* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

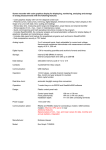

Download SCADAPack 6601 Hardware Manual

Alternating current wikipedia , lookup

Voltage optimisation wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Flip-flop (electronics) wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Buck converter wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Mains electricity wikipedia , lookup

Power electronics wikipedia , lookup

Analog-to-digital converter wikipedia , lookup

Schmitt trigger wikipedia , lookup