Friction - Fiitjee

... When solid bodies move through liquids and gases, they also experience this opposing force of friction. For example, a kite flying in the air, an aeroplane moving through air and a submarine moving through water. The force of friction experienced by a body moving over some liquid surface is very sma ...

... When solid bodies move through liquids and gases, they also experience this opposing force of friction. For example, a kite flying in the air, an aeroplane moving through air and a submarine moving through water. The force of friction experienced by a body moving over some liquid surface is very sma ...

Short-time Dynamics of Frictional Strength in Dry Friction

... approximately 0.2μm at measurement frequencies of up to 1MHz. The location X was varied between experiments over the range X=10-70mm. Measurement of the real contact area, A(x,t) along the interface is described, schematically, in Figure 1a. A more detailed description of this measurement technique ...

... approximately 0.2μm at measurement frequencies of up to 1MHz. The location X was varied between experiments over the range X=10-70mm. Measurement of the real contact area, A(x,t) along the interface is described, schematically, in Figure 1a. A more detailed description of this measurement technique ...

Visualization of Seifert Surfaces

... Via a number of steps in which the Seifert surface is deformed, cut, and glued, this equivalence can be shown, but it is not really intuitive. Closed surfaces are easier to understand, hence we studied how a closed surface can be generated that contains the Seifert surface as an embedded subsurface. ...

... Via a number of steps in which the Seifert surface is deformed, cut, and glued, this equivalence can be shown, but it is not really intuitive. Closed surfaces are easier to understand, hence we studied how a closed surface can be generated that contains the Seifert surface as an embedded subsurface. ...

Effect of iron oxide coatings on zinc sorption mechanisms

... phase present. Phyllosilicates and metal-(oxy)hydroxides are among the most reactive minerals in the environment [4]. The sorption mechanisms of metals on these individual sorbents are reasonably well understood. However, many metal oxides and oxyhydroxides, including iron oxides (i.e., ferrihydrite ...

... phase present. Phyllosilicates and metal-(oxy)hydroxides are among the most reactive minerals in the environment [4]. The sorption mechanisms of metals on these individual sorbents are reasonably well understood. However, many metal oxides and oxyhydroxides, including iron oxides (i.e., ferrihydrite ...

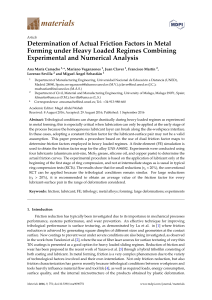

Determination of Actual Friction Factors in Metal Forming

... Recent studies published by Hua et al. [5] and Zhang and Ou [6] show the enthusiastic interest of the scientific community to develop new methods for friction characterization and to discover new relationships between classical friction models, respectively. The most widely accepted methodology to c ...

... Recent studies published by Hua et al. [5] and Zhang and Ou [6] show the enthusiastic interest of the scientific community to develop new methods for friction characterization and to discover new relationships between classical friction models, respectively. The most widely accepted methodology to c ...

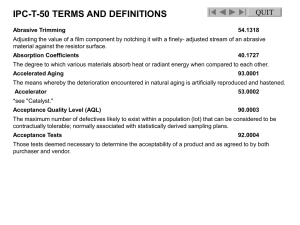

ipc-t-50 terms and definitions

... An electronic component whose basic character changes while operating on an applied signal. (This includes diodes, transistors, thyristors and integrated circuits that are used for the rectification, amplification, switching, etc., of analog or digital circuits in either monolithic or hybrid form.) ...

... An electronic component whose basic character changes while operating on an applied signal. (This includes diodes, transistors, thyristors and integrated circuits that are used for the rectification, amplification, switching, etc., of analog or digital circuits in either monolithic or hybrid form.) ...

The Force of Friction

... This section is only included in a formal lab report and is located at the beginning of the final report. The abstract should contain approximately 150 - 250 words in paragraph form and contain five distinct parts. Think of this an advertisement to read your report. ...

... This section is only included in a formal lab report and is located at the beginning of the final report. The abstract should contain approximately 150 - 250 words in paragraph form and contain five distinct parts. Think of this an advertisement to read your report. ...

Dynamic propagation of a macrocrack interacting with parallel small

... Figure 2. Diagonally Loaded Square Plate (DLSP) problem geometry. The material is chosen as Poly(methyl methacrylate) (PMMA), also known as acrylic or acrylic glass. The material properties are summarized in Table 1. The edge length of the plate is specified as 2w 0.15m . The length of the pre-cra ...

... Figure 2. Diagonally Loaded Square Plate (DLSP) problem geometry. The material is chosen as Poly(methyl methacrylate) (PMMA), also known as acrylic or acrylic glass. The material properties are summarized in Table 1. The edge length of the plate is specified as 2w 0.15m . The length of the pre-cra ...

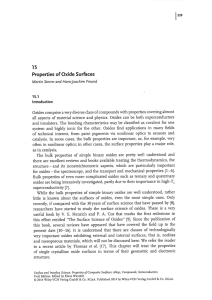

Properties of Oxide Surfaces

... Starting from the close-packed fcc and lncp array, one can realize the structure of oxides \¡¡ith different stoichiometry and coordination by filling the interstitial sites appropriately. The most important classes of oxide crystal structures and typical examples are summal.ized in Table L5. 1. A 1: ...

... Starting from the close-packed fcc and lncp array, one can realize the structure of oxides \¡¡ith different stoichiometry and coordination by filling the interstitial sites appropriately. The most important classes of oxide crystal structures and typical examples are summal.ized in Table L5. 1. A 1: ...

international union of pure and applied chemistry manual of symbols

... and/or the chemical nature of the adsorptive may be modified. It is sometimes difficult or impossible to discriminate experimentally between adsorption and absorption: in such cases it is convenient to use the non-committal term: sorption (together with its derived terms sorbent, sorbate, sorptive). ...

... and/or the chemical nature of the adsorptive may be modified. It is sometimes difficult or impossible to discriminate experimentally between adsorption and absorption: in such cases it is convenient to use the non-committal term: sorption (together with its derived terms sorbent, sorbate, sorptive). ...

Electronic transport at semiconductor

... in the bulk. This is surface-state bands. Sometimes an electron energy level in the allowed surface-state band is at the same time a level where bulk electrons are forbidden. For semiconductors, such surface-state bands become particularly important. The surface-state bands can alter the behaviour o ...

... in the bulk. This is surface-state bands. Sometimes an electron energy level in the allowed surface-state band is at the same time a level where bulk electrons are forbidden. For semiconductors, such surface-state bands become particularly important. The surface-state bands can alter the behaviour o ...

Effect of material and geometric parameters on deformations near

... Abstract. We analyze plane strain thermomechanical deformations of a prenotched rectangular plate impacted on one side by a prismatic body of rectangular cross-section and moving parallel to the axis of the notch. Both the plate and the projectile are made of the same material. Strain hardening, str ...

... Abstract. We analyze plane strain thermomechanical deformations of a prenotched rectangular plate impacted on one side by a prismatic body of rectangular cross-section and moving parallel to the axis of the notch. Both the plate and the projectile are made of the same material. Strain hardening, str ...

View paper - Andrew J. Gellman Research Group

... was then heated as a constant rate of 1 K/sec while using a mass spectrometer to measure the desorption rate of R-3-MCHO from the surface. The resulting TPD spectrum is a plot of R-3-MCHO desorption rate as a function of temperature. The second procedure differed only in that the R-3-MCHO was adsorb ...

... was then heated as a constant rate of 1 K/sec while using a mass spectrometer to measure the desorption rate of R-3-MCHO from the surface. The resulting TPD spectrum is a plot of R-3-MCHO desorption rate as a function of temperature. The second procedure differed only in that the R-3-MCHO was adsorb ...

Friction Lab

... affects the amount of static and kinetic friction. Static friction is the force of friction on the object when it is not moving. Kinetic friction is the friction on the object as the object is moving. Set the graph options to manual and range from 0 N to 7 N and up to 6 seconds. Set the data collect ...

... affects the amount of static and kinetic friction. Static friction is the force of friction on the object when it is not moving. Kinetic friction is the friction on the object as the object is moving. Set the graph options to manual and range from 0 N to 7 N and up to 6 seconds. Set the data collect ...

Materials_for_Automo..

... Although the major application of shot peening is related to improvement of fatigue characteristics, other useful applications have been developed, such as metal forming, straightening, improving resistance to stress corrosion, and testing the adhesion of plated deposits of silver on steel. Forming. ...

... Although the major application of shot peening is related to improvement of fatigue characteristics, other useful applications have been developed, such as metal forming, straightening, improving resistance to stress corrosion, and testing the adhesion of plated deposits of silver on steel. Forming. ...

unit 2 friction

... Figure 2.1 shows a block of mass m resting on a plane surface with application of force P1, P2 and P3 at which the body impends sliding, the self adjusting frictional forces will increase from F1, to F2 and finally F3 when the body tends to move. Thus, in the limiting condition, the resultant active ...

... Figure 2.1 shows a block of mass m resting on a plane surface with application of force P1, P2 and P3 at which the body impends sliding, the self adjusting frictional forces will increase from F1, to F2 and finally F3 when the body tends to move. Thus, in the limiting condition, the resultant active ...

Fracture of granular materials composed of arbitrary grain

... 2. Contacts and cohesive interactions model We aim to develop a model which is applicable to both non contacting and contacting particles, in order to represent a cemented material composed of particles surrounded by a cohesive phase. This type of material is present both in industrial and natural c ...

... 2. Contacts and cohesive interactions model We aim to develop a model which is applicable to both non contacting and contacting particles, in order to represent a cemented material composed of particles surrounded by a cohesive phase. This type of material is present both in industrial and natural c ...

(131904) Topic: Fracture of Metal Temperature Embrittlement

... A fracture is the separation of an object or material into two, or more, pieces under the action of stress. Fracture is consider as the end result of plastic deformation processes which results in creation of two or more new surface. Steps in fracture: 1. crack formation 2. crack propagation ...

... A fracture is the separation of an object or material into two, or more, pieces under the action of stress. Fracture is consider as the end result of plastic deformation processes which results in creation of two or more new surface. Steps in fracture: 1. crack formation 2. crack propagation ...

Ductile fracture

... A fracture is the separation of an object or material into two, or more, pieces under the action of stress. Fracture is consider as the end result of plastic deformation processes which results in creation of two or more new surface. Steps in fracture: 1. crack formation 2. crack propagation ...

... A fracture is the separation of an object or material into two, or more, pieces under the action of stress. Fracture is consider as the end result of plastic deformation processes which results in creation of two or more new surface. Steps in fracture: 1. crack formation 2. crack propagation ...

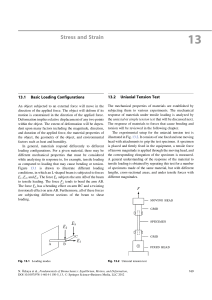

Stress and Strain

... slide individual papers relative to one another and generate frictional forces on the surfaces of individual papers. The shear stress is comparable to the intensity of the frictional force over the surface area upon which it is applied. Now, consider the cantilever beam illustrated in Fig. 13.8a. A ...

... slide individual papers relative to one another and generate frictional forces on the surfaces of individual papers. The shear stress is comparable to the intensity of the frictional force over the surface area upon which it is applied. Now, consider the cantilever beam illustrated in Fig. 13.8a. A ...

Dislocations

... be around E/10, E being the modulus of elasticity This strength is a function of the cohesive forces between the atoms Experimental values lie between 10 and 1000 times below this value These values are a due to very small flaws occurring throughout the material referred to as stress raisers ...

... be around E/10, E being the modulus of elasticity This strength is a function of the cohesive forces between the atoms Experimental values lie between 10 and 1000 times below this value These values are a due to very small flaws occurring throughout the material referred to as stress raisers ...

Analysis of forming thin titanium panels with stiffeners

... are presented. The numerical analysis results were compared with the experimental tests. It was concluded that in order to prevent panel deformation being a result of residual stresses, it is necessary to ensure adequate friction conditions on the contact surfaces between the deformed material and t ...

... are presented. The numerical analysis results were compared with the experimental tests. It was concluded that in order to prevent panel deformation being a result of residual stresses, it is necessary to ensure adequate friction conditions on the contact surfaces between the deformed material and t ...

Cao-Wang - Physical Chemistry of Solid Surfaces - Chapter 2 of Nanostrcutures and Nanomaterials.

... indicative that the impurities and defects are readily to be repelled from the interior to the surface of nanostructures and nanomaterials. At the individual nanostructure level, there are two approaches to the reduction of the total surface energy. One is to reduce the overall surface area, assumin ...

... indicative that the impurities and defects are readily to be repelled from the interior to the surface of nanostructures and nanomaterials. At the individual nanostructure level, there are two approaches to the reduction of the total surface energy. One is to reduce the overall surface area, assumin ...

Cellular materials made of stacked tubes : influence of the

... The first one was made of base metal material (Inco600BM), the second one was affected by the brazing heat treatment (Inco600HT), and the latest was submitted to the NiP layer deposition then followed by the brazing heat treatment (Inco600NiP). ...

... The first one was made of base metal material (Inco600BM), the second one was affected by the brazing heat treatment (Inco600HT), and the latest was submitted to the NiP layer deposition then followed by the brazing heat treatment (Inco600NiP). ...

Fact Sheet

... When properly sealed and coated, an aluminum vehicle body is inherently more corrosion resistant than an equivalent steel body. This corrosion-resistant quality is one of the reasons aluminum is a material of choice in the automotive, commercial transportation and defense industries. However, under ...

... When properly sealed and coated, an aluminum vehicle body is inherently more corrosion resistant than an equivalent steel body. This corrosion-resistant quality is one of the reasons aluminum is a material of choice in the automotive, commercial transportation and defense industries. However, under ...

Wear

In materials science, wear is erosion or sideways displacement of material from its ""derivative"" and original position on a solid surface performed by the action of another surface.Wear is related to interactions between surfaces and specifically the removal and deformation of material on a surface as a result of mechanical action of the opposite surface. The need for relative motion between two surfaces and initial mechanical contact between asperities is an important distinction between mechanical wear compared to other processes with similar outcomes.The definition of wear may include loss of dimension from plastic deformation if it is originated at the interface between two sliding surfaces.However, plastic deformation such as yield stress is excluded from the wear definition if it doesn't incorporate a relative sliding motion and contact against another surface despite the possibility for material removal, because it then lacks the relative sliding action of another surface.Impact wear is in reality a short sliding motion where two solid bodies interact at an exceptional short time interval. Previously due to the fast execution, the contact found in impact wear was referred to as an impulse contact by the nomenclature. Impulse can be described as a mathematical model of a synthesised average on the energy transport between two travelling solids in opposite converging contact. Cavitation wear is a form of wear where the erosive medium or counter-body is a fluid.Corrosion may be included in wear phenomenons, but the damage is amplified and performed by chemical reactions rather than mechanical action.Wear can also be defined as a process where interaction between two surfaces or bounding faces of solids within the working environment results in dimensional loss of one solid, with or without any actual decoupling and loss of material. Aspects of the working environment which affect wear include loads and features such as unidirectional sliding, reciprocating, rolling, and impact loads, speed, temperature, but also different types of counter-bodies such as solid, liquid or gas and type of contact ranging between single phase or multiphase, in which the last multiphase may combine liquid with solid particles and gas bubbles.