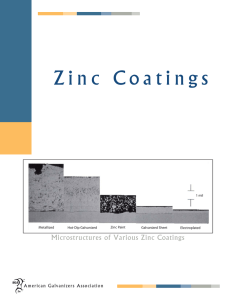

Zinc Coatings - Court Galvanizing Inc

... with recesses or blind holes may not by combustion of an oxygen-fuel gas be thoroughly coated because of flame or by electric arc. Processes have inaccessibility to the peening action of been developed for feeding molten the glass beads. It is also important that zinc directly into the spray nozzle, ...

... with recesses or blind holes may not by combustion of an oxygen-fuel gas be thoroughly coated because of flame or by electric arc. Processes have inaccessibility to the peening action of been developed for feeding molten the glass beads. It is also important that zinc directly into the spray nozzle, ...

Formation of Nanooctahedra in Molybdenum Disulfide and

... matches the conditions used to form Buckminsterfullerene.1 Recently, the search for inorganic fullerene-like materials has continued by examining more energetic synthetic techniques10-13 and other layered materials.10,14-16 The analogy with carbon, however, is not complete since caged structures wit ...

... matches the conditions used to form Buckminsterfullerene.1 Recently, the search for inorganic fullerene-like materials has continued by examining more energetic synthetic techniques10-13 and other layered materials.10,14-16 The analogy with carbon, however, is not complete since caged structures wit ...

Siloxane-containing polymers

... hydrocarbon present. Some of the compounds may darken if exposed to light or air for extended periods of time. ...

... hydrocarbon present. Some of the compounds may darken if exposed to light or air for extended periods of time. ...

Conversion Coatings - CORE

... Definition of Conversion Coating and Requirements of Conversion Coatings The aluminium surface, supporting its relatively thin air-formed film with associated flaws or defects, generally has good inherent corrosion resistance. However, for particular functions in selected environments, or for decora ...

... Definition of Conversion Coating and Requirements of Conversion Coatings The aluminium surface, supporting its relatively thin air-formed film with associated flaws or defects, generally has good inherent corrosion resistance. However, for particular functions in selected environments, or for decora ...

Metallic bonding

... This is the less efficient mode of packing commonly found in alkali metals (Group I elements). It utilizes only 68% of the available space. Body-centred cubic structure has 8 atoms at the corners of a cube and 1 atom at the centre. Each sphere has 8 nearest neighbours, thus the coordination number i ...

... This is the less efficient mode of packing commonly found in alkali metals (Group I elements). It utilizes only 68% of the available space. Body-centred cubic structure has 8 atoms at the corners of a cube and 1 atom at the centre. Each sphere has 8 nearest neighbours, thus the coordination number i ...

STRUCTURES OF CRYSTALS

... This is the less efficient mode of packing commonly found in alkali metals (Group I elements). It utilizes only 68% of the available space. Body-centred cubic structure has 8 atoms at the corners of a cube and 1 atom at the centre. Each sphere has 8 nearest neighbours, thus the coordination number i ...

... This is the less efficient mode of packing commonly found in alkali metals (Group I elements). It utilizes only 68% of the available space. Body-centred cubic structure has 8 atoms at the corners of a cube and 1 atom at the centre. Each sphere has 8 nearest neighbours, thus the coordination number i ...

Chapter 7 Theoretical investigation

... Iron is the most dominant catalyst that is used today for commercial production of diamond under high pressure. General Electric scientists in 1950s [Bovenkerk et al., 1959, Bundy et al., 1955] discovered that certain molten metals could catalyse the formation of diamond under high pressure. These m ...

... Iron is the most dominant catalyst that is used today for commercial production of diamond under high pressure. General Electric scientists in 1950s [Bovenkerk et al., 1959, Bundy et al., 1955] discovered that certain molten metals could catalyse the formation of diamond under high pressure. These m ...

Bonding and Properties of Compounds

... Covalent networks have very high melting and boiling points as many strong covalent bonds need to be broken in order to change state. They can also be very hard. E.g. Silicon Carbide (SiC) – carborundum, similar structure to diamond Tetrahedral shape ...

... Covalent networks have very high melting and boiling points as many strong covalent bonds need to be broken in order to change state. They can also be very hard. E.g. Silicon Carbide (SiC) – carborundum, similar structure to diamond Tetrahedral shape ...

(Lecture(21) - MSU Chemistry

... alkali'metal,'such'as'Na'or'K.'A'negative'charge'is'carried'by'the'aluminosilicate' framework'for'every'Al'substituted'for'Si,'and'the'alkali'metal'ions'then'occupy' nearby'sites'in'the'aluminosilicate'structure.' ...

... alkali'metal,'such'as'Na'or'K.'A'negative'charge'is'carried'by'the'aluminosilicate' framework'for'every'Al'substituted'for'Si,'and'the'alkali'metal'ions'then'occupy' nearby'sites'in'the'aluminosilicate'structure.' ...

Diamond-like carbon

Diamond-like carbon (DLC) is a class of amorphous carbon material that displays some of the typical properties of diamond. DLC is usually applied as coatings to other materials that could benefit from some of those properties.DLC exists in seven different forms. All seven contain significant amounts of sp3 hybridized carbon atoms. The reason that there are different types is that even diamond can be found in two crystalline polytypes. The usual one has its carbon atoms arranged in a cubic lattice, while the very rare one (lonsdaleite) has a hexagonal lattice. By mixing these polytypes in various ways at the nanoscale level of structure, DLC coatings can be made that at the same time are amorphous, flexible, and yet purely sp3 bonded ""diamond"". The hardest, strongest, and slickest is such a mixture, known as tetrahedral amorphous carbon, or ta-C. For example, a coating of only 2 μm thickness of ta-C increases the resistance of common (i.e. type 304) stainless steel against abrasive wear; changing its lifetime in such service from one week to 85 years. Such ta-C can be considered to be the ""pure"" form of DLC, since it consists only of sp3 bonded carbon atoms. Fillers such as hydrogen, graphitic sp2 carbon, and metals are used in the other 6 forms to reduce production expenses or to impart other desirable properties.The various forms of DLC can be applied to almost any material that is compatible with a vacuum environment. In 2006, the market for outsourced DLC coatings was estimated as about 30,000,000 € in the European Union. In October 2011, Science Daily reported that researchers at Stanford University have created a super-hard amorphous diamond under conditions of ultrahigh pressure, which lacks the crystalline structure of diamond but has the light weight characteristic of carbon.