2012

... 7. a) Draw the circle diagram for a 5 hp, 200v, 50Hz, 4-pole, 3-phase, star-connected induction motor from the following data: 200V,5A, 350 watts ii)100V,26A, 1700 watts. Rotor copper loss at stand still=half of the total copper loss. Estimate there from the full load current, power factor, speed, a ...

... 7. a) Draw the circle diagram for a 5 hp, 200v, 50Hz, 4-pole, 3-phase, star-connected induction motor from the following data: 200V,5A, 350 watts ii)100V,26A, 1700 watts. Rotor copper loss at stand still=half of the total copper loss. Estimate there from the full load current, power factor, speed, a ...

TechTopics No. 20 - Power factor correction capacitor

... are connected in parallel with the motor. The motor requires reactive power (kVARs) to create the magnetic flux. The power factor correction capacitor can supply the kVARs required by the motor when the motor is switched off. At the instant that the motor is switched off, the motor and the driven lo ...

... are connected in parallel with the motor. The motor requires reactive power (kVARs) to create the magnetic flux. The power factor correction capacitor can supply the kVARs required by the motor when the motor is switched off. At the instant that the motor is switched off, the motor and the driven lo ...

Using Xilinx CPLDs as Motor Controllers Summary

... variety of different uses in the consumer and industrial markets including a variety of different positioning systems; printers, scanners, plotters, disk drives, fax machines, and medical ...

... variety of different uses in the consumer and industrial markets including a variety of different positioning systems; printers, scanners, plotters, disk drives, fax machines, and medical ...

Theoretical developments

... The paper proposes a method of identifying the rotor position of a brushless DC (BLDC) motor and driving a motor smoothly form standstill without position sensors. Six current pulses are injected into every two phases of the motor and their first and second differences are compared in order to o ...

... The paper proposes a method of identifying the rotor position of a brushless DC (BLDC) motor and driving a motor smoothly form standstill without position sensors. Six current pulses are injected into every two phases of the motor and their first and second differences are compared in order to o ...

Document

... slip of 5% and develops a maximum torque of 250% of full load torque at a slip of 25%. Neglecting core loss and rotational losses and assuming that the resistances and inductances of the motor are constant, determine the starting torque (at rated voltage and frequency) of the motor expressed as perc ...

... slip of 5% and develops a maximum torque of 250% of full load torque at a slip of 25%. Neglecting core loss and rotational losses and assuming that the resistances and inductances of the motor are constant, determine the starting torque (at rated voltage and frequency) of the motor expressed as perc ...

Inductance, capacitance and resistance

... • In general the advantage of AC is that one can get more power for less weight. • The down side is batteries don’t do AC without help. • They also don’t self start as well as DC units with equal torque load. • A third type, the universal motor, works on both AC and DC, but these are not efficient, ...

... • In general the advantage of AC is that one can get more power for less weight. • The down side is batteries don’t do AC without help. • They also don’t self start as well as DC units with equal torque load. • A third type, the universal motor, works on both AC and DC, but these are not efficient, ...

Implementation of 3-Phase Induction Motor through Indirect Vector

... asynchronous or induction motor is the most widely used electrical drive. Separately excited dc drives are simpler in control because independent control of flux and torque can be brought about [9]. In contrast, induction motors involve a coordinated control of stator current magnitude and the phase ...

... asynchronous or induction motor is the most widely used electrical drive. Separately excited dc drives are simpler in control because independent control of flux and torque can be brought about [9]. In contrast, induction motors involve a coordinated control of stator current magnitude and the phase ...

parametric study of rotor slot shape on a cage induction motor

... Parameterisation of the rotor slot The parameterisation of the rotor slot is based on the previous slot shape shown in Fig.1. The chosen geometric parameters are: the radius r1, r2 and r3, the width w1, and the depths d1, d2 and d3. The authors have adopted a compromise between the need to optimise ...

... Parameterisation of the rotor slot The parameterisation of the rotor slot is based on the previous slot shape shown in Fig.1. The chosen geometric parameters are: the radius r1, r2 and r3, the width w1, and the depths d1, d2 and d3. The authors have adopted a compromise between the need to optimise ...

MOTOR DRIVE APPLICATION SYAHFITRI BIN SAIDIN A project repo

... This means that the motor does not inherently have a maximum speed for any particular applied voltage. Universal motors can be and are generally run at high speeds, 400016000 rpm, and can go over 20,000 rpm [8]. By way of contrast, induction motors cannot turn a shaft faster than allowed by the powe ...

... This means that the motor does not inherently have a maximum speed for any particular applied voltage. Universal motors can be and are generally run at high speeds, 400016000 rpm, and can go over 20,000 rpm [8]. By way of contrast, induction motors cannot turn a shaft faster than allowed by the powe ...

PowerPoint Template

... Robotic Arm command the gripper to open and close, and control wrist motion of 120 degrees, an extensive elbow range of 300°, base rotation of 270°, base motion of 180°, vertical reach of 15", horizontal reach of 12.6", and lifting capacity of 100g. Added features include a search light design on th ...

... Robotic Arm command the gripper to open and close, and control wrist motion of 120 degrees, an extensive elbow range of 300°, base rotation of 270°, base motion of 180°, vertical reach of 15", horizontal reach of 12.6", and lifting capacity of 100g. Added features include a search light design on th ...

Document

... resistor R = 9.0 Ω. A uniform magnetic field directed into the page has a magnitude of 0.30 T. (a) At what speed should bar move to produce an 8.5 mA current in the resistor? (b) At what rate is energy delivered to the resistor? (c) Explain the origin of energy being delivered to the resistor. ...

... resistor R = 9.0 Ω. A uniform magnetic field directed into the page has a magnitude of 0.30 T. (a) At what speed should bar move to produce an 8.5 mA current in the resistor? (b) At what rate is energy delivered to the resistor? (c) Explain the origin of energy being delivered to the resistor. ...

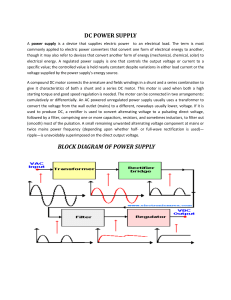

DC POWER SUPPLY BLOCK DIAGRAM OF POWER SUPPLY

... The introduction of DC motors to run machinery eliminated the need for local steam or internal combustion engines, and line shaft drive systems. DC motors can operate directly from rechargeable batteries, providing the motive power for the first electric vehicles. Today DC motors are still found in ...

... The introduction of DC motors to run machinery eliminated the need for local steam or internal combustion engines, and line shaft drive systems. DC motors can operate directly from rechargeable batteries, providing the motive power for the first electric vehicles. Today DC motors are still found in ...

Brushed DC electric motor

A brushed DC motor is an internally commutated electric motor designed to be run from a direct current power source. Brushed motors were the first commercially important application of electric power to driving mechanical energy,and DC distribution systems were used for more than 100 years to operate motors in commercial and industrial buildings. Brushed DC motors can be varied in speed by changing the operating voltage or the strength of the magnetic field. Depending on the connections of the field to the power supply, the speed and torque characteristics of a brushed motor can be altered to provide steady speed or speed inversely proportional to the mechanical load. Brushed motors continue to be used for electrical propulsion, cranes, paper machines and steel rolling mills. Since the brushes wear down and require replacement, brushless DC motors using power electronic devices have displaced brushed motors from many applications