structural implications of ultra-high performance fibre

... and non-negligible tensile strength and ductility, provided by multi-microcracking. This allows significant tensile forces to be sustained by elements in bending even without the use of ordinary reinforcement. Thanks also to the material’s resistance to environmental degradation, very thin structura ...

... and non-negligible tensile strength and ductility, provided by multi-microcracking. This allows significant tensile forces to be sustained by elements in bending even without the use of ordinary reinforcement. Thanks also to the material’s resistance to environmental degradation, very thin structura ...

Revisit and insight into the dilemma of strong and brittle materials

... middle of the 1950’s [6, 7]. We can easily predict higher flow stress and fracture stress for polycrystals with the finer grain size. However, there is a general recognition that the experimental data on the flow stress and fracture stress do not always follow the linear curve and deviate at smaller gr ...

... middle of the 1950’s [6, 7]. We can easily predict higher flow stress and fracture stress for polycrystals with the finer grain size. However, there is a general recognition that the experimental data on the flow stress and fracture stress do not always follow the linear curve and deviate at smaller gr ...

FATIGUE LIFE OF GRAPHITE/EPOXY LAMINATES SUBJECTED TO

... that, as anticipated from eq. (7), the trend of the data points is substantially linear, witnessing the suitability of the theoretical model. The value _ t = 0.0423 was calculated from the slope of the best fit straight line. Treating the data in Table II according to the procedure outlined previous ...

... that, as anticipated from eq. (7), the trend of the data points is substantially linear, witnessing the suitability of the theoretical model. The value _ t = 0.0423 was calculated from the slope of the best fit straight line. Treating the data in Table II according to the procedure outlined previous ...

microhardness studies

... Nanocrystalline materials provide a promising way to generate ductile ceramics but, poses new problems to physicists and material scientists on the property-structure relationship. In studying the mechanical behaviour of nanocrystalline metals and alloys, conflicting results have been obtained for t ...

... Nanocrystalline materials provide a promising way to generate ductile ceramics but, poses new problems to physicists and material scientists on the property-structure relationship. In studying the mechanical behaviour of nanocrystalline metals and alloys, conflicting results have been obtained for t ...

Dynamic propagation of a macrocrack interacting with parallel small

... (FEM), the peridynamic theory was introduced by Silling [14] as a new continuum mechanics formulation in order to solve problems with discontinuities such as cracks. Peridynamic theory uses displacements rather than displacement derivatives in its formulation. Hence, as opposed to classical continuu ...

... (FEM), the peridynamic theory was introduced by Silling [14] as a new continuum mechanics formulation in order to solve problems with discontinuities such as cracks. Peridynamic theory uses displacements rather than displacement derivatives in its formulation. Hence, as opposed to classical continuu ...

Ductile Ceramics

... strain rate characteristic of the given machine. Strain rate influences transition temperature both in single crystals and in polycrystalline materials. Moreover, in single crystals all the effects should be taken into account. In Fig. 2.3, the influence of orientation is indicated. Here, the BDT of ...

... strain rate characteristic of the given machine. Strain rate influences transition temperature both in single crystals and in polycrystalline materials. Moreover, in single crystals all the effects should be taken into account. In Fig. 2.3, the influence of orientation is indicated. Here, the BDT of ...

SINTERED MATERIALS WITH HIGH POROSITY

... Abstract. The paper represents a review of the research of the author related to sintered porous materials. It presents in a synthetic way the classification, the main properties and the functional characteristics of the porous sintered sheets: behaviour to mechanical stress, permeability and techno ...

... Abstract. The paper represents a review of the research of the author related to sintered porous materials. It presents in a synthetic way the classification, the main properties and the functional characteristics of the porous sintered sheets: behaviour to mechanical stress, permeability and techno ...

Mechanical Properties and Fracture Patterns of Graphene (Graphitic

... tion of their graphene-like strength [30, 17]. The mechanical properties of graphene have been intensively investigated by different methodologies, both in experiments and in theory. Based on atomic force microscope (AFM) nanoindentation experiments, it was found that the Young’s modulus of free st ...

... tion of their graphene-like strength [30, 17]. The mechanical properties of graphene have been intensively investigated by different methodologies, both in experiments and in theory. Based on atomic force microscope (AFM) nanoindentation experiments, it was found that the Young’s modulus of free st ...

Relationship between Yield stress and yield Strength on Various

... Yield strength vs. log10Z behaviour The values for yield strength due to load and torque ( against log10Z are plotted. From the graphs (figures 6 and 7), it is observed that the minimum value of Zener-Hollomon parameter (Z) for all the experimental data that will produce any reasonable value of yiel ...

... Yield strength vs. log10Z behaviour The values for yield strength due to load and torque ( against log10Z are plotted. From the graphs (figures 6 and 7), it is observed that the minimum value of Zener-Hollomon parameter (Z) for all the experimental data that will produce any reasonable value of yiel ...

potential of carnuba wax in ameliorating brittle fracture during tableting

... propagation. Hence, systems which deform readily under an applied stress also exhibit a low tendency towards brittle fracture, which explains the fracture-ameliorating effect of carnuba wax. Effect of particle size of the granules – At a given compression load the smaller granules produced harder ta ...

... propagation. Hence, systems which deform readily under an applied stress also exhibit a low tendency towards brittle fracture, which explains the fracture-ameliorating effect of carnuba wax. Effect of particle size of the granules – At a given compression load the smaller granules produced harder ta ...

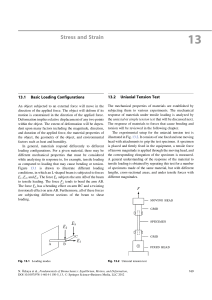

Stress and Strain

... Another method of representing the results obtained in a uniaxial tension test is by first dividing the magnitude of the applied force F with the cross-sectional area A of the specimen, normalizing the amount of deformation by dividing the measured elongation with the original length of the specimen, ...

... Another method of representing the results obtained in a uniaxial tension test is by first dividing the magnitude of the applied force F with the cross-sectional area A of the specimen, normalizing the amount of deformation by dividing the measured elongation with the original length of the specimen, ...

Brittle fracture - Flaney Associates

... Inclusions, porosity, thickness of material, position of defects. Uses a die to penetrate open defects. Surface cracks and porosity Uses a magnetic field and iron powder to locate surface and near surface defects. Surface cracks and defects Based on magnetic induction. ...

... Inclusions, porosity, thickness of material, position of defects. Uses a die to penetrate open defects. Surface cracks and porosity Uses a magnetic field and iron powder to locate surface and near surface defects. Surface cracks and defects Based on magnetic induction. ...

An energy-based approach for estimates of the stress-strain

... in the last decades. This happens in spite of the existence of a small volume of material in front of the crack (plastic zone) where the stresses are well above the yield point. The analysis of stress in notches, needed almost exclusively for fatigue design purposes, is performed with the help of th ...

... in the last decades. This happens in spite of the existence of a small volume of material in front of the crack (plastic zone) where the stresses are well above the yield point. The analysis of stress in notches, needed almost exclusively for fatigue design purposes, is performed with the help of th ...

Effect of Type and Volume Fraction of Aggregate on - IA

... cement ratio, and the maximum particle size of aggregate were kept constant, but the volume fraction of aggregate was varied from 0.0 (hep) to 0.60 in steps of0.15. The critical stress intensity factor of the hardened cement paste, for which LEFM is valid, was determined from centrally notched disc ...

... cement ratio, and the maximum particle size of aggregate were kept constant, but the volume fraction of aggregate was varied from 0.0 (hep) to 0.60 in steps of0.15. The critical stress intensity factor of the hardened cement paste, for which LEFM is valid, was determined from centrally notched disc ...

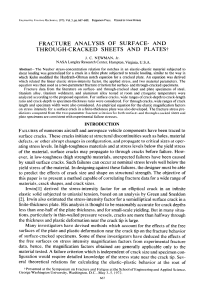

fracture analysis of surface- and through-cracked

... initial crack sizes were used in the analysis for all surface crack data because critical crack sizes (crack size at the failure load) are generally not reported. Slow crack extension before failure occurs in some surface-crack specimens, but is difficult to record. Also, examination of the fracture ...

... initial crack sizes were used in the analysis for all surface crack data because critical crack sizes (crack size at the failure load) are generally not reported. Slow crack extension before failure occurs in some surface-crack specimens, but is difficult to record. Also, examination of the fracture ...

The fracture toughness of a cordierite square lattice

... of the macroscopic, critical bending stress rcr on the outermost fibre of the bend specimen is such that the maximum tensile stress within any strut of the lattice attains the cellwall strength rTS . The resulting dependence of rcr =ru upon at=l2 is included in Fig. 4, for fixed a=H ¼ 1=2. (Recall tha ...

... of the macroscopic, critical bending stress rcr on the outermost fibre of the bend specimen is such that the maximum tensile stress within any strut of the lattice attains the cellwall strength rTS . The resulting dependence of rcr =ru upon at=l2 is included in Fig. 4, for fixed a=H ¼ 1=2. (Recall tha ...

Dislocations

... be around E/10, E being the modulus of elasticity This strength is a function of the cohesive forces between the atoms Experimental values lie between 10 and 1000 times below this value These values are a due to very small flaws occurring throughout the material referred to as stress raisers ...

... be around E/10, E being the modulus of elasticity This strength is a function of the cohesive forces between the atoms Experimental values lie between 10 and 1000 times below this value These values are a due to very small flaws occurring throughout the material referred to as stress raisers ...

a new frontier for deposit stress measurement

... = Stress in megapascals, MPa. Note: MPa x 145 = PSI. L = Length of substrate on which the deposit is applied in mm. For Deposit Stress Analyzer test strips, this value is 76.2 mm. t = Deposit average thickness in millimeters. M = Correction for modulus of elasticity difference between the deposit ...

... = Stress in megapascals, MPa. Note: MPa x 145 = PSI. L = Length of substrate on which the deposit is applied in mm. For Deposit Stress Analyzer test strips, this value is 76.2 mm. t = Deposit average thickness in millimeters. M = Correction for modulus of elasticity difference between the deposit ...

Strain Rate Dependent Flow Stress Characterization

... which increasingly become significant with miniaturization as explained by Razali and Qin (2013). The pioneering work in microforming by Geiger et al. (2001) on miniaturization effect on mechanical response first provided evidence that there is significantly changing mechanical properties with reduc ...

... which increasingly become significant with miniaturization as explained by Razali and Qin (2013). The pioneering work in microforming by Geiger et al. (2001) on miniaturization effect on mechanical response first provided evidence that there is significantly changing mechanical properties with reduc ...

lecture 10-12 mechanical failure

... rotors in jet engines and steam generators that experience centrifugal stresses, and high-pressure steam lines). Deformation under such circumstances is termed creep. It could be defined as the time-dependent and permanent deformation of materials when subjected to a constant load or stress. Creep ...

... rotors in jet engines and steam generators that experience centrifugal stresses, and high-pressure steam lines). Deformation under such circumstances is termed creep. It could be defined as the time-dependent and permanent deformation of materials when subjected to a constant load or stress. Creep ...

Chapter 3 Fracture

... Fracture strength of a brittle solid is related to the cohesive forces between atoms. One can estimate that the theoretical cohesive strength of a brittle material should ...

... Fracture strength of a brittle solid is related to the cohesive forces between atoms. One can estimate that the theoretical cohesive strength of a brittle material should ...

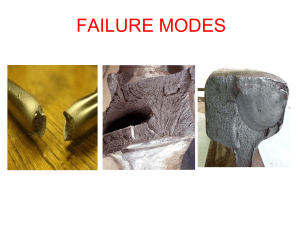

Failure Modes

... • The stress at which the material starts to behave in a non-elastic manner is called the elastic limit. • Between A & B, the material behaves elastically & regains the original position after removal of load. • Point ‘B’ denotes the elastic limit • As the load is increased beyond point B, there com ...

... • The stress at which the material starts to behave in a non-elastic manner is called the elastic limit. • Between A & B, the material behaves elastically & regains the original position after removal of load. • Point ‘B’ denotes the elastic limit • As the load is increased beyond point B, there com ...

Analysis of the Service Straining on the Beam

... loading using the formulas implicit from Mohr’s circles [1]. Using the modular and reconfigurable system cRIO was realized measuring during the driving the lorry FGS. Continuously measurement by strain gages was supported by accelerometers synchronically measurement. ...

... loading using the formulas implicit from Mohr’s circles [1]. Using the modular and reconfigurable system cRIO was realized measuring during the driving the lorry FGS. Continuously measurement by strain gages was supported by accelerometers synchronically measurement. ...

Stress - Delta University!

... • The elastic and proportional limits have nearly the same values, as they represent the same phenomena. ...

... • The elastic and proportional limits have nearly the same values, as they represent the same phenomena. ...

Size effect on structural strength

According to the classical theories of elastic or plastic structures made from a material with non-random strength (ft), the nominal strength (σN) of a structure is independent of the structure size (D) when geometrically similar structures are considered. Any deviation from this property is called the size effect. For example, conventional strength of materials predicts that a large beam and a tiny beam will fail at the same stress if they are made of the same material. In the real world, because of size effects, a larger beam will fail at a lower stress than a smaller beam.The structural size effect concerns structures made of the same material, with the same microstructure. It must be distinguished from the size effect of material inhomogeneities, particularly the Hall-Petch effect, which describes how the material strength increases with decreasing grain size in polycrystalline metals.The size effect can have two causes: statistical, due to material strength randomness, and energetic (and non-statistical), due to energy release when a large crack or a large fracture process zone (FPZ) containing damaged material develops before the maximum load is reached.The limitations of elasticity theory are discussed in good textbooks on the topic. The same holds for plasticity theory. Modern computational models do not have these limitations and they predict structural strength correctly for any size. The scientists that develop new material models make sure that the results agree with the size effect laws. The engineers that design exceptionally large structures make sure that the calculations do not include a size effect mistake.