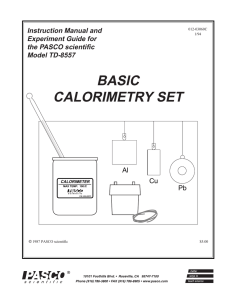

BASIC CALORIMETRY SET

... — Thermometer — Samples of aluminum, copper, and lead — Balance — Boiling water — Cool water ...

... — Thermometer — Samples of aluminum, copper, and lead — Balance — Boiling water — Cool water ...

Original Stirling Engine demonstration proposal

... confined volume, whereas the Stirling engine uses an external heat source to heat the working substance. The heat source can come from burning fossil fuels (such as gasoline), solar energy, decaying plant matter, or whatever is available [2]. In fact, all the Stirling engine requires to operate is a ...

... confined volume, whereas the Stirling engine uses an external heat source to heat the working substance. The heat source can come from burning fossil fuels (such as gasoline), solar energy, decaying plant matter, or whatever is available [2]. In fact, all the Stirling engine requires to operate is a ...

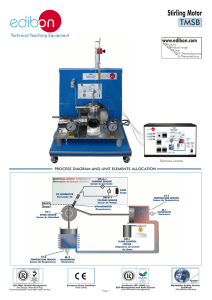

TMSB Stirling Motor www.edibon.com Technical Teaching Equipment

... source and another for the hot one). They are connected to a tube where the regenerator is located, which stores and transfers the heat, that enables to reach a higher efficiency. There is a piston in each cylinder, they move with a phase difference of 90º between them. Cylinders are connected by a ...

... source and another for the hot one). They are connected to a tube where the regenerator is located, which stores and transfers the heat, that enables to reach a higher efficiency. There is a piston in each cylinder, they move with a phase difference of 90º between them. Cylinders are connected by a ...

Applications of the Stirling engine

Applications of the Stirling engine range from mechanical propulsion to heating and cooling to electrical generation systems. A Stirling engine is a heat engine operating by cyclic compression and expansion of air or other gas, the ""working fluid"", at different temperature levels such that there is a net conversion of heat to mechanical work. The Stirling cycle heat engine can also be driven in reverse, using a mechanical energy input to drive heat transfer in a reversed direction (i.e. a heat pump, or refrigerator).There are several design configurations for Stirling engines that can be built, many of which require rotary or sliding seals, which can introduce difficult tradeoffs between frictional losses and refrigerant leakage. A free-piston variant of the Stirling engine can be built, which can be completely hermetically sealed, reducing friction losses and completely eliminating refrigerant leakage. For example, a Free Piston Stirling Cooler (FPSC) can convert an electrical energy input into a practical heat pump effect, used for high-efficiency portable refrigerators and freezers. Conversely, a free-piston electrical generator could be built, converting a heat flow into mechanical energy, and then into electricity. In both cases, energy is usually converted from/to electrical energy using magnetic fields in a way that avoids compromising the hermetic seal.