* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download [MI EMT0111A

Survey

Document related concepts

Telecommunications engineering wikipedia , lookup

Ground (electricity) wikipedia , lookup

Power over Ethernet wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Voltage optimisation wikipedia , lookup

Electronic paper wikipedia , lookup

Earthing system wikipedia , lookup

Buck converter wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Mains electricity wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Transcript

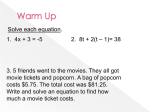

Master Instruction 06.97 MI EMT0111 A-(en) TI20 Intelligent Temperature Transmitter These intelligent transmitters are designed to perform measurements of temperature, voltage or resistance. The transmitters are approved for use in hazardous areas. They can either be mounted in a standard head housing as well as at a DIN rail. A rugged field housing allows EEx d applications. Bidirectional communication via the HART protocol is possible using the PC software ABO991 or the Universal Hand Terminal HT991. For the FOXCOM version configuration is made with the Hand Held Terminal HHT, PC-Software PC10 or directly from the I/A Series System. FEATURES • For all temperature sensors (resistance thermometers and thermocouples) • High accuracy over the complete temperature range • Intrinsically safe EEx ia IIC T4 ... T6 or EEx d in the field housing • Galvanic isolation between input and output • Open sensor and short-circuit detection • Can be mounted in a head housing, at a DIN rail or in a field housing • Continuous self diagnostics • Communication via HART or FOXCOM protocol (4 ... 20 mA and FOXCOM Digital) • Fast adaptation to a different measuring range without recalibration • Safety value configurable • Integrated current source for loop-check • Write protection • Redocumentation of measuring point • Customized characterization • Local display freely configurable • Conventional operation by means of the local keys of the LCD configurator • Software lock for local keys control • EMC protection in accordance with international standards and laws (CE) File Name: Foxboro_Transmitter_TI20_instr_D697 Repair and maintenance operations must be carried out by qualified personnel! 2 TI20 MI EMT0111 A-(en) CONTENTS CHP. CONTENTS PAGE 1 DEVICE SPECIFICATION......................... 3 12 MAINTENANCE, REPAIR ....................... 16 2 OPERATION PROCEDURE ..................... 3 12.1 Sight test at site ....................................... 16 2.1 Function diagram ....................................... 3 2.2 Operation ................................................... 3 3 ELECTRICAL CONNECTION ................... 4 12.2 12.2.1 12.2.2 12.2.3 Functional test ......................................... 16 Resistor Measurement ............................ 16 Voltage Measurement.............................. 17 Measurement of the Output Signal .......... 17 4 OPERATING THE TRANSMITTER BY MEANS OF THE LCD CONFIGURATOR ............................. 5 13 OPERATION BY MEANS OF HAND TERMINAL OR PC ....................... 18 4.1 Entering the “Setup Mode” ........................ 5 13.1 Operation by means of Hand Terminal.... 18 4.2 Exiting the “Setup Mode” ........................... 5 4.3 4.3.1 4.3.2 4.3.3 4.3.4 4.3.5 4.3.6 4.3.7 4.3.8 4.3.9 4.3.10 4.3.11 Configuration ............................................ 5 Sensor ....................................................... 6 Unit ............................................................ 6 Zero / Lower Range ................................... 6 Full Scale / Upper Range .......................... 6 Sensor Failsafe Detection ......................... 7 Failsafe value ............................................ 7 Trim 4 mA Analog Output .......................... 7 Trim 20 mA Analog Output ........................ 7 Trim Sensors ............................................. 7 Select Language........................................ 7 Return to “Operate Mode”.......................... 7 4.4 Fault Messages ......................................... 7 4.5 Setup Flowchart......................................... 8 5 MOUNTING ............................................... 9 5.1 DIN rail mounting ....................................... 9 5.2 Field Housing............................................. 9 5.3 Head Housing ............................................ 9 6 DIMENSIONS .......................................... 10 7 METHODS OF ELECTRICAL CONNECTION ................. 13 7.1 Rail installation ........................................ 13 7.2 Mounting in Field housing........................ 13 7.3 Top installation ........................................ 13 7.4 Grounding ................................................ 13 8 SAFETY REQUIREMENTS..................... 14 8.1 General requirements .............................. 14 8.2 Explosion protection ................................ 14 9 POWER SUPPLY.................................... 15 10 START-UP............................................... 16 11 SHUT-OFF .............................................. 16 13.2 Operation by means of a PC (HART) ...... 18 13.2.1 Hardware ................................................. 18 13.2.2 Software................................................... 18 13.3 Operation by means of a PC (FOXCOM) 18 14 TROUBLE SHOOTING ........................... 19 Further Documentations: Master Instruction MI EMO0110 A-(en) HT991 Universal Hand terminal for HART Devices Master Instruction MI EMO0112 A-(en) ABO991 Display and User Interface for HART devices HHT Instruction Book 3372 I/A Series Hand Held Terminal PC10 Instruction Book 3466 Intelligent Transmitter Configurator MI EMT0111 A-(en) TI20 3 1 DEVICE SPECIFICATION With LCD configurator (sensor connections code 1) Without LCD configurator (e.g. sensor connections code 3) 2 4 1 1 2 3 4 1 0 0 0.0 0 0 C 6 CELSIUS 5 3 1 Electronic 2 LCD Configurator 3 Local keys 4 Output terminals (4 ... 20 mA) 5 Sensor terminals 6 Mounting screws 2 OPERATION PROCEDURE 2 . 1 Function diagram CURRENT SOURCE SUPPLY COMMUN. option REFERENCE SENSOR INPUT A MUX D mV Ω TEMP. MEAS. SUPPLY LINE BREAK DETECTION µP MEMORY 64 KB EPROM D A OUTPUT KEYBOARD & DISPLAY Linearization Correction Program Code 2 . 2 Operation 1. 2. 3. 4. Analog Filter Software Filter (Smart Smoothing) Correction of input Signal (Temperature) Plausibility check of input signal (Line Break Detection) 5. Linearization 6. Data processing, calculation of the analog output value (4 ... 20 mA) 7. Output of the measured value (analog, digital (PV), indicator) 4 TI20 MI EMT0111 A-(en) 3 ELECTRICAL CONNECTION Sensor- and loop wires: For the selection of the sensor- and loop wires, please observe the national safety requirements. Resistance Thermometer or Resistor 2-wire 3-wire ϑ ϑ1 ϑ2 2 ϑ ∆ 2-wire ( ϑ1 - ϑ2 ) ( ϑ1 + ϑ2 ) 2-wire average 2 2 x 2-wire 1 ϑ 4-wire 3 1) 4 Thermocouple or Voltage Thermocouple or Voltage Difference ( ϑ1 ϑ2 ) Thermocouple with external cold junction compensation 1 ϑ2 2) 3 1) 2 ϑ1 4 Supply, Loop signal and Communication ( HART ) HT991 (HART) or HHT (FOXCOM) ≥ 2 5 0 Ω for HART ≥ 2 0 0 Ω for FOXCOM 1) Short circuit at transmitter 2) Option for mounting in a head housing MI EMT0111 A-(en) TI20 5 4 OPERATING THE TRANSMITTER BY MEANS OF THE LCD CONFIGURATOR The Temperature Transmitter is available with a LCD Configurator optional. The LCD Configurator consists of an indicator and two push buttons. There are two LCD Configurators that differ in terms of display comfort. One Line LCD Configurator 1 0 0.0 PV ( operate mode ) / Menu item ( setup mode ) The LCD configurator is either in the “Operate Mode” or the “Setup Mode” In the “Operate Mode” the PV is shown along with an analog bar graph and a user defined label (Three Line LCD Configurator only). For reconfiguring the transmitter, the configurator has to be set into the “Setup Mode”. In the “Setup Mode” instead of the process information the actual menu item to be entered is shown. Note that when more than seven characters are required to describe the function, the display keeps sequencing through two or more screens. For changing the configuration the local push buttons marked “NEXT” and “ENTER” are used. Buttons 4 .1 Entering the “Setup Mode” Three Line LCD Configurator Sign PV Unit - 2 0 0.0 0 C To start the “Operate Mode” press the key marked “NEXT”. The display starts to alternate between “RETURN TO OPERATE MODE” (for the Three Line LCD Configurator) resp. 9900 (for the One Line LCD Configurator). Pressing the key marked “ENTER” enters the “Operate Mode” whereas pressing the key marked “NEXT” enters the “Setup Mode”, and the first menu item is displayed. Analog bar graph CELSIUS Text label ( operate mode ) / Menu item ( setup mode ) Buttons The device can be reconfigured using the integrated push buttons. Please note that the data that can be changed using the local keys on the display only is part of the data stored in the device. The complete data set can be accessed using a PC or a Hand Terminal. The push buttons are marked NEXT respectively ENTER. They have the following function: NEXT: Display next menu item ENTER: Enter displayed menu item, resp. select displayed item 4 .2 Exiting the “Setup Mode” To exit the “Setup Mode”, press the key named “NEXT” as often until the message “RETURN TO OPERATE MODE” resp. 9900 appears. Pressing “ENTER” causes the device to exit the “Setup Mode” and to return to the “Operate Mode”. 4 .3 Configuration The positions of the configuration are constructed in a loop. When entering the loop, the first position selected is the sensor type. The configuration is done in the following sequence. For the order of the menu items, please refer to the setup flowchart on page 8 for the sequence of the configuration. 6 TI20 MI EMT0111 A-(en) 4.3.1 Sensor Displayed: SELECT SENSOR? resp. 9000 Pressing “ENTER” will enter this menu. The user may select from: Display LCD Configurator Three Line One Line T/C B 9001 T/C C 9002 T/C E 9003 T/C J 9004 T/C K 9005 T/C L 9006 T/C N 9007 T/C R 9008 T/C S 9009 T/C T 9010 T/C U 9011 T/CSPEZ 9012 2W OHMS 9013 2W PINP 2WSAMAP 2W SPEC 9014 9015 9016 3W OHMS 9017 3W PINP 3WSAMAP 3W SPEC 9018 9019 9020 4W OHMS 9021 4W DINP 4W SAMAP 4W SPEC 9022 9023 9024 MV 9025 HHT ONLY 9026 1) 2) Description Thermocouple Type B Thermocouple Type C Thermocouple Type E Thermocouple Type J Thermocouple Type K Thermocouple Type L Thermocouple Type N Thermocouple Type R Thermocouple Type S Thermocouple Type T Thermocouple Type U Thermocouple Special Ohm measurement, 2-wire PT100, DIN, 2-wire PT100, SAMA, 2-wire Special, 2-wire Ohm measurement, 3-wire PT100, DIN, 3-wire PT100, SAMA, 3-wire Special, 3-wire Ohm measurement, 4-wire PT100, DIN, 4-wire PT100, SAMA, 4-wire Special, 4-wire mV measurement Can only be configured using a Hand Terminal or PC. With Ohm and mV sensors, the menu item “Select Unit” does not appear. Instead Ohm resp. mv is automatically configured. Decade value being changed blinks 4.3.2 Unit Displayed: SELECT UNITS? resp. 9100 Pressing “ENTER” will enter this menu. The user may select from: Display LCD Configurator Three Line One Line DEG C 9132 DEG F 9133 DEG R 9134 DEG K 9135 Description 1) Unit °Celsius Unit °Fahrenheit Unit °Rankine Unit Kelvin 4.3.3 Zero / Lower Range Displayed: CHANGE ZERO? resp. 9200 Pressing “ENTER” selects this menu item. Before the numerical value can be changed, the sign has to be selected. After that, each decade value has to be entered separately. Display LCD Configurator Three Line One Line PLUS? 9201 MINUS? 9202 2) THOUSN? 2) HUNDRD? 2) TENS? 2) ONES? 2) TENTHS? 2) HUNDTH? Description Positive sign (e.g. + 600 C) Negative sign (e.g. - 60 C) Thousands Hundreds Tens Ones Tenths Hundredths 4.3.4 Full Scale / Upper Range Displayed: CHANGE FULL SCALE? resp. 9300 Pressing “ENTER” selects this menu item. Before the numerical value can be changed, the sign has to be selected. After that, each decade value has to be entered separately. Indication LCD Configurator Three Line One Line PLUS? 9301 MINUS? 9302 2) THOUSN? 2) HUNDRD? 2) TENS ? 2) ONES ? 2) TENTHS? 2) HUNDTH? Description Postive sign (e.g. + 600 C) Negative sign (e.g. - 60 C) Thousands Hundreds Tens Ones Tenths Hundredths MI EMT0111 A-(en) TI20 4.3.5 Sensor Failsafe Detection Displayed: SELECT SENSOR FAIL SAVE? The user may select from: Display LCD Configurator Three Line One Line ON OFF 9401 9402 resp. 9400 Description Turn sensor failsafe detection on Turn sensor failsafe detection off 4.3.6 Failsafe value Displayed: SELECT FAIL SAFE? resp. 9500 The user may select from: Display LCD Configurator Three Line One Line LOW 9501 HIGH 9502 OFF 9503 Description Failsafe value set to 3.6 mA Failsafe value set to 23.0 mA No Failsafe value allocation 4.3.7 Trim 4 mA Analog Output Displayed: TRIM 4 MA? resp. 9600 The user may select from: Display LCD Configurator Three Line One Line RAISE 9601 MA OUT? NEXT=+ 9610 LOWER MA OUT? 9602 NEXT=- 9620 Description Each time the pushbutton NEXT is pressed, the analog value increases by 4 µA Each time the pushbutton NEXT is pressed, the analog value decreases by 4 µA 4.3.8 Trim 20 mA Analog Output Displayed: TRIM 20 MA? resp. 9700 The user may select from: Display LCD Configurator Three Line One Line RAISE 9701 MA OUT? NEXT=+ 9710 LOWER MA OUT? 9702 NEXT=- 9720 1) 2) 4.3.9 Trim Sensors In this menu the sensor can be trimmed so that the device displays the correct value. TRIM DISPLY? rsp. 9800 Pressing “ENTER” selects this menu item. Before the numerical value can be changed, the sign has to be selected. After that, each decade value has to be entered separately. Display LCD Configurator Three Line One Line PLUS? 9801 MINUS? 9802 2) THOUSN? 2) HUNDRD? 2) TENS ? 2) ONES ? 2) TENTHS? 2) HUNDTH? Display LCD Configurator Three Line One Line GERMAN FRENCH 1) SPANISH ENGLISH Postive sign (e.g. + 600 C) Negative sign (e.g. - 60 C) Thousands Hundreds Tens Ones Tenths Hundredths Description German French Spanish English 4.3.11 Return to “Operate Mode” Pressing “ENTER” causes the device to leave the “Setup Mode” and to return to the “Operate Mode”. Displayed: RETURN TO OPERATE MODE? rsp. 9900 4 .4 Fault Messages Display LCD Configurator Three Line One Line FAIL SAFE 9999 Each time the pushbutton NEXT is pressed, the analog value increases by 4 µA DISPFAIL 1) Function only available with the Three Line LCD Configurator Decade value being changed blinks Description 4.3.10 Select Language Displayed: SELECT LANGUAGE? The user may select from: Description Each time the pushbutton NEXT is pressed, the analog value decreases by 4 µA 7 Description Fault in transmitter or line break / short-circuit Display Failure. PV cannot be displayed as resolution of the display not sufficient 8 TI20 MI EMT0111 A-(en) 4 .5 Setup Flowchart Select Input Thermocouple Type B Thermocouple Type C Thermocouple Type E Thermocouple Type J . . . 4 wire RTD Special Milivolt Input HHT only NEXT NEXT ENTER Select Input ? ENTER NEXT NEXT NEXT NEXT NEXT Select Unit Deg C ? NEXT Deg F ? NEXT Deg R ? NEXT Kelvin ? ENTER Select Unit ? ENTER NEXT NEXT Set Zero ENTER Plus ? NEXT ENTER NEXT Minus ? Change Zero ? ENTER Set blinking digit NEXT increments blinking digit ENTER sets digit NEXT Full Scale (Span) ENTER Plus ? NEXT ENTER NEXT Minus ? Change Full Scale ? (Span) ENTER Set blinking digit NEXT increments blinking digit ENTER sets digit NEXT Select Sensor Failsafe ENTER Failsafe On ? Select Sensor Failsafe ? ENTER NEXT NEXT Failsafe Off ? NEXT Select Transmitter Failsafe ENTER Select Transmitter Failsafe ? ENTER NEXT Failsafe Low ? Failsafe High ? Failsafe Off ? NEXT NEXT NEXT Trim 4.00 mA Raise mA output ? ENTER NEXT NEXT Lower mA output ? Trim 4.00 mA ? ENTER NEXT = + ENTER NEXT = - ENTER Trim 20.00 mA NEXT Raise mA output ? ENTER NEXT NEXT Lower mA output ? Trim 20.00 mA ? ENTER NEXT = + ENTER NEXT = - ENTER NEXT Trim Sensor ENTER Plus ? NEXT ENTER NEXT Minus ? Trim Sensor ? ENTER NEXT NEXT ENTER Set blinking digit increments blinking digit sets digit Select Language ENTER Select Language ? ENTER German ? NEXT French ? NEXT Spanish ? NEXT English ? NEXT Display Mode NEXT Return to Operate Mode Return to Operate ? ENTER Wait 5 seconds NEXT Display Mode NEXT MI EMT0111 A-(en) TI20 9 5 MOUNTING 5 .3 Head Housing NOTE When installing the transmitter or mounting in a housing, please observe the national safety requirements. The electronic with sensor connections code 2 and 3 are intended to be mounted into a head housing as per DIN 43729 Type TZ-A/BL. Gauge slides as per DIN 43735 respectively DIN 43762. Terminal socket type . . . . . . . . . B Max. numbers of terminals. . . . . 4 Distance between terminals (overall size) . . . . . . . . max. 33 mm 5 . 1 DIN rail mounting The electronic can be mounted at a DIN rail. SENSOR CONNECTIONS CODE 1 STANDARD SCREWS Pg 16 M24x1.5 DIN RAIL BRACKET FOR DIN RAIL MOUNTING 5 . 2 Field Housing Terminal socket 33 1.30 mm in 10 0.39 ~24 0.94 The electronic can be mounted in a field housing. For delivery with LCD configurator the cover has a glass window. 10 TI20 MI EMT0111 A-(en) Mounting instructions for type BIA 409 The Transmitter must be mounted in an enclosure providing a degree of protection of at least IP 20 per IEC 529, when installed in an indoor location, and in an enclosure providing a degree of protection of at least IP 44 per IEC 529, when installed in an outdoor location. Mounting instructions for type BN 409 A Temperature Transmitter without enclosure must be mounted in an enclosure providing a degree of protection of at least IP 54 per IEC 529. The degree of protection of at least IP 54 to IEC 529 is only achieved if cable entries are used that are suitable for the application and correctly installed. Cable entries must comply with Clause 5.3.2 of BS 6941. 6 DIMENSIONS mm in 1 42,8 1.685 SENSOR CONNECTIONS CODE 1 STANDARD SCREWS 4 2 3 32,64 1.285 28,45 1.120 44,2 1.740 2 3 4 26,16 1.030 1 SENSOR CONNECTIONS CODE 2 SOLDER TERMINALS 33 1.3 44,2 1.740 1 2 3 59,69 2.350 SENSOR CONNECTIONS CODE 3 COMPACT SCREWS 4 29,5 1.160 MI EMT0111 A-(en) 11 TI20 One line LCD configurator Three line LCD configurator 63,5 2.50 mm in 1 0 0.0 - 2 0 0.0 0 C CELSIUS 63,02 2.48 32,64 1.285 42,8 1.685 53,82 2.119 32,64 1.285 42,8 1.685 50,00 1.969 12 TI20 MI EMT0111 A-(en) DIMENSIONS (continued) Rail installation mm in 11 0.44 DIN RAIL FIXING SCREW BRACKET FOR DIN RAIL MOUNTING Field housing mm in X DN50 OR 2 in PIPE (BY USER) 29,4 1.16 9 0.35 1/2 NPT, 2 PLACES 10 0.39 WALL MOUNTING NOTE 2 89 3.5 45 1.77 NOTES DIMENSION X (NOTE 1) WITHOUT LCD COFIGURATOR WITH LCD COFIGURATOR 87 3.4 112 4.4 72 2.83 1. ALLOW 51 mm (2 in) CLEARANCE FOR COVER REMOVAL 2. EXTERNAL COVER LOCK AND GROUND SCREW LOCATION FOR ELECTRICAL CLASSIFICATION CODE EDZ AND FDZ 72 2.83 106 4.17 36 1.42 4.7 119 4.3 109 25 0.98 PIPE MOUNTING MI EMT0111 A-(en) TI20 7 METHODS OF ELECTRICAL CONNECTION 13 7 .3 Top installation For sensor connections codes (2) and (3): 7 . 1 Rail installation SENSOR CONNECTIONS CODE 1 STANDARD SCREWS DIN RAIL BRACKET FOR DIN RAIL MOUNTING 1 Loosely mount clamp for rail installation and electronic 2 Let electronic click into clamp rail 3 Tighten bolts for mounting 4 Connect sensor 5 Connect power supply 6 Mount LCD configurator, if necessary 1 2 3 4 5 6 Unscrew or unclap housing lid Insert cable through cable joint Connect sensor Connect power supply Mount electronic in the housing lid Watch cable lines when closing housing lid 7 . 2 Mounting in Field housing The temperature transmitter is fixed in the housing with 2 screws. When required the LCD configurator can be plugged in. The electronic automatically detects it. For the sensor and the 4 ... 20 mA loop an extra cable entry is available. 7 .4 Grounding A functional grounding is not required. In the event that the plant calls for a grounding conduct connection (potential balance, protection from electromagnetic influences) the corresponding connections have to be produced (ground housing). 14 TI20 MI EMT0111 A-(en) 8 SAFETY REQUIREMENTS 8 .1 General requirements 8 . 2 Explosion protection This device satisfies the conditions for safety class III according to EN 61010-1 (resp. IEC 1010-1). (Only if ordered accordingly) Work on electrical parts must be done by qualified personnel if any power supplies are connected to the instrument. The instrument must be used for its designated purpose and connected in accordance with its connection diagram. Locally applicable installation regulations for electrical equipment must be observed, e.g. in the Federal Republic of Germany DIN VDE 0100 and DIN VDE 0800. The instrument must be operated with safety extra-low voltage (SELV) or SELV-E (functional extra-low voltage with reliable disconnection). Safety precautions taken in the instrument may be rendered ineffectual if the instrument is not operated in accordance with the commissioning and maintenance instructions. Limitation of power supplies for fire protection have to be observed due to EN 61010-1, appendix F (resp. IEC 1010-1) Technical specifications for explosion protection see product specifications PSS EMT0111 A-(en) and certificates of conformity EX EMT0111 A-(de)(en) For installations in contact with explosive atmospheres, relevant national regulations and installation conditions must be observed, e.g. in the Federal Republic of Germany ElexV and DIN VDE 0165. Attention: When repairing explosion-proof equipment, observe the national regulations. The following applies to the Federal Republic of Germany: Repairs involving parts required for explosionproofing must either be carried out by the manufacturer or by authorized personnel and confirmed by a certificate. Cable entry The cable entries for explosion proof application Code EDZ, CENELEC EEx d or Code FDZ, FM explosionproof are 1/2 - 14 NPT (according to ANSI/ASME B1.20.1). “EEx d” certified instruments must be connected via cable glands resp. tube systems which satisfy the requirements of EN 50018 and have a separate certification. Unused openings must be closed according to EN 50018. Cover lock The cover must be locked to avoid opening under hazardous conditions. MI EMT0111 A-(en) 15 TI20 9 POWER SUPPLY Direct supply D. C. voltage Us = 12 ... 42 V 1) The supply is via the signal circuit in twin conduct technique to the connecting clamps plus and minus. Transformer Power Supply Unit (MUS) FOXBORO ECKARDT power supply units ( for example MUS925, see Product Specifications PSS EII 0110 A-(en) ) are available for intrinsically-safe applications. Us = 12...42 V Field Control room T MUS RL T 4...20mA Transmitter Connected device including line resistance (e.g. recorder) Load: The maximum permissible load resistor RB max. is calculated according to the following formula: RL max. = U S − 12 V 0,02 A Ω Us = Supply voltage Load characteristic for direct supply RL Ω 1500 1200 800 400 250 200 0 12 16 17 20 28 36 42 V US The load resistor must be min. 250 Ω with HART communication, min. 200 Ω with FOXCOM communication. 1) For explosion protected devices, please observe the safety provisions as outlined in item 8 Us 0/4...20mA Transmitter Power supply RL Connected device (e.g. recorder, controller, etc.) RL max. = 500 Ω 16 TI20 MI EMT0111 A-(en) 10 START-UP 11 SHUT-OFF Measuring start and measuring end were factory set as per order specification or per standard. – Prior to shut-down of the device measurements are to be taken to prevent disturbances of the operation. – Turn off power supply. Damping A damping of 1 s (63%-time) has been set by the factory. Installation Prior to start-up the installation has to be checked. Upon correct mounting and connection to the signal circuit, the transmitter is ready for operation. Dismounting of the device is done in the reversed sequence of mounting (⇒ item 5) MI EMT0111 A-(en) TI20 17 12 MAINTENANCE, REPAIR The safety regulations as outlied in item 8 are to be observed. 1 2 .1 Sight test at site 12.2.2 Voltage Measurement The following configuration has to be set: – Voltage Measurement – Measuring range 0 ... 100 mV The transmitter is maintenance-free. 1 2 3 4 1 2 .2 Functional test Check by means of a LCD Configurator or a Hand Terminal or a PC. For a workshop check-up the following auxiliaries are required: – Power source 0 ... 150 mV or potentiometer (0 ... 1000 Ohm) – Digital Multimeter – Power supply circuit DC 12 ... 42 V 12.2.1 Resistor Measurement The following configuration has to be set: – Resistor Measurement – Measuring Range 6 ... 500 Ohm 1 2 3 4 Short circuit 0 ... 150 mV Procedure: a) Bridge connecting clamps 3, 4 b) Connection of voltage generator to clamps 1, 2 c) Set voltage value d) Check possible over range (115 mV) e) Check possible line breakage 12.2.3 Measurement of the Output Signal The measurement takes place directly in the signal circuit. Loop side Short circuit Short circuit 0 ... 1000 Ω Supply U s Procedure: a) b) c) d) e) f) Bridge connecting clamps 1, 2, and 3, 4 Connection of potentiometer to clamps 2, 3 Indicate resistor value Check possible over range (> 500 Ohm) Check possible short circuit Check possible line breakage DC 12 ... 42 V (4 ... 20 mA) I 0000 Current meter 18 TI20 MI EMT0111 A-(en) 13 OPERATION BY MEANS OF HAND TERMINAL OR PC 1 3 . 2 Operation by means of a PC (HART) The operation of the digital transmitter can be done also by means of a PC or a Hand Terminal.1) To accomplish this, the digital transmitter has to be connected to a power supply of 17 V ... 42 V. A resistor of 250 Ω is to be connected to the supply circuit in sequence. 2) 13.2.1 Hardware The PC is required to have the following minimum equipment: 1 3 .1 Operation by means of Hand Terminal The Hand Terminal enables direct communication with the digital transmitter. With the connection of the Hand Terminal the contact structure of the connected transmitter is automatically produced. The type of device and the TAG number are shown at the Hand Terminal. Various possibilities such as configuration, indications, alignment, failure seeking, etc. may be called up by means of the Hand Terminal via menu. For the Hand terminal HT991 for HART devices see: PSS EMO0100 A-(en) Accessories for devices with HART Protokoll and MI EMO0110 A-(en) HT991 Universal Hand terminal for HART Devices. For the Hand Held Terminal HHT for FOXCOM devices see: PSS 2A-1Z3A HHT I/A Series Hand Held Terminal and HHT Instruction Book 3372 I/A Series Hand-Held Terminal. 1) 2) Please observe the safety provisions as outlined in item 8! Also see item 3 Electrical connection. PC IBM compatible, 386 processor Operating system DOS 3.0 Main memory 4 MB Screen monochrome, color or LCD Interfaces RS232 for communication Hard disk 1 parallel interface for printer For the conversion of the serial interface RS232 to the physical layer of the HART protocol the Modem MOD991 (RS232 / FSK) with galvanic separator is used. 13.2.2 Software The operation is done at the PC with the MMI (Man machine interface) for digital transmitters ABO991. The program corresponds to the draft of standard VDI/VDE 2187E pertaining to form, appearance, operational sequence and arrangement. Also see PSS EMO0100 A-(en) Accessories for devices with HART Protokoll and MI EMO0112 A-(en) ABO991 Display and User Interface for HART devices 1 3 . 3 Operation by means of a PC (FOXCOM) For FOXCOM devices see: PSS 2A-1Z3C PC10 Intelligent Transmitter Configurator and PC10 Instruction Book 3466 Intelligent Transmitter Configurator. MI EMT0111 A-(en) TI20 19 14 TROUBLE SHOOTING Fault Possible cause Remedy No output signal or output signal too low No power supply or power supply too low Connect Us = DC 12 .. 42 V Load impedance too high Check impedance Output signal too high Output signal fluctuates LCD Configurator blank Electrical connection exchanged Connect correctly Line break Check sensor leads Lower range value too low Adjust lower range value resp. lower value of the analog output Upper range value too low Adjust upper range value Electronic defect Check, Replace if necessary Lower range value too low Adjust lower range value Upper range value too high Adjust upper range value Electronic defect Check, Replace if necessary Electronic Check, Replace if necessary No power supply or power supply too low Check power supply LCD Configurator defect Replace LCD Configurator 20 TI20 MI EMT0111 A-(en) Subject to alterations - reprinting, copying and translation prohibited. Products and publications are normally quoted here without reference to existing patents, registered utility models or trademarks. The lack of any such reference does not justify the assumption that a product or symbol is free. FOXBORO ECKARDT GmbH Postfach 50 03 47 D-70333 Stuttgart Tel. # 49(0)711 502-0 Fax # 49(0)711 502-597 DOKT 533 956 058