* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Solar Powered Charging Station: Progress Report

Electrification wikipedia , lookup

History of electric power transmission wikipedia , lookup

Wireless power transfer wikipedia , lookup

Mains electricity wikipedia , lookup

Opto-isolator wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Solar car racing wikipedia , lookup

Power electronics wikipedia , lookup

Power inverter wikipedia , lookup

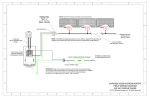

Power engineering wikipedia , lookup

Vehicle-to-grid wikipedia , lookup

Alternating current wikipedia , lookup

Life-cycle greenhouse-gas emissions of energy sources wikipedia , lookup

Solar Powered Charging Station: Final Presentation Design Team: Ben Hemp Jahmai Turner Rob Wolf, PE Sponsors: Conn Center for Renewable Energy Dr. James Graham, PhD Dr. Chris Foreman, PhD Revision B, 11/27/11 1 Agenda • • • • • Project Overview System Requirements Detailed Design Trade Studies and Research Test Results 2 Project Overview Original System Goals • Charge an electric vehicle (EV) from a charging station using 110 VAC, 60 Hz, 1ø as the charging source • Use power created by solar panels (SP’s) for the EV charging • For periods when an EV is not plugged into the charging station, store energy created by SP’s into a battery bank • If the battery bank is depleted, use grid-tied energy to make the charging times more predictable • Use instrumentation to detail the detail energy created by charging station and energy used by electrical grid • This semester’s team is expected to design the complete system, but is only expected to implement the solar charging aspect due to planning with subcontractors 3 Project Overview The Test Subject • Manufactured by NoGas LLC in Nashville, TN • 50 MPH top speed/50 mile range • 72 VDC, 40 AH Lithium batteries with Battery Management System (BMS) • Regenerative braking • Built-in charger • 340 lb carrying capacity • 120 VAC charging with 1 to 8 hr. max charge time • Front and rear hydraulic disk brakes • Hydraulic shocks front and rear 4 System Requirements 5 System Requirements First Requirement- Solar Array • A solar array of multiple SP’s for solar charging • A solar study should be conducted to determine the number and size of SP’s needed to charge the scooter • Solar study determined seven solar panels are needed to reach 3.5 kW/day for worst case month • Conn Center funded two panels by vendor of choice • Decisions regarding fabrication technology and make/buy • Funded SP’s are poly-crystalline • Mounting location and attachment techniques must be determined (W.S. building, build structure, etc.) • “Cart-style” structure chosen for mobility 6 System Requirements Alternative Energies (Danville, KY) • Received two 230W poly-crystalline panels from the Conn Center • Alternative Energies fabricates the panels • A preferred vendor 230 W Panel Specifications • Each panel has 60 cells • Vmax (1000W/m2, 25°C, AM 1.5) = 29.7 VDC • Imax (1000W/m2, 25°C, AM 1.5) = 7.5A • ~18% efficient • Size = 39.375” (~3.25’) x 65.5” (~5.5’) • ~ 2.0 yards2 or 1.9 m2 7 System Requirements 8 System Requirements Second Requirement- Inverter • Component is needed to convert DC power from SP’s to AC power for charging station • Determine between distributed vs. centralized • Distributed chosen due to: • Work at low DC voltages (150+ VDC at input required for most centralized inverters). Shut off at ~16 VDC. • Higher efficiency (compensates for shading, independent panel operation) • Expandability, can add a panel and inverter at a time. Centralized inverters are not flexible with expandibility. • Greater safety (low DC voltages) • Choose an inverter capable of supporting off-grid battery bank and future grid-tie • Distributed inverters must be grid-tied to function • Grid-tie circuit must be implemented this semester • Battery banks are not compatible with distributed inverters 9 System Requirements Enphase M215 Distributed Inverter • Maximum input power: 260W • Output power: 215W • DC operation range: 16V – 36V • Maximum modules for 240VAC 20A branch circuit: 17 • Inverters operate independently • Low-voltage operation • 96% efficiency • Works with 60-cell SP’s • Plug-and-play cabling • No high voltage DC wiring 10 System Requirements 11 System Requirements Third Requirement– Charging Station • Charging Station provides interface to : • Building grid-tie • Clamp-on for grounding rod • Plug with cord for EV charging • Provides instrumentation for system requirements: • All instrumentation located in enclosure with clear door: • • • • • Energy Meters Gateway 24 VDC Power Supply Terminal Blocks 120 VAC Receptacle 12 System Requirements Third Requirement– Charging Station (continued) 13 System Requirements Fourth Requirement– Transformer • Converts 120 VAC, 1ɸ from W.S. Speed grid to the 240 VAC, 1ɸ required for the M215 distributed to be grid-tied • 2kVA power rating 14 System Requirements Fifth Requirement– Gateway 15 System Requirements Sixth Requirement – Energy Meters • Two Eaton IQ150 energy meters. Takes measurements from two of 3 braches of the circuit. • Capable of measuring: • • • • • Voltage Amperage kW kVAR Frequency • Gathered information is sent to Gateway via RS-485 16 System Requirements Sixth Requirement – Energy Meters (continued) Voltage (V) Line - Neutral Power (W), Reactive Power (VAR), Power Factor 17 Amperage (A) System Requirements Seventh Requirement – Current Transformers (CT’s) • Measure current at specific branches in the circuit • Wires are wrapped once around the CT’s. CT’s measure the inside magnetic field. • Ratio used to compare current through the CT (branch circuit) vs. current output to the energy meters 18 System Requirements Seventh Requirement – Current Transformers (CT’s) • Measure current at specific branches in the circuit • Wires are wrapped once around the CT’s. CT’s measure the inside magnetic field. • Ratio used to compare current through the CT (branch circuit) vs. current output to the energy meters 19 System Requirements Eighth Requirement – 24 VDC Power Supply • Supplies 24 VDC to power the Gateway • Powered by 120 VAC 20 Detailed Design 21 Trade Studies and Research 22 Test Results 23 Questions? 24