* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download PDF

Wireless power transfer wikipedia , lookup

Alternating current wikipedia , lookup

Electrification wikipedia , lookup

Grid energy storage wikipedia , lookup

Voltage optimisation wikipedia , lookup

Power engineering wikipedia , lookup

Resonant inductive coupling wikipedia , lookup

Life-cycle greenhouse-gas emissions of energy sources wikipedia , lookup

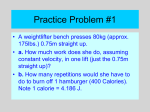

TECHNICAL REPORTS Energy Saving Technologies for Elevators Authors: Junichiro Ishikawa*, Hirokazu Banno* and Sakurako Yamashita* 1. Introduction In recent years, interest in energy saving has been increasing both in Japan and overseas, as well as in creating a low-carbon society. In the building industry too, there are moves to standardize methods for evaluating energy saving performance, mandate the reporting of energy saving performance, and also require the installation of facilities for improving energy saving performance. Amid this changing environment, there is growing competition to develop new devices and technologies in many fields related to energy saving. In the manufacture and development of elevators, energy saving performance has always been important, and new models have offered improved performance. Because the energy consumed by an elevator varies greatly according to its specifications and type of use, it is difficult to evaluate performance using a standard pattern. This paper summarizes the trends in energy saving technology for elevators and the power consumption characteristics of elevators that use this technology. It also describes the energy saving technology used in the standard “AXIEZ” elevator, which underwent a model change in June 2011, together with its effectiveness. 2. Transition of Energy Saving Technology The following table 1 shows the transition of drive control methods used in traction elevators and the energy consumed by them. Regarding high-speed elevators that travel at 120 m per minute or faster, in the latter half of the 1970s, the MG set was changed to the thyristor Leonard method, and the control circuit was replaced by a microprocessor. As a result of this switch to electronics, the control performance was greatly improved, and an energy saving of about 40% was attained. For a low-speed elevator that travels at no more than 105 m per minute, an induction motor fitted with a reduction gear was used. This type of elevator was widely used as the standard type of elevator in mediumto low-rise buildings. During the early 1970s, a thyristor was used to control the primary voltage applied to the induction motor, which enabled the speed of the elevator to be controlled more or less continuously. As a result, riding comfort was significantly improved, and the motor efficiency during acceleration and deceleration was increased. These improvements, together with the incorporation of a microprocessor in the control circuit, resulted in a 20% increase in efficiency compared to the conventional model. Subsequently, power transistors with excellent control characteristics appeared on the market, and great progress was made in the technology for a variable voltage variable frequency (VVVF) control method using these transistors, in other words, an inverter control method. Table 1 Transition of drive control method and energy consumption High-speed elevator Model Decade Ward-Leonard Control circuit Relay circuit Hoisting General device Ultra(motor) high- Energy consumption Gearless (DC motor) AC 2-step speed control 2010 2000 VVVF (inverter) Microprocessor Gearless (DC motor) 100% 1990 Thyristor Leonard speed Control circuit Low-speed elevator 1980 Motor control method Motor control method 95 72 %% Helical gear type (induction motor) Slim-type centrally wound construction Gearless Gearless (induction motor) 62% (permanent magnet-type synchronous motor) 57% Primary voltage control 54% 52% VVVF (inverter) Relay circuit Microprocessor Gearless Hoisting device (motor) Worm gear type (induction motor) Machine room Machine room exists Energy consumption *Inazawa Works 1970 Helical gear Gearless (permanent magnet-type (permanent synchronous motor) type magnet-type Slim-type centrally wound synchro(induction motor) nous motor) construction 100% 93% 74% 37% Machine room does not exist 32% 30% 29% 6 TECHNICAL REPORTS 3. Component Devices of an Elevator, and Energy Consumption Figure 1 shows the construction of an elevator. Figure 2 shows power waveform of a hoisting device motor. Among the various devices, the one that consumes the greatest amount of power instantaneously is the hoisting motor which raises and lowers the weight that balances against the weight of the car. Next is the electromagnetic brake that prevents the hoisting device from rotating, followed by the door motor that opens and closes the car doors. Because these devices are used only while the elevator is moving, they do not consume much energy Speed regulator Machine room Hoisting device Control panel Rope Upper car station Door motor Car Car door Balance weight Entrance button Entrance door Entrance Hoistway Rotational speed (%) Fig. 1 Construction of an elevator Ascending Descending Time Power consumption (%) Mitsubishi was the first company in the world to develop an elevator inverter, and in 1983, succeeded in making a commercially viable high-speed elevator. Inverter control is not only efficient, but also has characteristics which improve the power factor of the power source. As a result, it was possible to increase the efficiency by around 10% and also reduce the capacity of the power source facilities in the building by about 20%. In addition, the excellent control performance of this system permitted fine control of even induction motors, thus ensuring excellent riding comfort and highly efficient acceleration and deceleration. Particularly, in the case of a low-speed elevator, it was possible to increase the efficiency by a dramatic 50% compared to the conventional primary voltage control method. In 1990, a helical gear-type hoisting device was commercialized to replace the existing less-efficient worm gear hoisting device, thus improving transmission efficiency and riding comfort. Around the mid 1990s, a gearless hoisting device incorporating a permanent magnet synchronous motor (hereafter called a “PM gearless hoisting device”) was commercialized for high-speed (at least 120 m/min) and ultra-high-speed (at least 300 m/min) elevators. The use of permanent magnets led to a multi-polar compact motor, which was more efficient than an induction motor. In 1998, Mitsubishi released an elevator that does not require a machine room. In order to house the hoisting device and the control panel for this elevator inside the hoistway, a very quiet PM gearless hoisting device was adopted for low-speed elevators. To make the control panel slimmer, the drive section and power supply section were closely integrated. Also, a switching power supply was used as the control power supply to ensure a stable power supply voltage and reduce the conversion loss, thus reducing the power consumption. In 2001, Mitsubishi developed a slim-type PM gearless hoisting device which required even less space and allowed flexibility of layout, resulting in the rapid spread of machine room-less elevators. The motor diameter was increased, its thickness reduced, and a centralized winding construction was employed, significantly reducing copper loss and thus saving energy. At present, the PM gearless hoisting device is the main kind of hoisting device used throughout the entire range from ultra-high speed to high speed. Along with the increasing demand for energy saving, slim hoisting devices using a centralized winding construction are employed for high-speed elevators as well, resulting in energy saving. In this way, advances in motor drive technology over the past several decades have led to good riding comfort and space saving in elevators, and have also saved energy. Power running 100% load 50% load 0% load 0% load 50% load 100% load Regeneration Time Fig. 2 Power waveform of a hoisting device motor Mitsubishi Electric ADVANCE December 2013 7 TECHNICAL REPORTS Energy consumption Percentage of energy consumed (%) Total energy consumption Percentage occupied by control devices Percentage occupied by lighting Percentage occupied by the hoisting device motor * The elevator starting intervals are equal for each starting frequency. Low Starting frequency High Fig. 3 Relationship between the starting frequency of an elevator and the energy consumed while the elevator is moving short distances. Figure 3 shows the relationship between the starting frequency of an elevator and the energy consumed by the devices. Many low-speed elevators are used at low starting frequency. Under this condition, the absolute power consumption is small, but the percentage of the total electrical energy that is consumed continuously by the control devices is large. The lighting remains lit while the elevator is moving and also for a fixed period after it has stopped, so it is lit continuously when the starting frequency is low. Consequently, in the region where the starting frequency is low, the percentage of the total energy consumption is large. The percentage in the case of a hoisting device motor is high in the region where the starting frequency is high. As shown, the device that affects the total energy consumption changes according to the starting frequency. In addition, apart from the starting frequency, the energy consumption also changes according to the specifications of the devices and the car occupancy. These conditions differ greatly from one building to another, and change over time, so it is difficult to evaluate the energy saving performance of elevators in different buildings by using a specific representative pattern. Also, in order to effectively reduce the energy consumption under a variety of conditions, it is necessary to combine multiple methods according to each starting frequency. Conventionally, incandescent lamps or fluorescent lamps have been used to illuminate the elevator car, but the life of such lighting appliances depends greatly upon the number of times that they are switched on. For this reason, the lighting is kept on for a fixed period after the elevator stops, thus reducing the number of times that it can be switched on and extending its life. But with this method, the lighting is actually on for longer than necessary, so there is a limit to the energy saving effect of the automatic switch-off function. Recently, LED light sources have become cheaper and increasingly popular. One of their main features is that their life is determined mainly by the time during which they are on rather than by the number of times that they are switched on. All standard “AXIEZ” elevators use LED lighting in the ceiling of the car as the main kind of lighting. As a result, the electric power consumed by the LED ceiling lights is about half of that consumed by conventional fluorescent ceiling lights, and about 1/8 of that consumed by incandescent lights. Also, by reducing the time delay until the lamps are automatically turned off, the necessary standby power is reduced. In addition, the life of an LED light is about 3.3 times that of a fluorescent light, and about 26 times that of an incandescent light, thus reducing the lamp replacement frequency. By increasing the life of the lighting appliances and reducing the energy consumed by them, the life cycle cost and environmental impact are reduced. 4. “AXIEZ” Energy Saving Technology 4.2 Technology for utilizing energy regeneration 4.1 LED lighting As mentioned above, the power consumed by the lighting of an elevator car is reduced by a function that automatically switches off the lighting after the elevator car stops. Consequently, the lighting in an elevator car is switched on much more frequently than general lighting. 4.2.1 Regenerative converter system An elevator is suspended by a cable to which a weight is attached that balances against the weight of the car. By driving this cable with a motor, the elevator moves up or down. The balance weight is balanced against the car when the car is occupied by about half 8 TECHNICAL REPORTS of the rated number of passengers. If this weight balance is upset, the motor will be pulled to the heavier side. As a result, when the heavier side is raised, potential energy will be accumulated. Conversely, if the balance weight moves to the side that is pulled, the motor can be used as an electric generator, and the potential energy can be recovered as regenerative energy. In this way, the elevator is designed to capture a large amount of regenerative energy from potential energy in addition to kinetic energy. High-speed elevators have always made effective use of regenerative energy by using a regenerative converter. As shown in Fig. 4, the electrical circuit of the elevator is designed such that regenerative power returned from the motor is connected directly to the power source system of the building via a regenerative converter. This enables the regenerative power to be reused efficiently. Most low-speed elevators are installed in small buildings, so it is usually not possible to acquire facilities that can adequately consume regenerative electric power, and also there are size and cost limitations, so generally, the regenerative electric power is consumed by a resistor. However, in a medium- to large-scale building, there is currently no solution to this problem, even if there are adequate facilities. To overcome this issue, the regenerative converter of the “AXIEZ” elevator, which does not have a machine room, has been made sufficiently small that it can be installed in the hoistway. It is hoped that in the future, this technology will help save energy in low-speed elevators. 4.2.2 Regenerative electric power storage system As mentioned above, a regenerative converter often cannot be used in a small building. The ELE SAVE, Converter which Mitsubishi released in 2001, incorporates a nickel-hydrogen battery which provides enough power to operate the elevator for 10 minutes in the event of a power outage. The battery stores the regenerative electric power, and reuses it while the elevator is running, thus realizing an energy saving of about 20%. This system enables regenerative electric power to be used in small buildings as well. As a result of recent competition to develop electrical storage devices for power applications, the energy density, output density, repeated charging/discharging durability, and charging/discharging efficiency have improved. Among these storage devices, an electrical 2-layer capacitor has excellent repeated charging/discharge durability and high charging/discharging efficiency, and is environment-friendly. The ELE CHARGE regenerative storage system which Mitsubishi has commercialized uses an electrical 2-layer capacitor as the storage device. Although such a capacitor has the abovementioned merits, in order to incorporate it into an elevator, it was necessary to take countermeasures against deterioration caused by energizing the capacitor at high temperature, and also to design a circuit configuration and control method that made the most of the merits of the capacitor. To resolve these issues, the circuit of the ELE CHARGE was optimized and technology for monitoring the capacitor temperature and voltage was newly developed, thus at least doubling the replacement interval compared with a secondary battery, and also achieving an energy saving effect of about 25% (Fig. 5). 4.3 Energy saving effect A simulation evaluation of the energy consumed by the energy saving technologies mentioned so far was carried out. The results are shown in Tables 2 and 3. Capacitor Inverter PM Velocity feedback Inverter control circuit Car Rotor angle feedback Converter control circuit Gate drive circuit Current feedback Phase detection circuit Gate drive circuit Voltage feedback 3-phase AC power supply Current detector Permanent magnet motor Encoder Balance weight Line filter Current feedback PS: CT: PM: RE: RE CT AC reactor CT PS Controller Fig. 4 Drive system for an elevator with a regenerative converter Mitsubishi Electric ADVANCE December 2013 9 TECHNICAL REPORTS Converter Inverter Capacitor RE CT Line filter PM 3-phase AC power supply Current detector Permanent magnet motor Encoder Gate drive circuit Converter control circuit Inverter control circuit Car Velocity feedback PS: CT: PM: RE: Converter Rotor angle feedback Electrical 2-layer capacitor Current feedback Balance weight PS Controller Fig. 5 Regenerative electric power storage system The simulation was carried out under the operation conditions in chronological order, based on the measurement data of the traffic pattern. Table 2 shows the energy consumption improvement of the “AXIEZ” compared to the conventional model. By adopting energy saving technologies such as LED lighting, the energy consumption can be reduced by up to 20% compared to that of the conventional model. Also, by using LEDs for lighting, which accounts for a large proportion of the energy consumed, automatic switching-off of the lights can be optimized. Particularly, in a building where the operation frequency is low, a large energy saving effect will be obtained. Table 3 shows the energy consumption improvement which depends upon whether or not the regenerative converter system and/or the regenerative power storage system are used. Compared to when the regenerative converter system is not used, the energy consumption is reduced by up to 35%, and also compared to when the regenerative power storage system is not used, the energy consumption is reduced by up to 25%. Also, with both systems, the improvement of energy consumption tends to increase as the number of passengers and also the operation frequency increase. As mentioned above, the “AXIEZ” delivers excellent energy saving performance over a wide range of specifications and applications due to the use of LED lighting and technology for utilizing regeneration. 5. Conclusion This paper summarized the transition of energy saving technology for elevators and the power consumption characteristics of elevators that use this technology. It also described the new technology used in the new “AXIEZ,” and its effectiveness. Table 2 Improvement of energy consumption of AXIEZ Application Floor Residence: 9-person elevator 5th floor 9th floor 5th floor 10th floor 5th floor 10th floor Office: 11-person elevator Office: 15-person elevator Energy consumption improvement 20% 18% 17% 13% 13% 11% Table 3 Improvement of energy consumption due to technology for utilizing regeneration Application Floor Residence: 5th floor 9-person 9th floor elevator Office: 5th floor 11-person 10th floor elevator Office: 5th floor 15-person 10th floor elevator Regenerative Regenerative electric converter system power storage system improvement improvement 5% 2% 14% 10% 19% 12% 30% 21% 30% 25% 35% 20% In the future, the authors will work on promoting technologies for utilizing regeneration, and also reducing additional energy consumption caused by each device, in order to help prevent global warming. 6. Reference IKEJIMA Hiroyuki, ARAKI Hiroshi, SUGA Ikuro, TOMINAGA Shinji: Mitsubishi Energy Saving-type ELE SAVE Automatic Backup Device for Operating an Elevator in the Event of a Power Failure, Mitsubishi Giho, 75, No. 12, 782−785 (2001) 10