* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Scanning Electron Microscope - i-Explore International Research

Scanning electrochemical microscopy wikipedia , lookup

Nonlinear optics wikipedia , lookup

Schneider Kreuznach wikipedia , lookup

Chemical imaging wikipedia , lookup

Super-resolution microscopy wikipedia , lookup

Magnetic circular dichroism wikipedia , lookup

Lens (optics) wikipedia , lookup

Optical coherence tomography wikipedia , lookup

Diffraction topography wikipedia , lookup

Optical aberration wikipedia , lookup

Scanning tunneling spectroscopy wikipedia , lookup

Ultrafast laser spectroscopy wikipedia , lookup

Ultraviolet–visible spectroscopy wikipedia , lookup

Auger electron spectroscopy wikipedia , lookup

Vibrational analysis with scanning probe microscopy wikipedia , lookup

Photomultiplier wikipedia , lookup

Reflection high-energy electron diffraction wikipedia , lookup

Confocal microscopy wikipedia , lookup

Rutherford backscattering spectrometry wikipedia , lookup

Harold Hopkins (physicist) wikipedia , lookup

Photon scanning microscopy wikipedia , lookup

X-ray fluorescence wikipedia , lookup

Environmental scanning electron microscope wikipedia , lookup

Transmission electron microscopy wikipedia , lookup

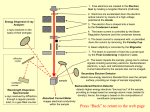

International Journal of IT, Engineering and Applied Sciences Research (IJIEASR) Volume 4, No. 7, July 2015 ISSN: 2319-4413 Scanning Electron Microscope Ramanjeet Kaur, Assistant Professor, Physics Department, R.S.D.College, Firozpur (Punjab) India ABSTRACT Two types of microscopes are used for microscopic study of materials, Light microscopes and Electron microscope. To overcome the limitations possessed by Light Microscopes, Electron microscopes were developed. These microscopes use a beam of energetic electrons to view objects on a very fine scale. In this paper Scanning Electron Microscope has been discussed. The main components of SEM, beam specimen interaction, various signals produced and their detection has been studied in detail. The effect of various operating parameters in SEM on the quality and resolution of image has been pointed out. The limitations in SEM Imaging, are Contamination and Charging of the sample used. Keywords Microscope, transmission, scanning, electron, electrongun 1. INTRODUCTION Electron microscopes are scientific instruments that use a beam of energetic electrons to examine objects on a very fine scale. Electron microscopes were developed due to the limitations of Light Microscopes which are limited by the physics of light. In the early 1930's this theoretical limit had been reached and there was a scientific desire to see the fine details of the interior structures of organic cells (nucleus, mitochondria...etc.).This required 10,000x plus magnification which was not possible using current optical microscopes. Electron microscopes are capable of much higher magnifications and have a greater resolving power than a light microscope, allowing it to see much smaller objects in finer detail [1]. 2. COMPARISON OF OPTICAL AND ELECTRON MICROSCOPE A. Optical Microscope An optical microscope is in principle nothing else than a simple lens system for magnifying small objects. The first lens, called the objective, has a short focal length (a few mm), and creates an image of the object in the intermediate image plane. This image can be looked at with another lens, the eye-piece, which can provide further magnification. The resolution of the image is limited by diffraction. The Abbe-Rayleigh criterion states that, for a wavelength λ , the smallest distance dmin between two point sources such that two can be resolved: dmin = 1.22 x λ/ 2 ΝΑ, where NA = n X sinα is called numerical aperture of the objective lens. Where n is the index of refraction in the object space, and α half the maximal angle under which the objective lens collects light from the object. Advantages and Disadvantages of Optical Microscope Advantages: • Direct imaging with no need of sample pretreatment, the only microscopy for real color imaging. • Fast and adaptable to all kinds of sample systems, from gas, to liquid, and to solid sample systems, in any shapes or geometries. • Easy to be integrated with digital camera systems for data storage and analysis. Disadvantages: • Low resolution, usually up to sub-micron or a few hundreds of nanometers, mainly due to the light diffraction limit. B. Transmission Electron Microscope (TEM) The transmission electron microscope (TEM) was the first type of Electron Microscope to be developed and is patterned sane as the light transmission microscope except that a focused beam of electrons is used instead of light to "see through" the specimen. It was developed by Max Knoll and Ernst Ruska in Germany in 1931. In transmission electron microscopy (TEM), a beam of highly focused electrons is directed toward a thinned sample (<200 nm). Normally no scanning required helps the high resolution, compared to SEM. These highly energetic incident electrons interact with the atoms in the sample producing characteristic radiations and particles providing information for materials characterization. Information is obtained from both deflected and nondeflected transmitted electrons, backscattered and secondary electrons, and emitted photons. i-Explore International Research Journal Consortium www.irjcjournals.org 1 International Journal of IT, Engineering and Applied Sciences Research (IJIEASR) Volume 4, No. 7, July 2015 ISSN: 2319-4413 composition, and crystalline structure and orientation of materials making up the sample [3]. Fig. 1 Overall design of optical microscope, a transmission electron microscope and a scanning electron microscope [2] Advantages and Disadvantages of TEM Advantages: Advantages: • High resolution, as small as 0.2 nm. • Direct imaging of crystalline lattice. • Delineate the defects inside the sample. • No metallic stain-coating needed, thus convenient for structural imaging of organic materials, Electron diffraction technique is used for phase identification, structure and symmetry determination, lattice parameter measurement, disorder and defect identification. Disadvantages: • To prepare an electron-transparent sample from the bulk is difficult (due to the conductivity or electron density, and sample thickness). Advantages and disadvantages of SEM: Advantages: • Almost all kinds of samples, conducting and nonconducting (stain coating needed) can be studied with SEM. • It is based on surface interaction so there is no requirement of electron-transparent sample. • With the help of this, imaging at all directions through x-y-z (3D) rotation of sample is possible. • The SEM has a large depth of field than OM, which allows a large amount of the sample to be in focus at one time and produces an image that is a good representation of the three-dimensional sample. It has high magnification than OM. The combination of higher magnification, larger depth of field, greater resolution, compositional and crystallographic information makes the SEM one of the most heavily used instruments in academic and national lab research areas and industry. Disadvantages: • Low resolution, usually above a few tens of nanometers. • Usually required surface stain-coating with metals for electron conducting. 3. DIFFERENT COMPONENTS OF SEM The main components of a typical SEM are electron column, scanning system, detectors, display, vacuum system and electronics controls (fig. 2). C. Scanning Electron Microscope The first scanning electron microscope (SEM) was constructed in 1938 (Von Ardenne) with the first commercial instruments around 1965. Its late development was due to the electronics involved in "scanning" the beam of electrons across the sample. The scanning electron microscope (SEM) uses a focused beam of high-energy electrons to generate a variety of signals at the surface of solid specimens. Several interactions with the sample that result in the emission of electrons or photons occur as the electrons penetrate the surface. These emitted particles can be collected with the appropriate detector to yield valuable information about the material. The most immediate result of observation in the scanning electron microscope is that it displays the shape of the sample. The resolution is determined by the beam diameter. The signals that derive from electronsample interactions reveal information about the sample including external morphology (texture), chemical i-Explore International Research Journal Consortium Fig.2 Overall design of SEM [5] www.irjcjournals.org 2 International Journal of IT, Engineering and Applied Sciences Research (IJIEASR) Volume 4, No. 7, July 2015 A. Electron Guns: The purpose of the electron gun is to produce a stable beam of electrons of adjustable energy. There are three main types of electron guns: Tungsten hairpin, Lanthanum hexaboride (LaB6) and Field emission. Field emission gun: FEG cathode consists of a sharp metal usually Tungsten tip with a radius of less than 100 nm. A potential difference (V1= extraction voltage) is established between the first anode and the tip. The result is an electric field, concentrated at the tip, which facilitates electron emission. The potential difference between the tip and the second grounded anode determines the accelerating voltage. The higher the accelerating voltage the faster the electrons travel down the column and the more penetrating power they have. There are two types of FEGs: Cold and thermally assisted Field emission guns. Both types of field emission require that the tip remain free of contaminants and oxide and thus they require Ultra High Vacuum condition (10-10to 10-11 Torr ). In the cold FEG the electric field produce by the extraction voltage lowers the work function barrier and allows electrons to directly tunnel through it and thus it facilitates emission. The cold FEGS must have their tip flashed (briefly heated) periodically to free absorbed gas molecules. The thermally assisted FEG (Schottky field emitter) uses heat and nitride coating in addition to voltage to overcome the potential barrier level. Although the FEG has a moderate emission current, its Brightness value is orders of magnitude greater than the thermionic Tungsten and LaB6sources. It is found that brightness is 105, 106, 108 and 108 respectively for Tungsten, LaB6, thermal and cold FEG. Brightness is the beam current per unit area per solid angle 2 [Β=4i /(π d α ) ] and, unlike current, it is conserved down p p p the column. Brightness increases linearly with accelerating voltage (V0) of the gun. The higher the accelerating voltage the faster the electrons travel down the column and the more penetrating power they have. The high brightness is due to small source size as the beam exits the gun. This Source Size for FEGs is of the order of nanometers rather than microns for the other emission sources. The ability to have enough probe current (and thus potential signal) in a probe of small diameter allows the FEGSEM to obtain the resolution it does. The ability to achieve a small probe diameter is directly related to the source size or the diameter of the electron beam exiting the gun. An electron beam emanating from a small source size is said to have high spatial coherency. Electron beams can also be characterized in terms of temporal coherency. ISSN: 2319-4413 A beam with high temporal coherency will have electrons of the same wavelength. In reality there is a certain energy spread associated with the beam. It is found that lower energy spreads result in better resolution and are particularly important in low accelerating voltage imaging. These enhanced properties of FEG come with cost. To achieve the vacuum levels they require very expensive vacuum systems must be attached to these microscopes. The advantages of coherent beam source will be negated if the beam is interacting with molecules on its path down the column. The vacuum at the gun level of the column is kept at 10-10 to 10-11 Torr and the vacuum in the specimen chamber is in the 10-5 to 10-6 Torr range [4]. B. Lenses in SEM The purpose of the electron lenses is to produce a convergent electron beam with desired crossover diameter. The lenses are metal cylinders with cylindrical hole, which operate in vacuum. Inside the lenses magnetic field is generated, which in turn is varied to focus or defocus the electron beam passing through the hole of the lens. Condenser lenses SEMs employ one to three condenser lenses to de-magnify the electron beam crossover diameter in the electron gun to a smaller size. The first and second condenser lenses control the amount of demagnification. After the beam passes the anode it is influenced by two condenser lenses that cause the beam to converge and pass through a focal point. What occurs is that the electron beam is essentially focused down to 1000 times its original size. In conjunction with the selected accelerating voltage the condenser lenses are primarily responsible for determining the intensity of the electron beam when it strikes the specimen [5]. The Objective Lens The final lens in the column called objective lens focuses the probe on the sample. The design of the lenses often incorporates space for the scanning coils, the stigmator and the beam limiting aperture. Since the high currents flowing through the lenses generate excessive heat, they are cooled usually by circulating water. The objective lens controls the final focus of the electron beam by changing the magnetic field strength. The crossover image is finally de-magnified to a ~ 10nm beam spot which carries a beam current of approximately 10-9 - 10-13 A. By changing the current in the objective lens, the magnetic field strength changes and therefore the focal length of the objective lens is changed and hence focusing changes. There are three basic designs of the final (objective) lens: Pinhole or conical lens: In this lens the specimen is outside the lens and its magnetic field. Typical focal lengths for the pinhole final i-Explore International Research Journal Consortium www.irjcjournals.org 3 International Journal of IT, Engineering and Applied Sciences Research (IJIEASR) Volume 4, No. 7, July 2015 lens are between 5 to 40 mm. These have two main operational advantages. First, specimen size is limited by the size of the specimen chamber and not by the lens. Second the variable working distance allows control over the depth of field and size of the imaged area. Immersion lens: This lens is used for specimen small enough of the order of mm to be placed inside the lens. The immersion lens has a very short focal distance range of 2 to 5 mm. A small specimen is placed directly inside the lens gap. Because lens aberrations scale with focal distance, this type of lens yields the lowest aberrations, the smallest probe size, and the highest image resolution. Secondary electrons spiral upward in the strong magnetic field of the lens and are collected by the detector positioned above the lens. This lens generally is not suitable for detecting BSE. Snorkel lens: In this lens the specimen is outside the lens but inside its magnetic field. The snorkel lens combines the best features of both the pinhole and the immersion lenses. Its magnetic field extends outside the lens and reaches the specimen. This design puts restrictions for imaging of magnetic specimens, which could be drawn inside lens with negative consequences for the samples and the SEM. The advantage is that it has low aberrations, and the sample size is not limited by the lens gap. The aberrations of the final lens and consequently the resolution are controlled by a final lens aperture, which affects the beam convergence angle. The final lens aperture has three important effects on the final probe. First there is an optimum aperture angle that minimizes aberrations. Second, the current in the final probe is controlled by the size of the aperture. And third, the probe convergence angle α controls the depth of field. Smaller the angle α greater is the depth of field. Spot size in SEM is minimized at the expense of current. The general approach in SEM is to minimize the probe diameter and maximize the probe current. The minimum probe diameter depends on the spherical aberration of the SEM electron optics, the gun source size, the electron optical brightness and the accelerating voltage. The probe size, which directly effects resolution, can be decreased by increasing the brightness. The electron optical brightness β is a parameter that is function of the electron gun performance and design. For all types of electron guns, brightness increases linearly with accelerating voltage, so every electron source is 10 times as bright at 10 kV as it is at 1 kV. Decreasing the wavelength and the spherical aberration also decreases the probe size. The maximum beam current depends on several parameters. The brightness can be increased by increasing the accelerating voltage, the limiting tendency here is that increasing the accelerating voltage too much ISSN: 2319-4413 increases the volume of generation of X-rays and thus limits resolution. As a consequence increasing the accelerating voltage can be done successfully up to about 30 kV, above that the resolution is effected negatively. Decreasing the spherical aberration is another way of increasing the maximum current. This is achieved more successfully in the immersion type lenses. The above considerations for maximum probe current and minimum probe diameter ignore the contribution of chromatic aberrations. These cannot be ignored when operating at low accelerating voltages in the range of 2 kV or less. The dependence of the probe current becomes much more complex due to the chromatic aberration term. 4. BEAM SPECIMEN INTERACTION AND VARIOUS SIGNALS A. Interaction Volume The combined effect of the elastic and inelastic interactions is to distribute the beam electrons over a three-dimensional “interaction volume” [6]. The concept of interaction volume of the primary beam electrons and the sampling volume of the emitted secondary radiation are important both in interpretation of SEM images and in the proper application of quantitative X-ray microanalysis. The image details and resolution in the SEM are determined not by the size of the electron probe by itself but rather by the size and characteristics of the interaction volume. When the accelerated beam electrons strike a specimen they penetrate inside it to depths of about 1 μm and interact both elastically and in elastically with the solid, forming a limiting interaction volume from which various types of radiation emerge, including BSE, SE, characteristic and brehmsstrahlung x-rays, and cathodeluminescence in some materials. The combined effect of elastic and inelastic scattering controls the penetration of the electron beam into the solid. The resulting region over which the incident electrons interact with the sample is known as interaction volume. The interaction volume has several important characteristics, which determine the nature of imaging in the SEM. The energy deposition rate varies rapidly throughout the interaction volume, being greatest near the beam impact point. The interaction volume has a distinct shape. For lowatomic-number target it has distinct pear shape. For intermediate and high-atomic number materials the shape is in the form of hemi-sphere. The interaction volume increases with increasing incident beam energy and decreases with increasing average atomic number of the specimen. Ultimately the resolution in the SEM is controlled by the size of the interaction volume. i-Explore International Research Journal Consortium www.irjcjournals.org 4 International Journal of IT, Engineering and Applied Sciences Research (IJIEASR) Volume 4, No. 7, July 2015 B. Basic signals of SEM The electrons interact with the atoms at or close to sample surface and produce signals that contain information about the sample's surface topography, composition, and other properties such as electrical conductivity. The types of signals produced by an SEM include secondary electrons, back-scattered electrons (BSE), characteristic X-rays, light (cathodo-luminescence), specimen current and transmitted electrons as shown in figure 2. Secondary electrons: SEs are generated by 3 different mechanisms [6]: • SE(I) are produced by interactions of electrons from the incident beam with specimen atoms. These SEs are produced in close proximity to the incident beam and thus represent a high lateral resolution signal. • SE(II) are produced by interactions of high energy BSEs with specimen atoms. Both lateral and depth distribution characteristics of BSEs are found in the SE(II) signal and thus it is a comparatively low resolution signal. SE(III) are produced by high energy BSEs which strike the pole pieces and other solid objects within the specimen chamber. Images produced with the SE signal will reveal something termed the “edge effect” [7] Edges and ridges of the sample emit more SEs and thus appear brighter in the image. Detection Secondary electrons are having low energy. These can be easily collected by placing a positive voltage (100 - 300V) on the front of the detector. The type of detector used is called photomultiplier tube. ISSN: 2319-4413 attract them would also attract the incident beam. The most common detector used is called a surface barrier detector. It sits above the sample, below the objective lens. BSE which strike it are detected. Surface barrier detectors are solid state devices made up of semiconducting materials. A semiconducting material has a filled valence band and an empty conduction band similar to ceramic materials. When a BSE electron strikes the detector, electrons in the material move from valence to conduction band. The electrons are now free to move in the conduction band or drop back into the valence band. If a potential is applied, the e- and e+ can be separated, collected and the current is measured. The strength of the current is proportional to the number of BSE that hit the detector. Characteristic X-rays: These are emitted when the electron beam removes an inner shell electron from the sample, causing a higher energy electron to fill the shell and release energy. These characteristic X-rays are used to identify the composition and measure the abundance of elements in the sample. For secondary electrons the sampling depth is from 10 to 100 nm and diameter equals the diameter of the area emitting backscattered electrons. BSE are emitted from much larger depths compared to SE. Secondary electrons (SE) are accelerated to the front of the detector by a bias voltage of 100 - 500 eV. They are then accelerated to the scintillator by a bias of 6- 12 KeV, (10 KeV is normal). Scintillator is doped plastic or glass covered with a fluorescent material. A thin (700Å) layer of Al covers it to prevent light from causing fluorescence. The 10keV potential allows the SE to get through the Al and fluoresce. The light photons travel down the tube (guide) to a photocathode which converts them into electrons. The electrons move through the detector, producing more electrons as they strike dynodes. An output electron pulse is then detected. Back-scattered electrons (BSE): These are beam electrons that are reflected from the sample by elastic scattering. BSE are often used in analytical SEM along with the spectra made from the characteristic X-rays. Because the intensity of the BSE signal is strongly related to the atomic number (Z) of the specimen, BSE images can provide information about the distribution of different elements in the sample. Detection Since BSE have high energies, they can’t be pulled in like secondary electrons. Because a potential grid used to Fig.3 Production of various signals from the sample [8] 5. IMAGE FORMATION One of the most surprising aspects of scanning electron microcopy is the apparent ease with which SEM images of three-dimensional objects can be interpreted by any observer with no prior knowledge of the instrument. This is somewhat surprising in view of the unusual way in which image is formed, which seems to differ greatly from i-Explore International Research Journal Consortium www.irjcjournals.org 5 International Journal of IT, Engineering and Applied Sciences Research (IJIEASR) Volume 4, No. 7, July 2015 normal human experience with images formed by light and viewed by the eye. The SEM image is a 2D intensity map in the analog or digital domain. Each image pixel on the display corresponds to a point on the sample, which is proportional to the signal intensity captured by the detector at each specific point. Unlike optical or transmission electron microscopes no true image exists in the SEM. It is not possible to place a film anywhere in the SEM and record an image. It does not exist. The image is generated and displayed electronically. The images in the SEM are formed by electronic synthesis, no optical transformation takes place, and no real of virtual optical images are produced in the SEM. In an analog scanning system, the beam is moved continuously; with a rapid scan along the X-axis (line scan) supplemented by a stepwise slow scan along the Y-axis at predefined number of lines. The time for scanning a single line multiplied by the number of lines in a frame gives the frame time. In digital scanning systems, only discrete beam locations are allowed. The beam is positioned in a particular location remains there for a fixed time, called dwell time, and then it is moved to the next point. When the beam is focused on the specimen, an analog signal intensity is measured by the detector. The voltage signal produced by the detector’s amplifier is digitized and stored as discrete numerical value in the corresponding computer registry. Typically, the intensity is digitized into 8 bits (256 levels), 12 bits (4096) or 16 bits (65,536). The digital image is viewed by converting the numerical values stored in the computer memory into an analog signal for display on a monitor. 6. VARIOUS OPERATING PARAMETERS IN SEM A. Accelerating voltage: The accelerating voltage can be varied by the operator from < 1 kV to 30 kV. Increasing accelerating voltage will: • It decreases lens aberrations. The result is a smaller probe diameter (when considering it alone) and thus better resolution. • It increases the probe current at the specimen. A minimum probe current is necessary to obtain an image with good contrast and a high signal to noise ratio. • It potentially increase charge-up and damage in specimens that are non-conductive and beam sensitive. For imaging polymers and ceramics, voltages below 10 kV should be used [9]. B. Probe Diameter The probe diameter or spot size can be varied on FEGSEM by altering current to a condenser lens. Decreasing the probe diameter will: • • • ISSN: 2319-4413 enable greater resolution. Resolving small specimen features require probe diameters of similar dimensions. decrease lens aberration due to a stronger lens setting. decrease probe current. C. Emission current: Increase of the emission current has following effects: • It increases the probe current at the specimen. • Potentially increase charge up and damage in specimens that are nonconductive and beam sensitive. D. Depth of Field The height over which a sample can be clearly focused is called the Depth of Field. The SEM has a large depth of field which produces the images that appear 3-dimensional in nature. Depth of field is improved by: • Longer working distance • Smaller objective apertures • Lower magnifications E. Objective aperture size: The objective apertures on FEGSEM have a range of sizes that can be selected. Decreasing the diameter of the aperture will: • decrease lens aberrations and thus increase resolution. • decrease the probe current. • decrease the convergence angle of the beam and thus increase depth of focus. F. Working distance: The working distance is adjustable on FEGSEM. Increasing the working distance will: • increase depth of focus. • increase probe size and thus decrease resolution. • increase the effects of stray magnetic fields and thus decrease resolution. • increase aberrations due to the need for a weaker lens to focus. 7. DEFECTS IN SEM IMAGING A. Contamination The term contamination describes the collective phenomena by which the surface of a specimen undergoes deposition of a foreign substance, generally a carbonaceous material derived from the breakdown of hydrocarbon. The effect of this surface deposit is generally observed as a “scan square” when the magnification is reduced while centered on the previous field of view. Contrast arises in such image because of the change in the SE coefficient caused by the deposition of foreign i-Explore International Research Journal Consortium www.irjcjournals.org 6 International Journal of IT, Engineering and Applied Sciences Research (IJIEASR) Volume 4, No. 7, July 2015 material. This can be avoided by starting imaging at low magnifications and gradually increasing it. Contamination can affect the signal at high resolution imaging. Hydrocarbon molecules are attracted to the beam location and form build-up, which obscures the fine detail features. In addition, contamination can be a serious limitation to voltage microscopy [10]. Contamination can be reduced in first place by improving the vacuum in the specimen chamber. Also anticontamination devices can be employed, which cool area in the close vicinity of the specimen so that hydrocarbon migration is reduced. This can be achieved also by cooling directly the sample. Another solution is exposure of the specimen to an intense ultraviolet light prior to SEM imaging. The UV light can crosslink a surface contamination layer and fix it at its place, so later build-up is minimized. ISSN: 2319-4413 8. CONCLUSION Electron microscopes are preferred to Light Microscopes because of their high power of magnification and resolution. SEM uses electrons in the place of light beam for microscopic view. The main components of a typical SEM are electron column, scanning system, detectors, display, vacuum system and electronics controls. The beam interacts with the specimen to produce various signals which include secondary electrons, back-scattered electrons, characteristic X-rays, specimen current and transmitted electrons. The operating parameters like accelerating voltage, depth of field, probe diameter, emission current, objective aperture size and working distance effect the image quality, resolution and focusing of the image. The samples used in SEM Imaging get defected due to contamination and charging. REFERENCES B. Charging When the beam interacts with the sample part of the incident electrons are emitted back, but larger fraction remains in the specimen as the beam electrons lose their initial energy and are captured by the specimen. This charge flows to ground if the specimen is conductor and a suitable connection exists to conduct away the charges. If the ground path is broken, even conducting specimen quickly accumulates charge and its surface potential rises. Charging is more often observed whenever a specimen or portion of it is an insulator. The charges injected by the beam cannot readily flow to ground. The resulting accumulation of charge is a complex, dynamic phenomenon. The specimen is in a continually changing state of surface potential due to the accumulation and discharge of electrons. Charging manifests itself in images in a variety of ways. When local charging alters the surface potential, the field lines of the detector potential, which exist around the sample, are disrupted, and collection of SE is greatly altered. A contrast mechanism develops known as voltage contrast in which the potential distribution across the surface is imaged. Some areas appear extremely bright because they are negative relative to the E-T detector and enhance SE collection. Other areas appear black because they charge positively and suppress the collection of SE. The difficulty arises because the contrast due to surface potential becomes so large that it overwhelms the contrast from the true features of the sample. [1] https://www.jic.ac.uk/microscopy/intro_EM.html [2] http://web.utk.edu/~prack/MSE%20300/SEM.pdf [3] http://serc.carleton.edu/research_education/geoche msheets/techniques/SEM.html [4] http://www.charfac.umn.edu/sem_primer.pdf [5] M.T. Postek, K.S. Howard, A.H. Johnson and K.L. McMichael, Scanning Electron Microscopy: A Student’s Handbook, (Ladd Research Ind., Inc.Williston, VT., 1980). [6] http://emalwww.engin.umich.edu/courses/semlectur es/semlec.html#anchor659909 [7] http://www.cas.muohio.edu/~emfweb/EMTheory/O H_Index.html [8] C.E. Lyman, D.E. Newbury, J.I. Goldstein, D.B. Williams, A.D. Romig, J.T. Armstrong, P. Echlin, C.E. Fiori, D.C. Joy, E. Lifshin and Klaus-Ruediger Peters, Scanning Electron Microscopy, X-Ray Microanalysis and Analytical Electron Microscopy: A Laboratory Workbook, (Plenum Press New York, N.Y., 1990). [9] http://www.jeol.com/sem/docs/sem_guide/tbcontd. html (accessed 1 Feb 2005). [10] JEOL: A Guide to Scanning Microscope Observation [11] http://cfamm.ucr.edu/documents/sem-intro.pdf Effects due to charging can be minimized by coating the sample with conductive film, by utilizing rapid scanning, by imaging with BSE, and low accelerating voltage [11]. i-Explore International Research Journal Consortium www.irjcjournals.org 7