* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Technical Description PCM Modules ZM modular

Survey

Document related concepts

Transcript

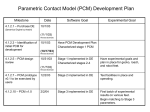

Technical Description Date: July 2013 LJU Automatisierungstechnik GmbH PCM Modules ZM modular Field bus connection: DeviceNet DN Version 1 with ZM-DN modules WNR 60134 or WNR 60138 © LJU Automatisierungstechnik GmbH Am Schlahn 1 14476 Potsdam Germany Tel.: +49 (0) 33201 / 414-0 Fax: +49 (0) 33201 / 414-19 E-mail: [email protected] Internet: www.ljuonline.de | www.grenzebach.com The standard names, trade names, product names etc. used in this technical documentation may also be brand names even when not specially indicated and as such subject to the statutory stipulations. July 2013 ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN Table of Contents Table of Contents 1 General Information ..................................................................................... 6 1.1 Information about the Technical Description ................................................ 6 1.2 Symbols in the Documentation .................................................................. 7 1.3 Limitation of Liability ................................................................................ 8 1.4 Copyright................................................................................................ 8 1.5 Conformity .............................................................................................. 8 1.6 Proper use .............................................................................................. 9 1.7 Spare Parts and Repair ............................................................................. 9 1.8 Disposal Instructions and Environmental Specifications ...............................10 1.9 Warranty ...............................................................................................10 1.10 Customer Service ...................................................................................10 1.11 Modifications and Alterations ....................................................................11 1.12 Personnel and qualification.......................................................................11 2 3 System - Overview ..................................................................................... 12 2.1 Principle of the modular PCM-System ........................................................12 2.2 Important Note - Power Supply ................................................................13 2.3 Important notice for command rail segmentation ........................................14 Central Module ZM-DN ................................................................................ 15 3.1 General Facts .........................................................................................15 3.2 Design of the Central Module ZM-DN .........................................................16 3.3 Monitoring and Protection Function ...........................................................16 3.4 Installation and Commissioning ................................................................16 3.4.1 Installation ....................................................................................16 3.4.2 Synchronization .............................................................................16 3.5 Technical Data and Connections ...............................................................17 3.5.1 Technical Data of the Central Module ZM-DN .....................................17 3.5.2 Connections of the Central Module ZM-DN ........................................18 3.6 DeviceNet Connection .............................................................................19 3.6.1 DeviceNet Connection .....................................................................19 3.6.2 DeviceNet Configuration Switch ........................................................20 3.6.3 LED Status Display .........................................................................20 ZM modular-DN V1_TB0018_en 3 Technical Description ZM modular DeviceNet DN Table of Contents 4 Pulse Code Module PCM-8-Bus.................................................................... 21 4.1 General .................................................................................................21 4.2 Design of the Pulse Code Module PCM-8-Bus ..............................................21 4.3 Monitoring and Protection Functions ..........................................................22 4.4 Installation ............................................................................................22 4.5 Technical Data and Connections ...............................................................23 4.5.1 Technical Data of the Pulse Code Module PCM-8-Bus ...........................23 4.5.2 Connections of the Pulse Code Module PCM-8-Bus ..............................24 5 Input Module EM-8-Bus .............................................................................. 25 5.1 General .................................................................................................25 5.2 Design of the Input Module EM-8-Bus........................................................25 5.3 Installation ............................................................................................26 5.4 Technical Data and Connections ...............................................................26 5.4.1 Technical Data of the Input Module EM-8-Bus ....................................26 5.4.2 Connections of the Input Module EM-8-Bus ........................................27 6 Digital Input Module DI-8-Bus .................................................................... 28 6.1 General .................................................................................................28 6.2 Design of the Digital Input Module DI-8-Bus ..............................................28 6.3 Installation ............................................................................................28 6.4 Technical Data and Connections ...............................................................29 6.4.1 Technical Data of the Digital Input Module DI-8-Bus ...........................29 6.4.2 Connections of the Digital Input Module DI-8-Bus ...............................30 7 Digital Output Module DO-8-Bus ................................................................. 31 7.1 General .................................................................................................31 7.2 Design of the Digital Output Module DO-8-Bus ...........................................31 7.3 Installation ............................................................................................31 7.4 Technical Data and Connections ...............................................................32 7.4.1 Technical Data of the Digital Output Module DO-8-Bus ........................32 7.4.2 Connections of the Digital Output Module DO-8-Bus............................33 8 4 Resistor Module RM-8-Bus (optional) ......................................................... 34 8.1 General .................................................................................................34 8.2 Design of the Resistor Module RM-8-Bus ....................................................34 8.3 Installation ............................................................................................34 ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN Table of Contents 8.4 Technical Data and Connections ...............................................................35 8.4.1 Technical Data of the Resistor Module RM-8-Bus ................................35 8.4.2 Connections of the Resistor Module RM-8-Bus ...................................35 9 Communication and System Configuration ................................................. 36 9.1 DeviceNet Communication .......................................................................36 9.2 Cyclic Data Exchange ..............................................................................37 9.2.1 Cyclic Data: System Controller -> ZM-DN: 28 bytes ..........................37 9.2.2 Cyclic Data: ZM-DN -> System Controller: 11 bytes .........................38 9.2.3 Cyclic Data: Counter Connection ......................................................38 9.3 Acyclic Data Exchange .............................................................................39 9.3.1 Acyclic Data: System Controller -> ZM-DN: 244 byte ..........................39 9.3.2 Acyclic Data: ZM-DN -> System Controller: 244 byte ..........................39 9.3.3 Acyclic data: Message Structure and Handshake ................................40 9.3.4 Acyclic Data: System Access Indexes ................................................42 9.4 ZM-DN Parameterization 38 Byte ..............................................................43 9.5 Default System Structure.........................................................................45 ZM modular-DN V1_TB0018_en 5 Technical Description ZM modular DeviceNet DN General Information 1 General Information 1.1 Information about the Technical Description This technical description contains technical information to the PCM-System with DeviceNet connection and the devices of the ZM modular system: Central module ZM-DN (WNR 60134 and 60138) PCM module PCM-8-Bus Input module EM-8-Bus Input module DI-8-Bus Output module DO-8-Bus Resistor module RM-8-Bus (option) It gives important information about the system and the devices. Please read this technical description carefully before using the device! It will ensure smooth operation and prevention of errors, defects and damage to the system. Moreover, universal safety and accident prevention specifications must be implemented at sites where the devices are in use. The technical description includes important instructions regarding the operation and safety; it is a part of the product and must readily available, close to the device, so that it is accessible to the personnel at all times. Every person who is assigned to work on or with the device must have read and understood this technical description before working with the devices. This is mandatory even if the concerned person has already worked with such a device or the like, or has been trained by the manufacturer. 6 ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN General Information 1.2 Symbols in the Documentation There are warning instructions and symbols in this technical description. It is absolutely mandatory to comply with these and follow them. These are working aids and they will warn you of possible damage to property and personnel. Always follow these instructions. Moreover, always follow the universal safety specifications and accident prevention specifications. Warning! This symbol along with the signal word “Warning” refers to a potentially dangerous situation that can lead to serious injuries or fatality if it is not avoided. Caution! This symbol along with the signal word “Caution” refers to a potentially dangerous situation that can lead to minor injuries and damage to property if it is not avoided. Note! This symbol indicates that there are additional and important information and tips on the relevant topic. See also! This symbol indicates that other detailed descriptions on the particular topic are available or provides references to other sections in this documentation. ZM modular-DN V1_TB0018_en 7 Technical Description ZM modular DeviceNet DN General Information 1.3 Limitation of Liability All data and instructions in this technical description have been compiled taking into consideration the applicable standards and specifications, the state-of-the-art technology and our knowledge and experience gained over the years. LJU Automatisierungstechnik GmbH is not liable for any damage or operational disorders arising due to: Non-compliance with the technical description Improper use Employment of untrained personnel Independent remodeling and modification of the device Moreover, non-compliance with the technical description absolves LJU Automatisierungstechnik GmbH of the warranty obligation. 1.4 Copyright The contents of this technical description should be treated as confidential. It is meant solely for persons working with the device. Handing over this technical document to third parties without written permission of the manufacturer is not allowed. Note! The content details, texts, drawings, images and other illustrations of the technical description are protected by copyright and are subject to the industrial property rights. Any improper utilization is punishable by law. 1.5 Conformity Devices of LJU Automatisierungstechnik GmbH have been designed to conform to the EU Guidelines. A copy of the EU certificate of conformity can be requested from LJU Automatisierungstechnik GmbH at any time. 8 ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN General Information 1.6 Proper use Devices of the ZM modular system are devices to control industrial and commercial transportation systems via PCM commands. Warning! Danger due to improper use! Any improper use and/or different use of the devices can lead to dangerous situations. Therefore: - Only use the devices in a proper manner. - Under all circumstances, comply with all technical data and permissible conditions at the site of operation. - Do not operate the devices in environments with hazardous oils, acids, gases, vapors, dust, radiation, etc. 1.7 Spare Parts and Repair Warning! Risk of injury due to spurious spare parts and incorrect repair! Spurious or faulty spare parts and repair can lead to damage, malfunctions or total failure and can impair safety. Therefore: - Use only original spare parts of the manufacturer. - Replace defective devices immediately and send them for repair. LJU-Automatisierungstechnik GmbH Module Type 24V DC 60xxx 123 WNR Ser.-Nr. Baujahr 2007 When ordering a spare part, specify the plant number WNR of the component and send it to the address given on the inner side of the covering sheet (page 2). The plant number is given on the type plate of the individual components. (see figure) Type plate with WNR Send in the defective device for repair with a short description of the error scenario, to the address given on the inner side of the covering sheet (page 2). ZM modular-DN V1_TB0018_en 9 Technical Description ZM modular DeviceNet DN General Information 1.8 Disposal Instructions and Environmental Specifications Provided no agreement for take-back or disposal has been made, the individual components of the device, after appropriate dismantling, have to be segregated and disposed of or recycled, according to the current stipulations. Materials marked with the recycling symbol or green dot have to be disposed of using the relevant recycling method. 1.9 Warranty The warranty covers only production defects and component defects. The manufacturer is in no way responsible for damage occurring during transit or unpacking. In no case and under no circumstances shall the manufacturer be liable under warranty for defects or damage caused by improper use, incorrect installation or impermissible operating conditions, or due to dust or aggressive substances. Consequential and accidental damage are excluded from the warranty. The warranty is valid for 12 months from the commencement of operation or 24 months after delivery, whichever is earlier. Resellers or distributors may negotiate different warranty periods in accordance with their terms and conditions of sale and delivery. If you have further questions relating to the warranty, please contact your supplier. 1.10 Customer Service Our service is available for technical information. Information about the responsible contact persons is available via telephone, fax, email or the Internet, see contacts on the inner side of the covering sheet (page 2). 10 ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN General Information 1.11 Modifications and Alterations To avoid danger and to ensure optimal performance, no modifications, remodeling or add-ons are allowed on the device, unless expressly approved by LJU Automatisierungstechnik GmbH. Warning! Risk of injury due to design modification! Unauthorized technical modifications can lead to considerable damage to persons and property. Therefore: - Replace the defective device! - Replace it with an LJU device of the same model. 1.12 Personnel and qualification Warning! Risk of injury due to inadequate qualification! Inappropriate handling can lead to considerable personal and property damage. Therefore: - The installation, operation and maintenance of the device must be carried out by trained and instructed personnel. ZM modular-DN V1_TB0018_en 11 Technical Description ZM modular DeviceNet DN System - Overview 2 System - Overview 2.1 Principle of the modular PCM-System internal LJU-Bus Field bus Central module ZM-DP ZM-DN L3 N 230 AC max 3 modules per type PCM module PCM-8-Bus L+ L- L3 max 2 modules Input Input Output module module module EM-8-Bus DI-8-Bus DO-8-Bus N N L- L+ L- 24 V DC 8 8 Outputs Inputs PCM 230V 50 Hz 8 Inputs digital 24 V 8 Outputs digital 24 V Command bar Message bar 12 ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN System - Overview 2.2 Important Note - Power Supply Important! All mentioned devices with L3-reference are designed for use with 230VAC! In case of main power of more than 230VAC it is mandatory to use a transformer to generate 230VAC! Principle: to the PCM-modules ZM modular-DN V1_TB0018_en 13 Technical Description ZM modular DeviceNet DN System - Overview 2.3 Important notice for command rail segmentation Important notice! Definitely to be observed! Consecutive command rail segments where switchover from PCM commands ≤10 to PCM commands >10 shall be performed, must be separated by active changeover segments. Carrier entry into changeover segment with previous segment command, switchover to following segment command only when carrier brush gear is located completely within changeover segment. Combinations of PCM commands ≤PCM10 will result in recognition of the smaller command by the control box. 14 ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN Central Module ZM-DN 3 Central Module ZM-DN 3.1 General Facts The ZM-DN module is a central module that can be controlled via DeviceNet and serves to generate mains-synchronized clock signals. A processor evaluates the mains power and sends mains-synchronized +24 VDC square wave voltages with various clock combinations over the internal bus to one or more pulse code modules. Up to 190 different codes can be generated: PCM 6 16 PCM codes PCM 10 190 PCM codes The codes are generated through relevant parameters of the PLC, which are transmitted over the DeviceNet bus to the ZM-DN. These codes are transmitted over the internal bus to the pulse code module PCM-8-Bus. The pulse code module can convert these signals directly into 230 V quasi sine half-wave combinations, since these signals run synchronized to the mains voltage, and feed them to the trolley controllers over the control rails (S1). Every pulse code command is detected depending to the software by the trolley controllers and executed. The user can freely assign the various commands like various speeds, forward/backward, for example, in trolleys controlled by frequency inverters. The hoisting function in integrated hoisting gears can be controlled in the same way. The advantages of this form of differentiated instructions, sent over only one control rail, (S1) are high jamming resistance and prevention of incorrect instructions caused by short circuit, wire break or reflections. Mix-up with the sinus signal of the mains power is avoided. ZM modular-DN V1_TB0018_en 15 Technical Description ZM modular DeviceNet DN Central Module ZM-DN 3.2 Design of the Central Module ZM-DN The mains supply of 24 VDC and 230 VAC is provided through 2 separate printedcircuit sub-unit terminals with threaded ends. The connection to the activating modules is implemented through a 37-pin plug connection. Besides the transmission of 5 VDC power supply for the downstream modules, this connection implements the coupling with the internal bus. The module is connected to the DeviceNet over a certified standard DeviceNet module AB4004 of HMS (integrated in the ZM-DN). The reference phase of the trolley controllers and the modules is fixed at L3. The 24VDC power supply is safeguarded using multi fuses. The ZM-DN can be optionally fitted with a 16 x 4 LCD display module. 3.3 Monitoring and Protection Function Monitoring of the mains voltage and supply voltage Error messages via DeviceNet bus Synchronization with other central modules in the installation Display “Ready for operation“ through 3 red LEDs for 24VDC, Main and Online (top down) Display “Synchronization” through separate red LED (down) 3.4 Installation and Commissioning 3.4.1 Installation The ZM-DN is designed for horizontal installation in a stationary housing. The module is mounted by locking on to a carrier rail. 3.4.2 Synchronization For synchronization with other central modules, these are connected with each other. The sync connections of the ZM modules must be connected in parallel. ZM 1 Sync1 16 Sync2 ZM 2 Sync1 Sync2 ZM modular-DN V1_TB0018_en ZM x Sync1 Sync2 Technical Description ZM modular DeviceNet DN Central Module ZM-DN 3.5 Technical Data and Connections 3.5.1 Technical Data of the Central Module ZM-DN General WNR 60134 for 50Hz 60138 for 60Hz Housing Polyamide attachable to rails Transparent lid Polycarbonate, break-proof Dimensions (W x H x D) 182 x 126 x 80mm Ambient temperature range +10C to +50C Storage temperature range -10ºC to +50ºC Humidity < 80% non-condensing Inputs DeviceNet over DeviceNet card Addressing 2 x HEX switch Outputs System bus Error reporting via DeviceNet DN Potential isolation Optocoupler Isolation voltage Ueff 2.5kV Fuse protection of the 24 VDC supply voltage Multi-fuses DeviceNet card AB4004 Supply input24VDC Current consumption ZM-DN: with 1 PCM and 1 EM module with 2 PCM and 2 EM modules with 3 PCM and 3 EM modules 110mA 140mA 170mA Supply input 230VAC Reference phase L3 230V /50Hz Reference potential N Power max. 50W Current consumption ZM-DN: with 1 PCM and 1 EM module with 2 PCM and 2 EM modules with 3 PCM and 3 EM modules additional 55mA 110mA 165mA 10mA per trolley in control segments Power dissipation No-load Full-load 1W 2W We reserve the right to make technical changes! ZM modular-DN V1_TB0018_en 17 Technical Description ZM modular DeviceNet DN Central Module ZM-DN 3.5.2 Connections of the Central Module ZM-DN X5 ZM-DN ZM- 1 2 3 X2 1 2 3 4 X4 X3 Programming 10 pole Pin assignment X2 1 N 2 L3 3 PE Pin assignment X4 18 1 Sync 1 2 Sync 2 3 L+ 4 L- ZM modular-DN V1_TB0018_en LJU System bus 37 pole DeviceNet 5 pole Technical Description ZM modular DeviceNet DN Central Module ZM-DN 3.6 DeviceNet Connection The central module is connected to the system controller via DeviceNet. The central module is equipped with a certified standard DeviceNet card AB4004 of HMS for the bus connection. See also! Detailed technical information of the used DeviceNet card can be obtained from the descriptions of the manufacturer. Can be obtained from www.hms.se! The field bus is connected to this module. The bus address (MAC-ID) is set via the DIP switch and the desired Baud rate is set. AB4004 1 2 3 # Description 1 DeviceNet connection 2 Configuration switch 3 Status-LEDs 3.6.1 DeviceNet Connection The ZM-DN is connected to the DeviceNet with a 5 pole printed-circuit sub-unit terminal with threaded ends. These are numbered from 1 to 5 (from left to right). Pin Signal Description 1 V- -24 VDC 2 CAN_L CAN_L bus line 3 Shield Cable shield 4 CAN_H CAN_H bus line 5 V+ +24 VDC ZM modular-DN V1_TB0018_en 19 Technical Description ZM modular DeviceNet DN Central Module ZM-DN 3.6.2 DeviceNet Configuration Switch The configuration switch is used to setting the baud rate and MAC-ID. The switches are numbered from 1 to 8 (from left to right). Setting of Baud rate: Switches 1-2 Setting of address: Switches 3-8 (MAC ID) Baud rate Sw. 1 Sw.2 125k OFF OFF 250k OFF ON 500k ON OFF (reserved) ON ON MAC-ID Sw. 3 (MSB Sw. 4 Sw. 5 Sw. 6 Sw. 7 Sw. 8 (LSB) 0 OFF OFF OFF OFF OFF OFF 1 OFF OFF OFF OFF OFF ON 2 OFF OFF OFF OFF ON OFF 3 OFF OFF OFF OFF ON ON … … … … … … … 62 ON ON ON ON ON OFF 63 ON ON ON ON ON ON 3.6.3 LED Status Display The actual state of the module is displayed with several LEDs. LED 1 Reserved 2 Network State 3 Reserved 4 Module State 20 Status Description - Reserved Off Green Green (flashing) Red Red (flashing) Not powered / not online Link OK, online, connected Online, not connected Critical link failure Connection timeout - Reserved for later use Off Green Green (flashing) Red Red (flashing) No power to device Device operational Data size bigger than configured Irrecoverable fault Minor fault ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN Pulse Code Module PCM-8-Bus 4 Pulse Code Module PCM-8-Bus 4.1 General The pulse code module PCM-8-Bus serves to control trolleys over a control rail with up to 190 different commands, such as slow/fast forward, slow/fast reverse, variable speeds in assembly areas, hoist/lower to various positions with various speeds and various positioning behaviors. The commands transmitted over DeviceNet from the PLCs at higher levels are converted by the central module ZM-DN into mains-synchronized timing signals and then converted by the pulse code module into a pulse-code, which can be clearly recognized by the trolley controller. The advantages: Safeguard against incorrect instructions that could be caused by short circuit, grounding or line break Differentiated control transmission over one control rail System realization without N-type rail Control from the PLC directly via DeviceNet Galvanic isolation through Optocoupler Unlimited hysteresis by using semiconductor switches Protection wiring of the output ports and short-circuit protection Error reporting over DeviceNet The pulse code module has 8 output ports, which means that up to 8 control rail sections can be driven by one pulse code module. 4.2 Design of the Pulse Code Module PCM-8-Bus The pulse code module PCM-8-Bus is connected to the internal bus over a 37-pin plugconnector. The timing signals are transmitted from the central module over the internal bus. By using mains-synchronized pulses, the output signal is always started in the voltage zero-crossing of phase L3 (disconnect in power zero-crossing). The maximum delay time between input and output signals caused by this is 10 ms at 50 Hz. The 8 output ports must be connected with the assigned control rail sections using printed-circuit sub-unit terminals with threaded terminal ends. The other modules of the system are connected over the internal bus, using a 37-pin plug-connector. The reference phase of the trolley controller and the module is assigned to L 3. ZM modular-DN V1_TB0018_en 21 Technical Description ZM modular DeviceNet DN Pulse Code Module PCM-8-Bus 4.3 Monitoring and Protection Functions Output-side short circuit protection (semiconductor switches) Error monitoring for: Interruption of the supply voltage Activation of the safety circuit (multi-fuse) Disturbance reports over the bus Can be used as individual disturbance report or together with several modules as composite disturbance Protective wiring of the output ports to prevent overvoltage (varistors) The signal form of the pulse code module's output signals (e.g. drive commands) is monitored by the micro-controller integrated in the trolley controller. If the signal form varies due to disruptive influences, the trolley is stopped immediately. This also holds good for line breaks, short circuits and grounding. Mixing different pulse code signals, e.g. when traversing rail sections, is possible only to a limited extent when using asynchronous drive commands (codes 2-9) (discussion and approval required). Mixing asynchronous drive commands (codes 2-9) with code numbers > 9 is to be avoided at all costs. 4.4 Installation The pulse code module is designed for horizontal installation in a stationary housing. The module is secured by fastening it to a mounting rail. Anti-capacitance shielded signal cable is to be used for connections between the pulse code modules and the control rail sections, and is to be separated from power cables. Use load resistors against over-crossings. Recommendation : e.g. UNITRONIC Li2YCY signal cable 22 ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN Pulse Code Module PCM-8-Bus 4.5 Technical Data and Connections 4.5.1 Technical Data of the Pulse Code Module PCM-8-Bus General WNR 60336 Housing Polyamide attachable to rails Transparent lid Polycarbonate, break-proof Dimensions (W x H x D) 112 x 126 x 80mm Ambient temperature range +10C to +50C Storage temperature range -10ºC to +50ºC Humidity < 80% non-condensing Inputs System bus Outputs 8 Error reporting via System bus Potential isolation Optocoupler Isolation voltage Ueff 2.5kV Output parameters Reference phase L3 Output switch elements FET Protection wiring Varistor Output power per output max. 1A Total output power max. 1A Short circuit protection Semiconductor switches Trolley stops for: Short circuit against N, L1, L2 Line break Interruption of the supply voltage Power dissipation No-load Full-load 2W 10W We reserve the right to make technical changes! ZM modular-DN V1_TB0018_en 23 Technical Description ZM modular DeviceNet DN Pulse Code Module PCM-8-Bus 4.5.2 Connections of the Pulse Code Module PCM-8-Bus X5 LJU System bus 37 pole LJU System bus 37 pole X3 PCM-8-Bus X1 1 2 3 4 5 6 7 8 9 10 Pin assignment X1 1 L3 2 PCM 1 3 PCM 2 4 PCM 3 5 PCM 4 6 PCM 5 7 PCM 6 8 PCM 7 9 PCM 8 10 24 N ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN Input Module EM-8-Bus 5 Input Module EM-8-Bus 5.1 General The input module EM-8-Bus converts the 230V AC composite error messages, relayed from the trolley over the status rail, to the signal level of the internal bus. This provides for transmission of the input signals over DevicNet to the PLC. The module has 8 input ports. This means that signals from up to 8 rail sections can be converted by one input module. The signal input ports are designed to distinguish between positive half-waves (presence) and negative half-waves (error messages). The signals with positive and negative half-waves are displayed differently by LED in the module for each input port. The advantages: Compact modular design Galvanic isolation through Optocoupler Input switching threshold 140VAC Differentiated display of (positive/negative) half-waves for each input 5.2 Design of the Input Module EM-8-Bus The input module EM-8-Bus is connected with the internal bus using a 37-pin plug connector. The input signals are sent via internal bus to the DeviceNet module, which then transmits them via DeviceNet to the PLC. The 8 input ports and the reference potential (N) must be connected to the assigned control-rail sections or the power supply using printed-circuit sub-unit terminals with threaded terminal ends. Other modules of the system are connected using a second 37-pin plug connector. The reference phase of the trolley controllers and of the module is assigned to L3. ZM modular-DN V1_TB0018_en 25 Technical Description ZM modular DeviceNet DN Input Module EM-8-Bus 5.3 Installation The input module EM-8-Bus is designed for horizontal installation in a stationary housing. The module is secured by fastening it to a mounting rail. Anti-capacitance shielded signal cable is to be used for the cable connections between the input modules and the control rail sections, and is to be separated from power cables. Recommendation : e.g. UNITRONIC Li2YCY signal cable 5.4 Technical Data and Connections 5.4.1 Technical Data of the Input Module EM-8-Bus General WNR 60247 Housing Polyamide attachable to rails Transparent lid Polycarbonate, break-proof Dimensions (W x H x D) 112 x 126 x 80mm Ambient temperature range +10C to +50C Storage temperature range -10ºC to +50ºC Humidity < 80% non-condensing Inputs 8 Outputs System bus Potential isolation Optocoupler Isolation voltage Ueff 2.5kV Input parameters Reference phase L3 Reference potential N Input voltage for signal 0 0V to 110VAC Input voltage for signal 1 140V to 245VAC Input power per input max. 10mA Power dissipation No-load Full-load 2W 10W We reserve the right to make technical changes! 26 ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN Input Module EM-8-Bus 5.4.2 Connections of the Input Module EM-8-Bus X5 LJU System bus 37 pole LJU System bus 37 pole X3 EM-8-Bus X1 1 2 3 4 5 6 7 8 9 10 Pin assignment X1 1 2 Input E 1 3 Input E 2 4 Input E 3 5 Input E 4 6 Input E 5 7 Input E 6 8 Input E 7 9 Input E 8 10 N ZM modular-DN V1_TB0018_en 27 Technical Description ZM modular DeviceNet DN Digital Input Module DI-8-Bus 6 Digital Input Module DI-8-Bus 6.1 General The digital input module DI-8-Bus is used to get 24VDC digital signals from automation devices in the process. For example, signals are received from the most varied sensors, such as approach switches, photoelectric barriers and limit switches, and converted in such a way that they can be transmitted over the internal data bus to the DeviceNet module, which in turn sends them to the PLC. These input signals can also be transmitted over the internal data bus to a digital output module, to control indicator lamps in the process for example. The module has 8 digital 24VDC input ports, which means that signals from as many as 8 different devices can be converted and transmitted over the internal bus. The advantages: Compact modular design Galvanic isolation through Optocoupler Input switching threshold 10VDC LED display for each input port 6.2 Design of the Digital Input Module DI-8-Bus The digital input module DI-8-Bus is connected with the internal bus using a 37-pin plug connector. The input signals are sent via the internal bus to the DeviceNet module and/or to a digital output module. The 8 input ports must be connected to the required devices, initiator lamps etc., over printed-circuit sub-unit terminals with threaded terminal ends. Other modules e.g. an output module, are connected using a second 37-pin plug connector. 6.3 Installation The digital input module DI-8-Bus is designed for horizontal installation in a stationary housing. The module is secured by fastening it to a mounting rail. 28 ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN Digital Input Module DI-8-Bus 6.4 Technical Data and Connections 6.4.1 Technical Data of the Digital Input Module DI-8-Bus General WNR 60003 Housing Polyamide attachable to rails Transparent lid Polycarbonate, break-proof Dimensions (W x H x D) 78 x 126 x 80mm Ambient temperature range +10C to +50C Storage temperature range -10ºC to +50ºC Humidity < 80% non-condensing Inputs 8 Outputs System bus Potential isolation Optocoupler Isolation voltage Ueff 2.5kV Input parameters Reference potential - 24VDC Digital 24 VDC for signal 0 0V to 3.5VDC Digital 24 VDC for Signal 1 10V to 30VDC Input power per input < 10mA Power dissipation No-load Full-load 1W 2W We reserve the right to make technical changes! ZM modular-DN V1_TB0018_en 29 Technical Description ZM modular DeviceNet DN Digital Input Module DI-8-Bus 6.4.2 Connections of the Digital Input Module DI-8-Bus X5 LJU System bus 37 pole LJU System bus 37 pole X3 DI-8-Bus 1 2 3 4 5 6 7 8 9 10 X1 Pin assignment X1 1 2 Digitaler Input DI 1 3 Digitaler Input DI 2 4 Digitaler Input DI 3 5 Digitaler Input DI 4 6 Digitaler Input DI 5 7 Digitaler Input DI 6 8 Digitaler Input DI 7 9 Digitaler Input DI 8 10 30 L- ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN Digital Output Module DO-8-Bus 7 Digital Output Module DO-8-Bus 7.1 General The digital output module DO-8-Bus serves to output 24VDC digital signals to automation devices in the process. For example, signals based on converted signals from a digital input or from the PLC can be sent to signal or indicator lamps. Signals from the PLC are transmitted via DeviceNet and the internal data bus. The incoming digital signals, which result in a digital output signal, are transmitted via the internal bus. The module has 8 digital 24VDC output ports, which means that as many as 8 signals can be output. The advantages: Compact modular design Galvanic isolation through Optocoupler LED display for each output port 7.2 Design of the Digital Output Module DO-8-Bus The digital output module DO-8-Bus is connected with the internal bus using a 37-pin plug connector. The signals from the DeviceNet module and/or from a digital input module are transmitted over the internal bus. The 8 output ports and the 24 VDC power supply are connected with the devices, indicator lamps etc., using printed-circuit sub-unit terminals with threaded terminal ends. Other modules e.g. an input module, are connected using a second 37-pin plug connector. 7.3 Installation The digital output module DO-8-Bus is designed for horizontal installation in a stationary housing. The module is secured by fastening it to a mounting rail. ZM modular-DN V1_TB0018_en 31 Technical Description ZM modular DeviceNet DN Digital Output Module DO-8-Bus 7.4 Technical Data and Connections 7.4.1 Technical Data of the Digital Output Module DO-8-Bus General WNR 60004 Housing Polyamide attachable to rails Transparent lid Polycarbonate, break-proof Dimensions (W x H x D) 78 x 126 x 80mm Ambient temperature range +10C to +50C Storage temperature range -10ºC to +50ºC Humidity < 80% non-condensing Inputs System bus Outputs 8 Potential isolation Optocoupler Isolation voltage Ueff 2.5kV Output parameters Reference potential + 24VDC Outputs Digital 24 VDC max. power per output 1A Total output power < 2A Power dissipation No-load Full-load 1W 4W We reserve the right to make technical changes! 32 ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN Digital Output Module DO-8-Bus 7.4.2 Connections of the Digital Output Module DO-8-Bus LJU System bus 37 pole X5 LJU System bus 37 pole X3 DO-8-Bus 1 2 3 4 5 6 7 8 9 10 X1 Pin assignment X1 1 L+ 2 Digitaler Output DO 1 3 Digitaler Output DO 2 4 Digitaler Output DO 3 5 Digitaler Output DO 4 6 Digitaler Output DO 5 7 Digitaler Output DO 6 8 Digitaler Output DO 7 9 Digitaler Output DO 8 10 L- ZM modular-DN V1_TB0018_en 33 Technical Description ZM modular DeviceNet DN Resistor Module RM-8-Bus (optional) 8 Resistor Module RM-8-Bus (optional) 8.1 General The resistor module RM-8-Bus serves the compensation of the capacities of the control bus and rails, that is used to the transfer of PCM- and half-wave signals for the control of trolleys. The use of load-resistors in the control bus is necessary to the guarantee of a certain signal transfer. 8.2 Design of the Resistor Module RM-8-Bus The resistor module has 8 outputs, that at most 8 rail sections can be compensated. The 8 output cables and L3 will be connected by using printed-circuit sub-unit terminals with threaded terminal ends. 8.3 Installation The resistor module RM-8-Bus is designed for horizontal installation in a stationary housing. The module is secured by fastening it to a mounting rail. Caution! The module can warm up! The installation must permit adequate air-circulation to prevent the accumulation of heat. L3 L3 rail section 34 ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN Resistor Module RM-8-Bus (optional) 8.4 Technical Data and Connections 8.4.1 Technical Data of the Resistor Module RM-8-Bus General WNR 60412 Housing Polyamide attachable to rails Transparent lid Polycarbonate, break-proof Dimensions (W x H x D) 112 x 126 x 80mm Ambient temperature range +10C to +50C Storage temperature range -10ºC to +50ºC Humidity < 80% non-condensing Inputs 1 x L3 Outputs 1 x L3 8 x Resistor 22kOhm Power dissipation No-load Full-load 0W 20W We reserve the right to make technical changes! 8.4.2 Connections of the Resistor Module RM-8-Bus Pin assignment X1 RM-8-Bus X1 1 2 3 4 5 6 7 8 9 1 L3 IN 2 L3 OUT 3 Output R1 4 Output R2 5 Output R3 6 Output R4 7 Output R5 8 Output R6 9 Output R7 10 Output R8 10 ZM modular-DN V1_TB0018_en 35 Technical Description ZM modular DeviceNet DN Communication and System Configuration 9 Communication and System Configuration 9.1 DeviceNet Communication The system controller communicates with the ZM-DN central module over the DeviceNet module. The DeviceNet module makes available several data areas for data exchange. Data from system controller -> ZM-DN: Name: Size: Reached with: [Bytes] Content: Offset: [Bytes] Output 1 28 Polled IO Cyclic data: Outputs on the slave 0 Output 2 244 Generic Message Acyclic data: Handshake + messages 240 Output 3 (Not used) 8 Generic Message Acyclic data: Handshake + message header 240 Output 4 (Not used) 240 Generic Message Cyclic data: Even unused areas 0 Data from ZM-DN -> System controller: Name: Size: Reached with: [Bytes] Content: Offset: [Bytes] Output 1 11 Polled IO Cyclic data: Outputs on the slave 0 Output 2 244 Generic Message Acyclic data: Handshake + messages 11 Output 3 (Not used) 15 Generic Message Acyclic data: Handshake + message header 0 Output 4 (Not used) 4 Generic Message Cyclic data: Even unused areas 11 Following data is exchanged here: Cyclic Data from system controller -> ZM-DN: Output 1 28 Bytes data: Data from ZM-DN -> System controller: Input 1 11 Bytes Acyclic Data from system controller -> ZM-DN: Output 2 244 Bytes data: Data from ZM-DN -> System controller: Input 2 244 Bytes Hint! The transfer of acyclic data from and to the module is necessary only if the options of enhanced parameterization are used! 36 ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN Communication and System Configuration 9.2 Cyclic Data Exchange In cyclic data exchange, the system controller sends the desired output data to the slave and reads the current input data from the slave. The communication takes place over the access points Output 1 and Input 1. The data flow is parameterized in the DeviceNet parameterization as “polled” connection. (see ZMDN_52_Zyklisch_Azyklisch_11inp_28outp.pdf: section 2.1) In case of ZM-DN, the slave is a modular parameterizable slave! In the default configurations described here, 28 / 11 Bytes are transferred cyclically between the system controller and the slave! As described later in this documentation, the slave (if necessary) can also be operated with parameterizations other than this default configuration! Then the number of inputs/outputs as well as the significance and position of the bytes within the messages can differ from the following details. 9.2.1 Cyclic Data: System Controller -> ZM-DN: 28 bytes Byte Meaning Note 0 Command Byte 00H = Normal mode 88H = Without Online->Offline Automatic reset 1 Cyclic Counter see 9.2.3 2 9 PCM – Output 1.0 PCM – Output 1.7 1. Output card 8 x PCM outputs 10 17 PCM – Output 2.0 PCM – Output 2.7 2. Output card 8 x PCM outputs 18 25 PCM – Output 3.0 PCM – Output 3.7 3. Output card 8 x PCM outputs 26 DIG – Output Byte 1 1. Output card 8 x Digital 24 VDC outputs 27 DIG – Output Byte 2 2. Output card 8 x Digital 24 VDC outputs ZM modular-DN V1_TB0018_en 37 Technical Description ZM modular DeviceNet DN Communication and System Configuration 9.2.2 Cyclic Data: ZM-DN -> System Controller: 11 bytes Byte Meaning Note Error status Byte (Automatically resetting) 00H 01H 02H 04H 08H 10H 20H 40H 80H 1 Cyclic Counter see 9.2.3 2 EM – Input 1 Pos. 3 EM – Input 1 Neg. 1. Input card 8 x PCM inputs: Positive half wave 8 x PCM inputs: Negative half wave 4 EM – Input 2 Pos. 5 EM – Input 2 Neg. 6 EM – Input 3 Pos. 7 EM – Input 3 Neg. 8 DIG – Input Byte 1 1. Input card 8 x Digital 24 VDC inputs 9 DIG – Output Byte 2 2. Input card 8 x Digital 24 VDC inputs 10 DIG – Output Byte 3 3. Input card 8 x Digital 24 VDC inputs 0 = = = = = = = = = No error Error Configuration Error Mains frequency Error PCM output card Error Digital output card Error EEPROM Reserved Error Communication DeviceNet Error Parameterization 2. Input card 8 x PCM inputs: Positive half wave 8 x PCM inputs: Negative half wave 3. Input card 8 x PCM inputs: Positive half wave 8 x PCM inputs: Negative half wave 9.2.3 Cyclic Data: Counter Connection The ZM-DN module sends back the counter received in Byte 1 in its response message to Byte 1. If the module is in ONLINE state and the counter reading does not change within 2000 ms, then it switches to OFFLINE state, deletes all connected outputs and triggers a (local) hardware reset, if this is not disabled due to an entry of 88H in the command byte. The system control must cyclically activate this counter to maintain the data flow. Moreover, the system controller (regardless on the bus cycle running asynchronous to the program cycle) can thus easily detect whether a new response message exists. Recommended procedure: Comparison: Counter of output data equal to counter of input data? yes => Receive new data from slave! => Evaluate + Trigger monitoring 38 Program processing Equalize output data counter to (counter of input data + 1) ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN Communication and System Configuration 9.3 Acyclic Data Exchange In acyclic data exchange, the system controller can send data messages to the slave or read data messages from it using CIP Generic Messages. The communication takes place over the access points Output 2 and Input 2. The messages are always 244 Bytes long and consist of a message header that always needs to be filled up as well as the useful data. 9.3.1 Acyclic Data: System Controller -> ZM-DN: 244 byte Configuration of message for Output 2: Message type: CIP Generic Service Code: 10 Hex Object Type: 04 Hex Object ID: 151 Decimal Object Attribute: 03 Hex Source: 244 Byte memory in Scanner Scope with sending message Num. of elements: 244 Decimal Destination: 244 Byte Dummy memory in Scanner Scope DeviceNet-Code: SetData 9.3.2 Acyclic Data: ZM-DN -> System Controller: 244 byte Configuration of message for Input 2: Message Type: CIP Generic Service Code: 0E Hex Object Type: 04 Hex Object ID: 101 Decimal Object Attribute: 03 Hex Source: DeviceNet-Code: GetData - Num. of elements: 0 Decimal Destination: 244 Byte Memory in Scanner Scope with receipt message ZM modular-DN V1_TB0018_en 39 Technical Description ZM modular DeviceNet DN Communication and System Configuration 9.3.3 Acyclic data: Message Structure and Handshake The acyclic messages from and to the slave have the following structure: Byte Meaning Note 0 Acyclic counter Job number 1 Service Code Response Code 10 Hex 0E Hex 2 Access index see 9.3.4. 3 Length of following data 0 … 240 4 243 DeviceNet-Code: SetData DeviceNet-Code: GetData Data Max. 240 Byte ata flow between System controller -> Slave -> System controller: If data is to be sent to the slave, the following schema is to be applied! Acyclic counter, job number: A new job number is to be entered in this counter for every new message. The slave evaluates this number and processes the message only if the job number has changed! (After a reset, the slave initializes itself with the job number 80 Hex.) Service Code: Enter 10 Hex => Data master -> Slave Enter 0E Hex => Data slave -> Master Access index / Enter length of following data See 9.3.4. Send the job to the memory area Output 2 via message See 9.3.1. As soon as the slave has received the message, it processes the message and generates a response message in its memory area Input 2. The system controller must wait for this (timer and/or wait counter in cyclical data exchange) or must read the response several times if need be, via read message! Read the response from the memory area Input 2 via message See 9.3.2. Acyclic counter, job number: The slave enters the job number of the received message in its response message. If the job number does not match (yet), the slave has not yet processed the slave. The response must be read again. 40 ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN Communication and System Configuration Access index: The slave copies the access index of the received message into its response message. Response Code: The slave codes its response in this byte: 80 Hex = 1000 0000: ERROR 40 Hex = 0100 0000: OK 10 Hex = 0001 0000: Response to DN code: SetData => Data Master -> Slave 0E Hex = 0000 1110: Response to DN code: GetData => Data Slave -> Master Response Code ERROR with enhanced error message: If the slave responds with an error (Bit 7 = 1) (at least during the software development!), the enhanced error code, if generated, should be evaluated. If 2 is entered in Byte 3 “Length of following data“ (i.e. 2 bytes of data follow), the error reason is entered in Byte 4 and 5. Following error codes are currently generated by the standard LJU firmware: 0xFF: False data length 0xB0: Access to an invalid index OR Access locking error during access 0xC3: Resource not available 0xC9: Resource not in this segment 0xC8: Resource not reachable (no communication) 0xC2: Resource is busy Response Code OK: If the slave responds with an OK (Bit 6 = 1), the message sent to it could be processed correctly and any received data can be copied. ZM modular-DN V1_TB0018_en 41 Technical Description ZM modular DeviceNet DN Communication and System Configuration 9.3.4 Acyclic Data: System Access Indexes The following system access points are implemented in the slave: Meaning Length READ [Byte] Length WRITE [Byte] 01 Hex (R/W) Cyclic input/output data 11 28 7F Hex (R/W) Parameter (setting, mapping of I/O ranges) 38 38 Access Index Index 01H: Cyclic input/output data Through this access point, the same variables as in cyclic data exchange can be addressed. (see 9.2.1.) Index 7FH: Parameter (setting, mapping of I/O areas) Through this access point, the IO mapping of the slave can be set. Parameters! A table with the meaning of the parameters is given under “ZM-DN Parametrization”. Warning! The number and position of I/O data for the cyclic data exchange is calculated from this parameter data! The parameters are stored on the slave in an EEPROM, so that the slave can automatically start with the specified parameters. An incorrectly parameterized slave cannot be addressed correctly through the cyclic service! These parameters CANNOT be set through the DeviceNet parameterization! Only the memory areas of the DeviceNet communication modules can be set (conditionally) there. Therefore we recommend that the slave be operated in its default configuration! If a different system-specific parameterization is selected, the system controller can (must) supply the slave with a parameterization through this access point 42 ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN Communication and System Configuration 9.4 ZM-DN Parameterization 38 Byte In case of ZM-DN, the slave is a modular parameterizable slave! In the default configurations described here, 28/11 Bytes are transferred cyclically between the system controller and the slave! The number and position of I/O data for the cyclic data exchange is calculated from this parameter data! The parameters are stored on the slave in an EEPROM, so that the slave can automatically start with the specified parameters. Attention! A slave with incorrect parameter settings cannot be correctly addressed through the cyclic service! Permanently defined parameterizations: Some parameterizations are permanently defined in the firmware of the ZM-DN module. For selecting these, the mode configuration switch present on the module (2 x 16 time rotary switch in the middle of the assembly) is used. This is requested when the system software is started, the desired parameter record is determined depending on the setting, and saved in the EEPROM of the assembly. Coding Switches 00 Hex Function Normal” start with the parameters saved currently in the EEPROM Saves the DEFAULT parameters (described here) in the FF Hex EEPROM and then starts the module with these values! Determines the assemblies connected to the central module using FE Hex Autodetect, generates the parameters using this data, saves these in the EEPROM and then starts the module with these values. FD Hex Byte Deletes the parameters saved in EEPROM. Def. Value Param. Meaning Defaultpos. Output Input Byte Byte 0 PCM Module 1: Fixed code Enable Mask 0 1 PCM Module 1: Channel 1: PCM-Code: 0 - 190 1 2 2 PCM Module 1: Channel 2: PCM-Code: 0 - 190 2 3 3 PCM Module 1: Channel 3: PCM-Code: 0 - 190 3 4 ZM modular-DN V1_TB0018_en 43 Technical Description ZM modular DeviceNet DN Communication and System Configuration Byte Def. Value Param. Meaning Defaultpos. Output Input Byte Byte 4 PCM Module 1: Channel 4: PCM-Code: 0 - 190 4 5 5 PCM Module 1: Channel 5: PCM-Code: 0 - 190 5 6 6 PCM Module 1: Channel 6: PCM-Code: 0 - 190 6 7 7 PCM Module 1: Channel 7: PCM-Code: 0 - 190 7 8 8 PCM Module 1: Channel 8: PCM-Code: 0 - 190 8 9 9 PCM Module 2: Fixed code Enable Mask 0 10 PCM Module 2: Channel 1: PCM-Code: 0 - 190 9 10 11 PCM Module 2: Channel 2: PCM-Code: 0 - 190 10 11 12 PCM Module 2: Channel 3: PCM-Code: 0 - 190 11 12 13 PCM Module 2: Channel 4: PCM-Code: 0 - 190 12 13 14 PCM Module 2: Channel 5: PCM-Code: 0 - 190 13 14 15 PCM Module 2: Channel 6: PCM-Code: 0 - 190 14 15 16 PCM Module 2: Channel 7: PCM-Code: 0 - 190 15 16 17 PCM Module 2: Channel 8: PCM-Code: 0 - 190 16 17 18 PCM Module 3: Fixed code Enable Mask 19 PCM Module 3: Channel 1: PCM-Code: 0 - 190 17 18 20 PCM Module 3: Channel 2: PCM-Code: 0 - 190 18 19 21 PCM Module 3: Channel 3: PCM-Code: 0 - 190 19 20 22 PCM Module 3: Channel 4: PCM-Code: 0 - 190 20 21 23 PCM Module 3: Channel 5: PCM-Code: 0 - 190 21 22 24 PCM Module 3: Channel 6: PCM-Code: 0 - 190 22 23 25 PCM Module 3: Channel 7: PCM-Code: 0 - 190 23 24 26 PCM Module 3: Channel 8: PCM-Code: 0 - 190 24 25 27 EM Module 1: Positive half-wave 1 2 28 EM Module 1: Negative half-wave 2 3 29 EM Module 2: Positive half-wave 3 4 30 EM Module 2: Negative half-wave 4 5 31 EM Module 3: Positive half-wave 5 6 32 EM Module 3: Negative half-wave 33 DA Module 1: Dig 24V outputs 25 26 34 DA Module 2: Dig 24V outputs 26 27 35 DE Module 1: Dig 24V inputs 7 8 36 DE Module 2: Dig 24V inputs 8 9 37 DE Module 3: Dig 24V inputs 9 10 0 6 7 The activation as well as the position of variables is parameterized in the data for the cyclic data flow. In case of default parameterization, the central module is a ZM-DN central module with maximum expansion of input/output modules. We recommend the use of this configuration for all the central modules present in the system and then to mark all the input-/output modules that are not connected in the system controller as “reserved” or “optional”. 44 ZM modular-DN V1_TB0018_en Technical Description ZM modular DeviceNet DN Communication and System Configuration 9.5 Default System Structure Default (maximum) configuration: Device list PCM-8-Bus EM-8-Bus DI-8-Bus DO-8-Bus Slave configuration (modules used) 8 2 1 1 bytes bytes byte byte Protocol PCM-8-Bus PCM-8-Bus PCM-8-Bus DO-8-Bus DO-8-Bus Outputs: 2 byte 8 byte 8 byte 8 byte 1 byte 1 byte 28 byte Protocol EM-8-Bus EM-8-Bus EM-8-Bus DI-8-Bus DI-8-Bus DI-8-Bus Inputs: 2 byte 2 byte 2 byte 2 byte 1 byte 1 byte 1 byte 11 byte ZM modular-DN V1_TB0018_en 45