Mechanics

... Machines using screw are called screw threads mechanism. For example, a screw jack is a common screw mechanism. These mechanisms have very large velocity ratio and mechanical advantage. Therefore, they can be used to lift a large load. Its working principle is shown in Fig. 14a. When the handle has ...

... Machines using screw are called screw threads mechanism. For example, a screw jack is a common screw mechanism. These mechanisms have very large velocity ratio and mechanical advantage. Therefore, they can be used to lift a large load. Its working principle is shown in Fig. 14a. When the handle has ...

Structure

... Machines using screw are called screw threads mechanism. For example, a screw jack is a common screw mechanism. These mechanisms have very large velocity ratio and mechanical advantage. Therefore, they can be used to lift a large load. Its working principle is shown in Fig. 14a. When the handle has ...

... Machines using screw are called screw threads mechanism. For example, a screw jack is a common screw mechanism. These mechanisms have very large velocity ratio and mechanical advantage. Therefore, they can be used to lift a large load. Its working principle is shown in Fig. 14a. When the handle has ...

MECHANICAL PRINCIPLES OUTCOME 4

... must equal the work done by the load so it follows that : FE XE = FL XL In a real machine, there is friction and energy is lost. The effort has to overcome the dead load of the lifting machine so some effort FS is required before any external load is applied. If FL is the external load and this is p ...

... must equal the work done by the load so it follows that : FE XE = FL XL In a real machine, there is friction and energy is lost. The effort has to overcome the dead load of the lifting machine so some effort FS is required before any external load is applied. If FL is the external load and this is p ...

File

... operate a motor outside of its nominal voltage, the efficiency of the motor goes down, often requiring additional current, generating more heat and decreasing the lifespan of the motor. Aside from a “nominal voltage” DC motors also have an operating voltage range outside of which the manufacturer do ...

... operate a motor outside of its nominal voltage, the efficiency of the motor goes down, often requiring additional current, generating more heat and decreasing the lifespan of the motor. Aside from a “nominal voltage” DC motors also have an operating voltage range outside of which the manufacturer do ...

External gear pump

... A schematic of an external gear pump is shown in Figure 2. An external gear pump consists of two gears usually equal in size, which mesh externally and are housed in a pump case. Each gear is mounted on a shaft, which is supported by needle bearings in the case covers. One of these shafts is coupled ...

... A schematic of an external gear pump is shown in Figure 2. An external gear pump consists of two gears usually equal in size, which mesh externally and are housed in a pump case. Each gear is mounted on a shaft, which is supported by needle bearings in the case covers. One of these shafts is coupled ...

Grade 8 Science

... A wheel and axle is a simple machine that has parts that rotate, but those parts are attached about their centre, they are on the same axis. Gears, like the wheel and axle, use rotation, but they transfer the rotation to a different axis, the gears are not attached, they use teeth that mesh tog ...

... A wheel and axle is a simple machine that has parts that rotate, but those parts are attached about their centre, they are on the same axis. Gears, like the wheel and axle, use rotation, but they transfer the rotation to a different axis, the gears are not attached, they use teeth that mesh tog ...

Mechanical Workshop - Mid

... its speed or rotation are dependent on each other This is a basic characteristic, it is a ...

... its speed or rotation are dependent on each other This is a basic characteristic, it is a ...

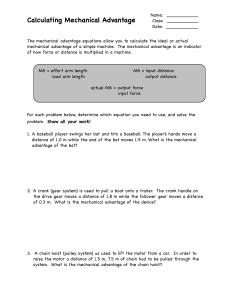

Calculating Mechanical Advantage

... The mechanical advantage equations allow you to calculate the ideal or actual mechanical advantage of a simple machine. The mechanical advantage is an indicator of how force or distance is multiplied in a machine. ...

... The mechanical advantage equations allow you to calculate the ideal or actual mechanical advantage of a simple machine. The mechanical advantage is an indicator of how force or distance is multiplied in a machine. ...

PSAA Curriculum

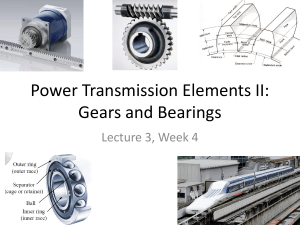

... A gear is a toothed wheel used to transmit power. Gears are used for four main reasons: 1) reverse the direction of rotation, 2) increase or decrease the speed of rotation, 3) move rotational motion to a different axis, and 4) keep the rotation of two axes synchronized. ...

... A gear is a toothed wheel used to transmit power. Gears are used for four main reasons: 1) reverse the direction of rotation, 2) increase or decrease the speed of rotation, 3) move rotational motion to a different axis, and 4) keep the rotation of two axes synchronized. ...

Mechanisms

... taking place and so the TORQUE of this system will be ________(high or low) Solution 2 By finding the PRIME factors of 24 a gearbox with more than one transmission of force can be designed which will increase the torque of the system. The prime factors of 24 are 4 x 3 x 2. A velocity reduction of 4: ...

... taking place and so the TORQUE of this system will be ________(high or low) Solution 2 By finding the PRIME factors of 24 a gearbox with more than one transmission of force can be designed which will increase the torque of the system. The prime factors of 24 are 4 x 3 x 2. A velocity reduction of 4: ...

Review for Wednesday`s Test

... • Connects components that are far away from one another. • The gears do not mesh together; they are connected with a chain (or sprocket) Direction of components ...

... • Connects components that are far away from one another. • The gears do not mesh together; they are connected with a chain (or sprocket) Direction of components ...

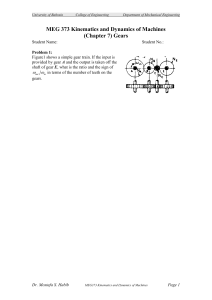

MEG 373 Kinematics and Dynamics of Machines

... carrying the cluster of gears A, B, and C. The follower shaft is splined and may be shifted along its axis by means of the shift link to bring gears E, G, and H into contact with the gears on the drive shaft. Design the transmission to produce speeds of 150, 350, and 550 rpm, and describe how motion ...

... carrying the cluster of gears A, B, and C. The follower shaft is splined and may be shifted along its axis by means of the shift link to bring gears E, G, and H into contact with the gears on the drive shaft. Design the transmission to produce speeds of 150, 350, and 550 rpm, and describe how motion ...

mechanisms_and_movement

... Gears are used to change speed in rotational movement. In the example above the blue gear has eleven teeth and the orange gear has twenty five. To turn the orange gear one full turn the blue gear must turn 25/11 or 2.2727r turns. Notice that as the blue gear turns clockwise the orange gear turns ant ...

... Gears are used to change speed in rotational movement. In the example above the blue gear has eleven teeth and the orange gear has twenty five. To turn the orange gear one full turn the blue gear must turn 25/11 or 2.2727r turns. Notice that as the blue gear turns clockwise the orange gear turns ant ...

Simple Machines - Miss Woods` Class

... Problems: For each of the following examples calculate: Work input, Work output, Efficiency, and Mechanical advantage and determine whether it is a speed or force advantage a. You push a 600N box up a ramp that is 10m long. The ramp is 5m high, and you put in 350N of effort. b. You use a first class ...

... Problems: For each of the following examples calculate: Work input, Work output, Efficiency, and Mechanical advantage and determine whether it is a speed or force advantage a. You push a 600N box up a ramp that is 10m long. The ramp is 5m high, and you put in 350N of effort. b. You use a first class ...

Mechanisms Levers Class 1 levers:

... In the drawing, the centre of each gear is shown by a cross. Each gear is drawn as two circles, one slightly larger than the other to show where the teeth would be. Teeth do not have to be drawn, but the number of teeth is written next to the gear, in this case 60 teeth and 15 teeth. Arrows indicate ...

... In the drawing, the centre of each gear is shown by a cross. Each gear is drawn as two circles, one slightly larger than the other to show where the teeth would be. Teeth do not have to be drawn, but the number of teeth is written next to the gear, in this case 60 teeth and 15 teeth. Arrows indicate ...

Axle

... This is a special type of bevel gear that has its teeth at right angles to the plane of the wheel. It attaches to a spur gear, or pinion gear at right-angles. Driven Gear This is a name given to any gear that is not connected to a power source and is therefore driven by the driver gear. Driver Gear ...

... This is a special type of bevel gear that has its teeth at right angles to the plane of the wheel. It attaches to a spur gear, or pinion gear at right-angles. Driven Gear This is a name given to any gear that is not connected to a power source and is therefore driven by the driver gear. Driver Gear ...

Topic5.Presentation.ICAM

... effort , to give a larger output force, called the load. • Examples; pulley systems, screw jacks, gear systems and lever systems. ...

... effort , to give a larger output force, called the load. • Examples; pulley systems, screw jacks, gear systems and lever systems. ...

Mechanical Systems

... A large gear (X) driving a smaller gear (Y) decreases torque and increases speed in the driven gear. Gears such as these are called multiplying gears. A small gear (Y) driving a larger gear (X) increases torque and reduces speed in the driven gear. Gears like these are called reducing gears. When th ...

... A large gear (X) driving a smaller gear (Y) decreases torque and increases speed in the driven gear. Gears such as these are called multiplying gears. A small gear (Y) driving a larger gear (X) increases torque and reduces speed in the driven gear. Gears like these are called reducing gears. When th ...

Chapter 7

... • Deals only with forces. • Mechanical Advantage > 1 means that the output force will be greater than the input force. (But the input distance will need to be greater than the output distance.) ...

... • Deals only with forces. • Mechanical Advantage > 1 means that the output force will be greater than the input force. (But the input distance will need to be greater than the output distance.) ...

Practice 4

... 1. A flywheel of radius 27.0 cm has an angular speed of 47.0 rpm. What is that in rad/s? 2. Convert 620 rad/s into rpm 3. A shaft of radius 8.50 cm rotates 7.00 rad/s. Through what angular displacement does it go in 1.20 s? 4. Find the angular speed in rpm of the second hand of a wall clock. 5. Find ...

... 1. A flywheel of radius 27.0 cm has an angular speed of 47.0 rpm. What is that in rad/s? 2. Convert 620 rad/s into rpm 3. A shaft of radius 8.50 cm rotates 7.00 rad/s. Through what angular displacement does it go in 1.20 s? 4. Find the angular speed in rpm of the second hand of a wall clock. 5. Find ...

GEARs Length Of Path Of Contact

... Tooth space . It is the width of space between the two adjacent teeth measured along the pitchcircle. Backlash. It is the difference between the tooth space and the tooth thickness, as measured along the pitch circle. Theoretically, the backlash should be zero, but in actual practice some backlash m ...

... Tooth space . It is the width of space between the two adjacent teeth measured along the pitchcircle. Backlash. It is the difference between the tooth space and the tooth thickness, as measured along the pitch circle. Theoretically, the backlash should be zero, but in actual practice some backlash m ...

Gear train

.jpg?width=300)

A gear train is a mechanical system formed by mounting gears on a frame so that the teeth of the gears engage.Gear teeth are designed to ensure the pitch circles of engaging gears roll on each other without slipping, providing a smooth transmission of rotation from one gear to the next.The transmission of rotation between contacting toothed wheels can be traced back to the Antikythera mechanism of Greece and the south-pointing chariot of China. Illustrations by the Renaissance scientist Georgius Agricola show gear trains with cylindrical teeth. The implementation of the involute tooth yielded a standard gear design that provides a constant speed ratio. Features of gears and gear trains include: The ratio of the pitch circles of mating gears defines the speed ratio and the mechanical advantage of the gear set. A planetary gear train provides high gear reduction in a compact package. It is possible to design gear teeth for gears that are non-circular, yet still transmit torque smoothly. The speed ratios of chain and belt drives are computed in the same way as gear ratios. See bicycle gearing.