Industrial Zinc Plating Processes

... The metal deposit distribution is affected by the variation of the cathode efficiency with current density. In plating solutions in which the cathode efficiencies decrease rapidly as current density increases, excess deposits will plate on edges and corners. This phenomenon is coined throwing power. ...

... The metal deposit distribution is affected by the variation of the cathode efficiency with current density. In plating solutions in which the cathode efficiencies decrease rapidly as current density increases, excess deposits will plate on edges and corners. This phenomenon is coined throwing power. ...

Chemistry of METALS

... (i)Bauxite ore- Hydrated aluminium oxide(Al2O3.2H2O) (ii)Mica ore-Potassium aluminium silicate(K2Al2Si6O16) (iii)China clay ore- aluminium silicate (Al2Si6O16) (iv)Corrundum-Anhydrous aluminium oxide(Al2O3) b)Extraction of aluminium from Bauxite/Halls cell/process) The main ore from which aluminium ...

... (i)Bauxite ore- Hydrated aluminium oxide(Al2O3.2H2O) (ii)Mica ore-Potassium aluminium silicate(K2Al2Si6O16) (iii)China clay ore- aluminium silicate (Al2Si6O16) (iv)Corrundum-Anhydrous aluminium oxide(Al2O3) b)Extraction of aluminium from Bauxite/Halls cell/process) The main ore from which aluminium ...

From Organometallic Zinc and Copper Complexes to Highly

... methanol detection by the GC-instrument), reaching a steady state after ~2 h and remaining at this level for the duration of each experiment (12 h). Initially, ethane was also detected, but production ceased by 5 hours (Fig. S7). It is proposed that the ethane evolution results from the reaction of ...

... methanol detection by the GC-instrument), reaching a steady state after ~2 h and remaining at this level for the duration of each experiment (12 h). Initially, ethane was also detected, but production ceased by 5 hours (Fig. S7). It is proposed that the ethane evolution results from the reaction of ...

Reduction Zinc Corrosion after Nitriding Processing

... different anodic and cathodic electrochemical reactions and there will be different result. There are some methods which could be done to protect zinc metal from corroding, one of them is nuclear technique by using plasma thermomechanical processes in this case is ion nitriding technology to modify ...

... different anodic and cathodic electrochemical reactions and there will be different result. There are some methods which could be done to protect zinc metal from corroding, one of them is nuclear technique by using plasma thermomechanical processes in this case is ion nitriding technology to modify ...

Microbial-induced synthesis of nanoparticles of zinc phosphate and

... and 20 ml Paenibacillus mucilaginosus culture were added to above solution, respectively. The reaction solution was also allowed to stand under static conditions at room temperature for 24 hours. The precipitations were filtrated and washed three times with deionized water and ethanol, and then drie ...

... and 20 ml Paenibacillus mucilaginosus culture were added to above solution, respectively. The reaction solution was also allowed to stand under static conditions at room temperature for 24 hours. The precipitations were filtrated and washed three times with deionized water and ethanol, and then drie ...

xy3-allyl Benzoic Acid, CsHa(COOH)1(OW)2(CsH6)3.---Thi

... A possible alternative which might be considered is that the action takes place in two steps: First, due to the effect of zinc chloride, the alcoholic group is replaced by chlorine. Second, a reaction similar to that of F'riedel and Crafts takes place giving the final product. This explanation i s ...

... A possible alternative which might be considered is that the action takes place in two steps: First, due to the effect of zinc chloride, the alcoholic group is replaced by chlorine. Second, a reaction similar to that of F'riedel and Crafts takes place giving the final product. This explanation i s ...

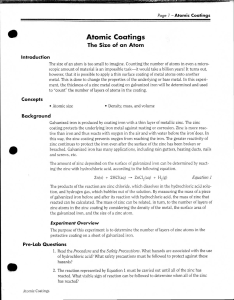

Lab: size of the atom

... Galvanized iron is produced by coating iron with a thin layer of metallic zinc. The zinc coating protects the underlying iron metal against rusting or corrosion. Zinc is more reactive than iron and thus reacts with oxygen in the air and with water before the iron'does. In this way, the zinc coating ...

... Galvanized iron is produced by coating iron with a thin layer of metallic zinc. The zinc coating protects the underlying iron metal against rusting or corrosion. Zinc is more reactive than iron and thus reacts with oxygen in the air and with water before the iron'does. In this way, the zinc coating ...

Effect Of Convection For Gaseous Hydrochloride

... common fixed bed processes. However, there appeared some condensed crystals of the product also at the entrance of the tube to the heated section. Apparently, there was an important effect of free convection, as the ZnCl2 vapor density was significantly higher than the density of other present gases ...

... common fixed bed processes. However, there appeared some condensed crystals of the product also at the entrance of the tube to the heated section. Apparently, there was an important effect of free convection, as the ZnCl2 vapor density was significantly higher than the density of other present gases ...

Zinc Carbonate - Di-Corp

... Avoid inhalation of dust. Do not get on skin, in eyes or on clothing. Keep container closed when not in use. Wear suitable protection for eyes and skin when handling. Use with adequate ventilation. Avoid contact with incompatible material. Store in cool, dry, well-ventilated area away from sources o ...

... Avoid inhalation of dust. Do not get on skin, in eyes or on clothing. Keep container closed when not in use. Wear suitable protection for eyes and skin when handling. Use with adequate ventilation. Avoid contact with incompatible material. Store in cool, dry, well-ventilated area away from sources o ...

Isotopes-Chemistry

... Same Element Different AtomIsotopes All atoms of a particular element are not exactly alike. Some elements have atoms with different masses (isotopes) ...

... Same Element Different AtomIsotopes All atoms of a particular element are not exactly alike. Some elements have atoms with different masses (isotopes) ...

Zinc smelting

Zinc smelting is the process of converting zinc concentrates (ores that contain zinc) into pure zinc. Zinc smelting has historically been more difficult than the smelting of other metals, e.g. iron, because in contrast, zinc has a low boiling point. At temperatures typically used for smelting metals, zinc is a gas that will escape from a furnace with the flue gas and be lost, unless specific measures are taken to prevent it.The most common zinc concentrate processed is zinc sulfide, which is obtained by concentrating sphalerite using the froth flotation method. Secondary (recycled) zinc material, such as zinc oxide, is also processed with the zinc sulfide. Approximately 30% of all zinc produced is from recycled sources.There are two methods of smelting zinc: the pyrometallurgical process and the electrolysis process. Both methods are still used. Both of these processes share the same first step: roasting.