* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Analog Input Module

Resistive opto-isolator wikipedia , lookup

Ground loop (electricity) wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Mains electricity wikipedia , lookup

Buck converter wikipedia , lookup

Flip-flop (electronics) wikipedia , lookup

Oscilloscope wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Oscilloscope history wikipedia , lookup

Oscilloscope types wikipedia , lookup

Schmitt trigger wikipedia , lookup

Switched-mode power supply wikipedia , lookup

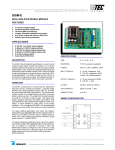

Analog Input Module DESCRIPTION Product Specifications and Installation Data HEC-ADC-40 The Horner Electric Analog Input Module HEC-ADC-40 is compatible with the Reliance Shark PLC. It provides 4 channels of 12-bit (plus sign) input, and each channel may be configured for 0-10V or 4-20mA analog inputs. Each channel converts an analog signal into a digital value of 0-4095, and that value is placed directly in the Shark I/O table as a word input. There are four word inputs required per module, one per channel. The analog input module may be placed in any slot of any Shark rack. SPECIFICATIONS Specification Voltage Current Specification Voltage Current Power Consumption 100mA @ 5VDC Digital Filtering 1 to 255 samples/update Number of Channels 4 Analog Filtering approximately 1kHz* 4, 16-bit (i.e. 0-1 thru 14-15) Input Impedence PLC Input Words Required PLC Output Words Required Measurable Input Range 1, 8-bit (i.e. 200) 0--10.24V 4-20.38mA Resolution 12-bits Accuracy +/- 2 counts Bus Isolation none >200Mohms 100ohms Maximum Voltage Input +15VDCC A/D Conversion Type Integrating A/D Conversion Time 45 channels per second Operating Temperature 0 to 60°C (32 to 140°F) Relative Humidity 5% to 95% non-condensing Installation Hints WIRING þ Wiring should be routed in its own conduit. Shielded, twisted wiring offers the best noise immunity. þ If shielded wiring is used, a good earth ground connection (on one end only) is critical. The frame ground (FG) terminal may be used as the shield ground point. þ The PLC power supply radiates a significant amount of noise. The analog input module should be physically located in a slot as far away from the power supply as possible. þ Connect a 14 gauge or larger conductor between the module FG terminal and the Shark Rack frame ground terminal. MAN0180-01 HARDWARE SETUP JP1 through JP4 Jumper Function Setting Hardware Watchdog Factory Set JP1 Chan. 0, 0-10V/4-20mA JP2 Chan. 1, 0-10V/4-20mA Jumper Function Setting JP7 PLC Select Factory Set See Module JP3 Chan. 2, 0-10V/4-20mA See Module See Module JP4 Chan. 3, 0-10V/4-20mA See Module Top Board JP8 Bottom Board Input Words Input Words PLC INTERFACE Units 4, 16-bit (i.e. 0-1 thru 14-15) A/D Counts Data Format bits 1-12 data, bit 16 sign Data Range 0-4095 Voltage Conversion V = counts x .0025 Current Conversion mA = (counts x .004) + 4 Output Words Output Words 1, 8-bit (i.e. 200) Units Samples/Update Legal Range 0 to 255 100 90 80 70 60 50 40 30 20 10 0 Digital Filtering. The Analog Input Module features selectable digital filtering, a technique whereby A/D conversions are averaged before being written to the PLC, enhancing signal stability. The effect of digital filtering on module response to a change in the analog input signal is illustrated in the above chart. The digital filtering level is set by setting the first module's output word to a value of 0-255. Legal values are 1-255 samples/update, or 0, which is sets the factory default of 4 samples/update.