* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Introduction to Manufacturing

Survey

Document related concepts

Transcript

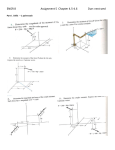

Introduction to Manufacturing Chapters 10 & 11: Metal Casting Processes and Equipment Metal Casting • Process in which molten metal is poured into a mold (shaped after the part to be manufactured), then allowed to cool and solidify. • After solidification occurs the part is removed from the mold to cool further. • The main objective is to produce parts free of defects and with the desired properties. Engr 241 1 Process Characteristics • Complex shapes that may have internal cavities • Large or small parts. • Can use materials which are otherwise hard to shape. • Economical. • Near net shape manufacturing. Engr 241 2 Considerations • Solidification – mold design and material effect cooling rate (Heat transfer). • Metal flow into mold cavity – Flow. Engr 241 3 Solidification of Metals • Pure metals have single cooling temperature. • Chill zone- (skin) small equiaxed grains. • Columnar zone- crystal growth inward. • Homogeneous nucleation- grains grow upon each other. Engr 241 4 Cooling Rates • Slow- course dendrites, large spacing. • Moderate- fine with small dendrite spacing. • Fast- amorphous structure. Engr 241 5 Cooling Rates (Cont.) • When grain size decreases • strength and ductility increase. • microporosity decreases. • cracks decrease. Lack of uniformity in grain size gives anisotropic properties Engr 241 6 Alloy Segregation • Microsegregation. • higher concentration of alloying elements at surface. • Normal Segregation. • higher concentration of alloying elements at center. Lower melting alloys forced to center. Engr 241 7 Alloy Segregation (Cont.) • Inverse Segregation • Metals with high concentrations of alloy elements lower concentration of alloying elements at center. Dentrites shrink, alloys fill • Gravity Segregation • high density inclusions or compounds sink, lighter elements float. • Inoculation • heterogeneous nucleation. Engr 241 8 Fluid Flow • Basic Casting System • Pouring basin (cup). • Sprue, runners- channels • Gate- entry point for mold • Riser- reservoir Engr 241 9 Fluid Flow (Cont.) • Bernoulli's Theorem. • pressure, velocity, elevation at any location, and frictional losses. • Continuity Law • rate of flow, permeability. • aspiration (non tapered sprue) • Flow Characteristics • laminar or turbulent. Engr 241 10 Fluidity • Capability of molten metal to fill the mold. • Metal Characteristics. • Casting Parameters. • (see p. 249) Engr 241 11 Heat Transfer During Cooling • Temperature Distribution. • flow, premature chilling- (Fig. 10-9) • Solidification Time (shapes). • ratio of volume to surface area. • Shrinkage- (Table 10.1). • contraction of the metal when cooled. • Grey iron expands. Engr 241 12 Defects • Metallic projections. • flash, fins, swells. • Cavities. • blow holes, pinholes, shrinkage. • Discontinuities. • cracks, cold or hot tearing, cold shuts. Engr 241 13 Defects (Cont.) • Defective surface. • folds, laps, scars, adhering sand, oxide. • Incomplete casting. • misruns, insufficient metal, runout. • Incorrect dimensions or shape. • Inclusions. • non-metallic, stress risers. Engr 241 14 Porosity • Caused by shrinkage or gasses. • Chills are used to increase the rate of solidification Engr 241 15 Molds • Expendable molds. • made of sand, plaster, or ceramics (mixed with bonding agents/binders). • broken up to remove casting. • Permanent molds • used repeatedly. • made from metals which maintain strength at high temperatures. Engr 241 16 Other (Molding) Methods • Composite molds. • two or more types of materials. • used to improve mold strength, cooling rates, cost of process. Engr 241 17 Sand Casting • Consists in placing a pattern in sand to make an imprint, incorporating a gating system, filling the cavity with molten metal, letting it cool, breaking the mold to remove the casting. • Traditional casting method. • Loose tolerances. • “poor” surface finish. • low cost. Engr 241 18 Sands • Silica based (SiO2), inexpensive, resistance to high temperature. • Naturally bonded (bank sands). • Synthetic (lake sands). • Grain size (permeability- heat transfer/gases out, collapsibility- sand breaks down easily). • Sand is typically conditioned Engr 241 19 Sands (Cont.) • Mulling- mixing sand with additives. • Additives: • Clay (bentonite)- for bonding/strength • Zircon, Olivine, and Iron silicate- to lower thermal expansion • Chromite- for high heat transfer Engr 241 20 Types of Sand Molds • Green Sand: • sand, clay, and water. • least expensive. • Cold-box: • organic and inorganic binders. • greater dimensional accuracy. • greater cost. Engr 241 21 Types of Sand Molds (Cont.) • No-bake: • synthetic liquid resin mixed with sand. • Cold-setting process- bonding of mold takes place without heat Engr 241 22 Mold Components (Fig. 11-4, p.265) • Flask. • Cope/Drag. • • • • • • Pouring basin or pouring cup. Sprue. Runner and gates. Risers (blind and open). Cores. Vents. Engr 241 23 Mold Patterns • Used to create sand molds • Made of wood, aluminum, steel, plastic, cast iron. • One piece (loose pattern). • simple shapes, low quantity production. • Split pattern • Two piece patterns, complex shapes. • Match plate • Split patterns secured to plate Engr 241 24 Mold Components • Cores- inner part of mold • Chaplets- anchors, supports for cores • Chill- insert for preferential cooling Engr 241 25 Shell Mold Casting • Uses binder which hardens in CO2 • Shell is formed from injected/poured sand over a mold • Close tolerance good surface finish, low cost. • Thin walled-low permeability Engr 241 26 Expendable-Pattern Casting • Also known as Lost Foam, Evaporativepattern, or Lost Pattern Casting • Polystyrene beads, bonded by hot die • Flask formed vaporizes during pouring Engr 241 27 Expendable Foam • Advantages (P. 275) • simple process, no parting lines, or riser system. • inexpensive flasks, minimum finishing and cleaning. • polystyrene is cheap and gives good detail. • economical for long production runs (pattern mold cost). • can be automated. Engr 241 28 Plaster-Mold Casting • • • • • • Plaster of paris with talc and silica flour. Water mix- pour as a slurry. Low permeability (gas cannot escape). Good surface and details. Cools slowly. “Lower” temperature alloys (Mg, Al, Zn) Engr 241 29 Ceramic-Mold Casting • Also referred to as cope and drag investment casting. • Ceramic slurry is poured over a pattern, removed, and baked • Slurry: refractory mold materials (fine grained zircon, aluminum oxide, fused silica). • Good dimensional accuracy and surface finish, but expensive. Engr 241 30 Investment Casting (P. 278) • Lost-Wax Process • Consists in coating a pattern, made of wax or plastic, with a refractory material. Once the coating agent has dried, the mold is heated to remove the wax. • Superb finishing • Trends (RP). Engr 241 31 Vacuum Casting • Counter-gravity low pressure process. • Sand and urethane molded over metal die. • Gate is on the bottom. • Immersed into molten metal, which is drawn into mold cavity. • Thin wall, complex shapes, uniform properties, high volume, low cost. Engr 241 32 Die Casting • Molten metal is forced into a permanent mold (die) at high pressure. • Hot chamber and Cold chamber pressure casting • High production rates, high quality parts, good dimensions, complex shapes, good surface (net shape). Engr 241 33 Other Processes • Permanent Mold Casting. • Slush Casting. • Centrifugal Casting. • Squeeze Casting • Semi-solid Metal Forming. Engr 241 34 Economics of Casting Process Sand Casting Shell-mold Casting Plaster Casting Investment Casting Permanent-mold Casting Die Casting Centrifugal Casting Mold/Die L L-M L-M M-H M H M Cost Equipment L M-H M L-M M H H Labor L-M L-M M-H H L-M L-M L-M Production rate (parts/hr) < 20 < 50 < 10 < 1000 < 60 < 200 < 50 L - low, M - medium, H - high Engr 241 35