* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Studying and Improving the Efficiency of Water Electrolysis Using a

Josephson voltage standard wikipedia , lookup

Schmitt trigger wikipedia , lookup

Nanofluidic circuitry wikipedia , lookup

Nanogenerator wikipedia , lookup

Thermal runaway wikipedia , lookup

Operational amplifier wikipedia , lookup

Power electronics wikipedia , lookup

Voltage regulator wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Current source wikipedia , lookup

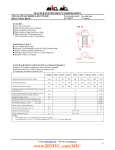

Power MOSFET wikipedia , lookup

Opto-isolator wikipedia , lookup

Surge protector wikipedia , lookup