464_lec.pdf

... The accuracy of a Finite Element Simulation for plastic deformation strongly depends on the chosen constitutive laws and the value of the material parameters within these laws. The identification of those mechanical parameters can be done based on homogeneous stress and strain fields such as those o ...

... The accuracy of a Finite Element Simulation for plastic deformation strongly depends on the chosen constitutive laws and the value of the material parameters within these laws. The identification of those mechanical parameters can be done based on homogeneous stress and strain fields such as those o ...

Suggested solutions to 2015 MEK2500 Mock Exam

... b (m) with coordinates (x1 , x2 ) ∈ [0, a] × [0, b]. Assume that the body is isotropic and homogeneous with Lamé parameters µ and λ and density ρ. We shall consider the case where the body is clamped at the ends where x1 = 0 or x1 = a (and x2 ∈ [0, b]), hence u = (0, 0) there. Assume that a constan ...

... b (m) with coordinates (x1 , x2 ) ∈ [0, a] × [0, b]. Assume that the body is isotropic and homogeneous with Lamé parameters µ and λ and density ρ. We shall consider the case where the body is clamped at the ends where x1 = 0 or x1 = a (and x2 ∈ [0, b]), hence u = (0, 0) there. Assume that a constan ...

Annealing Stages

... • It is also called age hardening or dispersion hardening, is a technique used to increase the yield strength of materials, including most structural alloys of aluminum, magnesium, nickel and titanium, and some stainless steels. • It relies on changes in solid solubility with temperature to produce ...

... • It is also called age hardening or dispersion hardening, is a technique used to increase the yield strength of materials, including most structural alloys of aluminum, magnesium, nickel and titanium, and some stainless steels. • It relies on changes in solid solubility with temperature to produce ...

Ch 1: Engineering materials

... Classification of Ceramic Materials Ceramics – inorganic compounds of one or more metals with a nonmetallic element. Eg Al2O3, SiC, Si2N3. Crystal structure of ceramic are complex They accommodate more than one element of widely different atomic size. The interatomic forces generally alternate betwe ...

... Classification of Ceramic Materials Ceramics – inorganic compounds of one or more metals with a nonmetallic element. Eg Al2O3, SiC, Si2N3. Crystal structure of ceramic are complex They accommodate more than one element of widely different atomic size. The interatomic forces generally alternate betwe ...

L6-Imperfections

... When metals are plastically deformed, some fraction of the deformation energy (~ 5%) is retained internally; the remainder is dissipated as heat. The major portion of this stored energy is as strain energy associated with dislocations. There are regions in which compressive, tensile, and shear latti ...

... When metals are plastically deformed, some fraction of the deformation energy (~ 5%) is retained internally; the remainder is dissipated as heat. The major portion of this stored energy is as strain energy associated with dislocations. There are regions in which compressive, tensile, and shear latti ...

Calculating the impact force of a mass on an elastic

... can be a large amount of energy absorption through plastic deformation, but the forces we will calculate, up to the proportional limit, are so large that collapse is going to be a done deal and we needn’t worry about the exact magnitude of the ensuing deformation and the relative amounts of plastic ...

... can be a large amount of energy absorption through plastic deformation, but the forces we will calculate, up to the proportional limit, are so large that collapse is going to be a done deal and we needn’t worry about the exact magnitude of the ensuing deformation and the relative amounts of plastic ...

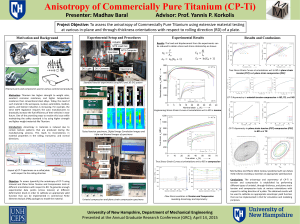

Downloadable - University of New Hampshire

... Motivation: Titanium has higher strength to weight ratio, excellent corrosion resistance, and higher temperature resistance than conventional steel alloys. Today, the need of such material in the aerospace, nuclear, automobile, medical, sports, and fashion industries is increasing. For example, the ...

... Motivation: Titanium has higher strength to weight ratio, excellent corrosion resistance, and higher temperature resistance than conventional steel alloys. Today, the need of such material in the aerospace, nuclear, automobile, medical, sports, and fashion industries is increasing. For example, the ...

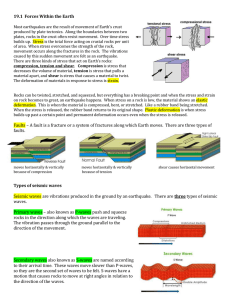

19.1-forces-within-Earth

... compression, tension and shear. Compression is stress that decreases the volume of material, tension is stress that pulls a material apart, and shear is stress that causes a material to twist. The deformation of materials in response to stress is strain. Rocks can be twisted, stretched, and squeezed ...

... compression, tension and shear. Compression is stress that decreases the volume of material, tension is stress that pulls a material apart, and shear is stress that causes a material to twist. The deformation of materials in response to stress is strain. Rocks can be twisted, stretched, and squeezed ...

DETERMINATION OF ACTIVATION ENERGY IN HOT

... Iron aluminides have been considered as potential candidates for high temperature structural applications primarily due to their attractive physical, oxidative, and mechanical properties [1]. Intermetallic compounds of Fe – 40 at. % Al type are formed by B2 FeAl phase. Their low density, comparative ...

... Iron aluminides have been considered as potential candidates for high temperature structural applications primarily due to their attractive physical, oxidative, and mechanical properties [1]. Intermetallic compounds of Fe – 40 at. % Al type are formed by B2 FeAl phase. Their low density, comparative ...

properties of materials

... The plasticity of a material is its ability to undergo some degree of permanent deformation without failure. Plastic deformation will take place only after the elastic range has been exceeded, beyond point b. Plasticity is an important property and widely used in several mechanical processes like fo ...

... The plasticity of a material is its ability to undergo some degree of permanent deformation without failure. Plastic deformation will take place only after the elastic range has been exceeded, beyond point b. Plasticity is an important property and widely used in several mechanical processes like fo ...

Low Cycle Fatigue in Aluminum Foam with Notch

... Metal foams are a new material being used in industry. These materials are used in lightweight structures due to their high strength to weight and stiffness to weight ratios. However, these materials have not been fully characterized yet. This research examined Alporas, a closed cell aluminum foam, ...

... Metal foams are a new material being used in industry. These materials are used in lightweight structures due to their high strength to weight and stiffness to weight ratios. However, these materials have not been fully characterized yet. This research examined Alporas, a closed cell aluminum foam, ...

Compression The mechanical properties of a ductile metal are

... Compression The mechanical properties of a ductile metal are generally obtained from a tension test. Compression behavior is of interest in the metal forming industry, since most processes: rolling and forging involve compression deformations of the metal. In compression an elastic range is exhibite ...

... Compression The mechanical properties of a ductile metal are generally obtained from a tension test. Compression behavior is of interest in the metal forming industry, since most processes: rolling and forging involve compression deformations of the metal. In compression an elastic range is exhibite ...

Slides for lecture #23

... diameter, the strain rate at that cross section increases, with enough strain rate sensitivity the section becomes harder and no further reduction leading to failure occurs. In fine grained (<10 µm) materials close to Tm very large strain rate sensitivity and strain to failure (up to 100-fold elonga ...

... diameter, the strain rate at that cross section increases, with enough strain rate sensitivity the section becomes harder and no further reduction leading to failure occurs. In fine grained (<10 µm) materials close to Tm very large strain rate sensitivity and strain to failure (up to 100-fold elonga ...

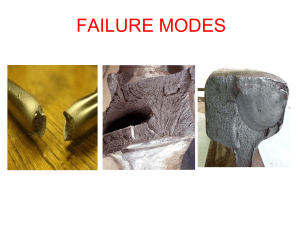

Failure Modes

... • If the load is removed, the specimen does not recover its original dimension & it is said to have undergone plastic deformation or plastic flow • The upper is yield point & denoted by YU, the highest stress before sudden extension occurs. • The lower YP (YL) is the lowest stress producing the larg ...

... • If the load is removed, the specimen does not recover its original dimension & it is said to have undergone plastic deformation or plastic flow • The upper is yield point & denoted by YU, the highest stress before sudden extension occurs. • The lower YP (YL) is the lowest stress producing the larg ...

3.6 Yield Phenomena 3.6.1 Introduction

... to accommodate the solute atom which locks the dislocation, hindering its motion. A larger force (stress) is necessary to move the dislocation, as the cloud of solute atoms is dragged with it. At some stage, the dislocation eventually breaks away from the atmosphere of solute atoms, resulting in red ...

... to accommodate the solute atom which locks the dislocation, hindering its motion. A larger force (stress) is necessary to move the dislocation, as the cloud of solute atoms is dragged with it. At some stage, the dislocation eventually breaks away from the atmosphere of solute atoms, resulting in red ...

1 - The Design Line

... (carbon/silica atoms tetrahedrally arranged which makes them very hard). Crystal; regular arrangement of particles. Amorphous materials – no regular structure Fibre structures – length-to-thickness ratio of >80 Melting, boiling – what happens to the particles? Pure substances = fixed melti ...

... (carbon/silica atoms tetrahedrally arranged which makes them very hard). Crystal; regular arrangement of particles. Amorphous materials – no regular structure Fibre structures – length-to-thickness ratio of >80 Melting, boiling – what happens to the particles? Pure substances = fixed melti ...

CHE 333 Class 19

... growth in a material. Simple energy balance used – energy applied is the stress and it is used up by creating fresh surface. Works well for brittle materials where no plastic deformation. For ductile materials energy absorbed is complicated by plastic deformation. Fracture mechanics relates the size ...

... growth in a material. Simple energy balance used – energy applied is the stress and it is used up by creating fresh surface. Works well for brittle materials where no plastic deformation. For ductile materials energy absorbed is complicated by plastic deformation. Fracture mechanics relates the size ...

Chapter 6: Mechanical Properties

... 1. Specimen with notch- Notch toughness 2. Specimen with crack- Fracture toughness Static (low strain rate) loading condition (tensile stress-strain test) 1. Area under stress vs strain curve up to the point of fracture. ...

... 1. Specimen with notch- Notch toughness 2. Specimen with crack- Fracture toughness Static (low strain rate) loading condition (tensile stress-strain test) 1. Area under stress vs strain curve up to the point of fracture. ...

212_khr.pdf

... concentrators and, as a rule, fracture sources. Therefore the formulation of strain criteria of fracture is actual problem. The present approach is formulated in papers [2-8]. Below generalization of this approach is offered with the formulation of fracture criterion including both the strain state ...

... concentrators and, as a rule, fracture sources. Therefore the formulation of strain criteria of fracture is actual problem. The present approach is formulated in papers [2-8]. Below generalization of this approach is offered with the formulation of fracture criterion including both the strain state ...

High Strain Mechanics and Its Importance in Crushing and Grinding

... explosion. Brittle materials behave differently when subjected to high strain rates as opposed to quasistatic strain rates. Quasi-static loading occurs when the stress pulse is slow enough for the system to remain in internal equilibrium. That is, material fracture develops as the stress pulse moves ...

... explosion. Brittle materials behave differently when subjected to high strain rates as opposed to quasistatic strain rates. Quasi-static loading occurs when the stress pulse is slow enough for the system to remain in internal equilibrium. That is, material fracture develops as the stress pulse moves ...

Poisson`s ratio

... overall gain or loss of volume in conditions of hydrostatic stress ( Ph ). If the Ph increases then the volume will decrease and the volume change will be negative. If the volume increases, Ph will decrease. Ph always has positive value and the negative sign in the compensation (R.H.S.) keeps this r ...

... overall gain or loss of volume in conditions of hydrostatic stress ( Ph ). If the Ph increases then the volume will decrease and the volume change will be negative. If the volume increases, Ph will decrease. Ph always has positive value and the negative sign in the compensation (R.H.S.) keeps this r ...

Document

... of the imposed strain. A harder metal will have a higher resistance to plastic deformation than a less hard metal The five hardening processes are: The Hall-Petch method is used to change the grain size in a material, which can affect the dislocation density. Smaller grain size will make the mater ...

... of the imposed strain. A harder metal will have a higher resistance to plastic deformation than a less hard metal The five hardening processes are: The Hall-Petch method is used to change the grain size in a material, which can affect the dislocation density. Smaller grain size will make the mater ...

Stress - Delta University!

... drawn and shaped into wire by means of tension. • When tensile forces are applied, the wire ...

... drawn and shaped into wire by means of tension. • When tensile forces are applied, the wire ...