* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download S02 Techno2 Hard Gelatin Capsules

Survey

Document related concepts

Transcript

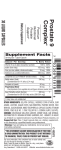

Hard Gelatin Capsules Definition A capsule is an edible package made from gelatin or other suitable material and filled with a drug(s) to produce a unit dosage, mainly for oral use. Hard gelatin capsules: or two-piece capsules which are composed of two pieces in the form of cylinders closed at one end. The shorter piece, called the “cap”, fits over the open end of the longer piece, called the “body”. Gelatin is the most commonly used material for capsule manufacturing. There is no pharmacopoeial (USP) restriction on the use of other suitable materials for capsule making. In recent years hydroxypropyl methylcellulose (HPMC) have been used in manufacturing hard capsules (Vegicap) in order to produce a shell with low moisture content. Composition of Hard Gelatin Capsule shell: Hard gelatin capsule shell contain the following ingredients: Gelatin. Colourants. Wetting agents. Preservatives. Gelatin Gelatin is a substance of natural origin. However, it does not occur as such in nature. It is prepared by the hydrolysis of collagen which is the main protein constituent of connective tissues. There are two types of gelatin depending on the preparation method: Type A: Derived from acid hydrolysis of collagen. It is manufactured mainly from pork skin Type B: Derived from alkali hydrolysis of collagen. It is manufactured mainly from animal bones (calf or beef bones) Gelatin Gelatin has been used for more than a hundred years in the manufacture of capsules. Its widespread popularity is probably due to: Safety: it is non toxic, widely used in foodstuffs and acceptable for use worldwide. Solubility: it is readily soluble in biological fluids at body temperature. Film forming properties: it is capable of producing strong flexible films (Thickness of the wall of a hard gelatin capsule is about 100m). Gelatin Quality Control of Gelatin: Viscosity: solution viscosity of a gelatin solution is dependent on the ratio of the two types of gelatin in the solution. Bloom Strength: It is the load in grams required to push a standard plunger 4 mm into a gel. It is a measure of the gel rigidity and is measured on a standard gel (6.66 %W/V) after maturing it at 10oC. Gelatin Bloom strength is a test that is borrowed from the food industry where it is used to quantify the rigidity of many gels in foodstuff production. Gelatin used in the manufacture of hard gelatin capsules has a bloom strength value of (200250 gm) while that used in the manufacture of soft gelatin capsules has a value of ~ 150 gm. Gelatin Standard probes for gelatin testing as shown above, are available for the assessment of Bloom strength/Gel strength. Colourants The colourants are used to give the capsules their distinct appearance. Colourants used in gelatin capsules can be either: Water soluble dyes Water insoluble pigments To prepare the range of colours seen in the capsules, dyes and pigments are mixed together in solutions or suspensions. Titanium dioxide is used as an opacifier to make the capsule opaque. Wetting agent According to USNF sodium lauryl sulphate is used at a level of not more than 0.15% w/w as a wetting agent in hard gelatin capsule to ensure that the lubricated metal moulds are uniformly covered when dipped in the gelatin solution. o Preservatives !!! • Preservatives were formerly added to hard capsules as an inprocess aid to prevent microbial contamination. • Hard gelatin capsules contain between 13 and 16% w/v of moisture. • Because the moisture is strongly bound to the gelatin molecules, gelatin usually doesn’t support microbial growth. • Manufacturers operating their plants in compliance with GMP do not have to include preservatives. Properties 1. Capsule Sizes For human use, eight sizes of capsules are available. The capacity of each size varies according to the combination of drugs and their apparent densities. Capsules are available as clear gelatin capsules or in a variety of colors. Empty Hard Gelatin Capsule Physical Specifications Size Outer Diamete r (mm) Height or Locked Length (mm) Actual Volume (mL) Typical Fill Weights (mg) 0.70 Powder Density 000 9.91 26.14 1.37 960 00 8.53 23.30 0.95 665 0 7.65 21.70 0.68 475 1 6.91 19.40 0.50 350 2 6.35 18.00 0.37 260 3 5.82 15.90 0.30 210 4 5.31 14.30 0.21 145 5 4.91 11.10 0.13 90 Capsule Sizes For a powder, the fill weight is calculated by multiplying the body volume by the tapped density. For liquids, the fill weight is calculated by multiplying the specific gravity of the liquid by the capsule body volume by 0.8. 2. Shape The usual shape of the capsule end is round. To ensure reliable closing of the filled capsules, capsule shells with locking grooves (or indentations) have been prepared. The two grooves fit into each other for tight closing and prevent accidental separation (or splitting) of the capsules. These capsules have a series of indentations on the inside of the cap and on the external surface of the body which, when the capsule is closed after filling, form an interference fit sufficient to hold them together during mechanical handling. Capsule Shape Traditional, non-inetrlocking Prefit Locked 3. Moisture content: Normally, empty capsules have significant amount (13-16%) of moisture that can act as a placticizer. At low relative humidity, moisture is lost and the capsule become brittle. Hygroscopic formulations can absorb water out of the shell leading to brittleness and drying-out of the shell. 4. Solubility: Gelatin is soluble at temperature above 30 C. Below 30 C, hard gelatin capsule absorb water, swell and distort. In body fluids or during dissolution at 37 C the shell dissolves and ultimately disappear. It is worth mentioning that vegicaps made of HPMC are soluble at temperature as low as 10 C. Capsule Filling Hard gelatin capsules can be filled with a large variety of materials of different physicochemical properties. Limitation in properties of materials for filling into capsules: Must not react with gelatin (e.g. formaldehyde causes crosslinking reaction that makes the capsule insoluble). Must not interfere with the integrity of the shell (materials with high level of free water, that can be absorbed by gelatin causing it to soften and distort). The volume of the unit dose must not exceed the size of capsule available. Capsule Filling Type of materials for filling into hard gelatin capsules: Dry solids: • Powders • Pellets • Granules • Tablets Semisolids: • Thermosoftening mixtures (during filling are in the molten state and fluid enough to be pumped and filled. On standing solidification happens. E.g. PEG 4000, solid fat. • Thixotropic mixtures: thin with low viscosity upon shearing by mixing and form hard mass with high viscosity upon standing when shearing ceases. During filling they are fluid and semisolid during shelf life. • Pastes Liquids: • Non-aqueous liquids: requires sealing by applying gealting solution at the cap-body joint to form sealing galatin band upon drying. If not sealed leakage at the joint will happen during handling. Sealing also reduces oxygen permeation into the content, protecting them from oxidation. Filling of Powder Formulations Bench-scale filling Used for small quantities of capsules ranging from 50 to 10 000 in number. Usually in community pharmacies, hospital pharmacies or even in the industry for special prescriptions or trials. They consist of sets of plastic plates with predrilled holes to take from 30-100 capsules of a specific size. Empty capsules are fed into the device either manually or with a simple loading device. Filling of Powder Formulations Bench-scale filling The bodies are locked in their plate by means of a screw and the caps in their plate are removed. The powder is placed onto the surface of the body plate and is spread with a spatula so that it is filled into the bodies. The cap plate is then repositioned over the body one and the capsules are rejoined using manual pressure. The uniformity of fill weight is very dependent upon good flow properties of the powder. Filling of Powder Formulations Filling of Powder Formulations Industrial scale filling: Machines for industrial scale filling of hard gelatin capsules come in great variety of shapes and sizes. The output ranges from 5000-15000/ hour. They vary from semi- to fully automatic. They can be continuous in motion like a rotary tablet press or intermittent where the machine performs its function on one set of capsules at a time. Filling of Powder Formulations The dosing systems in the industrial scale filling machines may be divided into two groups: Dependent systems: which use the capsule body directly to measure the powder. Uniformity of the fill weight can be achieved if the capsule is filled completely. Independent systems: where the powder is measured independently of the body in a special measuring device. Weight uniformity is not dependent on filling the body completely and the capsule can be part filled. Filling of Powder Formulations Dependent dosing (Auger) Systems: Consists of three stations Station 1 : For capsule feeding and Opening. Two rings with holes or bores (upper for caps and lower for bodies) are combined and placed under capsule holding hopper. the capsules are sucked by vacuum into the bores and vacuum is also used for separating capsule cap and body in a way capsule cap can stay in upper holding ring and capsule body can stay in lower holding ring. During feeding, the ring holders are rotated to allow for row-by-row capsule filling. Station 2: Powder filling station The holding rings are separated, and then the lower (body) holding ring is positioned on the rotary table. The powder hopper is pulled over the lower (body) holding ring, then auger inside powder hopper (compulsory feeder, such as rotating screw) is started to run and fill powder into the capsule body. Upon the lower holding ring turns one circle, the powder hopper is pushed to its original position away from the ring. Upon filling, the bodies should be completely filled for minimal weight variation and thus uniformity of fill weight is achieved only if the capsules are filled completely. Accordingly, the semiautomatic machines is classified as dosing dependent system meaning the system use the capsule body to measure the filled powder. Maximum total fill weight (with minimal weight variation) can be achieved at the lowest rotation al speed of the turntable and vice versa. More than one rotational cycle can be applied to ensure complete filling of the capsules. Filling of Powder Formulations Hopper Auger An Auger capsule filling machine using the ring system Capsule body plate Filling of Powder Formulations The weight of powder filled into the body is dependent on the time the body is underneath the hopper during the revolution of the plate holder. The dependent dosing systems are semiautomatic in operation, requiring an operator to transfer the capsule holder from one operation to the next. The output from such machines varies between 15,000 and 25,000 per hour and is dependent on the skill of the operator. Station 3: for capsule closing and ejection The upper holding ring and lower holding ring are put together, and then the holding rings are attached ahead of ejector. The closing plate is moved 180 degree to that shown in Figure 4 into the closing position. The ejector is aimed at the bores of holding ring, into which air pressure is applied to press capsules for closing. Afterward, air pressure is released and then the closing plate is restored to its original position. Air pressure is applied again to expel the capsules through the upper portion of the ring. Visit Instead of compressed air, pins can be used for closing and http://www.you ejection. The capsules upon ejection are collected through the tube.com/watch chute into a collector. Palletized or granular material can be filled ?v=r2FYbmwV_iU on this machine, however, it is desirable to remove the auger from For video the hopper in order to avoid crushing. It may also desirable to perform closing in a position other than the vertical position, such as the use of horizontal ejector. In vertical position, pellets or granules may escape from the body ring and this may cause damage to capsules. Filling of Powder Formulations Independent dosing systems: Fully automatic systems. Use a dosing mechanism that forms a ‘plug’ of powder that is transferred then to the capsule shell. Plugs are soft compacts formed at low compression forces (10-100 N). Plugs are soft because they are not the final dosage form, unlike tablets, as they will be contained inside a capsule shell. Filling of Powder Formulations There are two types of plug forming machines: Dosators. Tamping finger and dosing disc system. Filling of Powder Formulations Dosator systems: These consist of a dosing tube inside which there is a movable spring-loaded piston, thus forming a variable-volume chamber in the bottom of the cylinder. Filling of Powder Formulations The tube is lowered open end first into a bed of powder. As the powder enter the tube and fill the chamber it forms the plug. The plug may be further consolidated by applying a compression force with the piston. The assembly is then raised from the powder bed and is positioned over the capsule body. The plug is then ejected by lowering the piston. The weight of the fill can be adjusted by altering the position of the piston inside the tube (i.e. increasing or decreasing the volume) and by changing the depth of the powder bed. The dosator system is the most commonly used capsule filling system. Output could reach up to 150 000 / hour. Filling of Powder Formulations Tamping finger and dosing disc: In this system a dosing disc forms the bottom of a revolving powder hopper. The dosing disc has a series of accurately drilled holes in which powder plugs are formed by several sets of tamping fingers. Sets of tamping fingers (stainless steel rods) are lowered into them through the powder bed to compress the plug. Filling of Powder Formulations At each position the fingers push material into the holes, building up a plug before they index on to the next position. At the last position the finger pushes the plug through the disc into a capsule body. The powder fill weight can be varied by the amount of insertion of the fingers into the disc, by changing the thickness of the dosing disc, and by adjusting the amount of powder in the hopper. Formulation of Capsule Fillings A. Drug Low-dose potent drugs are the easiest to formulate for capsule filling. In this case the drug occupies only a small percentage of the total formulation (<20%) and so the properties of the mixture will be governed by the excipients chosen. On the other hand, in case of high dose drugs (500mg of an antibiotic), the excipients must be chosen carefully to exert their effect at low concentrations (<5%) and the properties of the mixture will be governed by that of the active ingredient. Powder Formulations: B. Diluent: Give plug forming properties. Should have the following ideal properties Good flow: obtainable using free flowing diluents and glidants. No adhesion: obtainable using lubricants. Cohesion: important for plug formation, using compressible diluents. For drugs that are readily soluble are best mixed with insoluble diluents such as starch, microcrystalline cellulose, or calcium sulfate, because they help the powder mass to break up without interfering with their solubility in the medium. For water insoluble hydrophobic drugs, water soluble diluents, such as lactose is chosen, because it will improve drug dissolution and bioavailability. This was studied for phenytoin (a hydrophobic drug). When it was formulated with lactose and given as capsules for n days, high plasma concentrations were achieved. When the same drug was given to the same patients but using calcium sulfate as a diluent, the plasma concentrations continuously dropped. When the former formulation using lactose was given for the rest of the study, the drug plasma concentrations were restored to their higher values gradually. Powder Formulations: C. Glidants Uniform filling of capsule bodies is mainly dependent on good powder flow. Glidants reduce inter-particulate friction, such as colloidal anhydrous silica, and talc. Low dose actives can be made to flow well by mixing them with free-flowing diluents. And thus glidant is usualy not necessary For high dose drugs, because little space is available for diluent addition, and flaowbility is governed by the drug, gildant addition is usually a must. Powder Formulations: D: Lubricants: reduce powder to metal adhesion, such as magnesium stearate. They exert their effect by coating the surface of other ingredients. Lubricants are usually hydrophobic materials that achieve their activity by coating the surface of pharmaceutical powders. At high levels they can reduce the solid mass wetability and thus reduce dissolution rate and drug release from pharmaceutical solids. However, lubricants are not always disadvantageous. They were shown to increase the dissolution rate of micronized powders. This is due to reduction in cohesiveness of the small particles, thus spreading more rapidly through the dissolution medium than the unlubricated particles. Studies have shown that the inclusion of an optimized level of magnesium stearate increased the dissolution rate. This was correlated to reduction in the hardness of the powder plug (softer plug, therefore easier to break a part). Effect of lubricant on drug dissolution from capsules This was demonstrated for the effect of magnesium stearate (MS) on rifampicin dissolution at different particle sizes (Figure to the right). The addition of MS reduced drug dissolution from coarse particles (180-355 m) due to reduction of wetability. However, for smaller particles (less than 75 m), an increased in dissolution rate was obtained. This was explained as due to reduction of particle cohesiveness leading to faster deagglumeration and spreading in the dissolution medium. Effect of lubricant on drug dissolution from capsules In another study the effect of magnesium stearate on hydrochlorthiazide was studied by measuring the time for 60% drug release (t60%). It was found that as the lubricant concentration increased up to 1%, t60% was continuously reduced meaning dissolution was enhanced. However, further increase in lubricant concentration beyond1% led resulted in relatively longer t60% (dissolution retardation). The declining portion of the plot was attributed to plug softening that dominated hydrophobic barrier action. The 2nd portion was attributed to hydrophobic coating and poor wetting. When t60% was plotted versus plug hardness high positive correlation was obtained meaning as the plug is harder dissolution rate becomes slower. Disniegrants Disntegrants are required to break filled powder mass into primary powder particles. Disintegrants acting as wicks, attract water into the plug Because a plug is less compacted than a tablet, starch can swell to disrupt it. Superdisintegrants are more effective, used at much lower concentration than starch and are best in breaking the capsule plug. A. Na Starch glycolate: Primojel®, Explotab® B. Croscarmellose: Ac-Di-Sol® C. Cross linked PVP: Crospovidone® Wetting agents Are used when the drug is poorly soluble and hydrophobic. They reduced interfacial tension between drug particles and the aqueous dissolution medium, promoting solvent penetration and wetability. Sodium lauryl sulphate at levels of 1% in combinatio with water soluble diluent has been to increase dissolution rate of poorly soluble drugs.