* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

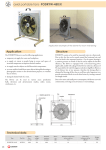

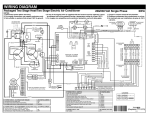

Download LENNOXOEMPARTS.COM G21/GSR21

Survey

Document related concepts

Transcript