Inductance in DC Circuits

... As you know, when the circuit is energized, it takes time for the current to go from zero to 10 amperes. When the first time constant is completed, the current in the circuit is equal to 63.2% of 10 amperes. Thus the amplitude of current at the end of 1 time constant is 6.32 amperes. ...

... As you know, when the circuit is energized, it takes time for the current to go from zero to 10 amperes. When the first time constant is completed, the current in the circuit is equal to 63.2% of 10 amperes. Thus the amplitude of current at the end of 1 time constant is 6.32 amperes. ...

IOSR Journal of Electrical and Electronics Engineering (IOSR-JEEE)

... fuse, B3=blown fuses, B4=no routine maintenance, B5=due to mechanical stress, B6=prime mover is not able to move the alternator, B7=due to insulation failure, B8=due to variation of speed, B9=rotor windings are kept open, B10=two or more coils in rotor winding are shorted with each other, B 11=coils ...

... fuse, B3=blown fuses, B4=no routine maintenance, B5=due to mechanical stress, B6=prime mover is not able to move the alternator, B7=due to insulation failure, B8=due to variation of speed, B9=rotor windings are kept open, B10=two or more coils in rotor winding are shorted with each other, B 11=coils ...

63-7062 - Variable Frequency Drive (VFD)

... Many of these can be replaced with a standard induction motor and a general purpose PWM VFD to provide a more reliable and cost effective solution to the VFD requirement. Using a VFD often provides energy conservation benefits and improvements in the accuracy of control as a bonus. Many opportunitie ...

... Many of these can be replaced with a standard induction motor and a general purpose PWM VFD to provide a more reliable and cost effective solution to the VFD requirement. Using a VFD often provides energy conservation benefits and improvements in the accuracy of control as a bonus. Many opportunitie ...

USER MANUAL REVISION PORTS ETC DCB-264 USERS GUIDE

... XP) or AMS Cockpit (can be downloaded for free from the AMS web site)). 3. A DCB-264. 4. A SIN-9 or SIN-11 serial adapter (SIN-11 recommended). 5. A +24* to 40Vdc power supply with adequate output power. 6. A compatible stepper motor. 7. A DC amp meter with bridge rectifier circuit. 8. A cooling fan ...

... XP) or AMS Cockpit (can be downloaded for free from the AMS web site)). 3. A DCB-264. 4. A SIN-9 or SIN-11 serial adapter (SIN-11 recommended). 5. A +24* to 40Vdc power supply with adequate output power. 6. A compatible stepper motor. 7. A DC amp meter with bridge rectifier circuit. 8. A cooling fan ...

Central vacuum cleaner cross-controls

... as the hose can be quite bulky and heavy. Various communication systems have been developed. Some systems sense sound or pressure in the pipes to turn the vacuum source on or off, see for example U.S. Pat. No. 5,924,164 issued 20 Jul. 1999 to Edward W. Lindsay under title ACOUSTIC COMMUNICATOR FOR C ...

... as the hose can be quite bulky and heavy. Various communication systems have been developed. Some systems sense sound or pressure in the pipes to turn the vacuum source on or off, see for example U.S. Pat. No. 5,924,164 issued 20 Jul. 1999 to Edward W. Lindsay under title ACOUSTIC COMMUNICATOR FOR C ...

22B-QS001G-EN-P PowerFlex 40 Adjustable Frequency AC Drive

... Mode]. All other stop sources are controlled by P037 [Stop Mode]. Important: The drive is shipped with a jumper installed between I/O Terminals 01 and 11. Remove this jumper when using I/O Terminal 01 as a stop or enable input. P036 [Start Source] ...

... Mode]. All other stop sources are controlled by P037 [Stop Mode]. Important: The drive is shipped with a jumper installed between I/O Terminals 01 and 11. Remove this jumper when using I/O Terminal 01 as a stop or enable input. P036 [Start Source] ...

micromaster 430

... rotating mechanical parts. Non-compliance with Warnings or failure to follow the instructions contained in this manual can result in loss of life, severe personal injury or serious damage to property. Only suitable qualified personnel should work on this equipment, and only after becoming familiar w ...

... rotating mechanical parts. Non-compliance with Warnings or failure to follow the instructions contained in this manual can result in loss of life, severe personal injury or serious damage to property. Only suitable qualified personnel should work on this equipment, and only after becoming familiar w ...

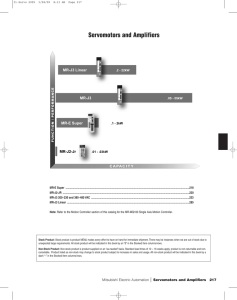

Servomotors and Amplifiers

... proportional to the square of (operating speed/rated speed). If the operating speed changes frequently or when the regeneration is constant (as with vertical feeds), find the regenerative heating value (W) in operation. Provisions must be made to keep this heating value below the tolerable regenerat ...

... proportional to the square of (operating speed/rated speed). If the operating speed changes frequently or when the regeneration is constant (as with vertical feeds), find the regenerative heating value (W) in operation. Provisions must be made to keep this heating value below the tolerable regenerat ...

SHEF40 Submersible/Effluent Pump

... enough water to activate the pump and repeat this cycle until satisfied with pump operation. NOTICE: For best performance of check valve when handling solids, do not install it with the discharge more than 45° above the horizontal. Do not install the check valve in a vertical position as solids may ...

... enough water to activate the pump and repeat this cycle until satisfied with pump operation. NOTICE: For best performance of check valve when handling solids, do not install it with the discharge more than 45° above the horizontal. Do not install the check valve in a vertical position as solids may ...

submersible pump with hazardous location motor end

... Operations 8. Turn switches to Auto position, and pumps should start and operate together until level drops to turn-off point. 9. Repeat this operation cycle several times before leaving the job. 10.Check voltage when pumps are operating, and check the amp draw of each pump. Check amps on each wire ...

... Operations 8. Turn switches to Auto position, and pumps should start and operate together until level drops to turn-off point. 9. Repeat this operation cycle several times before leaving the job. 10.Check voltage when pumps are operating, and check the amp draw of each pump. Check amps on each wire ...

Installation and Maintenance Instruction

... Two key specifications for each motorized pulley are Power (kW) and nominal belt speed (m/sec.), as given in the respective specifications in this catalogue Nominal belt speed is a design target, providing consistent choices among all models and powers. Actual full load belt speed is almost ne ...

... Two key specifications for each motorized pulley are Power (kW) and nominal belt speed (m/sec.), as given in the respective specifications in this catalogue Nominal belt speed is a design target, providing consistent choices among all models and powers. Actual full load belt speed is almost ne ...

LT1970A - 500mA Power Op Amp with Adjustable Precision Current Limit

... VEE (Pins 1, 10, 11, 20, 21): Minus Supply Voltage. VEE connects to the substrate of the integrated circuit die, and therefore must always be the most negative voltage applied to the part. Decouple VEE to ground with a low ESR capacitor. VEE may be a negative voltage or it may equal ground potential ...

... VEE (Pins 1, 10, 11, 20, 21): Minus Supply Voltage. VEE connects to the substrate of the integrated circuit die, and therefore must always be the most negative voltage applied to the part. Decouple VEE to ground with a low ESR capacitor. VEE may be a negative voltage or it may equal ground potential ...

Lesson -13:

... The three phase fully controlled bridge converter has been probably the most widely used power electronic converter in the medium to high power applications. Three phase circuits are preferable when large power is involved. The controlled rectifier can provide controllable out put dc voltage in a si ...

... The three phase fully controlled bridge converter has been probably the most widely used power electronic converter in the medium to high power applications. Three phase circuits are preferable when large power is involved. The controlled rectifier can provide controllable out put dc voltage in a si ...

BUM 62 T - Baumüller Services

... The supply part (mains side) for the generation of the DC link voltage is an uncontrolled diode bridge. To reduce the peak making current (deburdening during switch-on), the DC link capacitors are charged via a charge resistor which is bridged by a thyristor after switching-on. If the typical motor ...

... The supply part (mains side) for the generation of the DC link voltage is an uncontrolled diode bridge. To reduce the peak making current (deburdening during switch-on), the DC link capacitors are charged via a charge resistor which is bridged by a thyristor after switching-on. If the typical motor ...

Brushed DC electric motor

A brushed DC motor is an internally commutated electric motor designed to be run from a direct current power source. Brushed motors were the first commercially important application of electric power to driving mechanical energy,and DC distribution systems were used for more than 100 years to operate motors in commercial and industrial buildings. Brushed DC motors can be varied in speed by changing the operating voltage or the strength of the magnetic field. Depending on the connections of the field to the power supply, the speed and torque characteristics of a brushed motor can be altered to provide steady speed or speed inversely proportional to the mechanical load. Brushed motors continue to be used for electrical propulsion, cranes, paper machines and steel rolling mills. Since the brushes wear down and require replacement, brushless DC motors using power electronic devices have displaced brushed motors from many applications