* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download an investigation on flux density of three phase distrubuted air

Mains electricity wikipedia , lookup

Transmission line loudspeaker wikipedia , lookup

Power engineering wikipedia , lookup

Electrical substation wikipedia , lookup

Skin effect wikipedia , lookup

Alternating current wikipedia , lookup

Transformer wikipedia , lookup

History of electric power transmission wikipedia , lookup

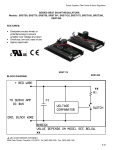

AN INVESTIGATION ON FLUX DENSITY OF THREE PHASE DISTRUBUTED AIR-GAP 3-5 LEGGED SHUNT REACTOR 1 EMRE KURT, 2AHMETYIGIT ARABUL, 3IBRAHIM SENOL, 4FATMA KESKIN ARABUL 1,2,3,4 Yildiz Technical University E-mail: [email protected], [email protected], [email protected], [email protected] Abstract- Nowadays, transmission and distribution lines provide to transport energy from production area to usage area. However, the reactive power balance on the long transmission lines do not provide, the quality of the power transmission and the efficiency of power line is low. To achieve this situation, reactive power compensation is needed and we provide that to use shunt reactors. The design state of shunt reactor is important to achieve this mission. It’s important to define the parameters of shunt reactor such as yoke heights and air-gap length to set inductance value of reactor. In this study, the important parameters of reactor is calculated and use this parameters to design a reactor. Modeled reactor isanalyzed with Finite Element Method (FEM). Shunt reactor core’s air-gap is distributed for examine the effect of fringing by leakage flux lines and inductance values. Shunt reactor’s main values which are used by Turkish Electricity Transmission Company (TEIAS) is selected. 3 and 5-legged core design reactors simulation results are discussed considering the TEIAS specifications. Index Terms- Shunt reactor, core design, distributed gapped-core,fringing effect system. This defined as Ferrati effect which is the operating voltage increase along the transmission lines. Shunt reactor consumed lagging reactive current and reduces the leading capacitive charging current of the line. Consequently, reduces the voltage rise. Another type of over voltage is caused by the interaction between line capacitance and any saturable portion of system’s inductance. When switching a transmission line which is terminated with transformer, the voltage at the end of the line can rise to a needed value to saturate the transformer’s inductance. Interaction between this parameters of the line can generate harmonics, causing over-voltage. To reduce these negative situations, a low non-saturable inductance can be connected parallel to transformer’s inductance. Shunt reactors used to provide this inductance for transmission lines [1]-[4]. Iron core reactors, have same construction with the transformers. It can be said shunt reactors are transformers without secondary windings. To reduce reactive power, magnetic circuit reluctance of shunt reactor should be increase. To achieve this value, distributed air-gap method have been used. Air-gap is the dominating parameter to determine reluctance because of core’s magnetic permeability [1].The distributed air-gap method can be used for reduce leakage flux. Eddy losses are decrease and ampere-turn efficiency increase [1,3]. I. INTRODUCTION Reactors are the most essential and supplemental component of transmission and distribution lines such as capacitors. According to usage purpose, reactors can connect shunt or series to the network. Reactors are connected either singularly or in conjunction with other basic components. Reactors are used for many purposes in transmission and distribution lines such as limiting fault current, harmonic filtering, reactive power compensation, reduction of ripple currents, load balancing [1]-[2]. High voltage transmission lines especially long ones, generate a lot of leading reactive power when the line loaded lightly. Conversely, they consume a lagging reactive power when the line loaded weighty. As a result, if the balance of reactive power is not provided, the voltage of line won’t be at the rated voltage. To provide reactive power balance, compensation procedure must be applied at the transmission and distribution lines for given working conditions [2]. Reactive power balance depends on two parameters of the line. These are charging capacity of line and line inductance. If line inductance is bigger than the charging capacity of line , reactive power balance will be negative. In this case, reactive power should be injected to the line. Conversely, if charging capacity of the line is bigger than the line inductance, reactive power balance will be positive and to achieve this situation line should be compensation. For heavy loaded lines, the reactive power balance is negative and it needs capacitive compensation which isprovided by shunt reactor generally [1]-[3]. The lightly loaded transmission systems can cause two types of overvoltage in the system because of large inherent capacitance. That can be controlled by using shunt reactors. The first type of over voltage created by the leading capacitive charging current of a lightly loaded transmission line which flows through the inductance of the line and the Fig. 1: Distributed Air-Gap Shunt Reactor Proceedings of The IRES 21st International Conference, Amsterdam, Netherland, 25th December 2015, ISBN: 978-93-85832-79-6 91 An Investigation On Flux Density Of Three Phase Distrubuted Air-Gap 3-5 Legged Shunt Reactor height (Hw) multiply we will find window area (Aw) of reactor. In this study, Hw / Bw ratio selected 2.1. The distance from the winding to the middle and side legs as well as to the top and bottom yokes ( Bi, Bs, Hu, Hd) is 60 cm. And values of 0.6, 3.2 (A/mm2) are for windings filling factor (Ku) and current density (J). Doing after all calculations, parameters of designing reactor are founded. Additionally, the yoke is a rectangular with a width (dy) equal to the outer diameter of the leg (Doc) and a thickness (Hy) of 80 cm, window width (Bw) and window height (Hw) are 330 cm and 693 cm. Similar with transformers, the flux density at the rated voltage depends on the winding turns.Laminated yokes provide an extra path for leakage flux and limit the level of leakage flux which passing through the reactor’s core. At the present time, shunt reactors are designing with distributed air-gaps. To decrease fringing flux which are enter and exit moves along the air-gap, these air-gaps distributed along legs [1]. To determine air-gaps, we need values of reactor’s reactive power, maximum flux density, frequency, inductance value which is increased cause of fringing effect, number of turns and stored energy between air-gaps. In this study, we simulated reactor which is changed air-gap numbers and observe how this change effect reactor [5]. II. STRUCTRE OF MODELING REACTOR (1) K = 4.44 ⋅ f ⋅ 103 ⋅ K t (2) Φm Kt = ( ) I e⋅N (3) r ly 0 r ay 0 = d y L Ag μ0 ⋅( ) lg L ol = (11) 2 ⋅ r lyw r ly0 (12) Fig. 2: Dimensions of 5-legged Reactor Core The parameters of the reactor are calculated according to the equations given above. Table 1 shows the parameters of the 3 phase shunt reactors. Q (5) After calculation these parameters, section area of the leg (Ai) and diameter of the leg can be find. d 2 Ai = π ⋅ ( ) 2 Sy (4) π 2 ( ⋅B ⋅ f ) μ0 m Bm (10) rly0 and ray0 that given parameters in equation 10 and 11 are ratios for 5 legged core and generally select between 2-3. Values of d0, dy, S0, Sy are shown in Fig. 2. To calculate Ag and lg values, we use max magnetic flux (Bm), frequency and magnetic permeability of air (μ0) in the formula given below. Φm = S0 Rated voltage (Ve), rated current (Ie), frequency (f), equivalent maximum magnetic flux (Φm), integers which are depend on transformers structure (Km and K), number of turns (N) as defined in equations given above. Winding turns can be calculate from value of reactor’s inductance and Ag / lg ratio. Ag is air-gap area and lg is total air-gap length. In this study, this ratio selected as 1.1 considering energy density values. Ai = (9) d0 V ⋅2e L = ω ⋅Q Ag ⋅ l g = (8) I e⋅ N Aw = K u⋅J In Turkey's transmission lines standards, reactor's core must be 5-legged. For this reason, 5 legged core design is done and essential equations for this are given in Equation 10 and 11. In this study, three phase shunt reactor designed for the values of rated voltage value as 420 kV and rated reactive power as 250 MVAr. Iron’s reluctance and copper losses are neglected. Equations which are used to calculate reactor modeling are given below. N = Aw = H w ⋅ B w Table I : Parameters of modeled reactor (6) (7) When reactor’s window width (Bw) and window Proceedings of The IRES 21st International Conference, Amsterdam, Netherland, 25th December 2015, ISBN: 978-93-85832-79-6 92 An Investigation On Flux Density Of Three Phase Distrubuted Air-Gap 3-5 Legged Shunt Reactor air-gap and there are many leakage flux. These leakage flux creates extra losses in the core. To observe these situations andsee mesh operations clearly, modeled reactor is simulated as shown in Fig. 4. III. MODELING OF THE REACTOR Three-dimensional FEM using for investigate a reactor which is modeled in section two and using assumptions given below: 1) Entire model of reactor is designed in Maxwell. 2) This study does not investigate Eddy losses, these losses neglected. Magnetostatic equations is used for the inductance calculation. Accuracy and validity of FEM is proven by recent projects [6]-[11]. According to this validity and accuracy, a three-dimensional model is created. , The Poisson Vector Equation (Eq.12) is solved to meshing the space of the problem and presuming linearity [12]. ⎛1 ur ⎞ ur ∇ × ⎜ μ ⋅ μ ∇× A ⎟ = J ⎝ 0 r ⎠ Fig. 4: Meshed Model of 3-Legged Reactor Core Model (13) After mesh operations, rated current (Ie) is applied to reactor coil and the model is simulated. As a result of applied current through the coil, magnetic flux lines and leakage flux are shown in Fig. 5. These leakage fluxes cause additional losses on the reactor. In Eq. 13,A is the magnetic potential vector and µr is the relative permeability.After the simulation, parameters such as flux density, magnetic flux density and magnetic potential vector are calculated easily. By the Eq.14,15,16which are given below, the density of the energy in the problem spaceand the inductance of the winding can be calculated. wm = 1 uur ur H⋅B 2 Wm = ∫∫∫ Wmdv L = 2⋅Wm Im (14) (15) (16) Where Wm, wm, B and H represent the magnetic energy, the density of the energy per volume, flux density vector, and magnetic field strength. During the FEM, the maximum current is applied, and in order to achieve accuracy, smaller meshes are used in every part of running program [9]. Fig. 5: Magnetic Flux Lines To reduce leakage fluxes and losses, total air-gap length distributed along the core legs equally. In this study, six different numbers of air-gaps as 1, 10, 20, 30, 40, 50 applied and simulated to see the effects of air-gap number on the flux distribution in the reactor. Air-gaps cause to reduce leakage fluxes and inductance value. As a result of this simulation, the relation between the number of air-gaps and the inductance value is shown in Fig.6. These results are expected such as mentioned above. IV. SIMULATION A. 3-Legged Core Design According to calculations in section 2 and 3, 3-legged modeled reactor is shown at Fig.3. 6.5 6 Inductance value 5.5 5 4.5 4 3.5 3 2.5 0 Fig. 3: 3-Legged Modeled Shunt Reactor 5 10 15 20 25 30 Number of air-gaps 35 40 45 50 Fig. 6: Inductance Values of 3-Legged Reactor Air-gaps are used to calibrate magnetic circuit reluctance and inductance value. However, these air-gaps cause some disadvantages. In non-distributed air-gap models, a lot of energy accumulate in the In Fig.7 includes magnetic flux lines at six different values of air-gaps and see clearly how to reduce leakage fluxes at the air gaps and legs edges. Proceedings of The IRES 21st International Conference, Amsterdam, Netherland, 25th December 2015, ISBN: 978-93-85832-79-6 93 An Investigation On Flux Density Of Three Phase Distrubuted Air-Gap 3-5 Legged Shunt Reactor Fig. 8: Meshed Model of 3-Legged Reactor Core Model In Fig.8, 5-legged reactor core is shown which is meshed. 5-legged core creates from 3-legged core how add two additional legs on sides. These additional legs provides an extra path for flux lines and fluxes that through in these paths reduce density at the main legs. As a result, leakage and losses are reduced. Inductance value is decreased as expected and this variation is shown at Fig.10. Fig. 7: Magnetic FluxDensity Changes of 3-Legged Reactor B. 5-Legged Core Design Turkish Electricity Transmission Company (TEIAS) is the authorized company to operate transmission lines in Turkey. According to TEIAS's specifications, reactor's core must be 5-legged. For this reason, 5-legged core design is done. Fig. 9: Magnetic Flux Density Changes of 5-Legged Reactor Fig.9 include flux lines which are different values of air-gap. When the Fig. 6 and Fig.10 analyzed, it is observed that 5-legged cores inductance values a bit more than 3-legged core. However, leakage fluxes a bit less than 3-legged core. 9 Inductance value 8 7 CONCLUSION 6 In this study, design and simulation progress of shunt reactors that is the most essential and supplemental part of transmission and distribution lines are studied. Shown the effect of air-gaps numbers change on the reactor is purposed. Simulations shows that air-gaps directly affectsthe inductance value and magnetic circuit reluctance. And also it is observed in some results that core design affects the leakage fluxes and 5 4 3 0 5 10 15 20 25 30 Number of air-gaps 35 40 45 50 Fig. 10: Inductance Values of 5-Legged Reactor Proceedings of The IRES 21st International Conference, Amsterdam, Netherland, 25th December 2015, ISBN: 978-93-85832-79-6 94 An Investigation On Flux Density Of Three Phase Distrubuted Air-Gap 3-5 Legged Shunt Reactor [4] A. Dönük '' Modeling and Design of Iron-Core Shunt Reactors With Discretely Distributed Air-Gaps'', ODTÜ, 2012 [5] A. Lotfi, M.Faridi, '' Design Optimization of Gapped-Core Shunt Reactor '', IEEE, Vol.48, No.4, April 2012 [6] T.Sakura, N.Takashi, K.Fujiwara, et al., 3D-finite element analysis of eddy cureent loss of three-phase shunt reactor, JSAEM 1(2003) 81-88 [7] L.Yan-ping, Z. Hai-ting, A.Zhen, “Leakage inductance calculation and simulation research of extra-high voltage magnetically controlled shunt reactor”, Mechanic Automation and Control Engineering(MACE), 2010 International Conference, pp, 4025-4028, June 2010 [8] A.B.J. Reece, T.W. Preston, Finite Element Methods in Electrical Power Engineering, Oxford University Press Inc., New York, 2000 [9] A. Lotfi, E. Rahimpour, ''Optimum Design of Core Blocks and Analyzing the Fringing Effect Shunt Reactors With Distributed Gapped-Core'', Elsevier, Electric Power Systems Research 101(2013) 63-70, 2013 [10] W. Enright, N. Watson, O. Nayak, ''Three-phase Five-limb Unified Magnetic Equivalent Circuit Transformer Models For PSCAD V3'', IPST '99, June 20-24 1999, Budapest-Hungary [11] L. Yan Ping, Z. Fang, Z. Hai-ting, A. Zhen, ''Leakage inductance calculation and simulation research of extra-high voltage magnetically controlled shunt reactor'', Mechanic Automation and Control Engineering (MACE), 2010 International Conference, pp. 4025-4028, June 2010 [12] A.B.J. Reece, T.W. Preston, '' Finite element methods in electrical power engineering'', Oxford University Press Inc., New York, 2000 the inductance values of reactor. Difference between 3 and 5-legged cores are leakage flux and inductance value. 3-legged core has better inductance value than 5-legged core but 5-legged core has small leakage fluxes than 3-legged core. For these reasons, TEIAS would rather 5-legged core shunt reactors in Turkey power transmission systems. As a result, 3 or 5-legged cores will select application specifications. For future study, cost function of reactor will calculate according to reactor dimensions, using materials and reactor’s losses. By calculate cost function, efficiency of reactor will be increase. Conversely, losses of reactor will be decreased. REFERENCES [1] [2] [3] M. Heatcote , '' J&P Transformer Book '' , 2007 Tao Zheng,Zhao, Y.J.; Ying Jin; Chen, P.L.; Zhang, F.F., “Design and Analysis on the Turn-to-Turn Fault Protection Scheme for the Control Winding of a Magnetically Controlled Shunt Reactor”, IEEE Transactions, Volume:30, Issue:2, April 2015 H. Turan, “DemirÇekirdekli, HavaAralığıBulunanReaktörÇeşitlerininİrdelenmesiveBirProt otipiçinUygulamaÖrneği”, KocaeliUniversitesi, 2010 Proceedings of The IRES 21st International Conference, Amsterdam, Netherland, 25th December 2015, ISBN: 978-93-85832-79-6 95