Induction_Motor

... decreases with increased load, since the increase in rotor current is completely overshadowed by decrease in rotor P.F. • For a typical induction motor, pullout torque is 200 to 250 % of rated full-load torque • And starting torque (at zero speed) is about 150% of full-load torque • Unlike synchrono ...

... decreases with increased load, since the increase in rotor current is completely overshadowed by decrease in rotor P.F. • For a typical induction motor, pullout torque is 200 to 250 % of rated full-load torque • And starting torque (at zero speed) is about 150% of full-load torque • Unlike synchrono ...

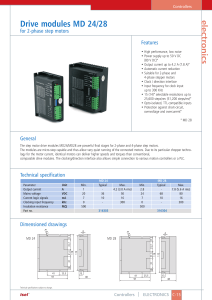

Technical Data - Ordering Data - MD 24-28

... • Opto-isolated, TTL-compatible inputs • Protection against short-circuit, overvoltage and overcurrent* * MD 28 ...

... • Opto-isolated, TTL-compatible inputs • Protection against short-circuit, overvoltage and overcurrent* * MD 28 ...

MOTOR CONTROL STARTER

... currents) making up the stator The difference between induction and synchronous motors is that the rotor for an induction motor can travel at a different speed than the stator. This is called Slip. ...

... currents) making up the stator The difference between induction and synchronous motors is that the rotor for an induction motor can travel at a different speed than the stator. This is called Slip. ...

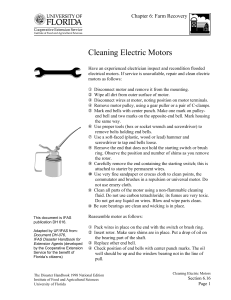

Cleaning Electric Motors - The Disaster Handbook

... Use proper tools (box or socket wrench and screwdriver) to remove bolts holding end bells. Use a soft-faced (plastic, wood or lead) hammer and screwdriver to tap end bells loose. Remove the end that does not hold the starting switch or brush ring. Observe the position and number of shims as you remo ...

... Use proper tools (box or socket wrench and screwdriver) to remove bolts holding end bells. Use a soft-faced (plastic, wood or lead) hammer and screwdriver to tap end bells loose. Remove the end that does not hold the starting switch or brush ring. Observe the position and number of shims as you remo ...

Slide 1 - Cobb Learning

... What is an Electromagnet? When an electric current is passed through a coil of wire wrapped around a metal core, a very strong magnetic field is produced. This is called an electromagnet. The more coils wrapped around the core, the stronger the magnetic field that is produced. This stronger mag ...

... What is an Electromagnet? When an electric current is passed through a coil of wire wrapped around a metal core, a very strong magnetic field is produced. This is called an electromagnet. The more coils wrapped around the core, the stronger the magnetic field that is produced. This stronger mag ...

Hola Agustin - UniMAP Portal

... It is so named because it is shaped and looks something like a turnable squirrel cage. Simply, the windings are heavy copper bars shorted together by copper rings. A low voltage is induced in these shorted windings by the rotating three-phase stator field. Because of the short circuit, a relatively ...

... It is so named because it is shaped and looks something like a turnable squirrel cage. Simply, the windings are heavy copper bars shorted together by copper rings. A low voltage is induced in these shorted windings by the rotating three-phase stator field. Because of the short circuit, a relatively ...

012235240AB

... taken in choosing the best value for aluminum thickness which yields maximum thrust at a required efficiency. Further , increase in the number of poles, results in increase in the thrust. So, from the parametric analysis it can be concluded that the input parameters like the slip, thickness of alumi ...

... taken in choosing the best value for aluminum thickness which yields maximum thrust at a required efficiency. Further , increase in the number of poles, results in increase in the thrust. So, from the parametric analysis it can be concluded that the input parameters like the slip, thickness of alumi ...

Simulation and Speed Control of 3-Phase Induction Motor

... jerks during starting. On the other hand, higher value of rotor resistance leads to lesser jerks while having no effect on the steady state time. The vector control analysis of an induction motor allows the decoupled analysis where the torque and the flux components can be independently controlled ( ...

... jerks during starting. On the other hand, higher value of rotor resistance leads to lesser jerks while having no effect on the steady state time. The vector control analysis of an induction motor allows the decoupled analysis where the torque and the flux components can be independently controlled ( ...

Induction motor

An induction or asynchronous motor is an AC electric motor in which the electric current in the rotor needed to produce torque is obtained by electromagnetic induction from the magnetic field of the stator winding. An induction motor therefore does not require mechanical commutation, separate-excitation or self-excitation for all or part of the energy transferred from stator to rotor, as in universal, DC and large synchronous motors. An induction motor's rotor can be either wound type or squirrel-cage type.Three-phase squirrel-cage induction motors are widely used in industrial drives because they are rugged, reliable and economical. Single-phase induction motors are used extensively for smaller loads, such as household appliances like fans. Although traditionally used in fixed-speed service, induction motors are increasingly being used with variable-frequency drives (VFDs) in variable-speed service. VFDs offer especially important energy savings opportunities for existing and prospective induction motors in variable-torque centrifugal fan, pump and compressor load applications. Squirrel cage induction motors are very widely used in both fixed-speed and variable-frequency drive (VFD) applications. Variable voltage and variable frequency drives are also used in variable-speed service.