* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download T V-Series Innovative Technologies 480125_V_Serie.indd 1

Survey

Document related concepts

Transcript

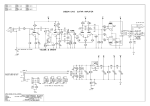

V-Series Innovative Technologies T 480125_V_Serie.indd 1 28.03.2008 13:20:15 Uhr 480125_V_Serie.indd 2 28.03.2008 13:20:17 Uhr Consistent high-end quality, consistent two-channel sound To celebrate our 25th anniversary year we decided to develop the V-series for the lover of stereo sound. This project involved making further improvements to familiar, proven machinery - such as valve amplifiers and turntables - by introducing the latest technologies and components, with the aim of coaxing unsurpassed sound quality from them. These units all feature a combination of solid aluminium and special high-quality acrylic which is visually extremely pleasing. These materials also give superb results in audio terms, as they combine to produce superb damping and neutrality of sound. The V-series has now expanded to embrace four individual machines: the V 10 valve integrated amplifier, the G 10 turntable, the D 10 MKII CD-SACD player and the P 10 valve pre-amplifier. The V 10 was the first device in this new audiophile product line, and represents a genuine highlight for any design and technology enthusiast. Offering 2 x 80 Watts of power the V 10 undoubtedly provides a unique performance compared with its competitors, as it is the first unit to incorporate the newly developed EL 509/2 valve as standard. With these valves and its new and highly sophisticated circuit design and components, the V 10 offers a level of performance never before encountered. The G 10 turntable is the second machine in our audiophile series, and once again sets new standards. The machine is equipped with unique technologies which have never previously been employed in this form, both in terms of mechanical design and electronics. As an option we offer the G 10 with either of two very carefully matched tone arm systems. The G 10 S version is equipped with a special tone arm from SME, and a high-end magnetic pick-up system which is made for us by the Benz company. The G 10 R features a special Rega tone arm and a Benz high output cartridge. An accurately matched high-end phono pre-amplifier can be installed directly in the G 10. The D 10 MK II is an audiophile CD-SACD player, and like its associates it constitutes an absolute high-end machine at the most elevated level of technology. One special feature is certainly the analogue valve output and filter stage which follows the converter stage; these valves are responsible for all the amplification and filtering processes. This overall design is totally unique, as it ensures that every aspect of the sound quality is determined by the valves alone, i.e. they are not incorporated simply for show. The P 10 valve pre-amplifier is the latest machine in our analogue high-end two-channel series. It features the very latest circuit topology, designed to exploit the advantages and sound quality of classic valves to achieve a level of performance never before attained. Its broad frequency bandwidth, supremely delicate reproduction and spontaneously lively nature make it one of the best pre-amplifiers available anywhere. Its mechanical construction reflects the same high technical level and overall design philosophy of the other V-series components. The P 10 is an outstanding choice as a pre-amplifier for any highquality power amplifier, but is also a particularly good match to our CRITERION TCI-series of active loudspeakers. 480125_V_Serie.indd 3 28.03.2008 13:20:26 Uhr V 10 valve integrated amplifier Special high-voltage capacitors in the mains power supply 450 Watt main transformer exploiting torroidal technology Encapsulated torroidal audio transformers in solid aluminium enclosures, machined from solid Shock absorbers in the case feet T+A elektroakustik GmbH has been in existence for almost 30 years, and we have been building amplifiers and valve output stages since 1984 - so we can certainly claim to have plenty of experience in this field. The V 10 features a range of technologies which have never been seen before in valve amplifiers. In our view high output power is a fundamental necessity, but not at the cost of hideous case designs and Utopian expense. We found the solution to this conundrum in new valve types which have never been used before, in combination with an ingenious circuit design which we have termed SPPP (Single Primary Push Pull). This eliminates the symmetry problems in the output transformers of conventional valve amplifiers. As ever, we consider excellent measured results to be of extreme importance. However, this is not entirely straightforward with valve amplifiers, for even some designs which have gained good test results feature upper limit frequencies of only 30 to 50 kHz. That’s not enough for us! Our V 10 effortlessly achieves 100 kHz thanks to the newly developed torroidal audio transformers which SPPP technology enables us to exploit. A crucially important factor to our developers was the stability of the amplifier’s sound qualities and technical performance in practical daily usage. The problem here is the valves themselves: on the one hand individual examples from normal production vary enormously, and on the other the valves are very sensitive in operation and suffer inevitable ageing effects. To overcome these problems we have again introduced measures which we believe to be unique: all valves are subjected to a sophisticated selection process, and only the units exhibiting the closest tolerances are approved for use in our amplifiers. At the same time a micro-processor constantly monitors all the system’s operational parameters, such as signal levels, currents and overload margins. All the device’s activities are recorded by a form of dynamic counter, and this information is used to calculate the residual run-time of the valves, so that they can be replaced in good time in order to maintain the amplifier’s sound quality. The normal useful life of the valve set is in the range 3000 to 5000 hours, depending on load and stress levels. For example, a cold start shortens the valves’ lives more than switching on after the pre-warming phase. Idle current levels can be displayed and adjusted at any time. 480125_V_Serie.indd 4 28.03.2008 13:20:26 Uhr The mechanical construction and case design of an amplifier of this type must fulfil the most exacting requirements. Any hint of mechanical jolting or vibration has a significant adverse effect on sound quality. For this reason the basic cradle is of strong steel construction, mounted on four shock absorbers. The external aluminium components are of sandwich construction, since this is more efficient at damping body sound, while the thick acrylic panel suppresses and absorbs vibration and prevents microphony effects. The audio transformers, the main transformer and the output stage capacitors are encapsulated in solid aluminium containers which prevent resonance effects and effectively disperse generated heat. The amplifier can be operated using either the F 10 remote control handset or the controls on the unit itself. The left-hand rotary switch selects the mode of operation and the input. OFF: The V 10 is switched off and can only be switched on manually - not using the remote control handset. STBY: The V 10 can be switched on using the remote control handset. HEAT: Valve heating is switched on, high tension is switched off. HV: Heating and high tension are switched on, the V 10 is ready for use. Sources: TUNER, DISC, AUX, AUX/PH, RECORDER The buttons control the following functions: MON: Recorder monitor function. SPKR: Switches the pair of loudspeakers on or off. PHO: Switches the headphone output on or off (via a voltage distributor at the valve output). BIAS: Switches to higher idle current: lower harmonic distortion but reduced power. INFO: Display of residual valve lifetime and idle currents. BAL: Balance control. The right-hand rotary knob controls the volume via a high-quality ALPS motorised potentiometer. ECC 83 / LPS double triode pre-amplifier section with very low harmonic distortion The intelligently controlled cooling fan ensures optimum operating conditions Sophisticated power output stage circuit design Separate voltage stabilisation for each output valve High-performance mains power supply with precision voltage stabilising circuit 480125_V_Serie.indd 5 Input stage with shortest possible signal paths and gold-contact relays 28.03.2008 13:20:32 Uhr G 10 turntable As you would expect, we intend the G 10 to set new standards once again. Turntables are mechanical playback systems, and it is therefore vitally important to eliminate all external mechanical influences and interference, or at least to damp and suppress them as effectively as possible. That is why T+A has approached the development of this product from two directions: the first aim was to develop a motor system which ran completely smoothly and evenly; the second was to eliminate structural sound, resonance and vibration in the entire system. The motor we use is a high-quality synchronous unit fitted with a machined belt pulley which drives the disc platter by means of a special rubber belt. This is an excellent solution which is employed in many high-end turntables. However, T+A does not stop there. Instead we tackle the problem of uneven motor running by going straight to the root of the problem. We now have many years of experience in using DSPs to control complex processes, and this led the T+A developers to come up with the brilliant idea of accurately optimising the motor coil voltage curve using a DSP, as this would ensure that the motor would run with a complete absence of chatter and vibration, i.e. absolutely evenly and smoothly. Even the start-up of the heavy turntable is a gentle, gradual process using torque control. The wow and flutter of the motor are immeasurably low, and this completely eliminates the usual interference caused by unregulated motors, as well as removing otherwise inevitable fluctuations caused by variations in mains frequency and voltage. And DSP motor control has yet another major advantage to offer: the platter’s rotational speed is controlled directly, eliminating the need to move the belt by hand when selecting either of the two available rotational speeds (33 and 45 rpm). The mechanical design and cabinet construction are no less important than the electrical requirements, for they also have the most exacting requirements to fulfil. Every hint of shock and vibration has a serious adverse effect on sound quality, and that is why the G 10 features a very heavy cabinet which houses all the sub-assemblies. The rigid steel cradle of the main body is supported on four shock absorbers. The external aluminium parts are of sandwich construction for effective damping of structural sound; the thick acrylic plate is bonded to the steel main cover in order to suppress and absorb vibration and resonance. Of particular importance is a resonance absorber within the main body; this is filled with sand and lead to absorb any structural sound inherent in the metal components. The disc platter is a laminated construction consisting of solid aluminium, five brass weights and a 10 mm thick acrylic platter. This is an extremely accurate extrusion, rolled and finally laser-cut. Aluminium is a very stiff, strong material, while acrylic has extremely good damping characteristics. The combination of the two materials in a laminate results in an extremely strong, torsionally stiff composite, suppressing and eliminating every trace of resonance and the most minute structural sounds. The platter is acoustically completely inert, thereby providing the perfect basis for trouble-free disc tracking by the pick-up cartridge. The production process of the aluminium platter is extremely complex, and would be impossible without the latest automatic CNC machinery, since the component is precision-machined - including the boring of the bearing hole - in a single process, without re-chucking (removal from the machine)! This method of production ensures that the bearing is located in the platter with 100% precision, with zero tolerance, and this in turn provides absolutely perfect accuracy of the whole mechanical system. The manufacturing tolerance of the inverted sintered bronze / polished steel plain bearing is extremely tight at 5 µm. 480125_V_Serie.indd 6 28.03.2008 13:20:39 Uhr Bonded Teroson lamination for damping The resonance absorber: filled with sand and lead, glued to the base plate, this sucks up all vibration and resonance. Aluminium disc platter bearing cradle and polished steel spindle Enclosed synchronous drive motor Sophisticated mains power supply and DSP control board Shock absorbers in the cabinet feet. Extremely lownoise high-end phono pre-amplifier with separate voltage stabilisation circuit, ultra-low background noise and accurate cartridge matching facilities. Available in two versions for MM and MC pick-up cartridges (as an option) High-quality wiring using special Audio Koax cable PH-G10 As an option we can supply this superb phono pre-amplifier module based on our proven PH 2000. The module is installed exactly where it belongs, namely immediately adjacent to the tone arm output. This arrangement avoids from the outset the problem of stray fields in the highly sensitive cartridge output signals. The mains power supply features a refined stabilisation circuit, and individual circuit topology specifically for MM or MC cartridges is provided. Comprehensive shielding ensures extremely low levels of noise and interference. The PH-G10 MM / MC is fitted with DIL switches for matching the unit to the pick-up cartridge in use. G 10 R We supply the G 10 in two carefully matched versions. The letter “R” indicates that this variant employs a tone arm made for us by the REGA company. The arm itself is manufactured in a single process from pressure-cast aluminium, and features internal damping. The balance weight is made of non-magnetic tungsten; the high specific density of this material makes it possible to produce a very heavy weight of minimum size, reducing the leverage acting upon the arm. The high-quality two-layer lacquer finish provides additional arm damping. The cartridge employed in this version is the System C05 high-output MC unit, made for us by the Swiss company Benz. G 10 S The second version “S” is fitted with a tone arm made for us by SME. The tubular arm is made of chrome-plated stainless steel with internal damping, while the support system and tube carrier are made of pressure-cast aluminium. The balance weight is made of nonmagnetic tungsten; the high specific density of this material makes it possible to produce a very heavy weight of minimum size, reducing the leverage acting upon the arm. The entire tone arm base and pivot bearing housing are made of chrome-plated brass. The cartridge employed in this version is the System C10 high-end MC unit, made for us by the Swiss company Benz. 480125_V_Serie.indd 7 28.03.2008 13:20:44 Uhr D 10 CD-SACD player The D 10 MK II is the most unusual SACD player available anywhere in the world; it is an absolute high-end machine, from the case to the valve output stage. The results in terms of sound quality are incredible, and at least equal to the vinyl disc. The D 10 is equipped with an absolutely first-class disc mechanism and decoder, and a superb quadruple D/A converter. Two specially developed, carefully matched mains power supply sections provide power entirely independently to the analogue and digital sections. For the digital components we employ a secondary switch-mode mains section, with a torroidal transformer which offers excellent stability under load; for the analogue valve output stage we have developed an extremely stable high-voltage mains section which features a reservoir capacity corresponding to more than 100,000 µF with a conventional pre-amplifier. Quadruple D/A converter The new converter is unique even by the standards of T+A. The D 10 is fitted with no fewer than eight Burr Brown D/A converters - acknowledged as the best of all types. The quadruple converter is an enhancement of the differential converter, reducing uncorrelated converter errors to one quarter, and background noise by 6 dB. The effort invested in this converter layout is immense, but the results are worth it! As you would expect, the machine exploits a freely programmable signal processor, which means that it provides the characteristic T+A switchable oversampling algorithms for CD playback, enabling the user to select the optimum reproduction to suit any particular disc. Our engineers have also developed four-stage oversampling and noise-shaper circuits for SACD playback, which generate different filter gradients and secondary wave suppression, providing a highly effective means of fine-tuning the sound characteristics to match the other links in the equipment chain. The converter stage is followed by an ingenious valve output stage. To prevent any danger of the digital section influencing the analogue circuit, these two sections are separated and de-coupled using a unique T+A technique. Opto-couplers transfer the control signals optically, while the latest magnetic, jitter-free iCouplers from Analog Devices are employed for the high-speed data signals. The net result is genuine high-end analogue sound quality both with CD as well as SACD. Fine mechanical systems The mechanical construction of the machine maintains the same philosophy and superb quality as the other V-series components. The combination of solid aluminium and special high-quality acrylic is extremely pleasing visually, and gives superb results in audio terms. The high mass of the metal and the damping effect of the acrylic ensure that the top-loader disc mechanism is totally de-coupled and isolated from the outside world. The components of the top-loader are machined and turned from solid blocks of aluminium. The complex cover sealing ring is turned from a single piece of metal, and bonded permanently to the acrylic plate. This design provides outstanding damping and absolute freedom from resonance effects, as well as sealing the disc hermetically from the environment. 480125_V_Serie.indd 8 28.03.2008 13:21:06 Uhr Valve output stage The really striking aspect of the D 10 is the section which follows the converters: its analogue valve output and filter stage. The pre-amplifier consists of the extremely linear, low-distortion 12AX7 LPS double triode, while the output stage features the ECC 99 double triode, with its high current delivery capacity. All the amplification and filtering is carried out by these valves. This concept is totally unique, and ensures that all the machine’s sound characteristics are determined by the valves - they are not just there for show! With the ECC 99 we have also succeeded in keeping the output resistance to below 100 Ohm. This is a sensational value for a valve pre-amplifier, and we think it must be a record! The DSD process used for SACD inevitably generates increased background noise in the region above about 40 kHz, and not all amplifiers can cope with this. In the simplest case the amplifier just becomes very warm, but in many instances the amplifier also generates intermodulation effects or other distortion products, and these can have an adverse and extremely disturbing effect in the audible frequency range. One solution would have been for us to limit the frequency response of the player to the lowest common denominator, in order to cope with amplifiers of moderate quality, and this would certainly have been the safe route. However, we were not content with this, so we decided to equip the D 10’s valve output stage with a means of switching the bandwidth between 60 kHz and 120 kHz. By this means it is possible to set up the player very accurately to match any amplifier, and there is no need to forfeit anything in terms of frequency response and phase linearity in systems which incorporate a good amplifier with a wide bandwidth. Naturally all T+A amplifiers are an excellent match for the machine. Decoder board for the CD-SACD mechanism Extremely stable secondary switch-mode mains section with torroidal transformer 480125_V_Serie.indd 9 Converter board with 8-channel double-mono quadruple circuit Main circuit board featuring the valve output amplifier High-voltage mains power supply 28.03.2008 13:21:22 Uhr P 10 valve pre-amplifier The P 10 valve pre-amplifier is the latest unit in our series of high-end two-channel analogue equipment. Its no-compromise construction and the equally uncompromising sophistication of its circuit design elevate this pre-amplifier to the very highest level. Even from the outside, the arrangement of the valves clearly indicates the amplifier’s totally symmetrical double mono layout. The signal paths are absolutely identical, as is the sound quality. The interior of the machine (see right page) confirms this beyond all doubt. Circuit concept: the P 10’s five valves per channel represent an extraordinary level of complexity. Why such complication? The answer is simple: we were not prepared to accept the quality of sound which was available in the 1950’s. Modern highresolution source devices, with their unprecedented bandwidth, dynamic characteristics and minimal harmonic distortion, are far more demanding than their predecessors. If we insist on maintaining the very highest standards in terms of sound quality and musicality, and if the pre-amplifier is not to become the limiting factor in the reproduction chain as far as sound quality is concerned, then simplistic electronic concepts are no longer acceptable. All the amplifying stages of the P 10 take the form of differential cascode amplifiers. This circuit design is responsible for the machine’s extremely broad frequency bandwidth and excellent linearity. The amplifier valves are the “LPS” version (Long Plate / Spiral Filament) of the 12AX7, whose outstanding feature is particularly low distortion. The potential sound quality of these valves has already been proved in the D 10 and the front end of the V 10. In fact, the linearity and quality of the P 10’s amplification stages are so high that we decided against including any form of negative feedback. Even though the classic negative feedback is entirely absent, the P 10’s total harmonic distortion and frequency linearity values are excellent. The output stage is of fully symmetrical construction, and features both asymmetrical (Cinch) and symmetrical (XLR) signals. The excellent ECC99 high-current triode valve has proved its worth in the D 10, and we decided to use the same component for the P 10 as it enables us to achieve outstandingly low output impedances. The result is that it can drive active loudspeakers or output stages without any problem, even where long cables are required. All-pole input section: when the inputs are switched on the P 10, “all poles” are switched - i.e. the earth connection of the source device is switched in addition to the signal conductor. This is very complex to implement, but ensures that all source devices are galvanically isolated. At any one time only a single device - the one currently selected for listening - is connected to the amplifier. In conventional Hi-Fi systems earth currents are free to wander around between the individual components, and these can have a significant adverse effect on sound quality. The problem is solved completely by the allpole input selection system adopted for the T+A P 10. As with the V 10, the input switch is based on an extremely solid mechanical angular rotation device featuring a zero-wear opto-electronic sensor. This control, with its slop-free operation and accurate magnetic detents, gives a feeling of incredible solidity and precision. 480125_V_Serie.indd 10 28.03.2008 13:21:45 Uhr Floating ground concept: balancing and interference currents, some of them significant, flow between the earth connections of Hi-Fi devices. These currents can result in unwanted dips in voltage at the connecting leads, and interference potential at the amplifier’s input, either of which can have a perceptible adverse effect on the sound. We were determined to eliminate these unwanted effects in the P 10, and have adopted a solution which is entirely new in the field of audio equipment. The low-impedance earth connection can be isolated at the amplifier’s inputs, and we employ differential amplifiers in the P 10’s input instead of a conventional earth-related amplification circuit. This technology is used in ultra-sensitive laboratory measuring equipment, where it is known as a “floating ground” circuit. The important factor with this type of circuit is that the input stage must be able to cope well with high common mode voltages. However, this is precisely the point where, by their very nature, valves have an advantage over semi-conductors. Valves operate at high voltages - more than ten times higher than those used with transistors - and this makes them ideally suited to this purpose. Since this advantage applies to any source device, i.e. including those which do not feature XLR outputs, we consider this concept to be more flexible than the use of XLR inputs. Mains power supplies, voltage supply: valve amplifiers place much more exacting demands on the mains power supply than conventional transistor units. The anodes of valves require high operating voltages - in our case more than 350 V - as well as high-current heating voltages. These requirements are very divergent, and for this reason the P 10 is fitted with separate, specialised mains sections. A shared basic feature of both mains power supplies is their layout as high-frequency flyback converters. This type of circuit effectively eliminates the low-frequency hum interference which is unavoidable with conventional mains transformers. For the heating circuit we use a D.C. voltage which is stabilised extremely accurately, and also features a “softstart”. This feature also prevents feedback hum, and avoids premature valve failure, as they are heated gently and always operate at the optimum heating voltage, regardless of fluctuations in the mains voltage. The overall result is an extended effective life of the delicate amplifier valves. A micro-processor constantly monitors the entire system. The anode voltage is also stabilised electronically with great accuracy. The slightest residual interference to the anode voltages is eliminated by the use of separate passive filter circuits for each channel, and reservoir capacitors of extreme dimensions (2000 iF / 450 V). Opto-electronic input selector switch with magnetic detent. Two-stage volume control with ALPS precision quadruple potentiometer for minimum possible total harmonic distortion and optimum signal : to noise performance. Only the highest-quality components are used throughout, including mica capacitors, 1% metal film resistors and film capacitors. Compound case consisting of steel, machined aluminium and acrylic. Socket for the superb PHE-MC and PHEMM phono modules. Case feet with integral shock absorbers. Low-impedance Cinch and XLR outputs for professional-standard connections, even with long cables. 480125_V_Serie.indd 11 Input stage with minimal-length signal paths and galvanic all-pole isolation of source devices. 28.03.2008 13:21:56 Uhr Disc stabiliser weight and disc brush of solid machined aluminium construction. The brush is made of real horsehair, is carefully balanced and effectively removes dust particles without causing damage to the disc. The protective cover is made of clear acrylic and is mounted on swivelling hinges. The PH-G10 MM and PH-G10 MC phono modules are designed to fit directly in the G 10. 480125_V_Serie.indd 12 28.03.2008 13:22:24 Uhr All T+A components are developed and designed in-house; this applies both to loudspeakers and electronic units. Our team of highly-qualified physicists, engineers and technicians are linked by their single common goal: best possible sound quality. For this reason we never accept off-the-peg solutions; instead we design and develop each part precisely for its specific purpose. One result of this insistence is the countless dedicated tools and processes which we have evolved. All T+A products have an unmistakable “house appearance” - from loudspeaker drive units to cabinets! At T+A we use SOLID EDGE - one of the most sophisticated high-performance 3-D CAD programs available - for designing and developing all the mechanical components, whether it is a loudspeaker cone, a pressure-cast speaker cradle or a complete high-end machine. Anechoic chamber used for developing loudspeaker drive units, crossovers and cabinets. 480125_V_Serie.indd 13 28.03.2008 13:22:45 Uhr Specifications V 10 Nominal output Load impedance Bandwidth Total harmonic distortion High-level inputs Output Valves Control interface Remote control handset Dimensions (H x W x D) Weight Available finishes 2 x 80 Watts RMS 4 or 8 Ohm, switchable 8 Hz - 100,000 Hz (-3 dB) < 0.07% at 1 Watt < 0.5% at full load 5, switched using gold-contact relays 1 tape out 2 x ECC 83 low-distortion double triode (pre-amplifier) 2 x ECL 82 triode / pentode (= 6BM8) (input stage for power amplifier) 2 x ECC 99 double triode with large current supply capacity (driver stage) 4 x EL 509/ II new audio power pentode (power output stage) Special T+A torroidal broadband audio transformer (output transformer) R-Link F 10 (included) 18 x 44 x 39 cm (7 x 17.3 x 15.4 ") 25 kg (55 lb) Silver aluminium, Titanium G 10 Principle Motor Rotational speeds Wow and flutter Rumble Disc platter Bearing technology Mains power supply Pick-up system Type Output voltage Frequency response Terminal impedance Channel separation Stylus compliance Stylus form Tracking force Recommended phono pre-amplifier Control interface Dimensions (H x W x D) Weight Available finishes Optional accessories 480125_V_Serie.indd 14 High-end belt-driven turntable mounted in special heavy chassis with resonance de-coupled sound absorber. Quartz-controlled synchronous motor with precision DSP-controlled optimisation of motor coil voltage curve. Wow and flutter not measurable 33 1/3 and 45 rpm, electronically switched +/- 0.02% 82 dB Laminated acrylic-aluminium, weighing 4.4 kg. Solid aluminium baseplate, precision-machined including centre bore in one process, without re-chucking, 32 mm deep. Inverted, hardened, polished steel; close-tolerance plain sintered bronze bush 220 / 240 V 50 Hz C05 C10 MC, high-output MC 2.2 mV 0.8 mV 15 Hz - 20 kHz 20 Hz - 25 kHz 47 kOhm 500 Ohm - 1 kOhm 25 dB 35 dB 10 µm / mN 15 µm / mN elliptical, 7.5 x 18 µm line contact, 6 x 40 µm 20-22 mN (2-2.2 g) 18-20 mN (1.8-2 g) PH-G10 MM PH-G10 MC R-Link, automatic power-on via V 10 16 x 44 x 39 cm (6.3 x 17.3 x 15.4 ") 15 kg (33 lb) Silver aluminium, Titanium Disc stabiliser weight, disc brush, acrylic cover 28.03.2008 13:23:07 Uhr D 10 MK II Audio formats Audio outputs (analogue) Output level / impedance Audio outputs (digital) D/A converter for CDDA D/A converter for SACD Valve output stage Frequency response Total harmonic distortion Effective system dynamics Signal: noise ratio (A-weighted) Channel separation Control interface Remote control Dimensions (H x W x D) Weight Available finishes CD, CD-R / RW, SACD stereo Stereo (quadruple circuit with 8 converters) 2.5 Veff / 100 Ohm 1 x co-axial, 1 optical IEC 60958 (CDDA / LPCM) Double mono quadruple 4 x 24-bit, 384 kHz Sigma / Delta Double mono quadruple DSD differential converter 2 x 12AX7 LPS double triode 2 x ECC 99 double triode CD SACD normal SACD wide < 0.015 % 2 Hz - 20 kHz 2 Hz - 60 kHz 2 Hz - 120 kHz CD 98 dB SACD 100 dB 100 dB 100 dB R-Link via V 10 17 x 44 x 39 cm (6.7 x 17.3 x 15.4 ") 14 kg (31 lb) Silver aluminium, Titanium P 10 Double-mono valve pre-amplifier of fully symmetrical construction Frequency response Total harmonic distortion Amplification Volume control range Max. channel deviation at -60 dB Volume control High-level inputs Input impedance Max. input voltage Outputs Output impedance Symmetrical Asymmetrical Headphones Valves per channel Control interface Remote control handset Dimensions (H x W x D) Weight Available finishes 0.1 Hz - 250 kHz (+0 / -3 dB) < 0.01% 3.5 times 0 … 90 dB < 0.2 dB Quadruple ALPS precision potentiometer RS 232 control interface, TASI surround interface 20 kOhm 6 Veff AUX1, AUX2, AUX/PH, TUNER, DISC, RECORDER IN AUX/PH can be upgraded with the PHE MM or PHE MC phono module; switchable “floating ground” < 150 Ohm Four-pin XLR with control voltage (three-pin optional) Cinch, Tape OUT 32 - 600 Ohm 1 x 12AX7-LPS double triode 2 x 12-AT7-EH double triode 2 x ECC 99 double triode mounted in ceramic sockets R-Link F 10 (included) 17 x 44 x 39 cm (6.7 x 17.3 x 15.4 ") 10 kg (22 lb) Silver aluminium, Titanium Technical modifications reserved 480125_V_Serie.indd 15 28.03.2008 13:23:07 Uhr T elektroakustik GmbH & Co. KG Planckstr. 9 - 11 | D-32052 Herford | Telephone +49 (0) 52 21 / 7676-0 www.TAelektroakustik.com | [email protected] 480125_V_Serie.indd 16 28.03.2008 13:23:07 Uhr