as cement. Metals Metals are used as structural framework for larger buildings such as skyscrapers, or as an external surface covering. Copper Copper has been used for hundreds of years. It is light brown in colour and can very flexible in its nature. It is extremely resistant to corrosion and, when exposed, it forms a protective coating which is light in colour. Glass Glass is used to cover openings in a building and they provide the ability to both let light into rooms while at the same time keeping inclement weather outside. Masonry Masonry such as clay brickwork is made from selected clays that are moulded or cut into shape and fired in ovens. Timber Lightweight timber construction has a long history in Australia where it is the most common house construction type Insulation Insulation acts as a barrier to heat flow and is essential to keep your home warm in winter and cool in summer. A well insulated and well designed home will provide year round comfort, cutting cooling and heating bills by half. Ceramics Ceramic is a non-metallic inorganic solid. It is prepared by the action of heat and consecutive cooling. They can have crystalline structures or be amorphous like glass. Plasterboard Plasterboard is also referred to as dry wall or wallboard. It is hydrated gypsum sandwiched between two layers of paper Properties of materials Certain materials are designed to have specific properties. For example, a material may be designed to have very high compressive strength, such as an engineering brick. All materials have certain qualities and characteristics that can be defined and tested. Strength This is the ability of a material to stand up to forces being applied without it bending, breaking, shattering or deforming in any way. Elasticity This is the ability of a material to absorb force and flex in different directions, returning to its original position. Plasticity This is the ability of a material to change in shape permanently. Ductility This is the ability of material to change shape (deform), usually by stretching along its length. Tensile strength This is the ability of a material to stretch without breaking or snapping. Malleability This is the ability of a material to be reshaped in all directions without cracking. Toughness This is a characteristic of a material that does not break or shatter when receiving a blow or under a sudden shock. Hardness This is the ability of a material to resist scratching, wear and tear and indentation. The construction industry generates a large percentage of the waste that ends up in our landfills. The different types of construction and building waste consists of: concrete-based masonry timber bricks plasterboard plastics rubber paint cement glass steel. Minimise your impact There are several ways to minimise your impact on the environment with your selection of materials. Avoid over-estimating when ordering materials. Specify and document exact requirements. Store materials sensibly to avoid damage. Have a recycling plan in place for incoming materials (e.g. packaging). Suggest and purchase environmentally approved materials. Minimise your impact Be informed and educated about waste reduction. Build to standard sizing. Make efficient use of the materials on hand. Minimise energy consumption by considering means and frequency of transportation. Material lifecycle Every material has a life of its own. Each material will start in a raw form, get processed and then be made into a finished product. At the end of its lifecycle it is disposed of. In the case of construction, it will most likely end up in landfill Determining the tolerances of materials Tolerance in materials is specifications that define the allowed variation for the form and the size of each material. Tolerance also allows variation in orientation and location between the material features. All materials have tolerances and each is subject to variation therefore the limits of variation must be specified. It is important to check the tolerance against the nature of work being performed. Australian Standards Many Australian Standards will give specifications on what is expected of a finished product. In addition to the standards, many building designers will produce a set of specifications that will spell out the requirements of a finished product. Finishing levels Many building contracts specify a finishing level for a material or product that is applied or installed in the building. Level 0 – temporary construction, undefined decoration. Sheets are nailed, glued or screwed in place. Level 1 – areas out of public view (concealed). Tool marks and ridges are acceptable in this finish. Level 2 – areas that don’t have appearance as their primary concern, e.g. garages and warehouses. Some minor tool marks and edges are sometimes visible. Level 3 – for areas that are to receive texture or heavy wall covering like paper. Level 4 – most commercial or domestic constructions are of a level 4 (using flat paints). Area will be illuminated with lighting. Free of marks and edges. Level 5 – for critical lighting/gloss paints Guide to Standards and Tolerances 2007 The purpose of the Guide is to set out in a single document both the regulated standards and a reasonable guide to standards in respect of nonregulated aspects of domestic building construction. The scope of the Guide The Guide is based on experience gained in facilitating the resolution of many domestic building disputes. It covers issues that are often of concern to building owners and builders. Material selection is based on safety, fire resistance, durability, serviceability, cost effectiveness, and compliance with Australian standards. As a builder or supervisor you will need certain key information about products that will assist you with the materials’ application, storage requirements, handling requirements, and ingredients. Clay Brick The high compressive strength of fired clay bricks have been exploited for millennia to build structures ranging from single storey houses to massive public buildings and enormous bridges. Fire Resistance Build-ability, Availability and Cost Durability and Moisture Resistance Toxicity and Breathability Environmental Impacts Fire Aspects of Building Materials The NCC specifies the following three aspects of fire resistant construction: Structural adequacy – the ability to maintain stability and adequate load bearing capacity. Integrity – the ability to resist the passage of flames and hot gasses specified in AS 1530.4. Insulation – the ability to maintain a temperature on the surface not exposed to the furnace below the limits specified in AS 1530.4. Safe and effective acceptance, handling and storage of building materials involves: Determining the effects (if any), of transportation on the materials upon receipt/delivery of the materials on-site Safely and correctly handling materials Storing the materials appropriately and protecting the materials using established storage/protection methods Inspecting the materials for defects before installation and taking appropriate action. Occupational Health & Safety on site (WHS?) Keep the working area clean and orderly to make movement of materials safer and easier; Observe all safety rules and regulations. The occupational health and safety regulations will support the safe and healthy handling of materials; There is maintenance involved on plant and equipment, ensure this is performed regularly in order to provide safe handling of materials; Report any safety hazards immediately, and correct them yourself if you are qualified to do so; Store materials and equipment properly; Deliveries. Storage of Materials Never store building materials in front of doorways or emergency exits. Storing materials in these areas creates trip hazards and can put lives at risk in the event of a fire or when people need to evacuate quickly Materials should be stored in areas close to the work area without interfering with the movement of vehicles, pedestrians and other traffic. Do not stack large quantities of bricks or timber on elevated work platforms such as scaffolding. Scaffolding is only designed as a workstation; not a storage area. The minimum amount of material to do the job at hand is all that should be stacked on the scaffold. Building materials should never be stacked on roadways, public verges, footpaths, next to fire hydrants, or on access roads. Store materials within the confines of the building site and in the conditions recommended for the type of material. Materials on Pallets Large amounts of materials are often moved on pallets using hand trolleys or forklifts. When stacking materials on pallets some very basic but important safe working practices apply. Bricks/Concrete Blocks As with timber products, bricks and concrete blocks are delivered in tightly strapped packs to building sites. This is to prevent movement and damage. Plasterboard Plasterboard is easily damaged. Moisture or water contact with the paper covering soaks through into the plaster, causing the sheeting to swell and weaken. Transportation of Building Materials The transportation of building materials is extremely important. The main concerns are: The possible damaging of building materials whilst in transport; How the materials are transported in the manufacturing process; How the materials are transported to the construction site. Some guidelines to consider when choosing materials include: Design for long life and adaptability, using durable low maintenance materials. Avoid building a bigger house than you need. This will save materials. Modify or refurbish instead of demolishing or adding. Ensure materials from demolition of existing buildings and construction wastes are reused or recycled. Use locally sourced materials (including materials salvaged on site) to reduce transport. Avoid wasteful material use. Select materials that can be re-used or recycled easily at the end of their lives using existing recycling systems. Ordering Materials There are numerous factors to consider when ordering materials including: Sourcing suppliers; Price; Quality of materials; Quality of service; Delivery times,. Points to consider when inspecting timber: Size Grade and Grading Method Moisture Content Species Treated Timber Why Test ? To achieve certification by complying with current guidelines and building regulations To ensure products are fit for purpose To find out why products are failing in use or during manufacture To develop new materials and new products through certification To solve patent disputes or resolve legal disputes To benchmark against competitors’ products. Why Test ? To achieve certification by complying with current guidelines and building regulations To ensure products are fit for purpose To find out why products are failing in use or during manufacture To develop new materials and new products through certification To solve patent disputes or resolve legal disputes To benchmark against competitors’ products. Test Available Tension: used to determine the tensile strength of various materials like metals and plastics. Compression: to determine the strength of metals like concrete by applying a range of compression forces to the materials. Flex: to determine the flexure of materials, e.g. plastics, by applying various bending forces. Impact: to determine the impact performance (heavy loads) of materials. Torsion: to test materials for bending and twists in materials. Chemical testing: used to test the properties of concrete, mortar, plaster and soil. Structural: on-site testing for concrete floors, posts, bridges, steel columns for load and, surface slip and skid, etc. Building Product Accreditation Building Product Accreditation is a system that allows a designer of an innovative product (which passes the relevant tests, procedures etc.) to apply for a Certificate of Accreditation by the Building Regulations Advisory Committee (BRAC). Testing – Concrete One of the materials that can be tested on-site is concrete. There are two separate tests performed on concrete. Slump test – shows the workability of concrete (how easy it is to use and place). Compression test – measures the strength of concrete when it is hardened. Testing – Timber In general, there are two main factors that influence the durability of timber in service. The first is the natural durability of the particular species. The second is the type and degree of hazard to which the timber is exposed. The natural durability of particular species is expressed as one of four Durability Classes. Class 1: Timbers of the highest natural durability. Class 2: Timbers of high natural durability. Class 3: Timbers of only moderate durability . Class 4: Timbers of low durability. Defects In accordance with the Domestic Building Contract Act, defective work is work that does not comply with the building warranty or fails to maintain the contract standard. Defect liability items must be obtained from the clients and defects must be rectified before client sign-off can be obtained Establish Records of Material Testing Communication with regulatory authorities and other stakeholders and to make sure of conformity with the relevant legislative, organisational and contractual requirements Maintenance of environmental controls and obligations Allocation and management of human resources Communication associated with facilitating dispute prevention and resolution Dispersal and scheduling of plant and equipment Participation in on-site meetings Management of expenditures Establish Records of Material Testing Site Diary Site reports Industry manuals Quality control procedures Complete site inspection checklists Structure of Quality Management Systems To achieve these purposes, quality systems consist of three fundamental and simple elements: Documents that describe what is done in the organisation to identify and achieve the Customers' requirements. An audit trail so that it is possible to see the system working as described in the documents. Records to prove that it has been working according to plan. Basic Quality Assurance Quality Plan/Quality Manual Inspection & Test Plan Non Conformance Report Quality Audits Test points / Hold points Non-conformance The cost of non-conformance is extremely hard to quantify. It has been said that on average, for ever customer complaint, there are 3 other customers who do not complain Complete project administration processes Finalisation processes Practical completion inspection Results of the inspection Hand-over procedures Certification requirements