Drives on Single Phase Supplies

... on a SWER supply. The sizing of the transformer and the VSD/motor loading on the supply needs to be taken into consideration when concerned about harmonics. The effect of excessive harmonics may cause overheating of electrical components such as transformers and cables. For the smaller motors operat ...

... on a SWER supply. The sizing of the transformer and the VSD/motor loading on the supply needs to be taken into consideration when concerned about harmonics. The effect of excessive harmonics may cause overheating of electrical components such as transformers and cables. For the smaller motors operat ...

ABB drives in chemical, oil and gas

... ACS 6000 (3 – 27 MW, up to 3.3 kV) ABB’s water-cooled ACS 6000 is a modular drive designed for the most dynamic and powerful single or multi-motor applications for synchronous, induction and permanent magnet motors. Inter-related motors can be connected to the same ACS 6000 via common DC bus, enabli ...

... ACS 6000 (3 – 27 MW, up to 3.3 kV) ABB’s water-cooled ACS 6000 is a modular drive designed for the most dynamic and powerful single or multi-motor applications for synchronous, induction and permanent magnet motors. Inter-related motors can be connected to the same ACS 6000 via common DC bus, enabli ...

AV4101271276

... A modified pulse width modulation technique for Z-source inverter based BLDC motor is proposed and analyzed in this project.The Z-source inverter can be used as Buck/Boost converter with lower cost and high efficiency. BLDC motors are used in electric vehicles where portability and efficiency are re ...

... A modified pulse width modulation technique for Z-source inverter based BLDC motor is proposed and analyzed in this project.The Z-source inverter can be used as Buck/Boost converter with lower cost and high efficiency. BLDC motors are used in electric vehicles where portability and efficiency are re ...

Starting and control of slip-ring induction motors

... torque during the pick-up period (torque at different speeds) is of little consequence. In such starters, there is no control over the time of start or resistance in the circuit (torque at different speeds) during the start-up period. Liquid rotor starters are one type and are suitable only for ligh ...

... torque during the pick-up period (torque at different speeds) is of little consequence. In such starters, there is no control over the time of start or resistance in the circuit (torque at different speeds) during the start-up period. Liquid rotor starters are one type and are suitable only for ligh ...

Sizing gensets for motor starting

... LRKVA at the maximum instantaneous voltage dip experienced by all the connected loads should remain the primary criteria. In lab testing with actual motors and very high inertia loads, researchers have found that because of the dynamics of motor inrush current and power factor changes, actual motor- ...

... LRKVA at the maximum instantaneous voltage dip experienced by all the connected loads should remain the primary criteria. In lab testing with actual motors and very high inertia loads, researchers have found that because of the dynamics of motor inrush current and power factor changes, actual motor- ...

Induction motor - KUET | Khulna University of Engineering

... of flux, the rotating vector indicates there is a rotating magnetic field within stator having constant amount of flux. The speed at which flux rotates is called synchronous speed. But this is apparent that rotating field cuts each of the coils also during rotation. So it induces a voltage into the ...

... of flux, the rotating vector indicates there is a rotating magnetic field within stator having constant amount of flux. The speed at which flux rotates is called synchronous speed. But this is apparent that rotating field cuts each of the coils also during rotation. So it induces a voltage into the ...

IOSR Journal of Electrical and Electronics Engineering (IOSR-JEEE)

... components, namely the prime mover, the energy transmitting device and the actual apparatus or equipment[1]. The function of the prime mover and the energy transmitting device is to impart the motion and operate actual apparatus. The most commonly used prime mover is, of course an electric motor, si ...

... components, namely the prime mover, the energy transmitting device and the actual apparatus or equipment[1]. The function of the prime mover and the energy transmitting device is to impart the motion and operate actual apparatus. The most commonly used prime mover is, of course an electric motor, si ...

Synchros

... inherently has some phase shift so the output voltages will differ some from the exact 0 or 180 degree relationship with the input voltage. In a synchro operated at 400 hz (no load) the output voltage will lead the input by several degrees. At the instant the excitation is applied to this loop the r ...

... inherently has some phase shift so the output voltages will differ some from the exact 0 or 180 degree relationship with the input voltage. In a synchro operated at 400 hz (no load) the output voltage will lead the input by several degrees. At the instant the excitation is applied to this loop the r ...

EXAMPLES OF STATOR WINDING PARTIAL DISCHARGE DUE TO INVERTER DRIVES

... magnet wire, and given the relatively small diameter of the magnet wire, it seems that partial discharge can sometimes originate in the air space between two adjacent turns [5-7]. Since the thin magnet wire insulation is primarily made from organic materials, if sufficient PD activity occurs, the in ...

... magnet wire, and given the relatively small diameter of the magnet wire, it seems that partial discharge can sometimes originate in the air space between two adjacent turns [5-7]. Since the thin magnet wire insulation is primarily made from organic materials, if sufficient PD activity occurs, the in ...

Sensorless position control of permanent magnet motors with

... increasingly widespread in automation applications because they permit to eliminate mechanical transmission devices. Among the commonly used structures for linear permanent magnet synchronous motors the tubular one allows to better exploit the permanent magnet flux reducing size and end effects. Sim ...

... increasingly widespread in automation applications because they permit to eliminate mechanical transmission devices. Among the commonly used structures for linear permanent magnet synchronous motors the tubular one allows to better exploit the permanent magnet flux reducing size and end effects. Sim ...

Hall Effect Sensors

... The next Hall states the rotor will pass through are 010 and 110. When the south pole without the dot reaches state 100, a complete electrical cycle has occurred, and the rotor has rotated through 360 electrical degrees. (Physically, it has rotated through 180 mechanical degrees.) At this point, the ...

... The next Hall states the rotor will pass through are 010 and 110. When the south pole without the dot reaches state 100, a complete electrical cycle has occurred, and the rotor has rotated through 360 electrical degrees. (Physically, it has rotated through 180 mechanical degrees.) At this point, the ...

670 X - Hall Effect Sensors

... Hall wire connected to the input, and the drive turned on. ❏ If no drive is available, connect the Hall wire to a 1KΩ pullup resistor. Connect the resistor to +5VDC. Connect Hall +5 and Hall Gnd to your power supply. Measure the voltage at the point where the Hall wire is connected to the resistor. ...

... Hall wire connected to the input, and the drive turned on. ❏ If no drive is available, connect the Hall wire to a 1KΩ pullup resistor. Connect the resistor to +5VDC. Connect Hall +5 and Hall Gnd to your power supply. Measure the voltage at the point where the Hall wire is connected to the resistor. ...

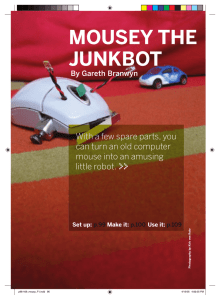

mousey the junkbot

... negative power bus. On electrolytic caps, the cathode is usually marked with a stripe or (-) symbol. 10d. Plug in one end of the higher-ohm resistor to connect with the capacitor anode, and jump the other end over the trench to a new node on the other side. 10e. Spread the transistor’s pins and plug ...

... negative power bus. On electrolytic caps, the cathode is usually marked with a stripe or (-) symbol. 10d. Plug in one end of the higher-ohm resistor to connect with the capacitor anode, and jump the other end over the trench to a new node on the other side. 10e. Spread the transistor’s pins and plug ...

Technical Data Sheet

... The TMC428 is a high-performance stepper motor control IC and can control up to three 2-phase-steppermotors (on this module, only one motor can be used). Motion parameters like speed or acceleration are sent ...

... The TMC428 is a high-performance stepper motor control IC and can control up to three 2-phase-steppermotors (on this module, only one motor can be used). Motion parameters like speed or acceleration are sent ...

SB800 - Marathon Motors Basic Training Manual

... energy losses and heat in the motor. Rotors for AC motors are heat treated to separate the aluminum bars from the rotor’s magnetic laminations. Shaft and bearing tolerances must be held to ten thousandths of an inch. The whole structure of the motor must be rigid to reduce vibration and noise. The s ...

... energy losses and heat in the motor. Rotors for AC motors are heat treated to separate the aluminum bars from the rotor’s magnetic laminations. Shaft and bearing tolerances must be held to ten thousandths of an inch. The whole structure of the motor must be rigid to reduce vibration and noise. The s ...

electrical machines ii - SK Engineering Academy

... 3. Why do cylindrical Alternators operate with steam turbines? Steam turbines are found to operate at fairly good efficiency only at high speeds. The high speed operation of rotors tends to increase mechanical losses and so the rotors should have a smooth external surface. Hence, smooth cylindrical ...

... 3. Why do cylindrical Alternators operate with steam turbines? Steam turbines are found to operate at fairly good efficiency only at high speeds. The high speed operation of rotors tends to increase mechanical losses and so the rotors should have a smooth external surface. Hence, smooth cylindrical ...

Brushless DC electric motor

Brushless DC electric motor (BLDC motors, BL motors) also known as electronically commutated motors (ECMs, EC motors) are synchronous motors that are powered by a DC electric source via an integrated inverter/switching power supply, which produces an AC electric signal to drive the motor. In this context, AC, alternating current, does not imply a sinusoidal waveform, but rather a bi-directional current with no restriction on waveform. Additional sensors and electronics control the inverter output amplitude and waveform (and therefore percent of DC bus usage/efficiency) and frequency (i.e. rotor speed).The rotor part of a brushless motor is often a permanent magnet synchronous motor, but can also be a switched reluctance motor, or induction motor.Brushless motors may be described as stepper motors; however, the term stepper motor tends to be used for motors that are designed specifically to be operated in a mode where they are frequently stopped with the rotor in a defined angular position. This page describes more general brushless motor principles, though there is overlap.Two key performance parameters of brushless DC motors are the motor constants Kv and Km.