* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Microstructured Transdermal System

Survey

Document related concepts

Transcript

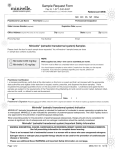

3M Drug Delivery Systems T R A N S D E R M A L S y stems The 3M Microstructured Transdermal System (MTS) White Paper / Spring 2009 Changing the Face of Drug Delivery ENABLING YOUR SUCCESS. Introduction Changing the Face of Drug Delivery The trend toward developing biopharmaceuticals over classic small molecules continues in the pharmaceutical industry. It is projected that by 2014, six of the top ten pharmaceutical products will be biologics. This trend has created new challenges in finding delivery methods that meet both the bioavailability and efficiency requirements of the therapy, as well as the needs of patients, who are seeking non-invasive, convenient and comfortable self-administration options. While injection systems such as pen injectors and autoinjectors are valued for speed and efficiency of delivery, these systems generally score low on patient satisfaction surveys. Conversely, transdermal drug delivery provides high patient satisfaction, second only to oral delivery, but is effective only for delivery of smaller, lipophilic molecules. A drug delivery platform offering the best characteristics of both a syringe and a transdermal patch would be well suited to meet the therapeutic and patient needs in the fast growing biopharmaceutical market. The 3M Microstructured Transdermal System (MTS) meets these needs. With MTS, 3M has leveraged core technologies in microreplication, micromolding, coating chemistries and manufacturing process optimization backed by fifty years of experience in drug delivery to expand the range of medications that can be delivered transdermally. MTS utilizes biocompatible, medical grade, polymeric microstructures to overcome the barrier properties of the stratum corneum and deliver previously undeliverable molecules transdermally, including the salt forms of small molecules, vaccines, peptides and proteins including antibodies. Table of Contents Microstructured Transdermal System (MTS) 1. 3M Transdermal Portfolio of Solutions 2. Transforming the Future of Transdermal Drug Delivery 3. Building on Our Core Technologies 4. Types of Microstructured Transdermal Systems – sMTS – hMTS 5. Partnering with 3M DDSD Spring 2009 1 1 3M Transdermal Portfolio of Solutions 3M excels at integrating adhesive, drug and components into a single, simple system that provides superior product stability and optimal system performance throughout the duration of the wear period in transdermal products. Our transdermal drug delivery technology has been used for decades to successfully deliver small-molecule drugs. Since then, we have pioneered several advancements, including our drug-in-adhesive (DIA) technology which has become the industry standard for passive delivery of small molecules. The 3M DIA system is a versatile platform that provides compatibility with a variety of drugs. Because the adhesive layer not only adheres the patch layers together and to the skin, but also contains the drug, DIA systems offer advantages in reduced size and improved conformability, helping drive patient preference and compliance. Continued advancements allow this system to deliver more than one drug in a single patch, resulting in added patient convenience. With the addition of MTS, 3M is expanding upon our already wide range of non-invasive, patient-friendly drug delivery solutions for transdermal delivery. Microstructured Transdermal System (MTS) Section Spring 2009 2 2 Transforming the Future of Transdermal Drug Delivery While there are many advantages to delivering drugs through the skin via existing DIA technology, patient-friendly, transdermal patches have traditionally been limited to the delivery of smaller, lipophilic molecules that can passively diffuse through the skin at rates sufficient for therapeutic effect. Given the trends in the pharmaceutical industry of increasing development of biopharmaceutical therapies, many of these new drugs are not compatible with diffusion-based technologies. The 3M MTS is a transdermal system for targeted delivery of biopharmaceuticals to the dermal/ epidermal layers of the skin. MTS uses biocompatible, medical grade polymeric microstructures to overcome the barrier properties of the stratum corneum and efficiently deliver a wide range of biopharmaceutical therapeutics, from peptides and antibodies. To meet the needs of the market, 3M has developed two Microstructured Transdermal Systems: solid and hollow. The solid Microstructured Transdermal System (sMTS) is designed for delivery of highly potent APIs or vaccines. 3M has also developed an MTS featuring hollow microstructures (hMTS) for low pain, fast delivery of relatively high volumes of liquid injectable formulations. MTS has the potential to improve health care delivery and provide key marketing advantages to your program: • Enables transdermal delivery of vaccines and proteins, including antibodies • Provides potential for increased utility/acceptance of new therapies • Is an easy-to-use system designed for self-administration • Provides a needle-free, minimal-pain delivery option to facilitate compliance and ease patient burden While other active transdermal systems exist, the efficiency of biopharmaceutical delivery is compromised and delivery can be burdensome to the patient. Adding an external energy source (e.g. battery) to the delivery system increases the costs, complexity, and waste associated with delivery. Additionally, these systems often cannot provide efficient delivery of the biopharmaceutical, requiring higher amounts of API, and the associated costs, to achieve the same therapeutic effect. Both sMTS and hMTS are wearable, self-contained, single-use devices that fully integrate the API and the delivery system for a simple, streamlined solution. Microstructured Transdermal System (MTS) SECTION Spring 2009 3 3 Building on Our Core Technologies At 3M, we leverage corporate expertise in microreplication and micromolding to create unique surfaces and structures. For the MTS, these sophisticated technologies allow us to create microstructures from 0.1 to 1mm in length that pierce the stratum corneum to increase the permeability of the skin, with minimal discomfort to the patient. The MTS array is molded from Class VI medical grade polymer. This material gives the array the strength necessary to penetrate the stratum corneum as well as the flexibility required to prevent fracture of the microstructures. During insertion studies conducted in swine, rodents, and humans, the microstructures maintained integrity. Unlike microstructures made of glass or metal which may fracture or break, the polymeric microstructures bend, but do not break under extreme force. BEFORE AFTER MTS ARRAYS BEFORE AND AFTER APPLICATION OF EXTREME FORCE AGAINST A RIGID SURFACE. Microstructured Transdermal System (MTS) SECTION Spring 2009 4 SECTION 4 Types of MTS Systems 3M has developed two types of MTS systems. The first features solid microstructures (sMTS) and is designed for systemic delivery of highly potent APIs or local delivery of vaccines. 3M has also developed an MTS featuring hollow microstructures (hMTS), a technology developed for fast, comfortable delivery of relatively high volumes of liquid injectable formulations. sMTS The sMTS consists of 300-1500 microstructures, 250-700µm tall, integrated into a small, wearable applicator/patch system. 3M uses precision coating technology to efficiently apply the API or vaccine directly to the tips of the microstructures for intra-dermal delivery. Upon application, the microstructures penetrate the stratum corneum and remain in the skin for 30 seconds to 15 minutes, allowing the API to diffuse from the structures into the tissue. Because sMTS requires an external application force sufficient to enable penetration of the skin by the microstructures, there is virtually no risk of disease transmissions associated with the use or disposal of this device. The sMTS cannot be reloaded or refilled, eliminating disease transmission associated with reuse of a delivery system. The sMTS can be disposed in a medical waste stream and requires no special accommodations for sharps disposal. sMTS for systemic delivery sMTS provides an ideal delivery system for highly potent proteins or peptides (e.g. interferons and hormones) that are typically incompatible with transdermal delivery. After formulation, the API is coated on the arrays at the target dose range (typically 0.1-600µg/array). The array, assembled in the application device/patch, is dried and packaged. Formulation development studies indicate good coating of a variety of compounds across a range of molecular weights and solubilities. By co-optimizing the formulation, array design and coating conditions, the amount of API on the arrays can be controlled. All formulations are designed to release rapidly (<15min) with some providing complete delivery in as little as 30 seconds. Microstructured Transdermal System (MTS) COATED ARRAYS Optimal API or vaccine delivery via sMTS is achieved by a combination of formulation and coating elements, coupled with a patch customized to provide microstructures of the best possible length and density required to embody key product characteristics. The coated sMTS arrays may improve stability of the API or vaccine, allowing for room temperature storage where a traditional liquid formulation may require refrigeration or freezing. Spring 2009 5 1.8 1.6 Naloxone, sera (pg/mL) Fig 1-1 In-vivo pharmacokinetic profiles following administration of naloxone by sMTS or subcutaneous injection 1.4 Avg sMTS (224 pg, n=3) 1.2 Avg SQ Injection (250 pg, n=2) 1 0.8 0.6 0.4 0.2 0 0 20 40 60 80 100 120 140 Time (minutes) Once the patch is applied, the drug diffuses away from the microstructures and enters the systemic circulation. Given the experimentally determined depth of penetration associated with the sMTS, API coated on the sMTS array will be delivered into the epidermis and dermis. Although the epidermis contains neither blood vessels nor nerve fibers, drug deposited there may diffuse through interstitial fluid into capillaries in the dermis for systemic distribution. The bioavailability and the elimination kinetics associated with sMTS delivery and subcutaneous injection appear similar, suggesting the absence of a depot associated with sMTS delivery. sMTS - biomolecule, app rox 20 kDa sMTS - biomolecule, app rox 10 kDa Blood Level (API/mL) sMTS - polype ptide, app rox 1 kDa sMTS - small molecule, salt 0 20 40 60 80 100 120 Time post dose (min) In-vivo data associated with a delivery study for parathyroid hormone (PTH) indicate that compounds like the 1-34 amino acid fragment of PTH can be delivered with the same efficiency as that achieved with subcutaneous injection of the same formulation. sMTS for vaccine delivery Vaccines, preparations containing one or more antigens designed to elicit a prophylactic or therapeutic immune response when administered to humans or animals, are typically delivered via intramuscular injection. Adverse side effects associated with delivery of high levels of a vaccine have been known to result from this type of immunization protocol. Administration requires a needle and can frequently be painful. Using sMTS, vaccines and adjuvants coated on the microstructures can be delivered directly to the dermal dendritic cells and Langerhans cells, cells specialized for processing and presenting antigens to the immune system. This directed delivery has the potential to dramatically enhance the therapeutic efficiency of a vaccine offering the possibility of dose sparing, thus minimizing side effects and reducing the per dose cost associated with delivery. An in-vivo dose titration study using a model protein antigen, ovalbumin, coupled with the 3M sMTS technology was conducted. When loaded at approximately 20µg/array, a full dose of the vaccine was delivered in 30 seconds, a time comparable to that necessary to administer an IM injection. Spring 2009 Microstructured Transdermal System (MTS) Fig 1-2 In-vivo pharmacokinetic profiles following administration of various molecules by sMTS 6 20 Figure 1-3 Residual ovalbumin content on sMTS plotted versus wear time 18 Residual Ovalbumin (mcg/array) 16 14 12 10 8 Residual ova (pg) post in-vivo application, n = 15 Average residual ova (pg) post in-vivo application 6 4 2 0 0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 Wear time (min) The anti-ovalbumin titer was determined eight weeks after the primary immunization, 4 weeks after the secondary dose. 100000 25 µg Ova 6.3 µg HD Ova 1.6 µg HD Ova 0.4 µg HD Ova 10000 1000 100 IM Injection IM Injection + 3M adjuv IM Injection + 3M adjuv 10 3M sMTS 3M sMTS + 3M adjuv 3M sMTS + 3M adjuv 1 For each dose, the sMTS administration outperformed the IM administration. These results indicate that when administered via sMTS, approximately one quarter of the dosed antigen was required to elicit a comparable immune response. The performance was matched or exceeded when the sMTS was used in conjunction with one of 3M’s two vaccine adjuvants compatible with intradermal delivery. (For more information on 3M vaccine adjuvants, visit www.3M.com/dds and click on TRL Agonists.) Microstructured Transdermal System (MTS) Anti-OVA titer, ELISA Units Figure 1-4 Anti-ova titer measured 8 weeks post dose for intramuscular injection and sMTS administration of ovalbumin Spring 2009 7 hMTS The 3M hollow Microstructured Transdermal System (hMTS) dramatically changes the landscape of transdermal delivery by offering a means of reproducibly and easily administering high volume liquid formulations into the skin. Like the sMTS, the hMTS platform utilizes medical-grade polymeric microstructures that penetrate the stratum corneum with minimal pain. However, with hMTS, small channels in each structure allow for fluid flow between the top and the bottom of the array, offering a means for effectively and comfortably delivering liquid formulations into the skin. The hMTS expands the potential for intradermal delivery, taking a technique-dependent injection-based delivery technology from the hands of skilled practitioners in a clinic and placing it into the hands of patients, allowing a means for simple, home-based self-administration. The 3M hMTS provides efficient, easy administration of liquid formulations of proteins, including antibodies. The hMTS is a unique technology, providing the opportunity for differentiation in markets crowded with me-too injectables. The hMTS has shown compatibility with many components of standard injectable formulations and is designed around a traditional glass cartridge to simplify the transition from a standard syringe or pen injector. 3M can optimize our existing device to meet the needs of a specific product or work with partners to provice a more customized device. hMTS for systemic delivery, in-vivo results The hMTS delivery system is a wearable mechanical system designed to apply the microstructured array into the skin and initiate infusion of a liquid formulation. T = 0 MIN, POST-PATCH REMOVAL Microstructured Transdermal System (MTS) The hMTS is designed to provide a means of simple, self-administration. The user opens the sterile package, primes the device and removes an adhesive liner from the base of the device. After positioning the device on the skin, a button is compressed to both apply the array onto the skin and initiate the infusion. A 1mL infusion typically takes 5-40 minutes depending on characteristics of the formulation. During infusion, the API is readily and efficiently taken up by the systemic circulation. In some cases, a small bleb may be visible as the formulation diffuses into the tissue. [After the device indicates complete infusion, it can be removed and disposed of.] T = 9 MIN, POST-PATCH REMOVAL Aqueous blue dye delivered via hMTS. The surface of the skin is dry and all dye is below the surface. Spring 2009 8 The hMTS is a wearable device designed to tolerate a low-level of activity during the infusion time. The low-profile device may be worn discreetly under a shirt sleeve or loose-fitting pants. Pharmacokinetic profiles collected upon administration of different API formulations, such as human growth hormone, naloxone, or a model monoclonal antibody demonstrate similar kinetics and bioavailability to those obtained via subcutaneous administration of the same formulation. 35 30 Avg hMTS infusion, 0.5mg hGH hGH, sera (ng/mL) Fig 1-5 In-vivo pharmacokinetic profiles following administration of human growth hormone by sMTS or by injection SC injection, 0.5mg hGH 25 20 15 10 5 0 0 50 100 150 200 250 300 350 400 450 Time post dose (min) hMTS clinical study results A small-scale tolerability study was conducted in humans using a placebo formulation administered with the hMTS proof-of-concept device. Results indicate that neither the application nor subsequent infusion (up to 1mL) cause discomfort in the patient. The device and the infusion were well-tolerated. Two hours after patch removal, nearly 50% of all infusion sites showed no visual vestige of the treatment and after three days that number had increased to 88%, with the remaining infusion sites being rated by a physician as “minimal erythema, barely perceptible.” 35 Annoying No Pain 1 30 2 3 No Pain Mild Pain Interferes with Activity Uncomfortable 4 5 6 7 8 Untolerable 9 Sever Pain Moderate Pain 10 Worst Pain Imaginable 25 20 15 10 5 0 1 2 3 4 5 6 7 8 9 10 Pain Score Although there are expected to be significant variations in patient experience, due partly to personal preferences and partly to the characteristics of the formulation, these clinical results demonstrate the potential for hMTS to provide a differentiating and patient-friendly technology for many injectables. Spring 2009 Microstructured Transdermal System (MTS) Number of Responses Fig 1-6 Distribution of Max Pain Scores associated with hMTS Infusion, 0.751.0 mL Placebo 9 5 Partnering with 3M DDS 3M Drug Delivery Systems is a global leader in transdermal drug delivery. With a proven track record, we understand the complex process of transdermal drug delivery system development, regulatory filings, and quality manufacturing. While our expertise is built upon our core technology platforms in skin adhesion, formulation and drug product development, 3M Drug Delivery Systems can draw from material and process technology expertise from across the 3M scientific community to deliver transdermal solutions to our pharmaceutical and biotech company partners. This expertise includes: • Microreplication • Surface chemistry • Micromolding • Proprietary coating • Process optimization and manufacturing From lab- and pilot- to full-scale manufacturing, 3M has the expertise, experience and capacity to meet your cGMP compliant development and manufacturing needs for MTS. Our internal development teams are available to develop and optimize an sMTS or hMTS solution specific to the needs of your biopharmaceutical or vaccine. Microstructured Transdermal System (MTS) Section Spring 2009 10 3M Drug Delivery Systems T R A N S D E R M A L S y stems When you need drug delivery results, experience matters. 3M Drug Delivery Systems offers more than 50 years of experience and proven success in technology, product development and manufacturing, coupled with our global regulatory expertise. We can offer a partnership that ensures a smooth process from start to finish and help you bring your products to market more quickly. Working with us, you get the speed to market that’s critical to the success of your new application. To find out more about MTS or any of our technologies: US: 1-800-643-8086 UK: 44 (0) 1509 613626 Japan: (81) 3-3709-9671 www.3M.com/mtswhitepaper ENABLING YOUR SUCCESS. Drug Delivery Systems Drug Delivery Systems Drug Delivery Systems 3M Center, building 275-03-E-10 St. Paul, MN 55144-1000 USA 1 800 643-8086 FAX 651 737-5265 3M.com/MTSWhitePaper 3M House, Morley Street, Loughborough, Leicestershire, LE11 1EP England +44 (0) 1509 613626 FAX +44 (0) 1509 613099 3M.com/MTSWhitePaper 33-1, Tamagawadai 2-chrome Setagaya-ku, Tokyo 158-8583 Japan (81)3-3709-9671 FAX (81)3-3709-8754 3M.com/MTSWhitePaper ©3M 2009. All Rights Reserved. 70-2009-8109-4