* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

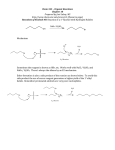

Download Protection (and Deprotection) of Functional Groups in Organic

Survey

Document related concepts

George S. Hammond wikipedia , lookup

Fischer–Tropsch process wikipedia , lookup

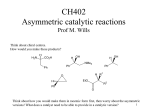

Enantioselective synthesis wikipedia , lookup

Kinetic resolution wikipedia , lookup

Discodermolide wikipedia , lookup

Asymmetric induction wikipedia , lookup

Physical organic chemistry wikipedia , lookup

Ene reaction wikipedia , lookup

Stille reaction wikipedia , lookup

Elias James Corey wikipedia , lookup

Hofmann–Löffler reaction wikipedia , lookup

Baylis–Hillman reaction wikipedia , lookup

Wolff–Kishner reduction wikipedia , lookup

Ring-closing metathesis wikipedia , lookup

Nucleophilic acyl substitution wikipedia , lookup

Strychnine total synthesis wikipedia , lookup

Transcript