Mechanisms

... The rack and pinion is used to convert between rotary and linear motion. The rack is the flat, toothed part, the pinion is the gear. Rack and pinion can convert from rotary to linear of from linear to rotary. The diameter of the gear determines the speed that the rack moves as the pinion turns. Rack ...

... The rack and pinion is used to convert between rotary and linear motion. The rack is the flat, toothed part, the pinion is the gear. Rack and pinion can convert from rotary to linear of from linear to rotary. The diameter of the gear determines the speed that the rack moves as the pinion turns. Rack ...

Gear Trains

... –Efficiency is highest in the middle of the torque range so you need to oversize your motor to run with high efficiency. –Most robots require relatively low speed and high torque so motor output is usually geared down. ...

... –Efficiency is highest in the middle of the torque range so you need to oversize your motor to run with high efficiency. –Most robots require relatively low speed and high torque so motor output is usually geared down. ...

Gear Trains

... range so you need to oversize your motor to run with high efficiency. – Most robots require relatively low speed and high torque so motor output is usually geared down. ...

... range so you need to oversize your motor to run with high efficiency. – Most robots require relatively low speed and high torque so motor output is usually geared down. ...

Gear Trains

... range so you need to oversize your motor to run with high efficiency. – Most robots require relatively low speed and high torque so motor output is usually geared down. ...

... range so you need to oversize your motor to run with high efficiency. – Most robots require relatively low speed and high torque so motor output is usually geared down. ...

Axle

... motion of the follower. Cams are found, for example, in car engines, sewing machines and ...

... motion of the follower. Cams are found, for example, in car engines, sewing machines and ...

Gear Trains

... range so you need to oversize your motor to run with high efficiency. – Most robots require relatively low speed and high torque so motor output is usually geared down. ...

... range so you need to oversize your motor to run with high efficiency. – Most robots require relatively low speed and high torque so motor output is usually geared down. ...

Gear - UniMAP Portal

... direction of the shafts in a machine drive without affecting then speed of rotation. Many more features need to specified before the gears can be produced. Furthermore, many successful, commercially available gears are made in some nonstandard form. For example, the addendum of the pinion is often m ...

... direction of the shafts in a machine drive without affecting then speed of rotation. Many more features need to specified before the gears can be produced. Furthermore, many successful, commercially available gears are made in some nonstandard form. For example, the addendum of the pinion is often m ...

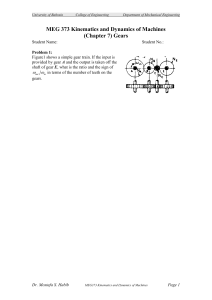

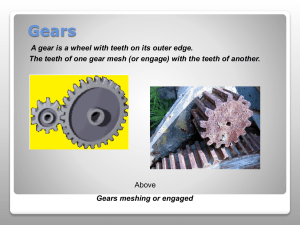

Gears

... A motor gear has 28 teeth and revolves at 100 rev/min. The driven gear has 10 teeth. What is its rotational speed? ...

... A motor gear has 28 teeth and revolves at 100 rev/min. The driven gear has 10 teeth. What is its rotational speed? ...

Slide 1

... A motor gear has 28 teeth and revolves at 100 rev/min. The driven gear has 10 teeth. What is its rotational speed? ...

... A motor gear has 28 teeth and revolves at 100 rev/min. The driven gear has 10 teeth. What is its rotational speed? ...

gears test 2

... 3.1 Demonstrates knowledge and understanding of how mechanical systems (e.g. pneumatic or hydraulic systems, gears, belt drive systems, pulley systems, linked lever systems) convert motion and force to give mechanical advantage, and represents them using systems diagrams. Learning Space: Assessment ...

... 3.1 Demonstrates knowledge and understanding of how mechanical systems (e.g. pneumatic or hydraulic systems, gears, belt drive systems, pulley systems, linked lever systems) convert motion and force to give mechanical advantage, and represents them using systems diagrams. Learning Space: Assessment ...

Synchronization gear

A synchronization gear, or a gun synchronizer, sometimes rather less accurately referred to as an interrupter, is attached to the armament of a single engined tractor-type aircraft so it can fire through the arc of its spinning propeller without bullets striking the blades. The idea presupposes a fixed armament directed by aiming the aircraft in which it is fitted at the target, rather than aiming the gun independently.There are many practical problems, mostly arising from the inherently imprecise nature of an automatic gun's firing, the great (and varying) velocity of the blades of a spinning propeller, and the very high speed at which any gear synchronizing the two has to operate.Design and experimentation with gun synchronization had been underway in France and Germany in 1913/14, following the ideas of August Euler, who seems to have been the first to suggest mounting a fixed armament firing in the direction of flight (in 1910). The first practical, (if far from reliable) gear to enter operational service was however that fitted to the Eindecker monoplane fighters that entered squadron service with the German Air Service in mid 1915. The success of the Eindecker led to numerous gun synchronization devices – culminating in the reasonably reliable hydraulic British Constantinesco gear of 1917. By the end of the war German engineers were well on the way to perfecting a gear using an electrical rather than a mechanical or hydraulic link between the engine and the gun, with the latter being triggered by a solenoid rather than by a mechanical ""trigger motor"".From 1918 to the mid-thirties the standard armament for a fighter aircraft remained two synchronized rifle calibre machine guns, firing forward through the propeller. During the late thirties, however, the main role of the fighter was increasingly seen as the destruction of large, all-metal bombers, for which the ""traditional"" light armament was inadequate.Since it was impractical to try to fit more than one or two extra guns in the constrained space available in the front of a single-engined aircraft's fuselage, this led to an increasing proportion of the armament being mounted in the wings, firing outside the arc of the propeller. There were in fact some advantages in dispensing with centrally mounted guns altogether. Nevertheless, the conclusive redundancy of synchronization gears did not finally come until the introduction of jet propulsion and the absence of a propeller for guns to be synchronized with.